Environmental Impact Assessment For Geothermal Brine Lithium Projects

SEP 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Geothermal Lithium Extraction Background and Objectives

Geothermal lithium extraction represents a significant advancement in sustainable resource development, emerging as a promising alternative to traditional lithium mining methods. The technology leverages existing geothermal power plants to extract lithium from the hot brines pumped from deep underground reservoirs. This dual-purpose approach has evolved over the past decade from conceptual research to pilot projects, with several commercial-scale operations now under development globally.

The historical trajectory of geothermal lithium extraction began in the 1970s when researchers first identified significant lithium concentrations in geothermal fluids. However, technological limitations prevented economically viable extraction until the 2010s, when advances in direct lithium extraction (DLE) technologies enabled more efficient separation of lithium from complex brine solutions. These technological breakthroughs coincided with growing global demand for lithium, driven primarily by the electric vehicle revolution and renewable energy storage requirements.

Current technological evolution focuses on optimizing extraction efficiency while minimizing environmental impacts. Key developments include selective adsorption materials, advanced membrane technologies, and electrochemical processes that can achieve higher recovery rates with lower energy consumption and chemical usage. The industry is witnessing a transition from laboratory-scale proof-of-concept to field demonstrations, with several companies reporting extraction efficiencies exceeding 90% in controlled environments.

The primary objective of geothermal lithium extraction is to establish environmentally responsible lithium production pathways that minimize land disturbance, water consumption, and carbon emissions compared to conventional mining and evaporative pond methods. Secondary objectives include developing economically viable processes that can operate at various brine concentrations and compositions, enabling wider geographical application beyond traditional lithium-rich regions.

Technical goals for the industry include reducing extraction costs below $5,000 per ton of lithium carbonate equivalent (LCE), achieving consistent recovery rates above 85% across varying brine chemistries, and developing closed-loop systems that return processed brine to the geothermal reservoir with minimal environmental impact. Additionally, the sector aims to establish standardized environmental impact assessment methodologies specifically tailored to geothermal lithium operations.

The convergence of renewable energy production and critical mineral extraction represents a paradigm shift in resource development, potentially addressing two crucial aspects of the clean energy transition simultaneously. As the technology matures, geothermal lithium extraction could significantly reshape global lithium supply chains, reducing dependence on concentrated production regions and mitigating geopolitical supply risks.

The historical trajectory of geothermal lithium extraction began in the 1970s when researchers first identified significant lithium concentrations in geothermal fluids. However, technological limitations prevented economically viable extraction until the 2010s, when advances in direct lithium extraction (DLE) technologies enabled more efficient separation of lithium from complex brine solutions. These technological breakthroughs coincided with growing global demand for lithium, driven primarily by the electric vehicle revolution and renewable energy storage requirements.

Current technological evolution focuses on optimizing extraction efficiency while minimizing environmental impacts. Key developments include selective adsorption materials, advanced membrane technologies, and electrochemical processes that can achieve higher recovery rates with lower energy consumption and chemical usage. The industry is witnessing a transition from laboratory-scale proof-of-concept to field demonstrations, with several companies reporting extraction efficiencies exceeding 90% in controlled environments.

The primary objective of geothermal lithium extraction is to establish environmentally responsible lithium production pathways that minimize land disturbance, water consumption, and carbon emissions compared to conventional mining and evaporative pond methods. Secondary objectives include developing economically viable processes that can operate at various brine concentrations and compositions, enabling wider geographical application beyond traditional lithium-rich regions.

Technical goals for the industry include reducing extraction costs below $5,000 per ton of lithium carbonate equivalent (LCE), achieving consistent recovery rates above 85% across varying brine chemistries, and developing closed-loop systems that return processed brine to the geothermal reservoir with minimal environmental impact. Additionally, the sector aims to establish standardized environmental impact assessment methodologies specifically tailored to geothermal lithium operations.

The convergence of renewable energy production and critical mineral extraction represents a paradigm shift in resource development, potentially addressing two crucial aspects of the clean energy transition simultaneously. As the technology matures, geothermal lithium extraction could significantly reshape global lithium supply chains, reducing dependence on concentrated production regions and mitigating geopolitical supply risks.

