Battery-Grade Purification Steps After Direct Lithium Extraction

SEP 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DLE Purification Technology Background and Objectives

Direct Lithium Extraction (DLE) technology has evolved significantly over the past three decades, emerging as a promising alternative to traditional evaporation pond methods for lithium recovery. The evolution began in the 1990s with rudimentary ion exchange and adsorption techniques, progressing through various technological iterations to today's sophisticated selective extraction systems. This technological progression has been driven by increasing global demand for lithium, primarily fueled by the exponential growth in electric vehicle production and energy storage systems.

The purification steps following DLE represent a critical bottleneck in the lithium supply chain. Historically, post-extraction purification relied on conventional chemical precipitation methods that were energy-intensive and environmentally problematic. Recent technological developments have focused on improving efficiency while reducing environmental impact, with significant breakthroughs occurring between 2015-2020 in membrane filtration and electrochemical purification techniques.

Current technological trends indicate a shift toward integrated purification systems that combine multiple separation technologies to achieve battery-grade purity levels (99.5%+ lithium carbonate equivalent). These systems increasingly incorporate advanced materials science, particularly in the development of selective membranes and adsorbents that can effectively separate lithium from contaminants such as sodium, magnesium, calcium, and boron at the molecular level.

The primary technical objective in DLE purification is to develop scalable, energy-efficient processes that can consistently produce battery-grade lithium compounds (lithium carbonate or lithium hydroxide) from diverse brine sources with varying impurity profiles. Secondary objectives include reducing water consumption, minimizing chemical reagent usage, and decreasing overall environmental footprint compared to traditional methods.

Another critical goal is reducing the time required for purification. Traditional evaporation methods require 18-24 months for concentration and purification, while advanced DLE purification aims to complete the entire process within days or weeks, significantly improving production responsiveness to market demands.

Cost reduction represents another fundamental objective, as current DLE purification steps often contribute 30-40% of the total production costs. Technological innovations aim to bring this below 20% while maintaining or improving purity levels to meet increasingly stringent battery manufacturer specifications.

The technological trajectory suggests that future developments will focus on continuous-flow purification systems with real-time monitoring and adaptive process control, potentially incorporating artificial intelligence for optimization of purification parameters based on incoming brine composition variations.

The purification steps following DLE represent a critical bottleneck in the lithium supply chain. Historically, post-extraction purification relied on conventional chemical precipitation methods that were energy-intensive and environmentally problematic. Recent technological developments have focused on improving efficiency while reducing environmental impact, with significant breakthroughs occurring between 2015-2020 in membrane filtration and electrochemical purification techniques.

Current technological trends indicate a shift toward integrated purification systems that combine multiple separation technologies to achieve battery-grade purity levels (99.5%+ lithium carbonate equivalent). These systems increasingly incorporate advanced materials science, particularly in the development of selective membranes and adsorbents that can effectively separate lithium from contaminants such as sodium, magnesium, calcium, and boron at the molecular level.

The primary technical objective in DLE purification is to develop scalable, energy-efficient processes that can consistently produce battery-grade lithium compounds (lithium carbonate or lithium hydroxide) from diverse brine sources with varying impurity profiles. Secondary objectives include reducing water consumption, minimizing chemical reagent usage, and decreasing overall environmental footprint compared to traditional methods.

Another critical goal is reducing the time required for purification. Traditional evaporation methods require 18-24 months for concentration and purification, while advanced DLE purification aims to complete the entire process within days or weeks, significantly improving production responsiveness to market demands.

Cost reduction represents another fundamental objective, as current DLE purification steps often contribute 30-40% of the total production costs. Technological innovations aim to bring this below 20% while maintaining or improving purity levels to meet increasingly stringent battery manufacturer specifications.

The technological trajectory suggests that future developments will focus on continuous-flow purification systems with real-time monitoring and adaptive process control, potentially incorporating artificial intelligence for optimization of purification parameters based on incoming brine composition variations.

Market Analysis for Battery-Grade Lithium Demand

The global lithium market is experiencing unprecedented growth driven primarily by the electric vehicle (EV) revolution and expanding energy storage systems. Battery-grade lithium demand is projected to reach 1.5 million metric tons of lithium carbonate equivalent (LCE) by 2030, representing a compound annual growth rate of approximately 25% from 2022 levels. This explosive growth trajectory has transformed lithium from a specialty chemical into a critical strategic resource for many nations.

