How To Recover Lithium From Geothermal Brines: Process Options And Tradeoffs

SEP 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Geothermal Lithium Extraction Background and Objectives

Lithium extraction from geothermal brines represents a promising frontier in sustainable resource development, combining renewable energy production with critical mineral recovery. The concept emerged in the 1970s but gained significant momentum only in the past decade as global demand for lithium has surged due to the rapid expansion of electric vehicle markets and energy storage systems. This technological approach leverages existing geothermal energy infrastructure to access lithium-rich brines, offering a potentially lower environmental impact alternative to traditional lithium mining methods.

Historically, lithium production has been dominated by hard rock mining and solar evaporation of salt flats, primarily in Australia, Chile, and Argentina. These conventional methods face increasing scrutiny due to their substantial land and water requirements, as well as their carbon footprint. Geothermal brine extraction presents an opportunity to address these concerns while simultaneously producing clean energy, creating a dual-revenue stream model that enhances economic viability.

The technical evolution of lithium recovery from geothermal sources has progressed through several key phases. Early efforts focused on simple precipitation methods, while recent innovations have explored selective adsorption materials, advanced membrane technologies, and electrochemical processes. Each advancement has aimed to improve selectivity, efficiency, and economic feasibility under the challenging conditions of geothermal brines, which typically contain high temperatures, complex chemical compositions, and variable lithium concentrations.

The primary objective of current research and development efforts is to establish commercially viable processes that can selectively extract lithium from geothermal brines at industrial scales. This involves optimizing extraction efficiency while minimizing energy consumption, chemical usage, and waste generation. Additional goals include developing systems that can operate continuously with minimal maintenance despite the corrosive nature of geothermal fluids.

Several regions globally show particular promise for geothermal lithium development, including the Salton Sea in California, the Upper Rhine Valley in Germany, and various locations in New Zealand, Japan, and Turkey. These areas combine favorable geological conditions with existing or planned geothermal energy infrastructure, creating natural testing grounds for emerging technologies.

The convergence of renewable energy production and critical mineral recovery positions geothermal lithium extraction as a strategically important technology with potential to contribute significantly to both clean energy transitions and supply chain security for battery materials. As such, it has attracted increasing attention from governments, industry players, and research institutions seeking to establish leadership in this emerging field.

Historically, lithium production has been dominated by hard rock mining and solar evaporation of salt flats, primarily in Australia, Chile, and Argentina. These conventional methods face increasing scrutiny due to their substantial land and water requirements, as well as their carbon footprint. Geothermal brine extraction presents an opportunity to address these concerns while simultaneously producing clean energy, creating a dual-revenue stream model that enhances economic viability.

The technical evolution of lithium recovery from geothermal sources has progressed through several key phases. Early efforts focused on simple precipitation methods, while recent innovations have explored selective adsorption materials, advanced membrane technologies, and electrochemical processes. Each advancement has aimed to improve selectivity, efficiency, and economic feasibility under the challenging conditions of geothermal brines, which typically contain high temperatures, complex chemical compositions, and variable lithium concentrations.

The primary objective of current research and development efforts is to establish commercially viable processes that can selectively extract lithium from geothermal brines at industrial scales. This involves optimizing extraction efficiency while minimizing energy consumption, chemical usage, and waste generation. Additional goals include developing systems that can operate continuously with minimal maintenance despite the corrosive nature of geothermal fluids.

Several regions globally show particular promise for geothermal lithium development, including the Salton Sea in California, the Upper Rhine Valley in Germany, and various locations in New Zealand, Japan, and Turkey. These areas combine favorable geological conditions with existing or planned geothermal energy infrastructure, creating natural testing grounds for emerging technologies.

The convergence of renewable energy production and critical mineral recovery positions geothermal lithium extraction as a strategically important technology with potential to contribute significantly to both clean energy transitions and supply chain security for battery materials. As such, it has attracted increasing attention from governments, industry players, and research institutions seeking to establish leadership in this emerging field.

Market Analysis for Lithium Demand in Clean Energy Transition

The global lithium market is experiencing unprecedented growth driven primarily by the clean energy transition. Lithium demand is projected to increase by 40-fold between 2020 and 2040 according to the International Energy Agency, with the battery sector accounting for over 80% of total consumption. This surge is directly linked to the rapid expansion of electric vehicle (EV) production and stationary energy storage systems, both critical components of decarbonization strategies worldwide.

