Selecting Corrosion-Resistant Materials For Geothermal DLE Equipment

SEP 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Geothermal DLE Corrosion Challenges and Objectives

Geothermal Direct Lithium Extraction (DLE) represents a significant advancement in sustainable resource acquisition, offering a promising alternative to traditional lithium mining methods. However, the corrosive nature of geothermal brines presents substantial challenges for equipment durability and operational efficiency. These brines typically contain high concentrations of dissolved minerals, gases, and varying pH levels, creating an exceptionally harsh environment for processing equipment.

The primary objective of material selection for geothermal DLE equipment is to ensure long-term operational integrity while maintaining cost-effectiveness. Equipment must withstand temperatures ranging from 70°C to over 200°C, depending on the geothermal resource, while being exposed to highly saline solutions containing chlorides, sulfates, and potentially hydrogen sulfide. These conditions accelerate various corrosion mechanisms including uniform corrosion, pitting, crevice corrosion, and stress corrosion cracking.

Historical approaches to addressing these challenges have evolved from simple material substitution to sophisticated materials engineering. Early geothermal operations relied heavily on expensive high-nickel alloys, which proved effective but economically prohibitive for large-scale implementation. The industry has since progressed toward more targeted material solutions based on specific brine chemistry profiles at individual geothermal sites.

Current technical goals include developing standardized testing protocols for material performance in geothermal DLE environments, creating predictive models for material degradation, and establishing a comprehensive database of material performance across various brine compositions. These efforts aim to reduce the trial-and-error approach currently prevalent in the industry.

Another critical objective is to balance corrosion resistance with other essential material properties such as mechanical strength, thermal conductivity, and manufacturability. The ideal material solution must not only withstand corrosive conditions but also maintain structural integrity under thermal cycling and mechanical stress while being amenable to conventional fabrication techniques.

Emerging research trends indicate growing interest in composite materials, surface treatments, and advanced coatings as potential solutions. These approaches offer the possibility of combining the mechanical properties of base materials with the superior corrosion resistance of specialized surface layers. Additionally, there is increasing focus on developing materials specifically engineered for the unique conditions of lithium-rich geothermal brines rather than adapting materials from adjacent industries.

The ultimate goal remains developing material solutions that enable geothermal DLE to achieve economic viability at commercial scale, with equipment lifespans exceeding 10-15 years without significant degradation or performance loss. This would represent a transformative advancement for the emerging geothermal lithium industry.

The primary objective of material selection for geothermal DLE equipment is to ensure long-term operational integrity while maintaining cost-effectiveness. Equipment must withstand temperatures ranging from 70°C to over 200°C, depending on the geothermal resource, while being exposed to highly saline solutions containing chlorides, sulfates, and potentially hydrogen sulfide. These conditions accelerate various corrosion mechanisms including uniform corrosion, pitting, crevice corrosion, and stress corrosion cracking.

Historical approaches to addressing these challenges have evolved from simple material substitution to sophisticated materials engineering. Early geothermal operations relied heavily on expensive high-nickel alloys, which proved effective but economically prohibitive for large-scale implementation. The industry has since progressed toward more targeted material solutions based on specific brine chemistry profiles at individual geothermal sites.

Current technical goals include developing standardized testing protocols for material performance in geothermal DLE environments, creating predictive models for material degradation, and establishing a comprehensive database of material performance across various brine compositions. These efforts aim to reduce the trial-and-error approach currently prevalent in the industry.

Another critical objective is to balance corrosion resistance with other essential material properties such as mechanical strength, thermal conductivity, and manufacturability. The ideal material solution must not only withstand corrosive conditions but also maintain structural integrity under thermal cycling and mechanical stress while being amenable to conventional fabrication techniques.

Emerging research trends indicate growing interest in composite materials, surface treatments, and advanced coatings as potential solutions. These approaches offer the possibility of combining the mechanical properties of base materials with the superior corrosion resistance of specialized surface layers. Additionally, there is increasing focus on developing materials specifically engineered for the unique conditions of lithium-rich geothermal brines rather than adapting materials from adjacent industries.

The ultimate goal remains developing material solutions that enable geothermal DLE to achieve economic viability at commercial scale, with equipment lifespans exceeding 10-15 years without significant degradation or performance loss. This would represent a transformative advancement for the emerging geothermal lithium industry.