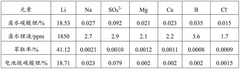

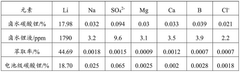

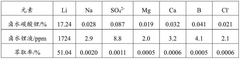

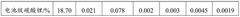

Battery manufacturers require extremely high purity lithium compounds (99.5% or higher) to ensure optimal battery performance, safety, and longevity. The quality requirements have become increasingly stringent as battery technology advances, with impurity tolerances measured in parts per million. Specifically, elements like sodium, potassium, calcium, magnesium, and iron must be reduced to minimal levels as they significantly impact battery efficiency and cycle life.

The market segmentation for battery-grade lithium shows distinct preferences between lithium carbonate and lithium hydroxide. While lithium carbonate has historically dominated, lithium hydroxide is gaining market share rapidly due to its suitability for high-nickel cathode materials used in long-range EVs. This shift is creating new purification challenges as hydroxide production requires different processing techniques.

Regional demand patterns reveal China's continued dominance in lithium processing, accounting for over 60% of global battery-grade lithium refining capacity. However, significant investments are underway in North America and Europe to establish regional supply chains, driven by both economic and national security concerns. These new facilities will require advanced purification technologies to meet local battery manufacturers' specifications.

Price premiums for battery-grade lithium versus technical-grade material highlight the economic value of effective purification processes. Battery-grade lithium compounds typically command a 15-30% premium, providing strong financial incentives for developing efficient purification technologies after direct lithium extraction (DLE).

Supply chain vulnerabilities have become increasingly apparent, with battery manufacturers seeking diversified and reliable sources of high-purity lithium. This has accelerated interest in DLE technologies that can access previously uneconomical resources, provided that cost-effective purification steps can be implemented to achieve battery-grade specifications.

The sustainability profile of lithium production is becoming a market differentiator, with customers increasingly demanding products with lower environmental footprints. Purification processes that minimize water usage, reduce chemical consumption, and lower energy requirements are gaining competitive advantages in the marketplace.

Battery manufacturers require extremely high purity lithium compounds (99.5% or higher) to ensure optimal battery performance, safety, and longevity. The quality requirements have become increasingly stringent as battery technology advances, with impurity tolerances measured in parts per million. Specifically, elements like sodium, potassium, calcium, magnesium, and iron must be reduced to minimal levels as they significantly impact battery efficiency and cycle life.

The market segmentation for battery-grade lithium shows distinct preferences between lithium carbonate and lithium hydroxide. While lithium carbonate has historically dominated, lithium hydroxide is gaining market share rapidly due to its suitability for high-nickel cathode materials used in long-range EVs. This shift is creating new purification challenges as hydroxide production requires different processing techniques.

Regional demand patterns reveal China's continued dominance in lithium processing, accounting for over 60% of global battery-grade lithium refining capacity. However, significant investments are underway in North America and Europe to establish regional supply chains, driven by both economic and national security concerns. These new facilities will require advanced purification technologies to meet local battery manufacturers' specifications.

Price premiums for battery-grade lithium versus technical-grade material highlight the economic value of effective purification processes. Battery-grade lithium compounds typically command a 15-30% premium, providing strong financial incentives for developing efficient purification technologies after direct lithium extraction (DLE).

Supply chain vulnerabilities have become increasingly apparent, with battery manufacturers seeking diversified and reliable sources of high-purity lithium. This has accelerated interest in DLE technologies that can access previously uneconomical resources, provided that cost-effective purification steps can be implemented to achieve battery-grade specifications.

The sustainability profile of lithium production is becoming a market differentiator, with customers increasingly demanding products with lower environmental footprints. Purification processes that minimize water usage, reduce chemical consumption, and lower energy requirements are gaining competitive advantages in the marketplace.

Current Purification Challenges After DLE

Despite the promising advancements in Direct Lithium Extraction (DLE) technologies, the post-extraction purification process remains a significant bottleneck in producing battery-grade lithium compounds. Current DLE methods typically yield lithium concentrates with various impurities that must be removed before the material can meet the stringent specifications required by battery manufacturers.

