Kinetics And Isotherm Models For Lithium Sorption In Geothermal Conditions

SEP 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lithium Extraction Technology Background and Objectives

Lithium has emerged as a critical resource in the global transition towards clean energy, with its demand projected to increase significantly in the coming decades. The evolution of lithium extraction technologies has progressed from traditional mining methods to more innovative approaches, with geothermal brine extraction representing one of the most promising frontiers. This technology leverages existing geothermal power infrastructure to extract lithium from the hot brines pumped from underground reservoirs, offering a potentially more sustainable alternative to conventional mining operations.

The historical development of lithium extraction from geothermal sources dates back to the 1980s, but significant technological advancements have only materialized in the last decade. The convergence of increasing lithium demand, environmental concerns about traditional extraction methods, and improvements in sorption technologies has created a renewed interest in geothermal lithium recovery. This approach aligns with global sustainability goals by potentially reducing water consumption, land disturbance, and carbon emissions compared to conventional lithium production methods.

Understanding the kinetics and isotherm models for lithium sorption under geothermal conditions represents a critical technical objective in advancing this field. These models describe the rate at which lithium ions are adsorbed onto selective materials (kinetics) and the equilibrium relationship between adsorbed lithium and its concentration in solution (isotherms) under the high temperature and high salinity conditions typical of geothermal brines. Accurate modeling is essential for designing efficient extraction systems and optimizing operational parameters.

The technical objectives of research in this area include developing robust mathematical models that can predict lithium sorption behavior across varying temperatures (typically 70-250°C), pressures, pH levels, and competing ion concentrations found in geothermal fluids. Additionally, there is a need to identify and characterize novel sorbent materials that maintain selectivity and capacity under these challenging conditions, while demonstrating sufficient durability for commercial applications.

Future technological trajectories point toward the integration of advanced materials science, process engineering, and digital modeling tools to overcome current limitations. The development of machine learning algorithms to predict sorption behavior, coupled with high-throughput screening of novel sorbent materials, represents a promising approach to accelerate innovation in this field. The ultimate goal is to establish economically viable processes that can extract lithium from geothermal brines at commercial scales, thereby diversifying the global lithium supply chain and reducing the environmental footprint of lithium production.

The historical development of lithium extraction from geothermal sources dates back to the 1980s, but significant technological advancements have only materialized in the last decade. The convergence of increasing lithium demand, environmental concerns about traditional extraction methods, and improvements in sorption technologies has created a renewed interest in geothermal lithium recovery. This approach aligns with global sustainability goals by potentially reducing water consumption, land disturbance, and carbon emissions compared to conventional lithium production methods.

Understanding the kinetics and isotherm models for lithium sorption under geothermal conditions represents a critical technical objective in advancing this field. These models describe the rate at which lithium ions are adsorbed onto selective materials (kinetics) and the equilibrium relationship between adsorbed lithium and its concentration in solution (isotherms) under the high temperature and high salinity conditions typical of geothermal brines. Accurate modeling is essential for designing efficient extraction systems and optimizing operational parameters.

The technical objectives of research in this area include developing robust mathematical models that can predict lithium sorption behavior across varying temperatures (typically 70-250°C), pressures, pH levels, and competing ion concentrations found in geothermal fluids. Additionally, there is a need to identify and characterize novel sorbent materials that maintain selectivity and capacity under these challenging conditions, while demonstrating sufficient durability for commercial applications.

Future technological trajectories point toward the integration of advanced materials science, process engineering, and digital modeling tools to overcome current limitations. The development of machine learning algorithms to predict sorption behavior, coupled with high-throughput screening of novel sorbent materials, represents a promising approach to accelerate innovation in this field. The ultimate goal is to establish economically viable processes that can extract lithium from geothermal brines at commercial scales, thereby diversifying the global lithium supply chain and reducing the environmental footprint of lithium production.

Geothermal Lithium Market Analysis and Demand Forecast

The global lithium market is experiencing unprecedented growth, primarily driven by the rapid expansion of electric vehicle (EV) production and renewable energy storage systems. Within this broader context, geothermal lithium extraction represents an emerging sector with significant potential to disrupt traditional lithium supply chains. Current market analysis indicates that conventional lithium sources, predominantly from hard rock mining and salt flat evaporation, are struggling to meet the surging demand, creating a strategic opportunity for geothermal lithium extraction technologies.

