Life-Cycle Assessment Of Lithium From Geothermal Brine Vs Hard-Rock Mining

SEP 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lithium Extraction Evolution and Objectives

Lithium extraction has undergone significant evolution over the past century, transitioning from traditional mining methods to more advanced technological approaches. Initially, lithium was primarily extracted from pegmatite deposits through conventional hard-rock mining techniques, which involved extensive drilling, blasting, and processing operations. This approach dominated the industry until the late 20th century when alternative extraction methods began to emerge.

The 1980s marked a pivotal shift with the development of brine extraction techniques in salt flats (salars), particularly in South America's "Lithium Triangle" encompassing Chile, Argentina, and Bolivia. This method relies on solar evaporation of lithium-rich brines pumped from beneath salt flats, representing a less energy-intensive alternative to hard-rock mining but requiring significant water resources and extensive land use.

Recent technological advancements have introduced geothermal brine extraction as a promising alternative. This method leverages existing geothermal power plants to extract lithium from the hot brines used for energy generation, potentially offering a dual-purpose solution that produces both renewable energy and critical battery materials with a reduced environmental footprint.

The evolution of lithium extraction technologies has been primarily driven by increasing global demand for lithium-ion batteries, which has grown exponentially with the rise of electric vehicles and renewable energy storage systems. Industry projections indicate that lithium demand could increase by 400-800% by 2030, necessitating more efficient and sustainable extraction methods.

The primary objectives in lithium extraction technology development now center on enhancing sustainability metrics across the entire life cycle. Key goals include reducing water consumption, minimizing land disturbance, decreasing carbon emissions, and improving resource efficiency. Particularly for geothermal brine extraction, objectives focus on optimizing selective lithium recovery processes, increasing extraction yields, and developing scalable technologies that can be deployed across diverse geothermal resources globally.

Another critical objective is developing comprehensive life-cycle assessment frameworks that accurately compare environmental impacts between traditional mining and emerging extraction technologies. These assessments aim to quantify impacts across multiple dimensions including greenhouse gas emissions, water usage, land disturbance, and waste generation throughout the entire supply chain from extraction to processing.

The industry also seeks to establish circular economy principles within lithium production systems, with objectives targeting improved recycling rates, reduced waste generation, and the development of closed-loop systems that minimize resource inputs and environmental outputs while maintaining economic viability.

The 1980s marked a pivotal shift with the development of brine extraction techniques in salt flats (salars), particularly in South America's "Lithium Triangle" encompassing Chile, Argentina, and Bolivia. This method relies on solar evaporation of lithium-rich brines pumped from beneath salt flats, representing a less energy-intensive alternative to hard-rock mining but requiring significant water resources and extensive land use.

Recent technological advancements have introduced geothermal brine extraction as a promising alternative. This method leverages existing geothermal power plants to extract lithium from the hot brines used for energy generation, potentially offering a dual-purpose solution that produces both renewable energy and critical battery materials with a reduced environmental footprint.

The evolution of lithium extraction technologies has been primarily driven by increasing global demand for lithium-ion batteries, which has grown exponentially with the rise of electric vehicles and renewable energy storage systems. Industry projections indicate that lithium demand could increase by 400-800% by 2030, necessitating more efficient and sustainable extraction methods.

The primary objectives in lithium extraction technology development now center on enhancing sustainability metrics across the entire life cycle. Key goals include reducing water consumption, minimizing land disturbance, decreasing carbon emissions, and improving resource efficiency. Particularly for geothermal brine extraction, objectives focus on optimizing selective lithium recovery processes, increasing extraction yields, and developing scalable technologies that can be deployed across diverse geothermal resources globally.

Another critical objective is developing comprehensive life-cycle assessment frameworks that accurately compare environmental impacts between traditional mining and emerging extraction technologies. These assessments aim to quantify impacts across multiple dimensions including greenhouse gas emissions, water usage, land disturbance, and waste generation throughout the entire supply chain from extraction to processing.

The industry also seeks to establish circular economy principles within lithium production systems, with objectives targeting improved recycling rates, reduced waste generation, and the development of closed-loop systems that minimize resource inputs and environmental outputs while maintaining economic viability.

Market Demand Analysis for Sustainable Lithium

The global lithium market is experiencing unprecedented growth driven by the rapid expansion of electric vehicle (EV) production and renewable energy storage systems. Current projections indicate the lithium market will grow from approximately 82,000 metric tons in 2020 to over 3 million metric tons by 2030, representing a compound annual growth rate exceeding 25%. This exponential demand trajectory has created urgent market pressure for sustainable lithium production methods.

