Managing Co-Extracted Elements In Geothermal Lithium Extraction

SEP 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Geothermal Lithium Extraction Background and Objectives

Geothermal lithium extraction represents a significant advancement in sustainable resource acquisition, combining renewable energy production with critical mineral extraction. This technology has evolved from traditional geothermal energy production, where the focus was primarily on heat and electricity generation, to a more comprehensive approach that recognizes the value of mineral-rich geothermal brines. The historical trajectory began in the 1980s with initial recognition of lithium presence in geothermal fluids, followed by conceptual extraction studies in the 1990s, and accelerating research and development efforts in the 2010s as lithium demand surged for battery applications.

The global transition to clean energy technologies has dramatically increased demand for lithium, with projections indicating a potential supply gap of up to 1.5 million metric tons by 2030. Geothermal lithium extraction offers a promising solution to this challenge, with significantly lower environmental impacts compared to conventional mining or evaporative pond methods. The technology leverages existing geothermal infrastructure while providing a continuous, weather-independent extraction process.

A critical aspect of geothermal lithium extraction is the management of co-extracted elements. Geothermal brines typically contain a complex mixture of dissolved minerals including potassium, magnesium, calcium, boron, manganese, zinc, and various rare earth elements. While lithium is the primary target, these co-extracted elements present both challenges and opportunities that must be addressed to optimize the economic and environmental performance of extraction operations.

The technical objectives for advancing co-extracted element management include developing selective extraction technologies that can efficiently separate lithium from other elements, creating economically viable recovery processes for valuable co-products, and establishing environmentally responsible methods for handling non-valuable elements. These objectives align with broader sustainability goals by maximizing resource utilization while minimizing waste generation.

Current research aims to transform what has historically been viewed as contamination issues into potential revenue streams through multi-element recovery systems. This approach requires interdisciplinary collaboration between geochemists, chemical engineers, materials scientists, and environmental specialists to develop integrated solutions that address the complex chemistry of geothermal brines.

The evolution of this technology is expected to follow a path from single-element extraction to comprehensive resource recovery systems, potentially revolutionizing how we approach mineral extraction by creating circular economy models within the mining sector. Success in this domain could significantly enhance the economic viability of geothermal lithium projects while simultaneously reducing their environmental footprint.

The global transition to clean energy technologies has dramatically increased demand for lithium, with projections indicating a potential supply gap of up to 1.5 million metric tons by 2030. Geothermal lithium extraction offers a promising solution to this challenge, with significantly lower environmental impacts compared to conventional mining or evaporative pond methods. The technology leverages existing geothermal infrastructure while providing a continuous, weather-independent extraction process.

A critical aspect of geothermal lithium extraction is the management of co-extracted elements. Geothermal brines typically contain a complex mixture of dissolved minerals including potassium, magnesium, calcium, boron, manganese, zinc, and various rare earth elements. While lithium is the primary target, these co-extracted elements present both challenges and opportunities that must be addressed to optimize the economic and environmental performance of extraction operations.

The technical objectives for advancing co-extracted element management include developing selective extraction technologies that can efficiently separate lithium from other elements, creating economically viable recovery processes for valuable co-products, and establishing environmentally responsible methods for handling non-valuable elements. These objectives align with broader sustainability goals by maximizing resource utilization while minimizing waste generation.

Current research aims to transform what has historically been viewed as contamination issues into potential revenue streams through multi-element recovery systems. This approach requires interdisciplinary collaboration between geochemists, chemical engineers, materials scientists, and environmental specialists to develop integrated solutions that address the complex chemistry of geothermal brines.

The evolution of this technology is expected to follow a path from single-element extraction to comprehensive resource recovery systems, potentially revolutionizing how we approach mineral extraction by creating circular economy models within the mining sector. Success in this domain could significantly enhance the economic viability of geothermal lithium projects while simultaneously reducing their environmental footprint.

Market Analysis for Co-Extracted Elements

The geothermal lithium extraction process yields not only lithium but also various co-extracted elements including manganese, zinc, boron, potassium, and magnesium. These elements represent significant economic opportunities that can transform the economics of geothermal lithium projects from marginally profitable to highly lucrative ventures.