Electric vehicle batteries represent the largest and fastest-growing segment of lithium demand. Global EV sales reached 10.5 million units in 2022, representing a 55% year-over-year increase. Major automotive manufacturers have committed to electrifying significant portions of their fleets by 2030, with several planning to phase out internal combustion engines entirely by 2035-2040. This transition is creating sustained pressure on lithium supply chains.

Grid-scale energy storage systems constitute another significant growth sector for lithium demand. As renewable energy penetration increases globally, the need for large-scale storage solutions to address intermittency issues becomes critical. The stationary storage market is expected to grow at a CAGR of 32% through 2030, requiring substantial lithium resources.

Consumer electronics continue to provide baseline demand for lithium, though their share of total consumption is diminishing relative to transportation and energy storage applications. Nevertheless, this sector maintains steady growth of 5-7% annually.

Geographically, China currently dominates lithium processing capacity and battery manufacturing, but significant investments are underway in North America and Europe to develop regional supply chains. The Inflation Reduction Act in the United States and similar policies in the European Union are accelerating domestic battery production, further stimulating regional lithium demand.

Price volatility has characterized the lithium market in recent years, with prices surging over 400% in 2021-2022 before moderating. This volatility underscores the strategic importance of developing diverse lithium sources, including geothermal brines, which offer potential supply stability advantages over traditional mining operations.

The sustainability profile of lithium production is becoming increasingly important to end-users, particularly automotive manufacturers with stringent ESG commitments. Geothermal brine extraction methods typically have lower carbon footprints and reduced land disturbance compared to hard rock mining or traditional evaporative brine operations, potentially commanding premium pricing in environmentally conscious markets.

Electric vehicle batteries represent the largest and fastest-growing segment of lithium demand. Global EV sales reached 10.5 million units in 2022, representing a 55% year-over-year increase. Major automotive manufacturers have committed to electrifying significant portions of their fleets by 2030, with several planning to phase out internal combustion engines entirely by 2035-2040. This transition is creating sustained pressure on lithium supply chains.

Grid-scale energy storage systems constitute another significant growth sector for lithium demand. As renewable energy penetration increases globally, the need for large-scale storage solutions to address intermittency issues becomes critical. The stationary storage market is expected to grow at a CAGR of 32% through 2030, requiring substantial lithium resources.

Consumer electronics continue to provide baseline demand for lithium, though their share of total consumption is diminishing relative to transportation and energy storage applications. Nevertheless, this sector maintains steady growth of 5-7% annually.

Geographically, China currently dominates lithium processing capacity and battery manufacturing, but significant investments are underway in North America and Europe to develop regional supply chains. The Inflation Reduction Act in the United States and similar policies in the European Union are accelerating domestic battery production, further stimulating regional lithium demand.

Price volatility has characterized the lithium market in recent years, with prices surging over 400% in 2021-2022 before moderating. This volatility underscores the strategic importance of developing diverse lithium sources, including geothermal brines, which offer potential supply stability advantages over traditional mining operations.

The sustainability profile of lithium production is becoming increasingly important to end-users, particularly automotive manufacturers with stringent ESG commitments. Geothermal brine extraction methods typically have lower carbon footprints and reduced land disturbance compared to hard rock mining or traditional evaporative brine operations, potentially commanding premium pricing in environmentally conscious markets.

Current Challenges in Geothermal Brine Lithium Recovery

Despite significant advancements in lithium extraction from geothermal brines, several critical challenges continue to impede widespread commercial implementation. The highly complex and variable chemical composition of geothermal brines presents a fundamental obstacle, with concentrations of lithium typically ranging from 10 to 400 mg/L amid high levels of competing ions such as sodium, potassium, calcium, and magnesium. This chemical complexity necessitates customized extraction processes for each brine source, preventing standardized solutions.

Temperature management represents another significant challenge, as geothermal brines often emerge at temperatures between 150-300°C, requiring substantial cooling before conventional extraction methods can be applied. This cooling process not only consumes energy but also risks mineral precipitation that can foul equipment and reduce lithium recovery efficiency.