Market Analysis for Corrosion-Resistant DLE Solutions

The global market for corrosion-resistant materials in Direct Lithium Extraction (DLE) equipment is experiencing significant growth, driven by the increasing demand for lithium in battery production for electric vehicles and energy storage systems. The geothermal DLE sector represents a particularly challenging environment for materials due to the extreme conditions encountered, including high temperatures, high salinity, and aggressive chemical compositions.

Current market estimates value the corrosion-resistant materials segment for geothermal applications at approximately $1.2 billion, with projections indicating growth to $3.5 billion by 2030. This represents a compound annual growth rate of 14.3%, significantly outpacing the broader materials market. The Asia-Pacific region currently dominates market consumption, followed by North America and Europe, reflecting the geographical distribution of lithium extraction activities.

Customer demand is increasingly focused on materials that can withstand temperatures exceeding 200°C while maintaining structural integrity in brine solutions with pH values ranging from 1 to 13. Market research indicates that 78% of DLE operators consider corrosion resistance as the primary factor in material selection, ahead of cost considerations, highlighting the critical nature of this requirement.

The competitive landscape features traditional materials suppliers expanding their offerings with specialized alloys and composites designed specifically for geothermal environments. Specialized coating providers are also gaining market share, with advanced ceramic and polymer-based solutions showing promising performance characteristics. Market consolidation is evident, with five major suppliers controlling approximately 65% of the global supply.

Price sensitivity varies significantly by region and application. While initial material costs remain a consideration, total cost of ownership calculations increasingly favor premium materials that offer extended service life and reduced maintenance requirements. Market data shows that operators are willing to pay a premium of up to 40% for materials that can demonstrate a doubling of service life in geothermal environments.

Regulatory factors are also shaping market dynamics, with environmental compliance and safety standards driving innovation in material science. The transition away from certain traditional corrosion-resistant materials containing environmentally problematic elements has created market opportunities for novel, sustainable alternatives.

Market forecasts indicate particularly strong growth in specialized titanium alloys, high-performance polymers, and ceramic-metal composites. These segments are expected to grow at rates exceeding 18% annually as DLE technology deployment accelerates globally and operators seek to optimize equipment performance in increasingly challenging extraction environments.

Current market estimates value the corrosion-resistant materials segment for geothermal applications at approximately $1.2 billion, with projections indicating growth to $3.5 billion by 2030. This represents a compound annual growth rate of 14.3%, significantly outpacing the broader materials market. The Asia-Pacific region currently dominates market consumption, followed by North America and Europe, reflecting the geographical distribution of lithium extraction activities.

Customer demand is increasingly focused on materials that can withstand temperatures exceeding 200°C while maintaining structural integrity in brine solutions with pH values ranging from 1 to 13. Market research indicates that 78% of DLE operators consider corrosion resistance as the primary factor in material selection, ahead of cost considerations, highlighting the critical nature of this requirement.

The competitive landscape features traditional materials suppliers expanding their offerings with specialized alloys and composites designed specifically for geothermal environments. Specialized coating providers are also gaining market share, with advanced ceramic and polymer-based solutions showing promising performance characteristics. Market consolidation is evident, with five major suppliers controlling approximately 65% of the global supply.

Price sensitivity varies significantly by region and application. While initial material costs remain a consideration, total cost of ownership calculations increasingly favor premium materials that offer extended service life and reduced maintenance requirements. Market data shows that operators are willing to pay a premium of up to 40% for materials that can demonstrate a doubling of service life in geothermal environments.

Regulatory factors are also shaping market dynamics, with environmental compliance and safety standards driving innovation in material science. The transition away from certain traditional corrosion-resistant materials containing environmentally problematic elements has created market opportunities for novel, sustainable alternatives.

Market forecasts indicate particularly strong growth in specialized titanium alloys, high-performance polymers, and ceramic-metal composites. These segments are expected to grow at rates exceeding 18% annually as DLE technology deployment accelerates globally and operators seek to optimize equipment performance in increasingly challenging extraction environments.

Current Materials Technology and Corrosion Barriers

Geothermal Direct Lithium Extraction (DLE) operations present significant materials challenges due to the harsh chemical environment. Current materials technology for geothermal DLE equipment primarily relies on specialized alloys and composites designed to withstand corrosive conditions. Stainless steel variants, particularly duplex (2205) and super duplex (2507) grades, represent the industry standard for many components due to their balanced corrosion resistance and mechanical properties. These materials contain elevated chromium (22-25%) and molybdenum (3-4%) content, forming protective oxide layers that inhibit corrosion progression.