The global market for these co-extracted elements is substantial and growing. Manganese, critical for steel production and increasingly for batteries, has a global market exceeding $20 billion with annual growth rates of 4-5%. The electric vehicle revolution has particularly intensified demand for high-purity manganese sulfate, with prices reaching premium levels compared to standard manganese ore.

Zinc markets, valued at approximately $40 billion globally, continue to expand at 2-3% annually, driven by galvanizing applications and increasing use in renewable energy storage systems. The medical and agricultural sectors also maintain steady demand for zinc compounds.

Boron compounds, essential for glass manufacturing, ceramics, and agricultural applications, command a specialized market worth over $2 billion. The emerging use of boron in advanced materials for nuclear applications and semiconductor manufacturing has created new high-value market segments with growth rates exceeding 6% annually.

Potassium, primarily valued for fertilizer production, represents a $25 billion market with relatively stable demand patterns tied to global agricultural production. However, high-purity potassium compounds for pharmaceutical and specialty chemical applications command significant price premiums.

Magnesium markets, valued at approximately $4 billion and growing at 3-4% annually, are experiencing increased demand from lightweight alloy applications in automotive and aerospace industries. The push for vehicle weight reduction to improve fuel efficiency continues to drive this growth.

Recovery and commercialization of these co-extracted elements can significantly improve project economics. Financial modeling indicates that revenue from these secondary products can contribute 30-45% of total project value in optimized extraction operations. This additional revenue stream transforms the financial profile of geothermal lithium projects, reducing payback periods by 2-3 years on average.

The market for these co-products also provides valuable diversification against lithium price volatility. As lithium markets have demonstrated significant price fluctuations in recent years, the relatively stable markets for elements like boron and manganese offer important revenue stabilization effects for project operators.

The global market for these co-extracted elements is substantial and growing. Manganese, critical for steel production and increasingly for batteries, has a global market exceeding $20 billion with annual growth rates of 4-5%. The electric vehicle revolution has particularly intensified demand for high-purity manganese sulfate, with prices reaching premium levels compared to standard manganese ore.

Zinc markets, valued at approximately $40 billion globally, continue to expand at 2-3% annually, driven by galvanizing applications and increasing use in renewable energy storage systems. The medical and agricultural sectors also maintain steady demand for zinc compounds.

Boron compounds, essential for glass manufacturing, ceramics, and agricultural applications, command a specialized market worth over $2 billion. The emerging use of boron in advanced materials for nuclear applications and semiconductor manufacturing has created new high-value market segments with growth rates exceeding 6% annually.

Potassium, primarily valued for fertilizer production, represents a $25 billion market with relatively stable demand patterns tied to global agricultural production. However, high-purity potassium compounds for pharmaceutical and specialty chemical applications command significant price premiums.

Magnesium markets, valued at approximately $4 billion and growing at 3-4% annually, are experiencing increased demand from lightweight alloy applications in automotive and aerospace industries. The push for vehicle weight reduction to improve fuel efficiency continues to drive this growth.

Recovery and commercialization of these co-extracted elements can significantly improve project economics. Financial modeling indicates that revenue from these secondary products can contribute 30-45% of total project value in optimized extraction operations. This additional revenue stream transforms the financial profile of geothermal lithium projects, reducing payback periods by 2-3 years on average.

The market for these co-products also provides valuable diversification against lithium price volatility. As lithium markets have demonstrated significant price fluctuations in recent years, the relatively stable markets for elements like boron and manganese offer important revenue stabilization effects for project operators.

Technical Challenges in Co-Element Management

The management of co-extracted elements in geothermal lithium extraction presents significant technical challenges that must be addressed for efficient and economically viable operations. These challenges stem from the complex chemical composition of geothermal brines, which typically contain various elements beyond lithium, including magnesium, calcium, sodium, potassium, boron, and heavy metals.

One primary challenge is the selective separation of lithium from other alkali and alkaline earth metals. Due to similar chemical properties, particularly between lithium and sodium or magnesium, conventional extraction methods often result in co-extraction, necessitating additional purification steps that increase operational costs and reduce efficiency. Current separation technologies struggle to achieve high selectivity without compromising recovery rates.