The corrosive nature of geothermal brines, characterized by high salinity, extreme pH conditions, and dissolved gases like hydrogen sulfide, accelerates equipment degradation and necessitates costly corrosion-resistant materials. This substantially increases capital expenditure and maintenance requirements for extraction facilities.

Selectivity issues persist across all extraction technologies. Adsorption methods struggle with ion competition, while membrane processes face fouling and scaling. Chemical precipitation approaches often co-precipitate unwanted elements, requiring additional purification steps. These selectivity challenges directly impact product purity and process economics.

Scale-up difficulties represent a critical barrier to commercialization. Laboratory-proven technologies frequently encounter unforeseen challenges when scaled to industrial levels, including flow distribution problems, reduced efficiency at larger volumes, and unexpected chemical interactions in continuous processing systems.

Environmental considerations pose increasing constraints, particularly regarding water consumption in water-stressed regions. Most current extraction processes require significant water inputs for dilution, washing, and regeneration steps. Additionally, the disposal of process residues containing concentrated levels of potentially harmful elements demands careful management.

Economic viability remains perhaps the most significant challenge. Current extraction costs from geothermal brines typically range from $5,000-$12,000 per ton of lithium carbonate equivalent, compared to traditional mining costs of $2,000-$5,000. This economic gap persists due to high energy requirements, specialized equipment needs, and the relatively low concentration of lithium in most geothermal resources.

Temperature management represents another significant challenge, as geothermal brines often emerge at temperatures between 150-300°C, requiring substantial cooling before conventional extraction methods can be applied. This cooling process not only consumes energy but also risks mineral precipitation that can foul equipment and reduce lithium recovery efficiency.

The corrosive nature of geothermal brines, characterized by high salinity, extreme pH conditions, and dissolved gases like hydrogen sulfide, accelerates equipment degradation and necessitates costly corrosion-resistant materials. This substantially increases capital expenditure and maintenance requirements for extraction facilities.

Selectivity issues persist across all extraction technologies. Adsorption methods struggle with ion competition, while membrane processes face fouling and scaling. Chemical precipitation approaches often co-precipitate unwanted elements, requiring additional purification steps. These selectivity challenges directly impact product purity and process economics.

Scale-up difficulties represent a critical barrier to commercialization. Laboratory-proven technologies frequently encounter unforeseen challenges when scaled to industrial levels, including flow distribution problems, reduced efficiency at larger volumes, and unexpected chemical interactions in continuous processing systems.

Environmental considerations pose increasing constraints, particularly regarding water consumption in water-stressed regions. Most current extraction processes require significant water inputs for dilution, washing, and regeneration steps. Additionally, the disposal of process residues containing concentrated levels of potentially harmful elements demands careful management.

Economic viability remains perhaps the most significant challenge. Current extraction costs from geothermal brines typically range from $5,000-$12,000 per ton of lithium carbonate equivalent, compared to traditional mining costs of $2,000-$5,000. This economic gap persists due to high energy requirements, specialized equipment needs, and the relatively low concentration of lithium in most geothermal resources.

Process Options for Geothermal Brine Lithium Extraction

01 Direct extraction methods for lithium recovery

Direct extraction methods involve selectively removing lithium from geothermal brines using specialized adsorbents, ion exchange resins, or membranes. These techniques offer advantages such as higher recovery rates, reduced processing time, and smaller environmental footprint compared to traditional evaporation methods. The process typically involves passing the brine through a medium that selectively captures lithium ions, followed by a stripping phase to recover concentrated lithium solution for further processing.- Direct extraction methods for lithium recovery: Direct extraction methods involve the selective removal of lithium from geothermal brines using specialized adsorbents, ion exchange resins, or membranes. These techniques offer advantages such as higher recovery rates, reduced processing time, and lower environmental impact compared to traditional evaporation methods. The process typically involves passing the brine through a medium that selectively captures lithium ions, followed by a stripping phase to recover concentrated lithium solution for further processing.

- Evaporation and concentration techniques: Evaporation-based recovery methods utilize solar energy or waste heat from geothermal power plants to concentrate lithium in brines through sequential evaporation. These methods involve a series of evaporation ponds where various salts precipitate at different concentration stages, eventually yielding lithium-rich solutions. While these techniques are relatively simple and energy-efficient, they require significant land area, are weather-dependent, and typically have longer processing times compared to direct extraction methods.