Market Analysis for Sustainable Lithium Production

The global lithium market is experiencing unprecedented growth driven by the rapid expansion of electric vehicle production and renewable energy storage systems. Current projections indicate the lithium market will reach $8.2 billion by 2027, with a compound annual growth rate of approximately 18.3% from 2022. This growth trajectory creates a significant opportunity for sustainable lithium extraction methods, particularly from geothermal brines, which offer environmental advantages over traditional mining operations.

Geothermal brine lithium extraction represents a potentially revolutionary segment within the broader lithium market. While conventional lithium production remains dominated by hard rock mining (primarily in Australia) and salt flat evaporation (predominantly in South America's "Lithium Triangle"), geothermal brine extraction is gaining attention as a more sustainable alternative. Market analysis indicates that geothermal lithium could capture up to 15% of global lithium production by 2030 if current technological and economic barriers are overcome.

Consumer demand for sustainably sourced materials is creating premium market opportunities for environmentally responsible lithium. Major automotive manufacturers including BMW, Volkswagen, and Tesla have publicly committed to sourcing materials with reduced environmental footprints, creating potential price premiums of 5-10% for verifiably sustainable lithium. This trend is reinforced by regulatory frameworks in Europe and North America that increasingly emphasize supply chain sustainability and environmental impact reduction.

Regional market analysis reveals particularly strong potential for geothermal lithium projects in the Salton Sea region of California, Germany's Upper Rhine Valley, and New Zealand's Taupo Volcanic Zone. These regions benefit from the dual advantage of existing geothermal energy infrastructure and proximity to manufacturing centers, reducing transportation emissions and costs.

Investment patterns further validate market interest, with venture capital funding for sustainable lithium extraction technologies increasing by 230% between 2019 and 2022. Strategic partnerships between technology developers, geothermal energy producers, and battery manufacturers are emerging as the preferred business model, distributing risk while accelerating commercialization timelines.

Market barriers remain significant, including higher initial capital expenditures compared to conventional extraction methods and uncertainty regarding long-term operational costs. However, lifecycle economic analysis suggests that when environmental externalities are properly accounted for, geothermal brine lithium extraction achieves cost parity with conventional methods while delivering superior environmental performance.

The competitive landscape is evolving rapidly, with specialized technology providers like EnergySource Minerals and Vulcan Energy Resources challenging established lithium producers. This competition is driving innovation in extraction efficiency and environmental performance, further enhancing the market potential for sustainable lithium production methods.

Geothermal brine lithium extraction represents a potentially revolutionary segment within the broader lithium market. While conventional lithium production remains dominated by hard rock mining (primarily in Australia) and salt flat evaporation (predominantly in South America's "Lithium Triangle"), geothermal brine extraction is gaining attention as a more sustainable alternative. Market analysis indicates that geothermal lithium could capture up to 15% of global lithium production by 2030 if current technological and economic barriers are overcome.

Consumer demand for sustainably sourced materials is creating premium market opportunities for environmentally responsible lithium. Major automotive manufacturers including BMW, Volkswagen, and Tesla have publicly committed to sourcing materials with reduced environmental footprints, creating potential price premiums of 5-10% for verifiably sustainable lithium. This trend is reinforced by regulatory frameworks in Europe and North America that increasingly emphasize supply chain sustainability and environmental impact reduction.

Regional market analysis reveals particularly strong potential for geothermal lithium projects in the Salton Sea region of California, Germany's Upper Rhine Valley, and New Zealand's Taupo Volcanic Zone. These regions benefit from the dual advantage of existing geothermal energy infrastructure and proximity to manufacturing centers, reducing transportation emissions and costs.

Investment patterns further validate market interest, with venture capital funding for sustainable lithium extraction technologies increasing by 230% between 2019 and 2022. Strategic partnerships between technology developers, geothermal energy producers, and battery manufacturers are emerging as the preferred business model, distributing risk while accelerating commercialization timelines.

Market barriers remain significant, including higher initial capital expenditures compared to conventional extraction methods and uncertainty regarding long-term operational costs. However, lifecycle economic analysis suggests that when environmental externalities are properly accounted for, geothermal brine lithium extraction achieves cost parity with conventional methods while delivering superior environmental performance.

The competitive landscape is evolving rapidly, with specialized technology providers like EnergySource Minerals and Vulcan Energy Resources challenging established lithium producers. This competition is driving innovation in extraction efficiency and environmental performance, further enhancing the market potential for sustainable lithium production methods.