Market projections suggest that global lithium demand will increase from approximately 500,000 metric tons of lithium carbonate equivalent (LCE) in 2021 to over 3 million metric tons by 2030. This represents a compound annual growth rate (CAGR) of over 20% for the decade. The geothermal lithium segment, while currently accounting for less than 1% of global production, is positioned for exponential growth due to its environmental advantages and potential for continuous production.

The demand for lithium from geothermal sources is particularly strong in regions with established geothermal resources such as the United States (Salton Sea), Germany (Upper Rhine Valley), New Zealand, and parts of East Africa. These areas benefit from the dual-purpose nature of geothermal operations, which can generate both electricity and extract valuable minerals, creating a compelling economic case.

Price forecasts for lithium remain bullish, with spot prices for battery-grade lithium carbonate having increased by over 400% between 2020 and 2022. While some market corrections have occurred, the structural supply deficit is expected to maintain premium pricing for high-purity lithium products through at least 2028, benefiting efficient extraction technologies like those being developed for geothermal brines.

Industry analysts highlight that geothermal lithium extraction offers several market advantages, including lower carbon footprint, reduced water consumption, and minimal land disturbance compared to conventional methods. These factors are increasingly important as battery manufacturers and EV producers face pressure to demonstrate sustainable supply chains, potentially commanding price premiums for "green lithium."

The investment landscape reflects growing confidence in geothermal lithium, with venture capital funding for specialized extraction technologies exceeding $300 million in 2022 alone. Major automotive manufacturers have begun securing offtake agreements and making strategic investments in geothermal lithium projects, indicating strong forward demand.

Regulatory trends also favor geothermal lithium development, with several governments classifying lithium as a critical mineral and implementing policies to support domestic production. The Inflation Reduction Act in the United States and similar initiatives in the European Union provide financial incentives that significantly improve the economics of geothermal lithium projects, accelerating market development.

Market projections suggest that global lithium demand will increase from approximately 500,000 metric tons of lithium carbonate equivalent (LCE) in 2021 to over 3 million metric tons by 2030. This represents a compound annual growth rate (CAGR) of over 20% for the decade. The geothermal lithium segment, while currently accounting for less than 1% of global production, is positioned for exponential growth due to its environmental advantages and potential for continuous production.

The demand for lithium from geothermal sources is particularly strong in regions with established geothermal resources such as the United States (Salton Sea), Germany (Upper Rhine Valley), New Zealand, and parts of East Africa. These areas benefit from the dual-purpose nature of geothermal operations, which can generate both electricity and extract valuable minerals, creating a compelling economic case.

Price forecasts for lithium remain bullish, with spot prices for battery-grade lithium carbonate having increased by over 400% between 2020 and 2022. While some market corrections have occurred, the structural supply deficit is expected to maintain premium pricing for high-purity lithium products through at least 2028, benefiting efficient extraction technologies like those being developed for geothermal brines.

Industry analysts highlight that geothermal lithium extraction offers several market advantages, including lower carbon footprint, reduced water consumption, and minimal land disturbance compared to conventional methods. These factors are increasingly important as battery manufacturers and EV producers face pressure to demonstrate sustainable supply chains, potentially commanding price premiums for "green lithium."

The investment landscape reflects growing confidence in geothermal lithium, with venture capital funding for specialized extraction technologies exceeding $300 million in 2022 alone. Major automotive manufacturers have begun securing offtake agreements and making strategic investments in geothermal lithium projects, indicating strong forward demand.

Regulatory trends also favor geothermal lithium development, with several governments classifying lithium as a critical mineral and implementing policies to support domestic production. The Inflation Reduction Act in the United States and similar initiatives in the European Union provide financial incentives that significantly improve the economics of geothermal lithium projects, accelerating market development.

Current Challenges in Geothermal Lithium Sorption

Despite significant advancements in lithium extraction technologies from geothermal brines, several critical challenges persist in the development and application of kinetics and isotherm models for lithium sorption under geothermal conditions. These challenges fundamentally limit the efficiency, scalability, and economic viability of direct lithium extraction (DLE) processes.