Titanium alloys, especially Grade 7 (Ti-0.15Pd) and Grade 12 (Ti-0.3Mo-0.8Ni), have demonstrated exceptional performance in high-chloride geothermal brines. Their natural passivation characteristics create stable oxide films that resist pitting and crevice corrosion, though their higher cost limits application to critical components where failure risks are unacceptable.

Nickel-based superalloys, including Hastelloy C-276 and Inconel 625, provide superior resistance against stress corrosion cracking in high-temperature brines containing hydrogen sulfide. These materials maintain structural integrity at temperatures exceeding 200°C while resisting localized corrosion, making them suitable for heat exchangers and pressure vessels in DLE systems.

Advanced ceramic materials and polymer composites represent emerging solutions for specific applications. Silicon carbide and zirconia ceramics offer excellent chemical inertness and wear resistance for pump components and valve seats. Fiber-reinforced polymers (FRPs) with vinyl ester or epoxy resins provide cost-effective alternatives for low-pressure piping systems and containment vessels.

Despite these technological advances, significant barriers remain. Material degradation mechanisms in geothermal environments are complex and often synergistic, involving combinations of general corrosion, pitting, crevice corrosion, and stress corrosion cracking. The variability of geothermal fluid chemistry between different reservoirs complicates material selection, requiring site-specific evaluation rather than standardized solutions.

Economic constraints present another major barrier, as highly corrosion-resistant materials often come with substantial cost premiums. The capital expenditure for titanium or nickel-based components can be 3-5 times higher than conventional alternatives, creating challenging cost-benefit calculations for project developers. Additionally, the long-term performance data for newer materials in geothermal DLE applications remains limited, introducing uncertainty in lifecycle cost projections.

Manufacturing limitations also restrict material options, particularly for complex geometries or large-scale components. Specialized welding procedures, post-weld heat treatments, and quality control measures are essential for maintaining corrosion resistance in fabricated equipment, adding complexity to manufacturing processes.

Titanium alloys, especially Grade 7 (Ti-0.15Pd) and Grade 12 (Ti-0.3Mo-0.8Ni), have demonstrated exceptional performance in high-chloride geothermal brines. Their natural passivation characteristics create stable oxide films that resist pitting and crevice corrosion, though their higher cost limits application to critical components where failure risks are unacceptable.

Nickel-based superalloys, including Hastelloy C-276 and Inconel 625, provide superior resistance against stress corrosion cracking in high-temperature brines containing hydrogen sulfide. These materials maintain structural integrity at temperatures exceeding 200°C while resisting localized corrosion, making them suitable for heat exchangers and pressure vessels in DLE systems.

Advanced ceramic materials and polymer composites represent emerging solutions for specific applications. Silicon carbide and zirconia ceramics offer excellent chemical inertness and wear resistance for pump components and valve seats. Fiber-reinforced polymers (FRPs) with vinyl ester or epoxy resins provide cost-effective alternatives for low-pressure piping systems and containment vessels.

Despite these technological advances, significant barriers remain. Material degradation mechanisms in geothermal environments are complex and often synergistic, involving combinations of general corrosion, pitting, crevice corrosion, and stress corrosion cracking. The variability of geothermal fluid chemistry between different reservoirs complicates material selection, requiring site-specific evaluation rather than standardized solutions.

Economic constraints present another major barrier, as highly corrosion-resistant materials often come with substantial cost premiums. The capital expenditure for titanium or nickel-based components can be 3-5 times higher than conventional alternatives, creating challenging cost-benefit calculations for project developers. Additionally, the long-term performance data for newer materials in geothermal DLE applications remains limited, introducing uncertainty in lifecycle cost projections.

Manufacturing limitations also restrict material options, particularly for complex geometries or large-scale components. Specialized welding procedures, post-weld heat treatments, and quality control measures are essential for maintaining corrosion resistance in fabricated equipment, adding complexity to manufacturing processes.