The primary challenge lies in the complex composition of DLE eluates, which contain varying levels of sodium, potassium, calcium, magnesium, boron, and other metal ions depending on the source brine and extraction method used. These impurities significantly impact battery performance, with even trace amounts potentially causing reduced cycle life, diminished capacity, and safety concerns in lithium-ion batteries.

Conventional purification approaches after DLE often involve multiple precipitation steps, ion exchange processes, and solvent extraction techniques. These methods typically require large volumes of chemicals, generate substantial waste streams, and consume significant energy. The multi-stage nature of these processes also leads to lithium losses at each step, reducing overall recovery rates to sometimes below 80%, which impacts economic viability.

Membrane-based separation technologies present their own challenges, including membrane fouling from organic compounds and scaling from precipitated salts. This necessitates frequent maintenance and replacement, increasing operational costs and downtime. Additionally, selective separation of lithium from chemically similar elements like sodium remains technically difficult with current membrane technologies.

Energy consumption represents another major hurdle, particularly in the evaporation and crystallization stages required to produce battery-grade lithium compounds. These energy-intensive processes contribute significantly to the carbon footprint and operational costs of lithium production facilities, undermining the sustainability benefits that DLE initially offers over traditional extraction methods.

Quality consistency is also problematic, as variations in feed composition from DLE processes can lead to fluctuations in final product purity. Battery manufacturers require extremely consistent lithium compounds with 99.5% or higher purity and strictly controlled impurity profiles, making robust quality control essential but challenging to maintain.

The scalability of purification systems presents additional complications, as laboratory-proven techniques often encounter unforeseen challenges when scaled to commercial production volumes. This scale-up gap has slowed the industrial implementation of novel purification approaches that show promise in research settings.

Water management remains a critical concern, with current purification processes requiring substantial volumes of fresh water for washing and dilution steps. This creates tension in water-scarce regions where many lithium resources are located, adding regulatory and social license complications to technical challenges.

The primary challenge lies in the complex composition of DLE eluates, which contain varying levels of sodium, potassium, calcium, magnesium, boron, and other metal ions depending on the source brine and extraction method used. These impurities significantly impact battery performance, with even trace amounts potentially causing reduced cycle life, diminished capacity, and safety concerns in lithium-ion batteries.

Conventional purification approaches after DLE often involve multiple precipitation steps, ion exchange processes, and solvent extraction techniques. These methods typically require large volumes of chemicals, generate substantial waste streams, and consume significant energy. The multi-stage nature of these processes also leads to lithium losses at each step, reducing overall recovery rates to sometimes below 80%, which impacts economic viability.

Membrane-based separation technologies present their own challenges, including membrane fouling from organic compounds and scaling from precipitated salts. This necessitates frequent maintenance and replacement, increasing operational costs and downtime. Additionally, selective separation of lithium from chemically similar elements like sodium remains technically difficult with current membrane technologies.

Energy consumption represents another major hurdle, particularly in the evaporation and crystallization stages required to produce battery-grade lithium compounds. These energy-intensive processes contribute significantly to the carbon footprint and operational costs of lithium production facilities, undermining the sustainability benefits that DLE initially offers over traditional extraction methods.

Quality consistency is also problematic, as variations in feed composition from DLE processes can lead to fluctuations in final product purity. Battery manufacturers require extremely consistent lithium compounds with 99.5% or higher purity and strictly controlled impurity profiles, making robust quality control essential but challenging to maintain.

The scalability of purification systems presents additional complications, as laboratory-proven techniques often encounter unforeseen challenges when scaled to commercial production volumes. This scale-up gap has slowed the industrial implementation of novel purification approaches that show promise in research settings.

Water management remains a critical concern, with current purification processes requiring substantial volumes of fresh water for washing and dilution steps. This creates tension in water-scarce regions where many lithium resources are located, adding regulatory and social license complications to technical challenges.

Current Post-DLE Purification Solutions

01 Adsorption-based lithium extraction methods

Direct Lithium Extraction (DLE) processes using selective adsorption materials to capture lithium ions from brines and other sources. These methods typically employ specialized adsorbents such as lithium ion sieves, inorganic ion exchange materials, or functionalized polymers that can selectively bind lithium ions over competing ions like sodium, magnesium, and calcium. The adsorption process is followed by desorption steps where lithium is recovered in a more concentrated form, which serves as the first step toward achieving battery-grade purity.- Adsorption-based Direct Lithium Extraction (DLE) methods: Adsorption-based DLE methods utilize selective adsorbents to capture lithium ions from brine solutions. These methods typically employ ion-exchange materials or lithium-selective sorbents that can selectively adsorb lithium over competing ions such as sodium, potassium, magnesium, and calcium. The lithium-loaded adsorbents are then subjected to desorption processes to recover concentrated lithium solutions, which undergo further purification to achieve battery-grade purity. This approach offers advantages in selectivity and can be applied to various brine sources.