The complex chemical composition of geothermal brines presents a primary obstacle. These brines contain high concentrations of competing ions such as sodium, potassium, calcium, and magnesium, which significantly interfere with lithium sorption processes. Current kinetic models struggle to accurately account for these multi-component competitive sorption dynamics, particularly at the elevated temperatures and pressures characteristic of geothermal environments.

Temperature variability across different geothermal reservoirs (ranging from 70°C to over 300°C) introduces substantial complexity in modeling sorption behavior. Most existing isotherm models were developed under standard laboratory conditions and fail to accurately predict sorption performance across the wide temperature ranges encountered in real geothermal systems. The temperature dependence of sorption parameters remains inadequately characterized in many models.

The high salinity of geothermal brines (often exceeding 200,000 mg/L total dissolved solids) creates significant deviations from ideal solution behavior. Current models frequently employ simplistic activity coefficient corrections that become increasingly inaccurate at these extreme ionic strengths, leading to poor predictive capability for lithium uptake and selectivity.

Temporal stability of sorbents under geothermal conditions represents another major challenge. The harsh chemical environment, including extreme pH conditions and the presence of scaling elements like silica, causes progressive degradation of sorbent materials. Existing kinetic models rarely incorporate these degradation mechanisms, resulting in overly optimistic predictions of long-term sorption performance.

Scale-up issues further complicate the application of laboratory-derived models to industrial operations. Mass transfer limitations, flow distribution problems, and channeling effects in large-scale sorption columns are inadequately represented in current modeling approaches, creating significant discrepancies between predicted and actual performance in pilot and commercial systems.

The dynamic nature of geothermal reservoirs introduces additional modeling challenges. Brine composition can fluctuate over time due to reservoir evolution or operational changes, requiring adaptive models that can accommodate these variations. Current static modeling approaches lack this flexibility, limiting their practical utility in long-term operations.

The complex chemical composition of geothermal brines presents a primary obstacle. These brines contain high concentrations of competing ions such as sodium, potassium, calcium, and magnesium, which significantly interfere with lithium sorption processes. Current kinetic models struggle to accurately account for these multi-component competitive sorption dynamics, particularly at the elevated temperatures and pressures characteristic of geothermal environments.

Temperature variability across different geothermal reservoirs (ranging from 70°C to over 300°C) introduces substantial complexity in modeling sorption behavior. Most existing isotherm models were developed under standard laboratory conditions and fail to accurately predict sorption performance across the wide temperature ranges encountered in real geothermal systems. The temperature dependence of sorption parameters remains inadequately characterized in many models.

The high salinity of geothermal brines (often exceeding 200,000 mg/L total dissolved solids) creates significant deviations from ideal solution behavior. Current models frequently employ simplistic activity coefficient corrections that become increasingly inaccurate at these extreme ionic strengths, leading to poor predictive capability for lithium uptake and selectivity.

Temporal stability of sorbents under geothermal conditions represents another major challenge. The harsh chemical environment, including extreme pH conditions and the presence of scaling elements like silica, causes progressive degradation of sorbent materials. Existing kinetic models rarely incorporate these degradation mechanisms, resulting in overly optimistic predictions of long-term sorption performance.

Scale-up issues further complicate the application of laboratory-derived models to industrial operations. Mass transfer limitations, flow distribution problems, and channeling effects in large-scale sorption columns are inadequately represented in current modeling approaches, creating significant discrepancies between predicted and actual performance in pilot and commercial systems.

The dynamic nature of geothermal reservoirs introduces additional modeling challenges. Brine composition can fluctuate over time due to reservoir evolution or operational changes, requiring adaptive models that can accommodate these variations. Current static modeling approaches lack this flexibility, limiting their practical utility in long-term operations.