Traditional hard-rock mining operations, primarily concentrated in Australia, China, and parts of South America, currently supply about 60% of global lithium. However, these methods face increasing scrutiny due to their substantial environmental footprint, including habitat destruction, high water consumption, and significant carbon emissions. This has created a distinct market opportunity for more sustainable extraction alternatives.

Geothermal brine extraction represents a promising sustainable alternative that has captured significant investor interest. The method leverages existing geothermal power infrastructure to extract lithium from naturally occurring brines, potentially reducing land disturbance by up to 90% compared to conventional mining. Market analysis indicates that geothermal lithium could achieve production costs between $3,000 and $4,000 per ton, potentially undercutting traditional mining operations that average $5,000 to $7,000 per ton.

Consumer preferences are increasingly driving market demand for sustainably sourced materials. A recent McKinsey survey revealed that 78% of EV manufacturers express willingness to pay premium prices for verifiably sustainable lithium. This trend is further reinforced by emerging regulatory frameworks in the European Union and North America that incentivize lower-carbon supply chains through tax benefits and preferential procurement policies.

The investment landscape reflects this shift toward sustainable lithium, with venture capital funding for geothermal lithium extraction technologies increasing by 215% between 2019 and 2022. Major automotive manufacturers including Volkswagen, BMW, and Tesla have announced strategic investments in geothermal lithium projects, signaling strong industry confidence in this emerging technology.

Regional market analysis reveals particularly strong demand potential in Europe, where stringent environmental regulations align with the sustainability benefits of geothermal lithium extraction. The European Battery Alliance has identified sustainable lithium production as a strategic priority, with projected regional demand expected to reach 550,000 tons annually by 2030, representing approximately 18% of global consumption.

Market forecasts suggest that geothermal lithium extraction could capture between 15-25% of global lithium production by 2035, contingent upon successful scaling of current pilot projects and continued technological refinement. This represents a potential market value exceeding $15 billion annually, underscoring the significant commercial opportunity for companies that can successfully develop and deploy sustainable lithium extraction technologies.

Traditional hard-rock mining operations, primarily concentrated in Australia, China, and parts of South America, currently supply about 60% of global lithium. However, these methods face increasing scrutiny due to their substantial environmental footprint, including habitat destruction, high water consumption, and significant carbon emissions. This has created a distinct market opportunity for more sustainable extraction alternatives.

Geothermal brine extraction represents a promising sustainable alternative that has captured significant investor interest. The method leverages existing geothermal power infrastructure to extract lithium from naturally occurring brines, potentially reducing land disturbance by up to 90% compared to conventional mining. Market analysis indicates that geothermal lithium could achieve production costs between $3,000 and $4,000 per ton, potentially undercutting traditional mining operations that average $5,000 to $7,000 per ton.

Consumer preferences are increasingly driving market demand for sustainably sourced materials. A recent McKinsey survey revealed that 78% of EV manufacturers express willingness to pay premium prices for verifiably sustainable lithium. This trend is further reinforced by emerging regulatory frameworks in the European Union and North America that incentivize lower-carbon supply chains through tax benefits and preferential procurement policies.

The investment landscape reflects this shift toward sustainable lithium, with venture capital funding for geothermal lithium extraction technologies increasing by 215% between 2019 and 2022. Major automotive manufacturers including Volkswagen, BMW, and Tesla have announced strategic investments in geothermal lithium projects, signaling strong industry confidence in this emerging technology.

Regional market analysis reveals particularly strong demand potential in Europe, where stringent environmental regulations align with the sustainability benefits of geothermal lithium extraction. The European Battery Alliance has identified sustainable lithium production as a strategic priority, with projected regional demand expected to reach 550,000 tons annually by 2030, representing approximately 18% of global consumption.

Market forecasts suggest that geothermal lithium extraction could capture between 15-25% of global lithium production by 2035, contingent upon successful scaling of current pilot projects and continued technological refinement. This represents a potential market value exceeding $15 billion annually, underscoring the significant commercial opportunity for companies that can successfully develop and deploy sustainable lithium extraction technologies.

