Hybrid Membrane–Sorbent Systems For Enhanced Lithium Recovery

SEP 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lithium Recovery Technology Background and Objectives

Lithium has emerged as a critical resource in the 21st century, primarily due to its essential role in energy storage technologies. The evolution of lithium recovery methods has progressed from traditional mining operations to more sophisticated extraction techniques, reflecting the growing demand and environmental concerns associated with conventional approaches. The global transition toward renewable energy and electric mobility has accelerated the need for efficient lithium recovery technologies, positioning it as a strategic resource in the clean energy revolution.

Historically, lithium extraction has relied on evaporative processes in salt flats and hard rock mining, both of which present significant environmental and efficiency challenges. The development trajectory has gradually shifted toward more sustainable and efficient recovery methods, with hybrid membrane-sorbent systems representing the cutting edge of this technological evolution. These systems combine the selectivity of sorbent materials with the separation efficiency of membrane technologies to address the limitations of conventional extraction methods.

The primary objective of hybrid membrane-sorbent technology development is to enhance lithium recovery efficiency while minimizing environmental impact and operational costs. Specifically, these systems aim to achieve higher lithium selectivity in complex brine compositions, reduce water consumption compared to evaporative methods, and decrease energy requirements for the overall extraction process. Additionally, the technology seeks to enable lithium recovery from unconventional sources such as geothermal brines and seawater, which contain lower lithium concentrations but represent vast potential resources.

Current technological goals include developing membrane materials with enhanced lithium permeability and rejection of competing ions, creating sorbents with improved lithium adsorption capacity and selectivity, and designing integrated systems that optimize the synergistic effects of both components. The ideal hybrid system would demonstrate rapid extraction kinetics, high recovery rates, minimal chemical consumption, and long operational lifespans under various brine conditions.

The advancement of hybrid membrane-sorbent systems aligns with broader sustainability objectives, including reducing the carbon footprint of lithium production, minimizing water usage in water-stressed regions, and enabling circular economy approaches through the potential recovery of other valuable elements present in brines. These technologies are expected to play a crucial role in meeting the projected lithium demand growth, which is anticipated to increase by 40-fold by 2040 according to the International Energy Agency.

Research efforts are increasingly focused on scalability and economic viability, with particular emphasis on reducing capital and operational expenditures to make these advanced recovery methods competitive with conventional approaches. The ultimate goal is to establish a technological foundation that supports sustainable lithium supply chains essential for the global energy transition.

Historically, lithium extraction has relied on evaporative processes in salt flats and hard rock mining, both of which present significant environmental and efficiency challenges. The development trajectory has gradually shifted toward more sustainable and efficient recovery methods, with hybrid membrane-sorbent systems representing the cutting edge of this technological evolution. These systems combine the selectivity of sorbent materials with the separation efficiency of membrane technologies to address the limitations of conventional extraction methods.

The primary objective of hybrid membrane-sorbent technology development is to enhance lithium recovery efficiency while minimizing environmental impact and operational costs. Specifically, these systems aim to achieve higher lithium selectivity in complex brine compositions, reduce water consumption compared to evaporative methods, and decrease energy requirements for the overall extraction process. Additionally, the technology seeks to enable lithium recovery from unconventional sources such as geothermal brines and seawater, which contain lower lithium concentrations but represent vast potential resources.

Current technological goals include developing membrane materials with enhanced lithium permeability and rejection of competing ions, creating sorbents with improved lithium adsorption capacity and selectivity, and designing integrated systems that optimize the synergistic effects of both components. The ideal hybrid system would demonstrate rapid extraction kinetics, high recovery rates, minimal chemical consumption, and long operational lifespans under various brine conditions.

The advancement of hybrid membrane-sorbent systems aligns with broader sustainability objectives, including reducing the carbon footprint of lithium production, minimizing water usage in water-stressed regions, and enabling circular economy approaches through the potential recovery of other valuable elements present in brines. These technologies are expected to play a crucial role in meeting the projected lithium demand growth, which is anticipated to increase by 40-fold by 2040 according to the International Energy Agency.

Research efforts are increasingly focused on scalability and economic viability, with particular emphasis on reducing capital and operational expenditures to make these advanced recovery methods competitive with conventional approaches. The ultimate goal is to establish a technological foundation that supports sustainable lithium supply chains essential for the global energy transition.