- Integration with geothermal energy production: Integrated systems combine lithium extraction with geothermal energy production, creating dual-purpose facilities that generate electricity while recovering valuable minerals. These systems utilize the heat and pressure from geothermal resources to power both energy generation and mineral extraction processes. The integration offers economic advantages through shared infrastructure and operational costs, while also improving the overall efficiency of resource utilization by extracting value from both the thermal energy and mineral content of geothermal brines.

- Selective precipitation and crystallization methods: Selective precipitation methods involve the addition of specific reagents to geothermal brines to trigger the formation of lithium-containing precipitates or crystals that can be separated from the solution. These techniques often utilize pH adjustment, temperature control, or chemical additives to selectively crystallize lithium compounds while leaving other elements in solution. The precipitated lithium compounds are then collected, purified, and processed further to obtain lithium products of commercial grade.

- Brine pre-treatment and impurity removal: Pre-treatment processes focus on removing impurities from geothermal brines before lithium extraction to improve efficiency and product purity. These methods include filtration, chemical precipitation, and ion exchange to eliminate elements such as calcium, magnesium, iron, and silica that can interfere with lithium recovery or contaminate the final product. Effective pre-treatment enhances the performance of subsequent extraction processes, extends the lifespan of extraction media, and improves the quality of recovered lithium compounds.

02 Evaporation and concentration techniques

Evaporation-based recovery methods utilize solar energy or waste heat from geothermal power plants to concentrate lithium in brines through sequential evaporation. These methods involve a series of evaporation ponds where various salts precipitate at different concentration stages, eventually yielding lithium-rich solutions. While these techniques are relatively simple and energy-efficient, they require significant land area, are weather-dependent, and typically have longer processing times compared to direct extraction methods.Expand Specific Solutions03 Integration with geothermal energy production

Integrated systems combine lithium extraction with geothermal energy production, creating dual-purpose facilities that generate electricity while recovering valuable minerals. These systems utilize the heat and pressure from geothermal operations to power the extraction process, improving overall energy efficiency. The integration allows for cost sharing between power generation and mineral recovery operations, making both processes more economically viable while reducing the environmental impact compared to standalone operations.Expand Specific Solutions04 Membrane and filtration technologies

Advanced membrane and filtration technologies employ specialized membranes, nanofiltration, or reverse osmosis systems to separate lithium from other components in geothermal brines. These methods can achieve high selectivity for lithium ions while rejecting competing ions such as sodium, magnesium, and calcium. The technologies offer advantages including continuous operation capability, reduced chemical consumption, and smaller physical footprint compared to traditional methods, though they may face challenges related to membrane fouling and energy requirements.Expand Specific Solutions05 Purification and conversion to commercial lithium compounds

After initial extraction from geothermal brines, lithium-rich solutions undergo purification and conversion processes to produce commercial-grade lithium compounds such as lithium carbonate or lithium hydroxide. These processes involve precipitation of impurities, pH adjustment, and crystallization steps to achieve the required purity levels. The choice of final lithium compound depends on market demands and intended applications, with lithium hydroxide generally preferred for high-performance battery applications and lithium carbonate for other industrial uses.Expand Specific Solutions

Key Industry Players in Geothermal Lithium Recovery

The lithium extraction from geothermal brines market is in its early growth stage, characterized by increasing commercial interest but limited large-scale deployment. The global market is projected to expand significantly as demand for lithium in battery applications surges, with estimates suggesting a multi-billion dollar opportunity by 2030. Technologically, the field remains in development with several competing extraction methodologies. Companies like Standard Lithium, Vulcan Energie, and Schlumberger are leading commercial development with direct lithium extraction (DLE) technologies, while research institutions including Rice University, MIT, and Chinese Academy of Sciences are advancing novel separation techniques. Academic-industry partnerships are accelerating technology maturation, though challenges in selectivity, recovery rates, and economic viability persist across different brine compositions.

Standard Lithium Ltd.