Existing Sorption Isotherm Models for Lithium Extraction

01 Adsorption kinetics models for lithium extraction

Various kinetic models are used to describe the rate of lithium adsorption onto sorbent materials. These models include pseudo-first-order, pseudo-second-order, and intraparticle diffusion models. The kinetic parameters derived from these models provide insights into the adsorption mechanism, rate-limiting steps, and the time required to reach equilibrium. Understanding these kinetics is crucial for designing efficient lithium extraction processes and optimizing operational parameters.- Adsorption kinetics models for lithium extraction: Various kinetic models are used to describe the rate of lithium adsorption onto different sorbents. These models include pseudo-first-order, pseudo-second-order, and intraparticle diffusion models. The kinetic parameters derived from these models help in understanding the adsorption mechanism, rate-controlling steps, and the time required to reach equilibrium. These parameters are crucial for designing efficient lithium extraction processes and optimizing operational conditions.

- Adsorption isotherm models for lithium recovery: Isotherm models describe the equilibrium relationship between the amount of lithium adsorbed and its concentration in solution at constant temperature. Common isotherm models include Langmuir, Freundlich, Temkin, and Dubinin-Radushkevich. These models provide important parameters such as maximum adsorption capacity, binding energy, and adsorption intensity. Understanding these parameters helps in selecting appropriate adsorbents and optimizing the lithium recovery process from various sources.

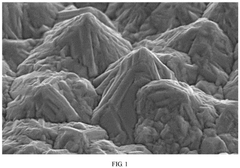

- Novel adsorbent materials for lithium sorption: Research focuses on developing novel adsorbent materials with enhanced lithium selectivity and capacity. These materials include ion-exchange resins, inorganic ion sieves, metal oxides, and composite materials. The sorption performance of these materials is characterized through kinetic and isotherm studies, providing parameters that quantify their effectiveness. Materials are evaluated based on factors such as adsorption capacity, selectivity, regeneration ability, and stability across multiple sorption-desorption cycles.

- Thermodynamic parameters of lithium sorption processes: Thermodynamic parameters such as Gibbs free energy change, enthalpy change, and entropy change provide insights into the nature and feasibility of lithium sorption processes. These parameters help determine whether the sorption process is spontaneous, exothermic or endothermic, and the degree of randomness at the solid-solution interface. Understanding these thermodynamic aspects is essential for optimizing process conditions and predicting the behavior of sorption systems under different temperature regimes.

- Factors affecting lithium sorption parameters: Various factors influence lithium sorption kinetics and isotherm parameters, including pH, temperature, initial lithium concentration, competing ions, and adsorbent dosage. Studies investigate how these factors affect parameters such as adsorption rate constants, equilibrium capacity, and selectivity coefficients. Understanding these relationships enables the optimization of operational conditions for maximum lithium recovery efficiency and the development of predictive models for process scale-up and industrial applications.

02 Isotherm models for lithium sorption equilibrium

Isotherm models describe the equilibrium relationship between the amount of lithium adsorbed on the sorbent and its concentration in solution at constant temperature. Common isotherm models include Langmuir, Freundlich, Temkin, and Dubinin-Radushkevich. These models provide important parameters such as maximum adsorption capacity, binding energy, and sorption intensity. The fitting of experimental data to these models helps in understanding the nature of the adsorption process and selecting appropriate sorbents for lithium recovery.Expand Specific Solutions03 Novel sorbent materials for enhanced lithium recovery

Research focuses on developing novel sorbent materials with high selectivity and capacity for lithium ions. These materials include ion-exchange resins, inorganic ion sieves, metal oxides, and composite materials. The sorption properties of these materials are characterized through kinetic and isotherm studies to determine their efficiency for lithium extraction from various sources such as brines, seawater, and geothermal fluids. The development of these materials aims to improve the economics and sustainability of lithium recovery processes.Expand Specific Solutions04 Thermodynamic parameters of lithium sorption processes

Thermodynamic parameters such as Gibbs free energy change, enthalpy change, and entropy change provide insights into the spontaneity, heat effects, and randomness of lithium sorption processes. These parameters are determined by studying the temperature dependence of sorption isotherms. Understanding the thermodynamics of lithium sorption helps in optimizing process conditions and predicting the behavior of sorption systems under different operating temperatures, which is essential for industrial-scale applications.Expand Specific Solutions05 Factors affecting lithium sorption performance