Technical Challenges in Geothermal Brine Lithium Recovery

Geothermal brine lithium extraction faces several significant technical challenges that currently limit its widespread commercial adoption. The primary obstacle is the low concentration of lithium in geothermal brines, typically ranging from 10 to 200 mg/L, necessitating the processing of enormous volumes of brine to achieve economically viable lithium production. This challenge is compounded by the complex chemical composition of geothermal brines, which contain numerous dissolved minerals and elements that can interfere with lithium extraction processes.

The high temperature and salinity of geothermal brines present additional technical difficulties. Temperatures often exceed 100°C, while total dissolved solids can range from 7% to over 25%, creating a harsh environment that accelerates equipment corrosion and scaling. These conditions significantly reduce the operational lifespan of extraction equipment and increase maintenance requirements, driving up operational costs.

Selective lithium extraction from such complex solutions represents another major technical hurdle. Current technologies struggle to achieve high lithium recovery rates while maintaining product purity. Direct Lithium Extraction (DLE) technologies, including ion exchange, adsorption, and membrane processes, show promise but still face challenges in selectivity, capacity, and durability under geothermal conditions.

Energy consumption presents a further challenge, as the processing of large brine volumes requires substantial energy inputs for pumping, heating, cooling, and separation processes. While geothermal plants can potentially provide some of this energy, the additional power requirements for lithium extraction may reduce the overall energy efficiency of geothermal operations.

Water management issues also complicate geothermal lithium recovery. The extraction process may require significant freshwater inputs for processing and washing steps, creating challenges in water-scarce regions. Additionally, the disposal or reinjection of processed brine must be carefully managed to prevent environmental contamination and maintain reservoir pressure.

Scale-up from laboratory to commercial scale represents a significant barrier. Many promising technologies have demonstrated effectiveness at small scales but encounter unforeseen challenges when scaled to commercial operations. The capital expenditure required for full-scale implementation remains high, with uncertain returns given the technical risks involved.

Finally, process integration with existing geothermal power operations presents complex engineering challenges. Lithium extraction systems must be designed to operate harmoniously with power generation systems without compromising either function, requiring sophisticated process engineering and control systems.

The high temperature and salinity of geothermal brines present additional technical difficulties. Temperatures often exceed 100°C, while total dissolved solids can range from 7% to over 25%, creating a harsh environment that accelerates equipment corrosion and scaling. These conditions significantly reduce the operational lifespan of extraction equipment and increase maintenance requirements, driving up operational costs.

Selective lithium extraction from such complex solutions represents another major technical hurdle. Current technologies struggle to achieve high lithium recovery rates while maintaining product purity. Direct Lithium Extraction (DLE) technologies, including ion exchange, adsorption, and membrane processes, show promise but still face challenges in selectivity, capacity, and durability under geothermal conditions.

Energy consumption presents a further challenge, as the processing of large brine volumes requires substantial energy inputs for pumping, heating, cooling, and separation processes. While geothermal plants can potentially provide some of this energy, the additional power requirements for lithium extraction may reduce the overall energy efficiency of geothermal operations.

Water management issues also complicate geothermal lithium recovery. The extraction process may require significant freshwater inputs for processing and washing steps, creating challenges in water-scarce regions. Additionally, the disposal or reinjection of processed brine must be carefully managed to prevent environmental contamination and maintain reservoir pressure.

Scale-up from laboratory to commercial scale represents a significant barrier. Many promising technologies have demonstrated effectiveness at small scales but encounter unforeseen challenges when scaled to commercial operations. The capital expenditure required for full-scale implementation remains high, with uncertain returns given the technical risks involved.

Finally, process integration with existing geothermal power operations presents complex engineering challenges. Lithium extraction systems must be designed to operate harmoniously with power generation systems without compromising either function, requiring sophisticated process engineering and control systems.

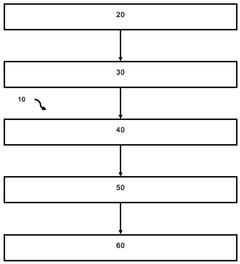

Current Environmental Assessment Methodologies

01 Environmental impact mitigation in geothermal brine lithium extraction

Various technologies have been developed to mitigate the environmental impact of lithium extraction from geothermal brines. These include closed-loop systems that minimize water consumption and prevent contamination of surrounding ecosystems, advanced filtration methods that reduce waste generation, and processes that allow for the reinjection of treated brine back into geothermal reservoirs. These approaches significantly reduce the environmental footprint compared to traditional lithium mining methods.- Water and brine management systems: Geothermal lithium extraction projects require sophisticated water and brine management systems to minimize environmental impact. These systems include methods for treating, recycling, and properly disposing of geothermal brines after lithium extraction. Proper management reduces the risk of contamination to surrounding water bodies and ecosystems, while also conserving water resources in often arid regions where these projects are located.