The presence of scaling elements such as calcium and silica poses another significant technical hurdle. These elements can precipitate during temperature and pressure changes in the extraction process, forming scale deposits that clog equipment, reduce heat transfer efficiency, and increase maintenance requirements. Scale formation not only disrupts continuous operation but also decreases the overall lithium recovery rate.

Corrosion management represents a critical challenge due to the high salinity and often acidic nature of geothermal brines. The combination of elevated temperatures, high mineral content, and potentially corrosive compounds accelerates the degradation of extraction equipment, pumps, and piping systems. This necessitates the use of specialized corrosion-resistant materials that significantly increase capital expenditures.

The handling of toxic elements co-extracted with lithium, including arsenic, antimony, and heavy metals, presents both technical and environmental challenges. These elements require specialized treatment and disposal protocols to prevent environmental contamination and ensure worker safety. The development of efficient removal processes for these contaminants without affecting lithium recovery remains technically demanding.

Energy consumption optimization during the management of co-extracted elements represents another significant challenge. The separation and purification processes required to handle multiple elements simultaneously are typically energy-intensive, potentially offsetting the environmental benefits of lithium production for green energy applications. Developing energy-efficient separation technologies is crucial for maintaining the sustainability profile of geothermal lithium extraction.

The variability in brine composition across different geothermal resources further complicates the development of standardized co-element management solutions. Each geothermal field may require customized extraction and purification processes, limiting economies of scale and technology transfer between projects. This variability necessitates adaptive and flexible processing systems capable of handling fluctuations in elemental concentrations.

One primary challenge is the selective separation of lithium from other alkali and alkaline earth metals. Due to similar chemical properties, particularly between lithium and sodium or magnesium, conventional extraction methods often result in co-extraction, necessitating additional purification steps that increase operational costs and reduce efficiency. Current separation technologies struggle to achieve high selectivity without compromising recovery rates.

The presence of scaling elements such as calcium and silica poses another significant technical hurdle. These elements can precipitate during temperature and pressure changes in the extraction process, forming scale deposits that clog equipment, reduce heat transfer efficiency, and increase maintenance requirements. Scale formation not only disrupts continuous operation but also decreases the overall lithium recovery rate.

Corrosion management represents a critical challenge due to the high salinity and often acidic nature of geothermal brines. The combination of elevated temperatures, high mineral content, and potentially corrosive compounds accelerates the degradation of extraction equipment, pumps, and piping systems. This necessitates the use of specialized corrosion-resistant materials that significantly increase capital expenditures.

The handling of toxic elements co-extracted with lithium, including arsenic, antimony, and heavy metals, presents both technical and environmental challenges. These elements require specialized treatment and disposal protocols to prevent environmental contamination and ensure worker safety. The development of efficient removal processes for these contaminants without affecting lithium recovery remains technically demanding.

Energy consumption optimization during the management of co-extracted elements represents another significant challenge. The separation and purification processes required to handle multiple elements simultaneously are typically energy-intensive, potentially offsetting the environmental benefits of lithium production for green energy applications. Developing energy-efficient separation technologies is crucial for maintaining the sustainability profile of geothermal lithium extraction.

The variability in brine composition across different geothermal resources further complicates the development of standardized co-element management solutions. Each geothermal field may require customized extraction and purification processes, limiting economies of scale and technology transfer between projects. This variability necessitates adaptive and flexible processing systems capable of handling fluctuations in elemental concentrations.

Current Co-Element Management Solutions

01 Direct extraction of lithium and co-elements from geothermal brines

Methods for directly extracting lithium and other valuable elements from geothermal brines using selective adsorption materials or ion exchange technologies. These processes target lithium as the primary element while simultaneously recovering co-elements such as zinc, manganese, and boron that are present in geothermal fluids. The extraction systems are designed to operate efficiently at the high temperatures and mineral concentrations characteristic of geothermal resources.- Direct lithium extraction from geothermal brines: Techniques for extracting lithium directly from geothermal brines involve specialized processes that target lithium ions while managing high temperatures and mineral content. These methods often use selective adsorption materials or membranes that can withstand geothermal conditions. The extraction systems are designed to integrate with existing geothermal power plants, creating a dual-purpose operation that generates both energy and valuable lithium compounds.