Various factors influence the kinetics and equilibrium of lithium sorption, including pH, temperature, initial lithium concentration, competing ions, and sorbent dosage. These factors affect the sorption parameters and overall efficiency of lithium recovery processes. Systematic studies of these factors help in establishing optimal conditions for maximum lithium recovery and developing robust sorption processes that can handle variations in feed composition and operating conditions.Expand Specific Solutions

Leading Companies in Geothermal Lithium Recovery

The lithium sorption kinetics and isotherm modeling in geothermal conditions market is in an early growth phase, with increasing interest driven by the global lithium demand surge for energy storage applications. The market size is expanding rapidly, projected to reach significant scale as geothermal lithium extraction emerges as a sustainable alternative to traditional mining. Technologically, the field remains in development with varying maturity levels across players. Companies like Eramet SA, BYD, and POSCO Holdings are advancing commercial applications, while research institutions such as Central South University, IFP Energies Nouvelles, and Qinghai Institute of Salt Lakes are developing fundamental sorption science. Sunresin New Materials and Commissariat à l'énergie atomique are focusing on specialized adsorption materials, positioning themselves at the intersection of materials science and lithium extraction technology.

IFP Energies Nouvelles

Technical Solution: IFP Energies Nouvelles has developed comprehensive lithium sorption technologies specifically adapted for geothermal conditions. Their approach integrates advanced material science with detailed kinetic and thermodynamic modeling to optimize lithium extraction from high-temperature brines. The company's technical solution employs specialized inorganic sorbents that maintain structural integrity and selectivity at temperatures up to 200°C, addressing a key challenge in geothermal lithium recovery. Their research has established that lithium sorption in geothermal conditions follows complex kinetic patterns best described by a combination of pseudo-second-order kinetics for initial uptake and intraparticle diffusion models for longer contact times. IFP has developed proprietary isotherm models that account for the effects of competing ions, pH variations, and temperature fluctuations typical in geothermal reservoirs. Their technology incorporates continuous flow systems with optimized residence times based on kinetic parameters, achieving lithium recovery rates exceeding 90% while minimizing energy consumption through heat integration with the geothermal power generation process.

Strengths: Strong integration with existing geothermal energy infrastructure; extensive experience in modeling complex fluid-solid interactions in high-temperature environments; comprehensive approach combining material development with process optimization. Weaknesses: Technology may require significant customization for different geothermal reservoir compositions and conditions.

Qinghai Institute of Salt Lakes, Chinese Academy of Sciences

Technical Solution: Qinghai Institute of Salt Lakes has developed advanced adsorption technologies specifically for lithium extraction from geothermal brines. Their research focuses on optimizing kinetic parameters and isotherm models for lithium sorption under high temperature and salinity conditions typical of geothermal reservoirs. They have pioneered the development of novel manganese oxide-based adsorbents with high selectivity for lithium ions even in the presence of competing cations such as sodium, potassium, and magnesium. Their technical approach incorporates a two-stage adsorption process that accounts for both physical and chemical sorption mechanisms, with detailed modeling of pseudo-second-order kinetics that better represents the lithium uptake behavior in geothermal conditions. The institute has conducted extensive experimental validation across temperature ranges from 25°C to 90°C, demonstrating how sorption capacity and kinetics are affected by geothermal parameters.

Strengths: Extensive experience with salt lake lithium extraction that translates well to geothermal applications; strong research capabilities in developing selective adsorbents for complex brine compositions. Weaknesses: Some of their technologies may require adaptation from salt lake to geothermal conditions, with different pressure and flow rate considerations.

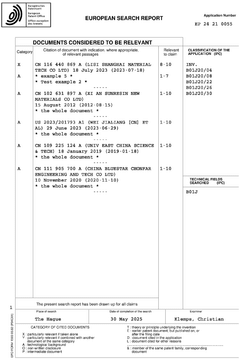

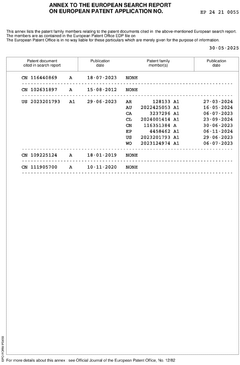

Critical Patents in Geothermal Lithium Sorption Technology

Lithium adsorbent, and preparation method and application thereof

PatentPendingEP4582177A1

Innovation

- A lithium adsorbent preparation method involving gradient stirring and a specific organic matrix of high-molecular polymer and vinylidene fluoride, which stabilizes lithium aluminum oxide crystallites and enhances mechanical strength and corrosion resistance.