- Emissions reduction and carbon capture technologies: Advanced technologies are being developed to reduce greenhouse gas emissions and capture carbon in geothermal lithium extraction operations. These innovations include closed-loop systems that minimize the release of gases from geothermal fluids and methods to capture and sequester carbon dioxide. By implementing these technologies, geothermal lithium projects can significantly lower their carbon footprint compared to traditional lithium mining methods.

- Land use and ecosystem protection measures: Environmental impact mitigation strategies for geothermal lithium projects include measures to minimize land disturbance and protect local ecosystems. These approaches involve compact facility design, habitat restoration plans, and monitoring systems to detect potential ecological impacts. Some projects incorporate wildlife corridors and buffer zones to maintain biodiversity and ecosystem functions in areas surrounding extraction facilities.

- Sustainable extraction and processing methods: Innovative extraction and processing methods are being developed to make geothermal lithium production more sustainable. These include direct lithium extraction technologies that reduce chemical usage, energy-efficient concentration processes, and methods that minimize waste generation. By improving the efficiency of lithium recovery from geothermal brines, these approaches reduce the environmental footprint of extraction operations while maximizing resource utilization.

- Energy efficiency and renewable integration: Geothermal lithium projects are implementing energy efficiency measures and integrating renewable energy sources to reduce environmental impact. These projects utilize the geothermal energy from the same brine used for lithium extraction to power operations, creating a more sustainable closed-loop system. Some facilities incorporate additional renewable energy sources such as solar or wind power to further reduce reliance on fossil fuels and decrease the overall carbon footprint of lithium production.

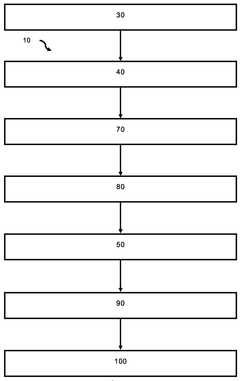

02 Waste management and resource recovery systems

Innovative waste management systems have been developed for geothermal brine lithium projects to handle byproducts and residues. These systems focus on recovering valuable minerals beyond lithium, treating waste streams to reduce harmful substances, and implementing zero-waste approaches. By recovering multiple resources from the same brine, these technologies improve the economic viability of projects while reducing their environmental impact through comprehensive resource utilization.Expand Specific Solutions03 Energy efficiency and carbon footprint reduction

Energy-efficient technologies for lithium extraction from geothermal brines focus on reducing the carbon footprint of operations. These include utilizing the geothermal energy itself to power extraction processes, implementing heat recovery systems, optimizing pumping and processing operations, and developing low-temperature extraction methods. These approaches significantly reduce greenhouse gas emissions compared to conventional lithium production methods, contributing to more environmentally sustainable operations.Expand Specific Solutions04 Water conservation and brine management

Water conservation technologies for geothermal lithium projects address one of the most significant environmental concerns in arid regions. These include advanced brine management systems that maximize water recycling, minimize freshwater consumption, prevent contamination of groundwater resources, and optimize the handling of highly saline solutions. By implementing these technologies, projects can significantly reduce their water footprint and minimize impacts on local water resources.Expand Specific Solutions05 Monitoring and control systems for environmental protection

Advanced monitoring and control systems have been developed to ensure environmental protection during geothermal brine lithium extraction. These systems include real-time sensors for detecting potential leaks or emissions, automated control mechanisms to prevent environmental incidents, comprehensive data collection for environmental compliance, and predictive analytics to anticipate and mitigate potential issues. These technologies enable operators to maintain strict environmental standards throughout the extraction process.Expand Specific Solutions

Key Industry Players and Competitive Landscape

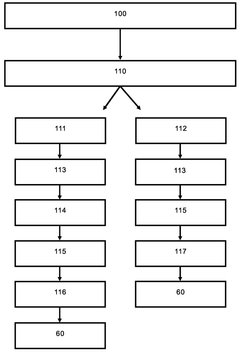

The geothermal brine lithium extraction market is in an early growth phase, characterized by increasing commercial interest due to its lower environmental footprint compared to traditional mining. The global lithium market is projected to reach $8.2 billion by 2028, with geothermal extraction representing a growing segment. Technologically, the field shows varying maturity levels among key players. International Battery Metals and EnergySource Minerals lead with advanced extraction technologies, while Vulcan Energy Resources is pioneering zero-carbon lithium production. Academic institutions like MIT and Rice University provide research support, while established energy companies such as Schlumberger and Baker Hughes are leveraging their expertise in geothermal operations to enter this space. Chinese companies like BYD and Qinghai Lithium Industry are also investing significantly in this emerging sector.