Technical Status and Barriers in Lithium Extraction Methods

The global lithium extraction landscape is currently dominated by two primary methods: traditional hard-rock mining and the emerging geothermal brine extraction. Hard-rock mining, particularly from spodumene deposits, represents approximately 60% of global lithium production, with major operations concentrated in Australia, China, and parts of South America. This method involves conventional mining techniques followed by energy-intensive concentration and conversion processes to produce lithium compounds.

Geothermal brine extraction, representing a growing alternative, currently accounts for approximately 40% of global production, primarily from salt flat operations in the "Lithium Triangle" of Chile, Argentina, and Bolivia. This method leverages naturally occurring lithium-rich brines that are pumped to the surface and processed through evaporation and chemical treatment.

The technical challenges facing hard-rock mining include high energy consumption, significant water usage, and substantial waste generation. The concentration process typically requires temperatures exceeding 1000°C, resulting in considerable carbon emissions. Additionally, the conversion of lithium minerals to usable compounds involves complex chemical processes with environmental implications.

For geothermal brine extraction, the primary technical barriers include variable lithium concentration in brines (typically 200-1400 mg/L), lengthy evaporation periods (12-18 months in traditional operations), and challenges in selective lithium recovery from complex brine compositions containing numerous competing ions. Water consumption remains significant, with estimates suggesting 500,000 gallons of water evaporation per ton of lithium produced in traditional solar evaporation operations.

Emerging direct lithium extraction (DLE) technologies aim to address these challenges by employing selective adsorption, ion exchange membranes, or electrochemical processes to extract lithium directly from brines without extensive evaporation. However, these technologies face scalability issues, high capital costs, and technical challenges related to adsorbent durability and selectivity in complex brine environments.

Recovery rates present another significant barrier, with hard-rock mining achieving approximately 50-70% lithium recovery, while traditional brine operations typically achieve 40-50%. Advanced DLE methods promise higher recovery rates (potentially 80-90%), but remain largely unproven at commercial scale.

The geographical distribution of technical capabilities shows concentration of hard-rock processing expertise in China and Australia, while brine expertise is centered in South America. North American and European entities are increasingly investing in both approaches, with particular emphasis on developing advanced DLE technologies to reduce environmental impacts and processing times.

Geothermal brine extraction, representing a growing alternative, currently accounts for approximately 40% of global production, primarily from salt flat operations in the "Lithium Triangle" of Chile, Argentina, and Bolivia. This method leverages naturally occurring lithium-rich brines that are pumped to the surface and processed through evaporation and chemical treatment.

The technical challenges facing hard-rock mining include high energy consumption, significant water usage, and substantial waste generation. The concentration process typically requires temperatures exceeding 1000°C, resulting in considerable carbon emissions. Additionally, the conversion of lithium minerals to usable compounds involves complex chemical processes with environmental implications.

For geothermal brine extraction, the primary technical barriers include variable lithium concentration in brines (typically 200-1400 mg/L), lengthy evaporation periods (12-18 months in traditional operations), and challenges in selective lithium recovery from complex brine compositions containing numerous competing ions. Water consumption remains significant, with estimates suggesting 500,000 gallons of water evaporation per ton of lithium produced in traditional solar evaporation operations.

Emerging direct lithium extraction (DLE) technologies aim to address these challenges by employing selective adsorption, ion exchange membranes, or electrochemical processes to extract lithium directly from brines without extensive evaporation. However, these technologies face scalability issues, high capital costs, and technical challenges related to adsorbent durability and selectivity in complex brine environments.

Recovery rates present another significant barrier, with hard-rock mining achieving approximately 50-70% lithium recovery, while traditional brine operations typically achieve 40-50%. Advanced DLE methods promise higher recovery rates (potentially 80-90%), but remain largely unproven at commercial scale.

The geographical distribution of technical capabilities shows concentration of hard-rock processing expertise in China and Australia, while brine expertise is centered in South America. North American and European entities are increasingly investing in both approaches, with particular emphasis on developing advanced DLE technologies to reduce environmental impacts and processing times.