Environmental Impact Assessment of Geothermal Lithium Recovery

The environmental implications of geothermal lithium recovery must be thoroughly assessed to ensure sustainable development of this promising technology. Geothermal lithium extraction offers significant environmental advantages over traditional mining methods, particularly by eliminating the need for large-scale open pit mines and evaporation ponds that characterize conventional lithium production.

The direct extraction of lithium from geothermal brines represents a substantially smaller land footprint compared to traditional methods. While conventional lithium mining can disturb thousands of hectares, geothermal lithium recovery typically requires only the surface area needed for processing facilities adjacent to existing geothermal power plants, resulting in minimal additional land disturbance.

Water consumption represents another critical environmental consideration. Traditional lithium production through evaporation ponds consumes vast quantities of water in often water-scarce regions. In contrast, geothermal lithium recovery systems operate in closed loops where brines are reinjected after lithium extraction, significantly reducing freshwater requirements and preserving local hydrological systems.

The carbon footprint of geothermal lithium recovery deserves particular attention. When integrated with existing geothermal power operations, the process can leverage already-available renewable energy, potentially creating a near-zero carbon lithium production pathway. This represents a substantial improvement over conventional lithium production, which often relies on fossil fuel energy sources.

Waste management considerations differ significantly between methods. While traditional lithium mining generates substantial solid waste and potentially harmful chemicals, geothermal lithium recovery primarily manages the chemistry of the brine itself. The primary environmental concern involves ensuring proper handling of any chemicals used in the sorption process and maintaining the integrity of reinjection wells to prevent groundwater contamination.

Local ecosystem impacts must also be evaluated. Geothermal lithium recovery avoids many of the habitat disruptions associated with traditional mining but requires monitoring for potential impacts from facility construction and operation. Particular attention should be paid to any changes in subsurface conditions that might affect local geological stability or groundwater systems.

Regulatory frameworks for environmental monitoring and compliance are still evolving for this emerging technology. Establishing robust baseline environmental data and ongoing monitoring protocols will be essential to track any potential impacts and ensure responsible development of geothermal lithium resources.

The direct extraction of lithium from geothermal brines represents a substantially smaller land footprint compared to traditional methods. While conventional lithium mining can disturb thousands of hectares, geothermal lithium recovery typically requires only the surface area needed for processing facilities adjacent to existing geothermal power plants, resulting in minimal additional land disturbance.

Water consumption represents another critical environmental consideration. Traditional lithium production through evaporation ponds consumes vast quantities of water in often water-scarce regions. In contrast, geothermal lithium recovery systems operate in closed loops where brines are reinjected after lithium extraction, significantly reducing freshwater requirements and preserving local hydrological systems.

The carbon footprint of geothermal lithium recovery deserves particular attention. When integrated with existing geothermal power operations, the process can leverage already-available renewable energy, potentially creating a near-zero carbon lithium production pathway. This represents a substantial improvement over conventional lithium production, which often relies on fossil fuel energy sources.

Waste management considerations differ significantly between methods. While traditional lithium mining generates substantial solid waste and potentially harmful chemicals, geothermal lithium recovery primarily manages the chemistry of the brine itself. The primary environmental concern involves ensuring proper handling of any chemicals used in the sorption process and maintaining the integrity of reinjection wells to prevent groundwater contamination.

Local ecosystem impacts must also be evaluated. Geothermal lithium recovery avoids many of the habitat disruptions associated with traditional mining but requires monitoring for potential impacts from facility construction and operation. Particular attention should be paid to any changes in subsurface conditions that might affect local geological stability or groundwater systems.

Regulatory frameworks for environmental monitoring and compliance are still evolving for this emerging technology. Establishing robust baseline environmental data and ongoing monitoring protocols will be essential to track any potential impacts and ensure responsible development of geothermal lithium resources.