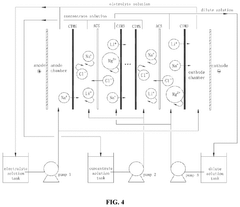

- Membrane and electrochemical purification techniques: Membrane and electrochemical techniques are employed in DLE processes to separate lithium from impurities. These methods include nanofiltration, electrodialysis, and electrochemical systems that leverage the different ionic properties of lithium and competing elements. Membrane technologies can effectively remove divalent ions like calcium and magnesium, while electrochemical approaches can concentrate lithium solutions through controlled potential gradients. These techniques are often combined with other purification steps to achieve the high purity levels required for battery-grade lithium compounds.

- Chemical precipitation and crystallization processes: Chemical precipitation and crystallization are critical steps in refining lithium solutions to battery-grade purity. These processes involve the addition of specific reagents to selectively precipitate impurities or to crystallize lithium compounds under controlled conditions. Sequential precipitation steps target different impurities, such as magnesium, calcium, boron, and transition metals. Crystallization techniques, including evaporative and cooling crystallization, are employed to obtain high-purity lithium compounds like lithium carbonate or lithium hydroxide that meet the stringent requirements for battery applications.

- Solvent extraction and ion exchange purification: Solvent extraction and ion exchange purification methods are employed to selectively separate lithium from complex brine solutions. These techniques utilize organic extractants or ion exchange resins with high selectivity for lithium ions. The process typically involves multiple extraction stages to progressively remove impurities and concentrate lithium. The purified lithium-rich solution is then processed further to produce battery-grade lithium compounds. These methods are particularly effective for handling brines with high magnesium content and can achieve high lithium recovery rates while maintaining product purity.

- Integrated multi-stage purification systems: Integrated multi-stage purification systems combine various separation and purification technologies to achieve battery-grade lithium purity. These comprehensive processes typically include pre-treatment steps to remove major impurities, followed by selective extraction of lithium, and final polishing stages to eliminate trace contaminants. The integration of different technologies such as adsorption, membrane separation, precipitation, and ion exchange allows for optimized performance in terms of lithium recovery, energy efficiency, and product quality. These systems are designed to handle the variability in feed composition while consistently producing high-purity lithium compounds suitable for battery applications.

02 Membrane and electrochemical purification techniques

Advanced purification methods that utilize membrane technologies and electrochemical processes to separate lithium from impurities. These techniques include electrodialysis, nanofiltration, and electrochemical cells that can selectively transport lithium ions while blocking other elements. The processes often operate based on differences in ion mobility, charge, or size, allowing for high selectivity in lithium purification. These methods are particularly effective for removing divalent ions and achieving the high purity levels required for battery-grade lithium compounds.Expand Specific Solutions03 Chemical precipitation and crystallization methods

Purification processes that involve chemical precipitation steps to remove impurities and crystallization techniques to obtain high-purity lithium compounds. These methods typically include pH adjustment, addition of specific reagents to precipitate impurities like magnesium, calcium, and heavy metals, followed by controlled crystallization to produce battery-grade lithium carbonate or hydroxide. Multiple crystallization stages may be employed to progressively increase purity levels, with careful control of temperature, concentration, and seeding to ensure proper crystal formation and impurity exclusion.Expand Specific Solutions04 Solvent extraction and ion exchange purification

Liquid-liquid extraction and ion exchange processes for separating lithium from contaminants in brine or leach solutions. These methods use specialized organic extractants or ion exchange resins that selectively bind with lithium ions. The lithium-loaded organic phase or resin is then treated to strip the lithium into a purified aqueous solution. Multiple extraction or ion exchange stages can be implemented to progressively remove specific impurities and achieve battery-grade purity levels. These techniques are particularly effective for processing complex brine compositions with high magnesium content.Expand Specific Solutions05 Integrated multi-stage purification systems