Current Extraction Solutions Comparison

01 Geothermal brine extraction methods

Lithium can be extracted from geothermal brines using various techniques. These methods involve pumping hot brine from underground reservoirs, extracting the lithium, and then reinjecting the brine back into the ground. This process is generally considered more environmentally friendly than traditional mining as it has a smaller physical footprint and uses renewable geothermal energy. Advanced extraction technologies can improve efficiency while reducing water usage and waste production.- Environmental impact of geothermal brine lithium extraction: Geothermal brine lithium extraction methods have specific environmental considerations. These processes typically use existing geothermal power plants to extract lithium from hot brines, reducing the need for new land disturbance. The environmental advantages include lower water consumption, reduced carbon footprint, and minimal land disruption compared to traditional mining. However, challenges include managing waste brine disposal, potential for induced seismicity, and impacts on local groundwater systems. Advanced technologies are being developed to mitigate these environmental concerns while maximizing lithium recovery efficiency.

- Hard-rock mining environmental challenges and mitigation strategies: Hard-rock lithium mining presents significant environmental challenges including extensive land disturbance, high water usage, energy consumption, and waste rock management. These operations typically involve open-pit mining, crushing, and chemical processing of lithium-bearing minerals like spodumene. Environmental impacts include habitat destruction, dust generation, acid mine drainage, and tailings disposal issues. Mitigation strategies focus on implementing closed-loop water systems, renewable energy integration, progressive land reclamation, and improved waste management techniques to reduce the overall environmental footprint of hard-rock lithium extraction operations.

- Water management and conservation in lithium extraction: Water management is a critical environmental concern in lithium extraction processes. Both geothermal brine and hard-rock mining methods require significant water resources, though in different ways. Innovative water conservation technologies include closed-loop systems, advanced filtration, water recycling, and zero liquid discharge approaches. These technologies aim to minimize freshwater consumption, reduce contamination risks, and protect local water resources. Particular attention is given to preventing groundwater pollution and managing the high salinity of process waters, especially in arid regions where lithium resources are often located.

- Energy efficiency and carbon footprint reduction in lithium processing: Energy consumption represents a significant environmental impact factor in lithium extraction and processing. Innovations focus on reducing the carbon footprint through integration of renewable energy sources, heat recovery systems, and process optimization. Direct lithium extraction technologies from geothermal brines can leverage existing geothermal energy infrastructure, significantly reducing greenhouse gas emissions compared to conventional methods. For hard-rock mining, energy-efficient crushing and grinding technologies, along with optimized chemical processes, help minimize overall energy requirements. These approaches collectively work to improve the sustainability profile of lithium production for battery applications.

- Waste management and resource recovery innovations: Advanced waste management approaches are being developed to address the environmental impacts of lithium extraction residues. These innovations include techniques for recovering valuable by-products from waste streams, reducing tailings volume, and neutralizing potentially harmful chemicals. Circular economy principles are being applied to transform waste materials into usable products, such as construction materials or soil amendments. Additionally, new methods for tailings stabilization and detoxification help minimize long-term environmental liabilities. These waste management strategies are essential for improving the overall sustainability of lithium production while maximizing resource utilization efficiency.

02 Hard-rock mining environmental impacts

Hard-rock mining for lithium involves extracting lithium-bearing minerals from rock deposits, typically through open-pit mining. This method has significant environmental impacts including land disturbance, habitat destruction, high water consumption, and the generation of waste rock and tailings. The processing of hard-rock lithium ore also requires energy-intensive crushing and chemical processing, leading to higher carbon emissions compared to brine extraction methods.Expand Specific Solutions03 Water management and conservation techniques

Water management is a critical environmental concern in lithium extraction. Innovative technologies focus on reducing water consumption and preventing contamination of local water sources. These include closed-loop water systems, advanced filtration methods, and water recycling processes. Some extraction methods also incorporate techniques to minimize evaporation losses and recover water from waste streams, significantly reducing the overall water footprint of lithium production operations.Expand Specific Solutions04 Waste reduction and management strategies

Managing waste from lithium extraction processes is essential for reducing environmental impact. Advanced methods include techniques for treating and repurposing tailings, recovering valuable by-products from waste streams, and implementing zero-discharge systems. Some innovations focus on reducing chemical usage in processing, neutralizing harmful compounds, and developing more efficient separation technologies that minimize waste generation while maximizing lithium recovery rates.Expand Specific Solutions05 Energy efficiency and carbon footprint reduction

Reducing the energy consumption and carbon footprint of lithium extraction operations is becoming increasingly important. Innovations include the integration of renewable energy sources, development of low-temperature extraction processes, and implementation of energy recovery systems. Some methods utilize waste heat from geothermal operations or incorporate solar and wind power to drive extraction processes. These approaches significantly reduce greenhouse gas emissions associated with lithium production while improving overall operational efficiency.Expand Specific Solutions