- Co-extraction of valuable minerals and elements: Geothermal brines often contain multiple valuable elements beyond lithium, including zinc, manganese, boron, and rare earth elements. Advanced extraction systems can be designed to sequentially or simultaneously recover these additional elements, maximizing the economic value of geothermal operations. These multi-element recovery systems typically involve staged precipitation, selective ion exchange, or sequential extraction processes that target different elements based on their chemical properties.

- Environmental impact reduction in geothermal extraction: Environmentally optimized geothermal lithium extraction processes focus on minimizing water usage, reducing chemical consumption, and implementing closed-loop systems. These approaches often include brine reinjection techniques that maintain reservoir pressure while preventing surface contamination. By integrating sustainable practices into extraction operations, these methods reduce the environmental footprint compared to traditional mining or evaporation pond techniques for lithium production.

- Energy integration and efficiency in extraction processes: Energy-efficient extraction systems leverage the thermal energy already present in geothermal brines to power separation processes. These integrated approaches utilize heat exchangers, pressure differential systems, and energy recovery devices to minimize external energy inputs. By designing extraction facilities that work synergistically with geothermal power generation, these systems maximize overall efficiency and reduce operational costs while extracting lithium and co-products.

- Advanced separation and purification technologies: Innovative separation technologies for geothermal lithium extraction include selective membranes, specialized adsorbents, and electrochemical systems. These technologies can achieve high recovery rates and purity levels while operating in challenging geothermal environments with high temperatures, pressures, and dissolved solids. Purification processes often involve multiple stages to remove contaminants and isolate specific elements, resulting in battery-grade lithium compounds and other valuable co-products.

02 Integrated geothermal energy and mineral recovery systems

Combined systems that harness geothermal energy for power generation while simultaneously extracting valuable minerals including lithium and associated elements. These integrated approaches maximize resource utilization by recovering thermal energy first and then extracting minerals from the cooled brine before reinjection. The dual-purpose systems improve the economic viability of geothermal operations by creating multiple revenue streams from a single resource.Expand Specific Solutions03 Selective extraction of rare earth elements and critical minerals

Technologies specifically designed to target rare earth elements and critical minerals that co-exist with lithium in geothermal brines. These methods employ specialized sorbents, membranes, or chemical precipitants that can selectively capture elements such as scandium, gallium, and rare earth metals from complex brine solutions. The selective extraction processes are engineered to operate efficiently despite the presence of competing ions and challenging chemical conditions in geothermal fluids.Expand Specific Solutions04 Brine pre-treatment and purification for enhanced element recovery

Methods for pre-treating geothermal brines to remove impurities and optimize conditions for subsequent lithium and co-element extraction. These processes include filtration, pH adjustment, temperature modification, and removal of scaling compounds to prevent interference with extraction technologies. Pre-treatment steps significantly improve the efficiency and selectivity of downstream extraction processes, resulting in higher recovery rates for lithium and associated valuable elements.Expand Specific Solutions05 Novel extraction equipment and system configurations

Specialized equipment and system configurations designed specifically for the challenges of geothermal lithium and co-element extraction. These innovations include modular extraction units, continuous flow systems, and specialized reactors that can withstand the harsh conditions of geothermal environments. The equipment incorporates advanced materials resistant to corrosion and scaling while providing efficient contact between extraction media and geothermal fluids to maximize recovery of lithium and associated elements.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The geothermal lithium extraction market is in its early growth phase, characterized by increasing commercial interest amid global lithium demand surge. While the market size remains relatively small compared to traditional extraction methods, it's projected to expand significantly as companies address technical challenges in managing co-extracted elements. Technology maturity varies across players, with companies like Lilac Solutions and Vulcan Energy Resources leading innovation in selective ion exchange technologies and zero-carbon extraction processes. Established industrial players such as BASF and Mineral Resources are leveraging their expertise in chemical processing to develop purification methods, while academic institutions including King Abdullah University of Science & Technology and Central South University are advancing fundamental research on separation techniques. The competitive landscape reflects a mix of specialized startups, established resource companies, and research institutions working to optimize element management in geothermal brines.