Scalability and Economic Viability Analysis

The scalability of lithium extraction technologies from geothermal brines represents a critical factor in determining their commercial viability. Current laboratory-scale kinetic and isotherm models demonstrate promising results for lithium sorption under geothermal conditions, but significant challenges emerge when considering industrial-scale implementation. The capital expenditure required for establishing a commercial lithium extraction facility from geothermal sources ranges from $50-150 million, depending on brine chemistry, desired production capacity, and geographical location.

Economic analysis indicates that the cost of lithium extraction from geothermal brines currently averages $3,500-5,000 per ton, compared to traditional mining methods at $2,000-3,500 per ton. However, this gap is narrowing as sorption technologies advance and economies of scale develop. The primary cost drivers include sorbent materials (30-40%), energy requirements for pumping and processing (20-25%), and infrastructure maintenance (15-20%).

Scaling factors significantly impact the economic equation. Laboratory models typically utilize small volumes of brine under controlled conditions, whereas industrial applications must process thousands of cubic meters daily with variable temperature and chemical composition. The degradation rate of sorbent materials increases substantially at scale, reducing their operational lifespan from theoretical projections of 500-1000 cycles to practical experiences of 200-400 cycles before replacement becomes necessary.

Return on investment calculations suggest a 4-7 year payback period for geothermal lithium extraction facilities, assuming current lithium carbonate prices remain above $15,000 per ton. Sensitivity analysis reveals that a 20% improvement in sorption kinetics could reduce operational costs by approximately 15%, while extending sorbent lifespan by 30% would decrease annual material replacement costs by 25%.

The economic viability is further enhanced by potential integration with existing geothermal power plants, creating dual-revenue streams from both electricity generation and lithium production. This integration can reduce overall capital costs by 15-25% compared to standalone lithium extraction facilities. Additionally, the environmental benefits of geothermal lithium extraction—including reduced land disturbance and water usage compared to traditional mining—may translate to regulatory advantages and potential carbon credits in certain jurisdictions.

Market projections indicate that as technology matures and scales, production costs could decrease by 30-40% over the next decade, potentially positioning geothermal lithium extraction as economically competitive with traditional sources while offering superior environmental performance. This trajectory depends heavily on continued advancements in sorption kinetics and material science to overcome the current scaling limitations identified in laboratory models.

Economic analysis indicates that the cost of lithium extraction from geothermal brines currently averages $3,500-5,000 per ton, compared to traditional mining methods at $2,000-3,500 per ton. However, this gap is narrowing as sorption technologies advance and economies of scale develop. The primary cost drivers include sorbent materials (30-40%), energy requirements for pumping and processing (20-25%), and infrastructure maintenance (15-20%).

Scaling factors significantly impact the economic equation. Laboratory models typically utilize small volumes of brine under controlled conditions, whereas industrial applications must process thousands of cubic meters daily with variable temperature and chemical composition. The degradation rate of sorbent materials increases substantially at scale, reducing their operational lifespan from theoretical projections of 500-1000 cycles to practical experiences of 200-400 cycles before replacement becomes necessary.

Return on investment calculations suggest a 4-7 year payback period for geothermal lithium extraction facilities, assuming current lithium carbonate prices remain above $15,000 per ton. Sensitivity analysis reveals that a 20% improvement in sorption kinetics could reduce operational costs by approximately 15%, while extending sorbent lifespan by 30% would decrease annual material replacement costs by 25%.

The economic viability is further enhanced by potential integration with existing geothermal power plants, creating dual-revenue streams from both electricity generation and lithium production. This integration can reduce overall capital costs by 15-25% compared to standalone lithium extraction facilities. Additionally, the environmental benefits of geothermal lithium extraction—including reduced land disturbance and water usage compared to traditional mining—may translate to regulatory advantages and potential carbon credits in certain jurisdictions.

Market projections indicate that as technology matures and scales, production costs could decrease by 30-40% over the next decade, potentially positioning geothermal lithium extraction as economically competitive with traditional sources while offering superior environmental performance. This trajectory depends heavily on continued advancements in sorption kinetics and material science to overcome the current scaling limitations identified in laboratory models.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!