International Battery Metals Ltd.

Technical Solution: International Battery Metals (IBAT) has developed a modular, mobile lithium extraction system specifically designed for geothermal brine projects with environmental considerations at its core. Their technology employs selective absorption materials that can be deployed in compact, transportable units, significantly reducing the environmental footprint compared to traditional evaporation ponds. IBAT's environmental assessment framework includes comprehensive monitoring of water usage efficiency, with their system designed to return over 90% of processed brine back to the reservoir. The company's environmental impact methodology incorporates real-time monitoring of potential contaminants and process emissions. Their modular approach allows for scalable operations that can be adjusted based on environmental constraints of specific sites. IBAT has implemented a comprehensive environmental management system that tracks key performance indicators related to energy consumption, chemical usage, and waste generation throughout the extraction process.

Strengths: Modular design allows for minimal site preparation and reduced land disturbance. High brine recovery rates (>90%) minimize water consumption and potential aquifer impacts. Mobile units can be relocated, allowing for site remediation if necessary. Weaknesses: The technology still requires chemical reagents for the absorption/desorption process, which must be carefully managed to prevent environmental contamination. Energy requirements for the process may be significant depending on the specific brine chemistry and lithium concentration.

BYD Co., Ltd.

Technical Solution: BYD has developed an integrated approach to environmental impact assessment for lithium extraction projects that connects extraction processes directly to battery manufacturing requirements. Their methodology focuses on lifecycle analysis that tracks environmental impacts from brine extraction through battery production and eventual recycling. For geothermal brine projects, BYD has implemented a direct lithium extraction technology that utilizes electrochemical processes to selectively remove lithium while minimizing chemical additives. Their environmental assessment framework includes comprehensive monitoring of energy consumption, water usage, and emissions throughout the extraction process. BYD's approach incorporates detailed baseline studies of local ecosystems prior to operations and continuous monitoring during production. The company has developed specific protocols for managing potential impacts on groundwater quality, land subsidence, and local biodiversity. Their environmental management system includes regular third-party verification and public reporting of environmental performance metrics.

Strengths: Vertical integration allows for optimization of extraction processes specifically for battery manufacturing requirements, potentially reducing overall environmental footprint. Extensive experience with battery recycling provides insights for designing extraction processes with end-of-life considerations. Weaknesses: As primarily a battery manufacturer rather than a mining company, BYD may have less specialized expertise in geothermal reservoir management and associated environmental challenges. Their approach may prioritize extraction efficiency over some environmental considerations if not carefully balanced.

Critical Patents and Innovations in Impact Mitigation

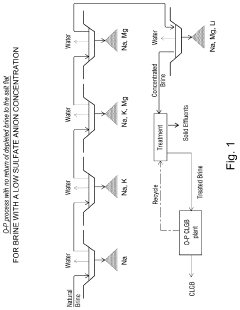

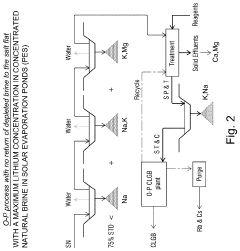

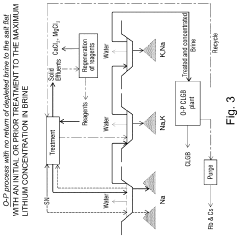

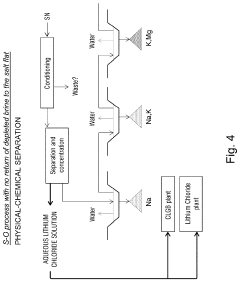

Method for obtaining concentrated brine of minimum impurity content from brine found in natural salt flats and salt marshes, said method having minimum environmental impact and maximum lithium recovery

PatentActiveUS11920211B2

Innovation

- A method involving initial pre-concentration through fractional crystallization in solar evaporation ponds, followed by cooling and chemical pre-treatment to reduce sulfate content, and final concentration stages, which minimizes reagent use and energy consumption, and avoids the crystallization of lithium-containing salts, ensuring maximum lithium recovery with low impurity content.