Baker Hughes Oilfield Operations LLC

Technical Solution: Baker Hughes has developed an advanced membrane-based separation technology for geothermal lithium extraction that specifically addresses co-extracted element management. Their system employs a multi-stage filtration process utilizing specialized nanofiltration and selective membranes that can separate lithium from other elements commonly found in geothermal brines, such as magnesium, calcium, boron, and silica. The technology incorporates anti-scaling treatments and continuous membrane cleaning systems to prevent fouling from precipitating minerals. Baker Hughes leverages their extensive experience in handling complex fluid systems from the oil and gas industry to manage the high temperatures and mineral-laden fluids characteristic of geothermal operations. Their process includes pre-treatment systems that adjust pH and remove suspended solids before the main separation process, followed by selective recovery stages that isolate lithium while diverting other elements for separate processing or safe disposal. The system is designed to operate continuously at geothermal wellheads, minimizing energy consumption by utilizing the natural heat and pressure of the geothermal resource[3][4].

Strengths: Leverages extensive experience in handling complex fluid systems from oil and gas operations; modular design allows for deployment at various scales; continuous operation capability reduces downtime; utilizes existing geothermal infrastructure. Weaknesses: Membrane technologies can be susceptible to fouling in high-mineral content brines; requires significant energy for pressure-driven separation; performance may vary with different brine compositions; relatively high operational costs for membrane replacement and maintenance.

Lilac Solutions, Inc.

Technical Solution: Lilac Solutions has developed an innovative ion exchange technology specifically designed for geothermal lithium extraction. Their proprietary ceramic ion exchange beads selectively absorb lithium from geothermal brines while leaving other elements behind. The process involves pumping brine through columns containing these beads, which capture lithium ions while allowing other elements to pass through. Once saturated, the beads are regenerated using a chemical solution that strips the lithium, producing a concentrated lithium solution ready for further processing. This closed-loop system operates continuously and can be deployed directly at geothermal plants. Lilac's technology addresses co-extracted elements by preventing their extraction in the first place, rather than removing them afterward, significantly reducing downstream purification requirements[1][2]. Their system can process brines with varying chemical compositions and has demonstrated lithium recovery rates exceeding 90% while maintaining high selectivity against magnesium, calcium, and other problematic elements.

Strengths: Highly selective for lithium with minimal co-extraction of contaminants; modular design allows for scalable implementation; operates at ambient temperature reducing energy requirements; faster extraction time compared to traditional evaporation methods. Weaknesses: Requires periodic replacement of ion exchange media; regeneration chemicals must be managed carefully; higher upfront capital costs compared to some conventional methods; technology is relatively new with limited long-term operational data.

Critical Patents in Selective Element Recovery

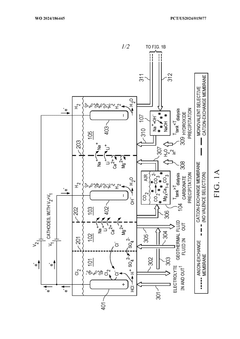

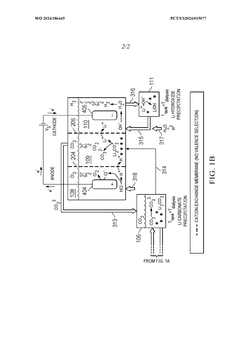

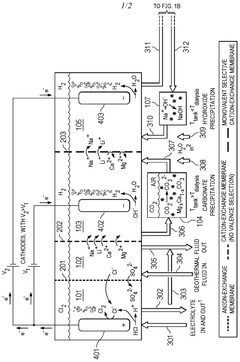

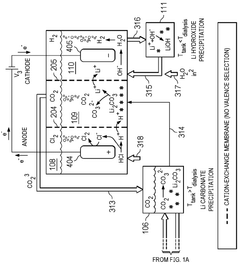

Chlor-alkali electrodialysis for lithium extration from geothermal fluids

PatentWO2024186445A1

Innovation

- The proposed chlor-alkali electrodialysis method uses a multi-compartment apparatus with ion-selective membranes to separate lithium from geothermal brines, producing lithium hydroxide, hydrogen gas, and sequestering CO2, while minimizing water usage and improving water quality.