Key Industry Players in Lithium Extraction Sector

The lithium extraction market is currently in a transitional phase, with geothermal brine extraction emerging as a potentially more sustainable alternative to traditional hard-rock mining. The global lithium market is projected to grow significantly, driven by electric vehicle battery demand, with market size expected to reach $8.2 billion by 2028. Technologically, companies like Vulcan Energy Resources are pioneering zero-carbon lithium extraction from geothermal brines, while established players such as Bangpu Recycling Technology focus on recycling approaches. Academic institutions including MIT, Central South University, and the China University of Geosciences are advancing research in both extraction methods. Geothermal extraction shows promising environmental advantages but remains less mature than conventional mining, with companies like GeoLith, Terralithium, and Livium developing proprietary DLE technologies to bridge this gap.

Vulcan Energie Ressourcen GmbH

Technical Solution: Vulcan Energy has developed a proprietary Zero Carbon Lithium™ extraction process that combines geothermal energy production with lithium extraction from geothermal brines in Germany's Upper Rhine Valley. Their Direct Lithium Extraction (DLE) technology selectively extracts lithium from geothermal brines using specialized adsorbents, eliminating the need for evaporation ponds. The process is powered by renewable geothermal energy generated from the same brine, creating a closed-loop system with minimal environmental impact. Life cycle assessments conducted by the company indicate their method produces lithium with a carbon footprint approximately 90% lower than traditional mining operations, consuming minimal land and water resources compared to conventional extraction methods.

Strengths: Zero carbon emissions approach; dual production of renewable energy and lithium; significantly reduced water consumption; no mining or evaporation ponds required; European-based supply chain reducing geopolitical risks. Weaknesses: Technology still scaling to commercial levels; higher initial capital costs; dependent on specific geothermal resource quality; limited to regions with suitable geothermal brines.

Sunresin New Materials Co., Ltd.

Technical Solution: Sunresin has developed advanced ion exchange and adsorption technologies specifically designed for lithium extraction from geothermal brines. Their proprietary lithium-selective adsorption resins demonstrate high selectivity for lithium ions even in brines with complex compositions and high magnesium-to-lithium ratios. The company's process involves passing geothermal brine through columns containing these specialized adsorbents, which selectively capture lithium while allowing other elements to pass through. The lithium is then eluted using a mild acid solution and processed into battery-grade lithium compounds. Life cycle assessments of their technology show significant reductions in water usage (approximately 70% less than evaporation methods), land disturbance (over 90% reduction compared to mining), and greenhouse gas emissions (50-60% lower than conventional methods) when extracting lithium from geothermal sources versus hard rock mining.

Strengths: High selectivity for lithium in complex brines; modular and scalable system design; rapid processing time compared to evaporation ponds; applicable to various brine compositions; reduced chemical consumption. Weaknesses: Higher energy requirements for resin regeneration; potential for resin fouling requiring periodic replacement; complex operational parameters requiring precise control; higher operational expertise needed.

Critical Technologies in Geothermal Brine Extraction

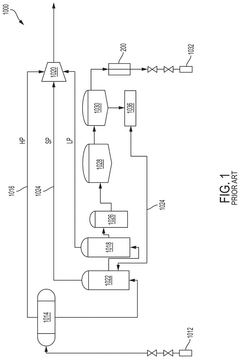

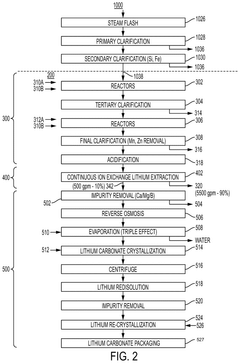

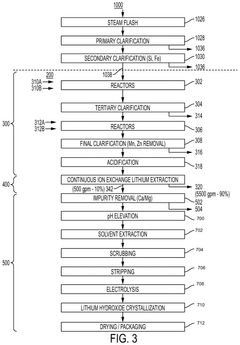

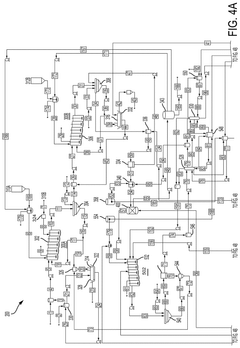

Process for recovery of lithium from a geothermal brine

PatentPendingUS20250162894A1

Innovation

- A system and process involving impurity removal, selective recovery of lithium chloride using a continuous counter-current ion exchange system, and conversion of lithium chloride to lithium carbonate or lithium hydroxide.