Technical Solution: Standard Lithium has developed a proprietary Direct Lithium Extraction (DLE) technology called "LiSTR" (Lithium Stirred Tank Reactor) specifically designed for extracting lithium from geothermal brines. Their process involves selective adsorption using a highly specific adsorbent material that captures lithium ions while rejecting other elements present in brines. The LiSTR process operates as a continuous system where brine flows through a series of stirred tank reactors containing the adsorbent, allowing for efficient lithium capture. After adsorption, lithium is eluted using a water-based solution, producing a clean, concentrated lithium chloride solution. This is then processed through crystallization and conversion steps to produce battery-grade lithium carbonate or hydroxide. Their demonstration plant in Arkansas has achieved recovery rates of over 90% while producing lithium carbonate with 99.97% purity[1]. The process requires minimal land use compared to evaporation ponds and can be deployed alongside existing brine operations.

Strengths: High selectivity for lithium with minimal impurities; rapid processing time (hours vs. months for evaporation ponds); significantly reduced water consumption; modular design allowing for scalability. Weaknesses: Higher capital expenditure compared to traditional evaporation methods; requires electricity for operation; technology still being scaled to full commercial implementation; specific adsorbent materials may have limited lifespan requiring periodic replacement.

Vulcan Energie Ressourcen GmbH

Technical Solution: Vulcan Energy has pioneered a "Zero Carbon Lithium" extraction process specifically designed for the deep geothermal brines of the Upper Rhine Valley in Germany. Their integrated approach combines geothermal energy production with lithium extraction, creating a unique carbon-neutral system. The process begins with extracting hot geothermal brine (160-180°C) from depths of 2-5km. This brine naturally contains dissolved lithium (150-200 mg/L). The thermal energy is first harvested to generate renewable electricity, which powers the entire lithium extraction process. After energy extraction, the still-warm brine passes through Vulcan's proprietary Direct Lithium Extraction (DLE) system using selective adsorption technology. Their adsorbent material selectively captures lithium ions while rejecting other elements. The lithium is then eluted using water-based solutions, concentrated, and purified before conversion to battery-grade lithium hydroxide. The post-processing brine is reinjected into the reservoir, creating a closed-loop system that minimizes environmental impact[2]. Their pilot plant has demonstrated lithium recovery rates exceeding 90%.

Strengths: Carbon-neutral or potentially carbon-negative process due to geothermal energy integration; closed-loop system with minimal water consumption; no mining or evaporation ponds required; produces both renewable energy and lithium from the same resource. Weaknesses: Limited to regions with suitable geothermal resources; requires significant upfront capital investment for both geothermal wells and processing facilities; technology still scaling to full commercial implementation; complex integration of energy and chemical processing systems.

Technical Analysis of Extraction Efficiency and Selectivity

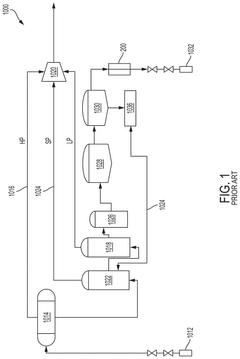

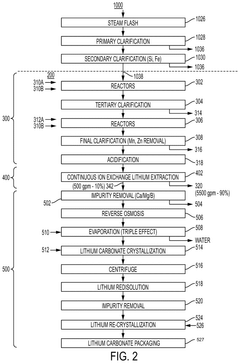

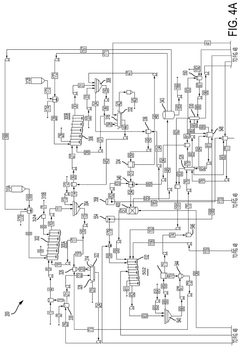

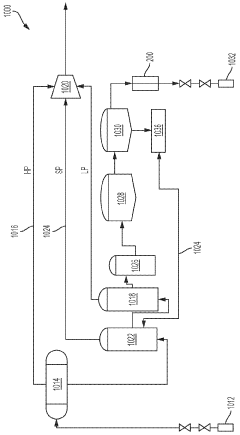

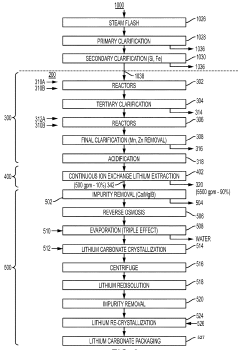

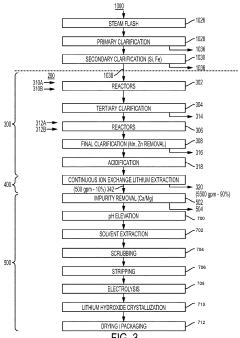

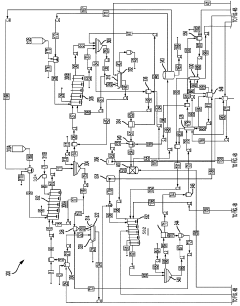

Process for recovery of lithium from a geothermal brine

PatentPendingUS20250162893A1

Innovation

- A system and process involving sequential steps: impurity removal, selective recovery of lithium chloride using a continuous counter-current ion exchange circuit, and conversion of lithium chloride to lithium carbonate or lithium hydroxide.