Methods for extracting elements from a solution

PatentWO2020093041A1

Innovation

- A process involving a continuous loop system with counterflow organic and aqueous phases, using alkaline agents and selective extractants like oximes and carboxylic acids to adjust pH and extract nickel and lithium individually, reducing the number of stages and waste production while enhancing recovery efficiency.

Environmental Impact Assessment

The environmental impact assessment of geothermal lithium extraction processes reveals significant considerations regarding co-extracted elements management. Geothermal brines typically contain various elements beyond lithium, including manganese, zinc, boron, and potentially toxic heavy metals such as arsenic, lead, and mercury. The handling and disposal of these co-extracted elements present substantial environmental challenges that must be addressed through comprehensive management strategies.

Water usage and potential contamination represent primary environmental concerns. The extraction process requires substantial water resources, potentially competing with agricultural and municipal needs in often water-stressed regions. Furthermore, improper management of process water containing co-extracted elements risks contamination of groundwater systems and surface water bodies, threatening aquatic ecosystems and drinking water supplies.

Air quality impacts arise primarily from the potential release of hydrogen sulfide and other volatile compounds during brine processing. These emissions can contribute to local air pollution and may pose health risks to nearby communities if not properly controlled through advanced filtration and capture technologies. Additionally, the energy-intensive nature of separation processes contributes to carbon emissions unless powered by renewable energy sources.

Land use considerations include the footprint of processing facilities and the potential for land subsidence due to brine extraction. The disposal of solid waste residues containing concentrated levels of co-extracted elements requires careful management to prevent soil contamination and ecological damage. Proper containment systems and monitoring protocols are essential to mitigate these risks.

Ecosystem disruption may occur through multiple pathways, including habitat alteration, changes in local hydrology, and potential bioaccumulation of toxic elements in food chains. Long-term ecological monitoring programs are necessary to detect and address unforeseen impacts on sensitive species and habitats surrounding extraction operations.

Regulatory frameworks governing the environmental aspects of geothermal lithium extraction vary significantly across jurisdictions, creating challenges for standardized impact assessment. The development of internationally recognized best practices for co-extracted elements management would enhance environmental protection while providing regulatory clarity for industry stakeholders.

Emerging technologies offer promising solutions for reducing environmental impacts, including closed-loop systems that minimize waste generation, selective extraction methods that reduce co-extraction of problematic elements, and beneficial use strategies that transform potential waste streams into valuable byproducts. These innovations may significantly improve the environmental profile of geothermal lithium operations when implemented at commercial scale.

Water usage and potential contamination represent primary environmental concerns. The extraction process requires substantial water resources, potentially competing with agricultural and municipal needs in often water-stressed regions. Furthermore, improper management of process water containing co-extracted elements risks contamination of groundwater systems and surface water bodies, threatening aquatic ecosystems and drinking water supplies.

Air quality impacts arise primarily from the potential release of hydrogen sulfide and other volatile compounds during brine processing. These emissions can contribute to local air pollution and may pose health risks to nearby communities if not properly controlled through advanced filtration and capture technologies. Additionally, the energy-intensive nature of separation processes contributes to carbon emissions unless powered by renewable energy sources.

Land use considerations include the footprint of processing facilities and the potential for land subsidence due to brine extraction. The disposal of solid waste residues containing concentrated levels of co-extracted elements requires careful management to prevent soil contamination and ecological damage. Proper containment systems and monitoring protocols are essential to mitigate these risks.

Ecosystem disruption may occur through multiple pathways, including habitat alteration, changes in local hydrology, and potential bioaccumulation of toxic elements in food chains. Long-term ecological monitoring programs are necessary to detect and address unforeseen impacts on sensitive species and habitats surrounding extraction operations.

Regulatory frameworks governing the environmental aspects of geothermal lithium extraction vary significantly across jurisdictions, creating challenges for standardized impact assessment. The development of internationally recognized best practices for co-extracted elements management would enhance environmental protection while providing regulatory clarity for industry stakeholders.

Emerging technologies offer promising solutions for reducing environmental impacts, including closed-loop systems that minimize waste generation, selective extraction methods that reduce co-extraction of problematic elements, and beneficial use strategies that transform potential waste streams into valuable byproducts. These innovations may significantly improve the environmental profile of geothermal lithium operations when implemented at commercial scale.