Comprehensive purification processes that combine multiple separation technologies in sequence to achieve battery-grade lithium purity. These integrated systems typically involve preliminary concentration steps, followed by a series of purification stages that may include adsorption, membrane separation, solvent extraction, ion exchange, and crystallization. The multi-stage approach allows for the targeted removal of specific impurities at each step, resulting in a highly efficient process for producing battery-grade lithium compounds that meet stringent purity requirements of >99.5% with minimal levels of critical impurities like sodium, magnesium, calcium, and heavy metals.Expand Specific Solutions

Key Industry Players in Lithium Purification

The battery-grade purification market following Direct Lithium Extraction (DLE) is in a growth phase characterized by rapid technological advancement and increasing demand driven by the electric vehicle boom. The global market is projected to expand significantly as lithium battery production scales up worldwide. Technologically, the field shows varying maturity levels, with established players like BASF Corp. and Sumitomo Metal Mining offering commercial solutions, while innovative approaches emerge from research institutions such as Central South University and Argonne National Laboratory. Chinese companies including Guangdong Bangpu and POSCO Holdings are advancing rapidly with integrated recycling-to-purification processes, while startups like Forager Station introduce novel electrochemical purification methods. The competitive landscape features both traditional metallurgical companies expanding into lithium processing and specialized technology firms focused exclusively on high-purity battery materials.

BASF Corp.

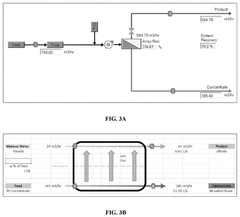

Technical Solution: BASF has developed an integrated post-DLE purification system leveraging their extensive chemical processing expertise. Their approach centers on a multi-phase impurity removal process that begins with selective precipitation of divalent cations using proprietary reagents that minimize lithium co-precipitation losses. The system incorporates advanced oxidation processes to decompose organic contaminants followed by specialized adsorbents that selectively remove boron and silica impurities. BASF's innovation includes a continuous crystallization technology that produces battery-grade lithium compounds through precisely controlled supersaturation and crystal growth parameters. The process employs sophisticated process control algorithms that continuously adjust operating parameters based on feed composition variations, maintaining consistent product quality. BASF has implemented elements of this technology in commercial operations in Europe and North America, achieving battery-grade lithium carbonate with 99.5% purity and demonstrating approximately 25% reduction in processing costs compared to conventional methods through reagent recycling and energy optimization.

Strengths: Robust operation with ability to handle feed composition variations; extensive chemical engineering expertise applied to process optimization; established global supply chain for reagents and equipment; demonstrated commercial viability. Weaknesses: Higher chemical consumption than some newer technologies; process complexity requiring sophisticated control systems; moderate water usage compared to most advanced systems.

Uchicago Argonne LLC

Technical Solution: Argonne National Laboratory has pioneered an innovative purification approach for post-DLE lithium processing that combines electrochemical separation with advanced membrane technology. Their system employs a selective electrochemical cell that preferentially extracts lithium ions while rejecting competing ions through precisely controlled electrical potential gradients. The process incorporates proprietary ceramic membranes with lithium-selective transport channels that achieve separation factors exceeding 1000:1 for lithium over sodium and potassium. A key innovation is their multi-stage impurity removal system that sequentially eliminates boron, silica, and transition metals through specialized sorbents and pH-controlled precipitation. The final purification employs crystallization under controlled temperature gradients to produce battery-grade lithium compounds with 99.9% purity. Argonne's process reduces energy consumption by approximately 40% compared to conventional methods while achieving higher purity levels suitable for next-generation battery applications.

Strengths: Exceptional purity levels (99.9%) suitable for advanced battery applications; significantly reduced energy consumption; minimal chemical reagent requirements; applicable to diverse lithium sources including geothermal brines. Weaknesses: Technology remains primarily at pilot scale; higher complexity requiring specialized operational expertise; membrane fouling issues may require frequent maintenance in certain applications.

Critical Technologies for Battery-Grade Lithium Production

Method for preparing battery-grade lithium carbonate from brine lithium carbonate

PatentWO2025065148A1

Innovation

- A simple process and environmentally friendly method are adopted to extract the brine lithium carbonate through an extraction agent, separate boron impurities and purify lithium carbonate, and remove the battery-grade lithium carbonate in one step, avoiding the consumption of liquid alkali.