Selective lithium extraction chemistry for geothermal brine

PatentWO2023102064A1

Innovation

- The method involves using host-guest complexes, specifically calixarenes and dendrimers with organic acids, to selectively extract lithium from geothermal brines by encapsulating lithium ions, which can be enhanced by incorporating these complexes into porous membranes and applying electrical potential.

Environmental Impact Assessment Framework

The Environmental Impact Assessment Framework for lithium extraction requires a comprehensive methodology to evaluate and compare the ecological footprints of geothermal brine extraction versus traditional hard-rock mining. This framework must incorporate multiple dimensions of environmental analysis to provide a holistic understanding of each method's sustainability profile.

The assessment begins with boundary definition, clearly delineating the scope of analysis from raw material acquisition through processing to end-of-life considerations. For geothermal brine extraction, this encompasses the energy inputs for pumping operations, chemical reagents for lithium separation, and infrastructure development. For hard-rock mining, it includes land clearing, drilling, blasting, crushing, and chemical processing steps.

Resource consumption metrics form a critical component, quantifying water usage, energy requirements, and land disturbance. Geothermal brine extraction typically demonstrates advantages in land disturbance metrics, requiring significantly less surface area disruption compared to open-pit mining operations. However, the energy intensity of brine concentration processes must be carefully evaluated against the mechanical energy demands of hard-rock extraction.

Emissions tracking constitutes another essential element, measuring greenhouse gases, particulate matter, and chemical releases throughout the extraction lifecycle. The framework must account for both direct emissions from operations and indirect emissions from energy generation supporting these processes. Preliminary studies suggest geothermal methods may offer reduced carbon footprints when powered by the same geothermal energy used for extraction.

Ecosystem impact assessment protocols within the framework evaluate biodiversity disruption, habitat fragmentation, and ecological succession patterns. Hard-rock mining typically presents more significant challenges in this domain due to extensive land transformation, while geothermal operations' impacts concentrate on potential thermal pollution and subsurface alterations.

Water quality monitoring systems must be integrated to track potential contamination pathways, including acid mine drainage from hard-rock operations and potential brine leakage or chemical contamination from geothermal processing. The framework should incorporate both immediate and long-term monitoring protocols to capture delayed environmental responses.

Waste management evaluation methodologies complete the framework, analyzing tailings disposal from hard-rock mining against spent brine management from geothermal operations. This includes volumetric assessments, toxicity characterization, and long-term stability projections for waste products from both extraction pathways.

The framework must ultimately enable standardized comparison through normalized metrics, allowing decision-makers to evaluate tradeoffs between different environmental impact categories across the two extraction methodologies.

The assessment begins with boundary definition, clearly delineating the scope of analysis from raw material acquisition through processing to end-of-life considerations. For geothermal brine extraction, this encompasses the energy inputs for pumping operations, chemical reagents for lithium separation, and infrastructure development. For hard-rock mining, it includes land clearing, drilling, blasting, crushing, and chemical processing steps.

Resource consumption metrics form a critical component, quantifying water usage, energy requirements, and land disturbance. Geothermal brine extraction typically demonstrates advantages in land disturbance metrics, requiring significantly less surface area disruption compared to open-pit mining operations. However, the energy intensity of brine concentration processes must be carefully evaluated against the mechanical energy demands of hard-rock extraction.

Emissions tracking constitutes another essential element, measuring greenhouse gases, particulate matter, and chemical releases throughout the extraction lifecycle. The framework must account for both direct emissions from operations and indirect emissions from energy generation supporting these processes. Preliminary studies suggest geothermal methods may offer reduced carbon footprints when powered by the same geothermal energy used for extraction.

Ecosystem impact assessment protocols within the framework evaluate biodiversity disruption, habitat fragmentation, and ecological succession patterns. Hard-rock mining typically presents more significant challenges in this domain due to extensive land transformation, while geothermal operations' impacts concentrate on potential thermal pollution and subsurface alterations.

Water quality monitoring systems must be integrated to track potential contamination pathways, including acid mine drainage from hard-rock operations and potential brine leakage or chemical contamination from geothermal processing. The framework should incorporate both immediate and long-term monitoring protocols to capture delayed environmental responses.