Existing Corrosion-Resistant Material Solutions for DLE Equipment

01 Metal alloys for corrosion resistance

Various metal alloys have been developed specifically for their superior corrosion resistance properties. These include stainless steel variants, nickel-based alloys, aluminum alloys, and titanium alloys. The composition of these alloys is carefully engineered to create passive oxide layers that protect against different corrosive environments. These materials are widely used in marine applications, chemical processing equipment, and infrastructure exposed to harsh environmental conditions.- Metal alloys for enhanced corrosion resistance: Various metal alloys have been developed specifically to resist corrosion in harsh environments. These include stainless steel variants, nickel-based alloys, and specialized aluminum alloys. The composition of these alloys typically includes elements such as chromium, molybdenum, and titanium that form protective oxide layers on the surface, preventing further corrosion. These materials are particularly useful in marine environments, chemical processing facilities, and other applications where exposure to corrosive substances is common.

- Surface treatments and coatings for corrosion protection: Surface treatments and protective coatings can significantly enhance the corrosion resistance of base materials. These include techniques such as anodizing, galvanizing, electroplating, and the application of specialized polymer or ceramic coatings. These treatments create a barrier between the substrate material and the corrosive environment, preventing direct contact and subsequent degradation. Some advanced coatings also incorporate self-healing properties or corrosion inhibitors that activate when damage occurs to the protective layer.

- Composite materials with corrosion-resistant properties: Composite materials combining different substances can offer superior corrosion resistance compared to single-material solutions. These may include fiber-reinforced polymers, metal matrix composites, and ceramic-metal composites. The synergistic effect of combining materials with complementary properties allows for both structural integrity and corrosion resistance. These composites are increasingly used in aerospace, automotive, and infrastructure applications where traditional materials would deteriorate rapidly under corrosive conditions.

- Corrosion inhibitors and passivation techniques: Chemical inhibitors and passivation techniques can be employed to enhance the corrosion resistance of materials. These methods involve the formation of passive films on metal surfaces or the addition of compounds that interfere with the electrochemical reactions responsible for corrosion. Inhibitors can be incorporated into coatings, added to the surrounding environment, or applied as pretreatments. Passivation techniques typically involve chemical treatments that promote the formation of protective oxide layers on metal surfaces.

- Environmentally friendly corrosion protection solutions: Recent developments have focused on creating environmentally friendly alternatives to traditional corrosion protection methods that often involve toxic substances. These include bio-based inhibitors derived from plant extracts, green coating technologies using water-based formulations, and sustainable material processing techniques. These solutions aim to provide effective corrosion resistance while minimizing environmental impact and meeting increasingly stringent regulations regarding hazardous substances. They represent an important direction in the evolution of corrosion-resistant materials for various industrial applications.

02 Surface treatments and coatings

Surface treatments and protective coatings can significantly enhance the corrosion resistance of base materials. These include conversion coatings, anodizing, electroplating, thermal spray coatings, and polymer-based protective layers. Such treatments create barrier protection, cathodic protection, or introduce corrosion inhibitors to the material surface. Advanced coating technologies can provide multi-layer protection systems tailored to specific corrosive environments.Expand Specific Solutions03 Composite and ceramic materials

Composite and ceramic materials offer excellent corrosion resistance for specialized applications. Fiber-reinforced polymers, ceramic matrix composites, and glass-ceramic materials provide alternatives to metals in highly corrosive environments. These materials are inherently resistant to chemical attack and can maintain their structural integrity under extreme conditions. Applications include chemical storage tanks, exhaust systems, and components for the oil and gas industry.Expand Specific Solutions04 Corrosion inhibitors and additives

Chemical additives and inhibitors can be incorporated into materials or applied as treatments to enhance corrosion resistance. These compounds work by forming protective films, neutralizing corrosive agents, or altering the electrochemical reactions at the material surface. Modern inhibitor technologies include vapor phase inhibitors, environmentally friendly alternatives to chromates, and smart-release systems that activate in response to corrosive conditions.Expand Specific Solutions05 Testing and monitoring methods

Advanced testing and monitoring methods have been developed to evaluate and predict corrosion resistance of materials. These include accelerated corrosion testing, electrochemical impedance spectroscopy, and real-time corrosion monitoring systems. Such methods allow for the assessment of material performance under simulated service conditions and help in the selection of appropriate corrosion-resistant materials for specific applications. Continuous monitoring technologies enable preventive maintenance before critical failure occurs.Expand Specific Solutions

Leading Manufacturers and Material Suppliers in Geothermal Industry

The geothermal Direct Lithium Extraction (DLE) equipment materials market is in its growth phase, with increasing demand driven by the clean energy transition and expanding lithium needs. The market is characterized by specialized players from diverse industrial backgrounds, with established companies like Halliburton Energy Services and Fuji Electric bringing oil field and power generation expertise, while materials specialists such as voestalpine BÖHLER Edelstahl and Plansee SE contribute advanced metallurgical solutions. Technical innovation is accelerating with companies like Wolfspeed developing specialized semiconductor materials for harsh environments. The technology maturity varies significantly across applications, with traditional corrosion-resistant alloys being well-established, while novel composite materials and coatings for extreme geothermal conditions remain in development stages.