System for recovery of lithium from a geothermal brine

PatentPendingUS20200189924A1

Innovation

- A system and process involving impurity removal, continuous counter-current ion exchange, and lithium chloride conversion to produce lithium carbonate or lithium hydroxide, with sequential steps for removing silica, iron, zinc, and manganese, using ion exchange circuits and solvent extraction to concentrate and purify lithium chloride.

Environmental Impact Assessment of Extraction Technologies

The environmental impact of lithium extraction from geothermal brines varies significantly across different technologies, with each method presenting unique ecological considerations. Direct lithium extraction (DLE) technologies generally demonstrate a smaller environmental footprint compared to traditional evaporation pond methods, particularly regarding land use and water consumption. DLE processes typically require less than 10% of the land area needed for evaporation ponds and can reduce freshwater consumption by up to 65%.

Water usage remains a critical environmental concern for all extraction methods. While traditional evaporation techniques consume approximately 500,000 gallons of water per ton of lithium carbonate produced, advanced DLE technologies have demonstrated potential reductions to approximately 170,000 gallons per ton. However, these improvements must be contextualized within the water-stressed regions where many geothermal resources exist.

Carbon emissions represent another significant environmental factor. The carbon footprint of lithium extraction from geothermal brines is estimated at 5-15 kg CO2e per kg of lithium carbonate equivalent (LCE), substantially lower than the 15-25 kg CO2e per kg LCE associated with hard rock mining operations. When geothermal energy powers the extraction process, these emissions can be further reduced by up to 30%.

Chemical usage in extraction processes presents additional environmental challenges. Ion exchange technologies typically employ strong acids for regeneration, while adsorption methods often require organic solvents. Recent innovations in solvent-free extraction have shown promise in reducing chemical waste by approximately 40%, though these technologies remain in early commercial deployment stages.

Waste management considerations vary by technology. Membrane-based systems generate concentrated brine streams requiring disposal, while adsorption technologies produce spent media that must be periodically replaced and properly disposed of. The industry is increasingly adopting circular economy principles, with approximately 65% of process chemicals now being recovered and reused in advanced systems.

Habitat disruption represents a final key consideration. While geothermal brine extraction generally disturbs less surface area than traditional mining, pipeline infrastructure and processing facilities still impact local ecosystems. Recent environmental impact studies indicate that implementing wildlife corridors and native vegetation buffers can reduce habitat fragmentation effects by up to 50%, representing an important mitigation strategy for future development.

Water usage remains a critical environmental concern for all extraction methods. While traditional evaporation techniques consume approximately 500,000 gallons of water per ton of lithium carbonate produced, advanced DLE technologies have demonstrated potential reductions to approximately 170,000 gallons per ton. However, these improvements must be contextualized within the water-stressed regions where many geothermal resources exist.

Carbon emissions represent another significant environmental factor. The carbon footprint of lithium extraction from geothermal brines is estimated at 5-15 kg CO2e per kg of lithium carbonate equivalent (LCE), substantially lower than the 15-25 kg CO2e per kg LCE associated with hard rock mining operations. When geothermal energy powers the extraction process, these emissions can be further reduced by up to 30%.

Chemical usage in extraction processes presents additional environmental challenges. Ion exchange technologies typically employ strong acids for regeneration, while adsorption methods often require organic solvents. Recent innovations in solvent-free extraction have shown promise in reducing chemical waste by approximately 40%, though these technologies remain in early commercial deployment stages.

Waste management considerations vary by technology. Membrane-based systems generate concentrated brine streams requiring disposal, while adsorption technologies produce spent media that must be periodically replaced and properly disposed of. The industry is increasingly adopting circular economy principles, with approximately 65% of process chemicals now being recovered and reused in advanced systems.