Waste management evaluation methodologies complete the framework, analyzing tailings disposal from hard-rock mining against spent brine management from geothermal operations. This includes volumetric assessments, toxicity characterization, and long-term stability projections for waste products from both extraction pathways.

The framework must ultimately enable standardized comparison through normalized metrics, allowing decision-makers to evaluate tradeoffs between different environmental impact categories across the two extraction methodologies.

Economic Viability Analysis

The economic viability of lithium extraction methods represents a critical factor in determining their commercial adoption and sustainability. When comparing geothermal brine extraction to traditional hard-rock mining, several economic parameters must be evaluated to provide a comprehensive assessment.

Capital expenditure (CAPEX) requirements differ significantly between these methods. Hard-rock mining operations typically demand substantial initial investments in excavation equipment, processing facilities, and infrastructure development. These costs can range from $300-600 million for medium-scale operations. Conversely, geothermal brine extraction can leverage existing geothermal power infrastructure, potentially reducing initial capital requirements by 20-30%, though specialized extraction technology still requires significant investment.

Operational expenditure (OPEX) analysis reveals distinct cost structures. Hard-rock mining incurs ongoing expenses related to drilling, blasting, crushing, and chemical processing, with labor costs representing 30-40% of operational expenses. Geothermal brine extraction demonstrates lower energy costs due to integration with power generation facilities, but faces challenges with maintenance of extraction equipment due to the corrosive nature of brines.

Production timeline considerations favor hard-rock mining for immediate returns, as these operations can typically reach full production capacity within 3-5 years. Geothermal projects often require longer development periods of 5-7 years before achieving optimal extraction rates, affecting short-term return on investment calculations.

Market sensitivity analysis indicates that both methods face exposure to lithium price volatility, though with different risk profiles. Hard-rock operations have higher break-even prices, estimated at $5,000-7,000 per tonne of lithium carbonate equivalent (LCE), while geothermal brine projects may achieve profitability at $4,000-6,000 per tonne LCE due to potential by-product revenue streams and lower energy costs.

Scaling economics present another important distinction. Hard-rock mining benefits from established economies of scale with predictable cost reductions as operations expand. Geothermal brine extraction technology remains in earlier commercialization stages, suggesting potential for significant cost improvements as technology matures and deployment increases.

Long-term economic resilience may favor geothermal extraction due to lower environmental remediation costs and reduced exposure to increasingly stringent mining regulations. The integration with renewable energy production also provides a hedge against rising carbon pricing mechanisms that could impact traditional mining operations.

Capital expenditure (CAPEX) requirements differ significantly between these methods. Hard-rock mining operations typically demand substantial initial investments in excavation equipment, processing facilities, and infrastructure development. These costs can range from $300-600 million for medium-scale operations. Conversely, geothermal brine extraction can leverage existing geothermal power infrastructure, potentially reducing initial capital requirements by 20-30%, though specialized extraction technology still requires significant investment.

Operational expenditure (OPEX) analysis reveals distinct cost structures. Hard-rock mining incurs ongoing expenses related to drilling, blasting, crushing, and chemical processing, with labor costs representing 30-40% of operational expenses. Geothermal brine extraction demonstrates lower energy costs due to integration with power generation facilities, but faces challenges with maintenance of extraction equipment due to the corrosive nature of brines.

Production timeline considerations favor hard-rock mining for immediate returns, as these operations can typically reach full production capacity within 3-5 years. Geothermal projects often require longer development periods of 5-7 years before achieving optimal extraction rates, affecting short-term return on investment calculations.

Market sensitivity analysis indicates that both methods face exposure to lithium price volatility, though with different risk profiles. Hard-rock operations have higher break-even prices, estimated at $5,000-7,000 per tonne of lithium carbonate equivalent (LCE), while geothermal brine projects may achieve profitability at $4,000-6,000 per tonne LCE due to potential by-product revenue streams and lower energy costs.

Scaling economics present another important distinction. Hard-rock mining benefits from established economies of scale with predictable cost reductions as operations expand. Geothermal brine extraction technology remains in earlier commercialization stages, suggesting potential for significant cost improvements as technology matures and deployment increases.

Long-term economic resilience may favor geothermal extraction due to lower environmental remediation costs and reduced exposure to increasingly stringent mining regulations. The integration with renewable energy production also provides a hedge against rising carbon pricing mechanisms that could impact traditional mining operations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!