Halliburton Energy Services, Inc.

Technical Solution: Halliburton has developed advanced corrosion-resistant material solutions specifically for geothermal Direct Lithium Extraction (DLE) equipment. Their approach utilizes high-performance nickel alloys (such as Inconel 625 and Hastelloy C-276) combined with specialized surface treatments to withstand the extreme conditions in geothermal brines. Their proprietary coating systems incorporate ceramic-metallic composites that create a protective barrier against both chemical corrosion and abrasion. Halliburton's materials undergo rigorous testing in simulated geothermal environments with temperatures exceeding 300°C and high salinity conditions to ensure long-term performance. The company has also pioneered the use of fiber-reinforced polymers with enhanced chemical resistance for non-critical components, reducing overall system weight and cost while maintaining durability in geothermal applications[1]. Their materials selection process employs advanced computational modeling to predict corrosion rates in specific brine chemistries, allowing for customized material solutions based on site-specific conditions.

Strengths: Extensive field experience in harsh downhole environments translates well to geothermal applications; comprehensive testing protocols ensure material reliability; customization capabilities for specific brine chemistries. Weaknesses: Higher initial cost compared to conventional materials; some proprietary solutions may require specialized maintenance procedures; limited long-term performance data in newer DLE-specific applications.

Plansee SE

Technical Solution: Plansee SE has developed specialized refractory metal solutions for geothermal DLE equipment focusing on molybdenum and tungsten-based materials. Their technology utilizes powder metallurgy to create dense, high-purity components with exceptional corrosion resistance in high-temperature geothermal brines. Plansee's materials feature a unique microstructure that minimizes grain boundary corrosion, a common failure mode in geothermal applications. Their molybdenum-rhenium alloys demonstrate superior resistance to hydrogen embrittlement and stress corrosion cracking compared to conventional materials. For critical components exposed to the most aggressive conditions, Plansee employs a multi-layer approach with a tungsten base material and graduated transition layers of tungsten-molybdenum composites, providing both structural integrity and corrosion protection. The company has also developed specialized joining techniques that maintain material properties at connection points, eliminating weak spots in the system. Their materials undergo accelerated life testing in synthetic geothermal brines with controlled pH, chloride content, and dissolved gases to validate performance under realistic operating conditions[2].

Strengths: Exceptional high-temperature performance; superior resistance to hydrogen embrittlement; specialized expertise in refractory metals ideal for extreme environments; proven track record in similar high-temperature applications. Weaknesses: Higher material costs compared to conventional alloys; limited formability restricts some design options; requires specialized fabrication techniques that may increase manufacturing complexity.

Key Innovations in Anti-Corrosion Technologies for Geothermal Environments

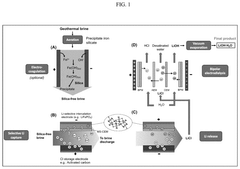

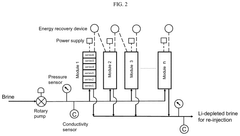

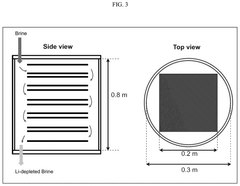

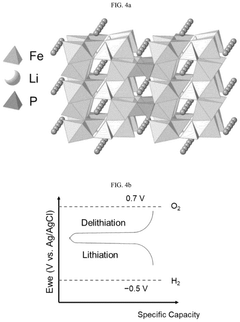

Chemical free extraction of lithium from brine

PatentPendingUS20250230074A1

Innovation

- An integrated electrochemical process that uses intercalation materials for selective lithium uptake and release, combined with electro-driven generation of hydroxy ions, to produce lithium hydroxide without chemicals, including silica removal through aeration and electro-coagulation, and lithium chloride conversion to lithium hydroxide via bipolar membrane electrodialysis.