Systems and methods for direct lithium extraction

PatentPendingUS20250011957A1

Innovation

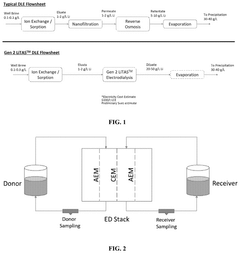

- The integration of selective membrane electrodialysis as a single step to simultaneously concentrate and purify lithium brines, reducing the number of required processing steps, capital and operating costs, and carbon footprint, while eliminating the need for large equipment at remote mining locations.

Environmental Impact Assessment of Purification Processes

The purification processes following Direct Lithium Extraction (DLE) present significant environmental considerations that must be thoroughly assessed. These processes, which typically include precipitation, ion exchange, solvent extraction, and membrane filtration, each generate distinct environmental footprints that vary in intensity and nature.

Water consumption represents one of the most critical environmental concerns in lithium purification. Traditional evaporation methods require approximately 500,000 gallons of water per ton of lithium produced. While DLE significantly reduces this figure, the subsequent purification steps still demand substantial water resources, particularly during washing and rinsing phases of precipitation and ion exchange processes.

Energy requirements for purification processes contribute substantially to the carbon footprint of battery-grade lithium production. Membrane filtration and electrodialysis systems, though efficient in separation, require continuous electrical input. Thermal processes used in crystallization and drying stages further increase energy demands, with estimates suggesting that purification accounts for 30-40% of the total energy consumption in lithium processing.

Chemical usage in purification presents additional environmental challenges. Precipitation methods typically employ sodium carbonate, sodium hydroxide, or calcium hydroxide, generating significant quantities of waste salts. Ion exchange resins require periodic regeneration with strong acids or bases, creating hazardous waste streams that necessitate specialized treatment.

Waste management issues extend beyond chemical waste to include spent filter media, exhausted resins, and membrane replacement. These materials often contain trace amounts of heavy metals and other contaminants that require proper disposal protocols. Current industry practices generate approximately 2-3 tons of solid waste per ton of battery-grade lithium produced.

Emissions from purification processes include both direct air pollutants and greenhouse gases. Solvent extraction methods may release volatile organic compounds (VOCs), while thermal processes contribute to CO2 emissions. Recent life cycle assessments indicate that purification steps contribute approximately 15-20% of the total greenhouse gas emissions in the lithium production chain.

Land use impacts, though less discussed, remain significant. Waste storage facilities, treatment ponds, and processing infrastructure expand the physical footprint of lithium production facilities. This aspect becomes particularly concerning when operations are located in ecologically sensitive areas or regions with competing land use priorities.

Regulatory frameworks governing these environmental impacts vary considerably across jurisdictions, creating challenges for standardized assessment and mitigation strategies. Leading producers are increasingly adopting voluntary environmental management systems that exceed regulatory requirements, recognizing that environmental performance increasingly influences market access and corporate valuation.

Water consumption represents one of the most critical environmental concerns in lithium purification. Traditional evaporation methods require approximately 500,000 gallons of water per ton of lithium produced. While DLE significantly reduces this figure, the subsequent purification steps still demand substantial water resources, particularly during washing and rinsing phases of precipitation and ion exchange processes.

Energy requirements for purification processes contribute substantially to the carbon footprint of battery-grade lithium production. Membrane filtration and electrodialysis systems, though efficient in separation, require continuous electrical input. Thermal processes used in crystallization and drying stages further increase energy demands, with estimates suggesting that purification accounts for 30-40% of the total energy consumption in lithium processing.

Chemical usage in purification presents additional environmental challenges. Precipitation methods typically employ sodium carbonate, sodium hydroxide, or calcium hydroxide, generating significant quantities of waste salts. Ion exchange resins require periodic regeneration with strong acids or bases, creating hazardous waste streams that necessitate specialized treatment.

Waste management issues extend beyond chemical waste to include spent filter media, exhausted resins, and membrane replacement. These materials often contain trace amounts of heavy metals and other contaminants that require proper disposal protocols. Current industry practices generate approximately 2-3 tons of solid waste per ton of battery-grade lithium produced.

Emissions from purification processes include both direct air pollutants and greenhouse gases. Solvent extraction methods may release volatile organic compounds (VOCs), while thermal processes contribute to CO2 emissions. Recent life cycle assessments indicate that purification steps contribute approximately 15-20% of the total greenhouse gas emissions in the lithium production chain.