Pressure control in a system and process for extracting lithium enriched eluates from an untreated brine

PatentWO2025036580A1

Innovation

- A system and process that directly injects untreated geothermal brine into a direct lithium extraction unit, utilizing a pressure control unit to manage pressure and optimize lithium extraction, thereby eliminating the need for pre-treatment and reducing costs and environmental impact.

Regulatory Framework and Compliance Requirements

The regulatory landscape for geothermal brine lithium extraction projects is complex and multifaceted, requiring compliance with various international, national, and local frameworks. At the international level, projects must adhere to standards set by organizations such as the International Organization for Standardization (ISO) and the International Energy Agency (IEA). These frameworks often focus on sustainable resource management, emissions reduction, and environmental protection principles that transcend national boundaries.

National regulations vary significantly across countries with geothermal resources. In the United States, projects fall under the jurisdiction of multiple federal agencies, including the Bureau of Land Management (BLM), Environmental Protection Agency (EPA), and Department of Energy (DOE). The National Environmental Policy Act (NEPA) mandates comprehensive environmental impact assessments before project approval. Similarly, countries like Chile and Argentina, with significant lithium reserves in geothermal brines, have established specific regulatory frameworks governing extraction activities in their salt flats.

Water management regulations are particularly critical for geothermal brine lithium projects. These operations must comply with stringent water rights laws, consumption limitations, and quality standards. The potential for groundwater contamination necessitates regular monitoring and reporting to relevant authorities. Additionally, many jurisdictions require detailed water management plans that address conservation, recycling, and potential impacts on local aquifers.

Air quality compliance requirements focus primarily on controlling emissions from geothermal power plants associated with lithium extraction. Regulations typically limit hydrogen sulfide, carbon dioxide, and particulate matter emissions. Modern projects increasingly face carbon footprint restrictions as countries implement climate change mitigation policies and move toward net-zero emission targets.

Waste management regulations govern the handling, storage, and disposal of spent geothermal fluids and extraction byproducts. These often contain elevated levels of minerals and potentially harmful elements that require specialized treatment. Many jurisdictions mandate detailed waste management plans, regular auditing, and implementation of best available technologies to minimize environmental impact.

Permitting processes typically involve multiple stages, including exploration permits, environmental licenses, water usage rights, and operational authorizations. These processes frequently require public consultation periods, allowing local communities and stakeholders to voice concerns. The timeline for obtaining all necessary permits can range from several months to years, depending on the jurisdiction and project complexity, representing a significant consideration in project planning and investment decisions.

National regulations vary significantly across countries with geothermal resources. In the United States, projects fall under the jurisdiction of multiple federal agencies, including the Bureau of Land Management (BLM), Environmental Protection Agency (EPA), and Department of Energy (DOE). The National Environmental Policy Act (NEPA) mandates comprehensive environmental impact assessments before project approval. Similarly, countries like Chile and Argentina, with significant lithium reserves in geothermal brines, have established specific regulatory frameworks governing extraction activities in their salt flats.

Water management regulations are particularly critical for geothermal brine lithium projects. These operations must comply with stringent water rights laws, consumption limitations, and quality standards. The potential for groundwater contamination necessitates regular monitoring and reporting to relevant authorities. Additionally, many jurisdictions require detailed water management plans that address conservation, recycling, and potential impacts on local aquifers.

Air quality compliance requirements focus primarily on controlling emissions from geothermal power plants associated with lithium extraction. Regulations typically limit hydrogen sulfide, carbon dioxide, and particulate matter emissions. Modern projects increasingly face carbon footprint restrictions as countries implement climate change mitigation policies and move toward net-zero emission targets.

Waste management regulations govern the handling, storage, and disposal of spent geothermal fluids and extraction byproducts. These often contain elevated levels of minerals and potentially harmful elements that require specialized treatment. Many jurisdictions mandate detailed waste management plans, regular auditing, and implementation of best available technologies to minimize environmental impact.