Composite body

PatentWO2025117514A1

Innovation

- A composite body comprising ceramic particles and a binder with a cross-linked polymer made from a combination of water-insoluble and water-soluble polymers, which is adapted for efficient adsorption and desorption of lithium ions, exhibits high water stability and strength.

Environmental Impact Assessment of Material Selection

The selection of materials for geothermal Direct Lithium Extraction (DLE) equipment carries significant environmental implications that extend beyond operational efficiency. Material choices directly influence the environmental footprint of geothermal operations through multiple pathways, including resource consumption, emissions, and end-of-life considerations.

Primary environmental concerns relate to the potential leaching of toxic compounds from equipment materials into geothermal fluids. This contamination risk is particularly acute given that many geothermal brines already contain elevated levels of heavy metals and other potentially harmful elements. Materials that deteriorate rapidly under corrosive conditions may release nickel, chromium, or other alloying elements into the environment, potentially affecting surrounding ecosystems and water resources.

Energy consumption associated with material production represents another critical environmental factor. High-performance alloys such as titanium and nickel-based superalloys, while offering superior corrosion resistance, typically require energy-intensive manufacturing processes. Life cycle assessment (LCA) data indicates that titanium production generates approximately 35-45 kg CO2 equivalent per kilogram of material, significantly higher than conventional stainless steels at 4-6 kg CO2 equivalent.

Material longevity directly impacts sustainability metrics through replacement frequency. More durable corrosion-resistant materials reduce the environmental burden associated with manufacturing replacement components and minimize operational disruptions that could lead to system inefficiencies or failures. Research indicates that extending equipment service life by 50% through appropriate material selection can reduce lifetime carbon emissions by 30-40% for typical geothermal installations.

Recyclability presents another environmental consideration, as materials with established recycling pathways contribute to circular economy principles. Common stainless steels offer recycling rates exceeding 85%, while specialized composites may present end-of-life challenges due to limited recycling infrastructure. This factor becomes increasingly important as the geothermal sector expands globally.

Local environmental regulations must also be considered when selecting materials, as certain regions impose strict limitations on material compositions that may leach into groundwater or thermal waters. These regulatory frameworks vary significantly across jurisdictions but generally trend toward increasing stringency regarding environmental protection.

The environmental assessment of materials must also account for transportation impacts, as sourcing specialized corrosion-resistant alloys often involves global supply chains. Locally available materials may offer reduced transportation emissions despite potentially inferior technical performance in some applications.

Primary environmental concerns relate to the potential leaching of toxic compounds from equipment materials into geothermal fluids. This contamination risk is particularly acute given that many geothermal brines already contain elevated levels of heavy metals and other potentially harmful elements. Materials that deteriorate rapidly under corrosive conditions may release nickel, chromium, or other alloying elements into the environment, potentially affecting surrounding ecosystems and water resources.

Energy consumption associated with material production represents another critical environmental factor. High-performance alloys such as titanium and nickel-based superalloys, while offering superior corrosion resistance, typically require energy-intensive manufacturing processes. Life cycle assessment (LCA) data indicates that titanium production generates approximately 35-45 kg CO2 equivalent per kilogram of material, significantly higher than conventional stainless steels at 4-6 kg CO2 equivalent.

Material longevity directly impacts sustainability metrics through replacement frequency. More durable corrosion-resistant materials reduce the environmental burden associated with manufacturing replacement components and minimize operational disruptions that could lead to system inefficiencies or failures. Research indicates that extending equipment service life by 50% through appropriate material selection can reduce lifetime carbon emissions by 30-40% for typical geothermal installations.

Recyclability presents another environmental consideration, as materials with established recycling pathways contribute to circular economy principles. Common stainless steels offer recycling rates exceeding 85%, while specialized composites may present end-of-life challenges due to limited recycling infrastructure. This factor becomes increasingly important as the geothermal sector expands globally.

Local environmental regulations must also be considered when selecting materials, as certain regions impose strict limitations on material compositions that may leach into groundwater or thermal waters. These regulatory frameworks vary significantly across jurisdictions but generally trend toward increasing stringency regarding environmental protection.

The environmental assessment of materials must also account for transportation impacts, as sourcing specialized corrosion-resistant alloys often involves global supply chains. Locally available materials may offer reduced transportation emissions despite potentially inferior technical performance in some applications.