Land use impacts, though less discussed, remain significant. Waste storage facilities, treatment ponds, and processing infrastructure expand the physical footprint of lithium production facilities. This aspect becomes particularly concerning when operations are located in ecologically sensitive areas or regions with competing land use priorities.

Regulatory frameworks governing these environmental impacts vary considerably across jurisdictions, creating challenges for standardized assessment and mitigation strategies. Leading producers are increasingly adopting voluntary environmental management systems that exceed regulatory requirements, recognizing that environmental performance increasingly influences market access and corporate valuation.

Supply Chain Resilience for Battery Materials

The global battery supply chain faces unprecedented challenges due to geopolitical tensions, resource nationalism, and concentration of critical materials in specific regions. For lithium, a key battery material, the supply chain resilience is particularly concerning as post-DLE (Direct Lithium Extraction) purification represents a critical bottleneck. Currently, over 60% of battery-grade lithium processing occurs in China, creating significant vulnerability for Western automotive and energy storage industries.

Supply chain resilience for battery materials requires diversification of processing capabilities across multiple regions. After DLE processes extract lithium from brines or other sources, the subsequent purification steps to achieve battery-grade quality (99.5% purity or higher) involve specialized technologies and significant capital investment. These purification facilities are not easily replicated in new locations due to technical expertise requirements, environmental permitting complexities, and economies of scale considerations.

Recent disruptions have highlighted the fragility of the current system. The COVID-19 pandemic caused severe delays in lithium chemical production, while trade tensions between major economies have accelerated concerns about supply security. Companies and governments are now implementing various strategies to enhance resilience, including nearshoring of processing facilities, formation of strategic stockpiles, and development of alternative purification technologies with lower capital intensity.

Investment in domestic purification capabilities has become a national security priority for many countries. The United States, European Union, Canada, and Australia have all launched initiatives to support development of local processing facilities. These include financial incentives, streamlined permitting processes, and research funding for innovative purification methods that can operate economically at smaller scales.

Technical innovations are emerging to address these challenges. New membrane-based purification systems, advanced electrochemical processes, and modular processing units are being developed to enable more distributed production networks. These technologies aim to reduce the minimum efficient scale for battery-grade lithium production, potentially allowing for more localized processing closer to either extraction sites or battery manufacturing facilities.

Long-term contracts and strategic partnerships between miners, processors, and battery manufacturers are becoming increasingly common as another resilience strategy. These arrangements provide financial security for investment in new purification facilities while ensuring priority access to materials during supply disruptions. Such vertical integration helps mitigate price volatility and supply uncertainty throughout the battery value chain.

Supply chain resilience for battery materials requires diversification of processing capabilities across multiple regions. After DLE processes extract lithium from brines or other sources, the subsequent purification steps to achieve battery-grade quality (99.5% purity or higher) involve specialized technologies and significant capital investment. These purification facilities are not easily replicated in new locations due to technical expertise requirements, environmental permitting complexities, and economies of scale considerations.

Recent disruptions have highlighted the fragility of the current system. The COVID-19 pandemic caused severe delays in lithium chemical production, while trade tensions between major economies have accelerated concerns about supply security. Companies and governments are now implementing various strategies to enhance resilience, including nearshoring of processing facilities, formation of strategic stockpiles, and development of alternative purification technologies with lower capital intensity.

Investment in domestic purification capabilities has become a national security priority for many countries. The United States, European Union, Canada, and Australia have all launched initiatives to support development of local processing facilities. These include financial incentives, streamlined permitting processes, and research funding for innovative purification methods that can operate economically at smaller scales.

Technical innovations are emerging to address these challenges. New membrane-based purification systems, advanced electrochemical processes, and modular processing units are being developed to enable more distributed production networks. These technologies aim to reduce the minimum efficient scale for battery-grade lithium production, potentially allowing for more localized processing closer to either extraction sites or battery manufacturing facilities.

Long-term contracts and strategic partnerships between miners, processors, and battery manufacturers are becoming increasingly common as another resilience strategy. These arrangements provide financial security for investment in new purification facilities while ensuring priority access to materials during supply disruptions. Such vertical integration helps mitigate price volatility and supply uncertainty throughout the battery value chain.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!