Regulatory Framework for Geothermal Resource Utilization

The regulatory landscape governing geothermal resource utilization varies significantly across jurisdictions, creating a complex framework that directly impacts lithium extraction operations and the management of co-extracted elements. In the United States, the Geothermal Steam Act of 1970 (amended in 2005) provides the primary federal regulatory structure, though it was not originally designed with lithium extraction in mind. This legislative gap has created challenges for companies seeking to commercialize lithium extraction from geothermal brines, as they must navigate regulations primarily focused on energy production rather than mineral extraction.

At the state level, California's AB 1657 (2020) established the Lithium Valley Commission to review and analyze opportunities and benefits from lithium extraction from geothermal brines. This represents one of the first regulatory frameworks specifically addressing the intersection of geothermal energy and lithium production. Similarly, Nevada has updated its regulatory approach to accommodate the emerging lithium extraction industry within its established geothermal regulatory structure.

Internationally, countries with significant geothermal resources have developed varying approaches. Germany's Mining Act (Bundesberggesetz) treats geothermal resources and associated minerals as separate legal entities, requiring distinct permits for extraction. In contrast, Chile's geothermal law (Law 19.657) integrates provisions for associated minerals, providing a more streamlined regulatory pathway for companies pursuing dual extraction.

Environmental regulations present another critical dimension, particularly regarding the disposal or management of co-extracted elements beyond lithium. The U.S. Environmental Protection Agency's Underground Injection Control Program regulates the reinjection of spent geothermal brines, which may contain various metals and minerals. Companies must demonstrate that their reinjection practices will not contaminate groundwater resources, a requirement that becomes more complex when selective extraction of certain elements alters brine chemistry.

Water rights regulations also significantly impact geothermal lithium extraction operations. In water-stressed regions like the American Southwest, the large volumes of brine processed for lithium extraction face increasing scrutiny under existing water management frameworks. The classification of geothermal brines as either water resources or mineral resources creates regulatory ambiguity that companies must navigate.

Emerging regulatory trends indicate a move toward more integrated frameworks that recognize the dual nature of geothermal lithium extraction. The European Union's Critical Raw Materials Act, proposed in 2023, specifically identifies geothermal brines as a potential domestic source of critical minerals and aims to streamline permitting processes while maintaining environmental safeguards. This represents a potential model for regulatory evolution in other jurisdictions seeking to balance resource development with environmental protection.

At the state level, California's AB 1657 (2020) established the Lithium Valley Commission to review and analyze opportunities and benefits from lithium extraction from geothermal brines. This represents one of the first regulatory frameworks specifically addressing the intersection of geothermal energy and lithium production. Similarly, Nevada has updated its regulatory approach to accommodate the emerging lithium extraction industry within its established geothermal regulatory structure.

Internationally, countries with significant geothermal resources have developed varying approaches. Germany's Mining Act (Bundesberggesetz) treats geothermal resources and associated minerals as separate legal entities, requiring distinct permits for extraction. In contrast, Chile's geothermal law (Law 19.657) integrates provisions for associated minerals, providing a more streamlined regulatory pathway for companies pursuing dual extraction.

Environmental regulations present another critical dimension, particularly regarding the disposal or management of co-extracted elements beyond lithium. The U.S. Environmental Protection Agency's Underground Injection Control Program regulates the reinjection of spent geothermal brines, which may contain various metals and minerals. Companies must demonstrate that their reinjection practices will not contaminate groundwater resources, a requirement that becomes more complex when selective extraction of certain elements alters brine chemistry.

Water rights regulations also significantly impact geothermal lithium extraction operations. In water-stressed regions like the American Southwest, the large volumes of brine processed for lithium extraction face increasing scrutiny under existing water management frameworks. The classification of geothermal brines as either water resources or mineral resources creates regulatory ambiguity that companies must navigate.

Emerging regulatory trends indicate a move toward more integrated frameworks that recognize the dual nature of geothermal lithium extraction. The European Union's Critical Raw Materials Act, proposed in 2023, specifically identifies geothermal brines as a potential domestic source of critical minerals and aims to streamline permitting processes while maintaining environmental safeguards. This represents a potential model for regulatory evolution in other jurisdictions seeking to balance resource development with environmental protection.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!