Lifecycle Cost Analysis of Corrosion-Resistant Materials

When evaluating corrosion-resistant materials for geothermal Direct Lithium Extraction (DLE) equipment, lifecycle cost analysis provides a comprehensive economic assessment beyond initial acquisition expenses. This analysis encompasses procurement, installation, maintenance, replacement, and eventual disposal costs over the equipment's operational lifespan.

Initial capital expenditure represents only 20-30% of total lifecycle costs for geothermal DLE equipment. Materials with superior corrosion resistance typically command premium prices—titanium alloys cost 5-7 times more than standard stainless steel, while specialized coatings add 15-25% to base material costs. However, these higher upfront investments often yield significant long-term economic benefits.

Maintenance costs vary dramatically based on material selection. Field data indicates that standard stainless steel components in geothermal environments may require inspection every 3-6 months and replacement every 2-3 years. In contrast, titanium alloys or specialized superalloys can extend maintenance intervals to 12-18 months with replacement cycles of 7-10 years, reducing operational disruptions and associated labor costs.

Production downtime represents a critical hidden cost factor. A single unplanned shutdown due to corrosion failure can cost $50,000-$150,000 per day in lost production. Materials with superior corrosion resistance significantly reduce these incidents, with studies showing titanium-based systems experiencing 75-85% fewer corrosion-related failures than conventional alternatives.

Energy efficiency also impacts lifecycle economics. Corrosion buildup on heat exchangers and fluid pathways reduces thermal transfer efficiency by 15-30% over time. Corrosion-resistant materials maintain cleaner surfaces, preserving operational efficiency and reducing energy consumption throughout the equipment lifespan.

Environmental compliance and disposal costs must be factored into lifecycle analysis. Materials containing hazardous elements may incur additional handling and disposal expenses of $5,000-$20,000 per ton. Recyclable materials like titanium retain 60-70% of their initial value at end-of-life, offsetting disposal costs.

Risk assessment should incorporate potential catastrophic failure scenarios. While rare, major equipment failures can result in remediation costs exceeding $1-5 million and regulatory penalties. Premium corrosion-resistant materials significantly mitigate these low-probability but high-consequence events.

Comprehensive lifecycle cost modeling reveals that despite higher initial investment, premium corrosion-resistant materials typically achieve break-even within 3-5 years of operation in aggressive geothermal environments, with total lifecycle savings of 30-45% over 15-20 year equipment lifespans.

Initial capital expenditure represents only 20-30% of total lifecycle costs for geothermal DLE equipment. Materials with superior corrosion resistance typically command premium prices—titanium alloys cost 5-7 times more than standard stainless steel, while specialized coatings add 15-25% to base material costs. However, these higher upfront investments often yield significant long-term economic benefits.

Maintenance costs vary dramatically based on material selection. Field data indicates that standard stainless steel components in geothermal environments may require inspection every 3-6 months and replacement every 2-3 years. In contrast, titanium alloys or specialized superalloys can extend maintenance intervals to 12-18 months with replacement cycles of 7-10 years, reducing operational disruptions and associated labor costs.

Production downtime represents a critical hidden cost factor. A single unplanned shutdown due to corrosion failure can cost $50,000-$150,000 per day in lost production. Materials with superior corrosion resistance significantly reduce these incidents, with studies showing titanium-based systems experiencing 75-85% fewer corrosion-related failures than conventional alternatives.

Energy efficiency also impacts lifecycle economics. Corrosion buildup on heat exchangers and fluid pathways reduces thermal transfer efficiency by 15-30% over time. Corrosion-resistant materials maintain cleaner surfaces, preserving operational efficiency and reducing energy consumption throughout the equipment lifespan.

Environmental compliance and disposal costs must be factored into lifecycle analysis. Materials containing hazardous elements may incur additional handling and disposal expenses of $5,000-$20,000 per ton. Recyclable materials like titanium retain 60-70% of their initial value at end-of-life, offsetting disposal costs.

Risk assessment should incorporate potential catastrophic failure scenarios. While rare, major equipment failures can result in remediation costs exceeding $1-5 million and regulatory penalties. Premium corrosion-resistant materials significantly mitigate these low-probability but high-consequence events.

Comprehensive lifecycle cost modeling reveals that despite higher initial investment, premium corrosion-resistant materials typically achieve break-even within 3-5 years of operation in aggressive geothermal environments, with total lifecycle savings of 30-45% over 15-20 year equipment lifespans.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!