Permitting processes typically involve multiple stages, including exploration permits, environmental licenses, water usage rights, and operational authorizations. These processes frequently require public consultation periods, allowing local communities and stakeholders to voice concerns. The timeline for obtaining all necessary permits can range from several months to years, depending on the jurisdiction and project complexity, representing a significant consideration in project planning and investment decisions.

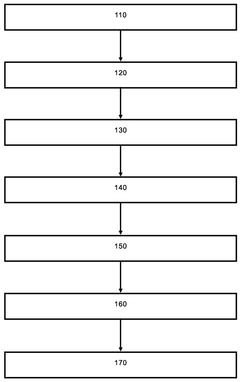

Water Resource Management and Conservation Strategies

Water resource management represents a critical component in geothermal brine lithium extraction projects, requiring comprehensive strategies to minimize environmental impacts while maximizing operational efficiency. Geothermal brine lithium extraction typically consumes significant water volumes, with estimates suggesting between 500-2,000 gallons of water per kilogram of lithium carbonate equivalent (LCE) produced. This substantial water footprint necessitates sophisticated management approaches, particularly in arid regions where lithium-rich brines are commonly found.

Closed-loop systems have emerged as a leading conservation strategy, enabling up to 80-90% of process water to be recycled back into operations. These systems significantly reduce freshwater consumption while minimizing wastewater discharge. Implementation of advanced membrane technologies, including reverse osmosis and nanofiltration, has demonstrated potential to recover up to 95% of water from brine streams, substantially improving water use efficiency metrics across operations.

Real-time monitoring systems utilizing IoT sensors provide continuous data on water quality parameters, consumption rates, and discharge volumes. These monitoring networks enable adaptive management responses to changing conditions, with some operations reporting 15-25% reductions in water consumption through implementation of sensor-based optimization systems. Additionally, predictive analytics tools help forecast water needs and identify conservation opportunities before resource constraints become critical.

Watershed-scale planning approaches have proven essential for sustainable water management. Comprehensive hydrological modeling that accounts for seasonal variations, climate change projections, and competing water uses enables more accurate assessment of project impacts on regional water resources. Several successful projects have implemented watershed management committees that include local stakeholders, regulatory authorities, and company representatives to collaboratively develop water allocation frameworks.

Alternative water sourcing strategies, including treated municipal wastewater and brackish groundwater utilization, offer promising pathways to reduce pressure on freshwater resources. Case studies from existing operations demonstrate that substituting 30-50% of freshwater requirements with alternative sources can significantly reduce environmental impacts while maintaining production efficiency.

Water conservation targets should be integrated into corporate performance metrics and regulatory compliance frameworks. Leading companies have established specific water intensity reduction goals, typically aiming for 3-5% annual improvements in water efficiency. These targets drive continuous innovation in water conservation technologies and operational practices throughout the lithium extraction process chain.

Closed-loop systems have emerged as a leading conservation strategy, enabling up to 80-90% of process water to be recycled back into operations. These systems significantly reduce freshwater consumption while minimizing wastewater discharge. Implementation of advanced membrane technologies, including reverse osmosis and nanofiltration, has demonstrated potential to recover up to 95% of water from brine streams, substantially improving water use efficiency metrics across operations.

Real-time monitoring systems utilizing IoT sensors provide continuous data on water quality parameters, consumption rates, and discharge volumes. These monitoring networks enable adaptive management responses to changing conditions, with some operations reporting 15-25% reductions in water consumption through implementation of sensor-based optimization systems. Additionally, predictive analytics tools help forecast water needs and identify conservation opportunities before resource constraints become critical.

Watershed-scale planning approaches have proven essential for sustainable water management. Comprehensive hydrological modeling that accounts for seasonal variations, climate change projections, and competing water uses enables more accurate assessment of project impacts on regional water resources. Several successful projects have implemented watershed management committees that include local stakeholders, regulatory authorities, and company representatives to collaboratively develop water allocation frameworks.

Alternative water sourcing strategies, including treated municipal wastewater and brackish groundwater utilization, offer promising pathways to reduce pressure on freshwater resources. Case studies from existing operations demonstrate that substituting 30-50% of freshwater requirements with alternative sources can significantly reduce environmental impacts while maintaining production efficiency.

Water conservation targets should be integrated into corporate performance metrics and regulatory compliance frameworks. Leading companies have established specific water intensity reduction goals, typically aiming for 3-5% annual improvements in water efficiency. These targets drive continuous innovation in water conservation technologies and operational practices throughout the lithium extraction process chain.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!