Habitat disruption represents a final key consideration. While geothermal brine extraction generally disturbs less surface area than traditional mining, pipeline infrastructure and processing facilities still impact local ecosystems. Recent environmental impact studies indicate that implementing wildlife corridors and native vegetation buffers can reduce habitat fragmentation effects by up to 50%, representing an important mitigation strategy for future development.

Economic Feasibility and Scaling Considerations

The economic feasibility of lithium recovery from geothermal brines hinges on several critical factors that must be carefully evaluated. Capital expenditure (CAPEX) requirements for establishing extraction facilities range from $20-50 million for pilot plants to $300-500 million for commercial-scale operations, representing a significant barrier to entry. Operating expenses (OPEX) are primarily driven by energy consumption, chemical reagents, and maintenance costs, which can vary substantially depending on the selected extraction technology.

Direct lithium extraction (DLE) technologies demonstrate promising economics at scale, with potential production costs between $3,000-$6,000 per ton of lithium carbonate equivalent (LCE), compared to traditional evaporation pond methods at $5,000-$8,000 per ton. However, these projections remain theoretical until more commercial-scale operations are established and validated.

Scaling considerations present unique challenges in geothermal lithium recovery. The transition from laboratory to commercial scale involves significant technical hurdles, including maintaining extraction efficiency at higher flow rates, managing equipment fouling from mineral scaling, and ensuring consistent performance across variable brine compositions. Pilot plant testing becomes essential to validate technology performance under real-world conditions before committing to full-scale implementation.

The economic viability is further influenced by lithium market dynamics, with current prices around $15,000-$20,000 per ton of LCE providing favorable margins for efficient operations. However, market volatility poses risks to long-term investment decisions, necessitating careful financial modeling that incorporates various price scenarios.

Infrastructure requirements represent another critical scaling consideration. Geothermal brine processing facilities require substantial land area, robust power supply, water treatment capabilities, and transportation infrastructure. The integration with existing geothermal power plants offers synergistic benefits through shared infrastructure and energy utilization, potentially reducing overall costs by 15-25%.

Environmental compliance costs must also be factored into economic assessments, including wastewater management, brine reinjection systems, and monitoring equipment. These expenses can add 10-15% to overall project costs but are essential for sustainable operations and maintaining social license to operate.

Return on investment timelines typically range from 5-8 years for well-designed operations, though this varies significantly based on technology selection, brine lithium concentration, and market conditions. Government incentives for critical mineral production and clean energy development can substantially improve these economics through tax benefits, grants, or expedited permitting processes.

Direct lithium extraction (DLE) technologies demonstrate promising economics at scale, with potential production costs between $3,000-$6,000 per ton of lithium carbonate equivalent (LCE), compared to traditional evaporation pond methods at $5,000-$8,000 per ton. However, these projections remain theoretical until more commercial-scale operations are established and validated.

Scaling considerations present unique challenges in geothermal lithium recovery. The transition from laboratory to commercial scale involves significant technical hurdles, including maintaining extraction efficiency at higher flow rates, managing equipment fouling from mineral scaling, and ensuring consistent performance across variable brine compositions. Pilot plant testing becomes essential to validate technology performance under real-world conditions before committing to full-scale implementation.

The economic viability is further influenced by lithium market dynamics, with current prices around $15,000-$20,000 per ton of LCE providing favorable margins for efficient operations. However, market volatility poses risks to long-term investment decisions, necessitating careful financial modeling that incorporates various price scenarios.

Infrastructure requirements represent another critical scaling consideration. Geothermal brine processing facilities require substantial land area, robust power supply, water treatment capabilities, and transportation infrastructure. The integration with existing geothermal power plants offers synergistic benefits through shared infrastructure and energy utilization, potentially reducing overall costs by 15-25%.

Environmental compliance costs must also be factored into economic assessments, including wastewater management, brine reinjection systems, and monitoring equipment. These expenses can add 10-15% to overall project costs but are essential for sustainable operations and maintaining social license to operate.

Return on investment timelines typically range from 5-8 years for well-designed operations, though this varies significantly based on technology selection, brine lithium concentration, and market conditions. Government incentives for critical mineral production and clean energy development can substantially improve these economics through tax benefits, grants, or expedited permitting processes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!