Market Analysis for Advanced Lithium Extraction Solutions

The global lithium market is experiencing unprecedented growth driven by the rapid expansion of electric vehicle (EV) production and renewable energy storage systems. Current market valuations place the lithium extraction industry at approximately $4 billion, with projections indicating a compound annual growth rate of 8-10% through 2030. This acceleration is primarily fueled by automotive manufacturers' aggressive electrification strategies and governmental policies promoting clean energy adoption worldwide.

Advanced lithium extraction solutions, particularly hybrid membrane-sorbent systems, are positioned to capture significant market share due to their superior efficiency and reduced environmental impact compared to traditional extraction methods. The market for these innovative technologies is expected to grow at nearly twice the rate of conventional extraction methods, potentially reaching $1.5 billion by 2028.

Demand-side analysis reveals that battery manufacturers are increasingly prioritizing suppliers who can demonstrate sustainable extraction practices while maintaining consistent quality and supply chain reliability. This shift creates a premium market segment for advanced extraction technologies that can deliver high-purity lithium with minimal environmental footprint.

Regional market assessment indicates that North America and Europe are emerging as key growth regions for advanced lithium recovery solutions, driven by substantial government investments in domestic supply chain development. The Inflation Reduction Act in the United States and the European Battery Alliance have allocated billions in funding specifically targeting sustainable critical mineral extraction technologies.

Market penetration barriers for hybrid membrane-sorbent systems include high initial capital requirements, technical complexity in scaling operations, and competition from established extraction methods. However, the significant operational cost advantages over time—including 30-40% reduction in water usage and 25% lower energy consumption—present compelling long-term value propositions for mining companies and brine operators.

Customer segmentation analysis identifies three primary market targets: traditional lithium mining operations seeking efficiency improvements, direct lithium extraction (DLE) technology developers requiring enhanced separation capabilities, and geothermal brine operators exploring lithium recovery as a revenue diversification strategy.

Pricing trends suggest that while advanced extraction solutions command a 15-20% premium over conventional technologies initially, the total cost of ownership analysis demonstrates superior returns on investment within 3-5 years of implementation, primarily through operational savings and higher lithium recovery rates.

Advanced lithium extraction solutions, particularly hybrid membrane-sorbent systems, are positioned to capture significant market share due to their superior efficiency and reduced environmental impact compared to traditional extraction methods. The market for these innovative technologies is expected to grow at nearly twice the rate of conventional extraction methods, potentially reaching $1.5 billion by 2028.

Demand-side analysis reveals that battery manufacturers are increasingly prioritizing suppliers who can demonstrate sustainable extraction practices while maintaining consistent quality and supply chain reliability. This shift creates a premium market segment for advanced extraction technologies that can deliver high-purity lithium with minimal environmental footprint.

Regional market assessment indicates that North America and Europe are emerging as key growth regions for advanced lithium recovery solutions, driven by substantial government investments in domestic supply chain development. The Inflation Reduction Act in the United States and the European Battery Alliance have allocated billions in funding specifically targeting sustainable critical mineral extraction technologies.

Market penetration barriers for hybrid membrane-sorbent systems include high initial capital requirements, technical complexity in scaling operations, and competition from established extraction methods. However, the significant operational cost advantages over time—including 30-40% reduction in water usage and 25% lower energy consumption—present compelling long-term value propositions for mining companies and brine operators.

Customer segmentation analysis identifies three primary market targets: traditional lithium mining operations seeking efficiency improvements, direct lithium extraction (DLE) technology developers requiring enhanced separation capabilities, and geothermal brine operators exploring lithium recovery as a revenue diversification strategy.

Pricing trends suggest that while advanced extraction solutions command a 15-20% premium over conventional technologies initially, the total cost of ownership analysis demonstrates superior returns on investment within 3-5 years of implementation, primarily through operational savings and higher lithium recovery rates.

Current Challenges in Hybrid Membrane-Sorbent Technologies

Despite significant advancements in hybrid membrane-sorbent systems for lithium recovery, several critical challenges continue to impede widespread commercial implementation. The integration of membrane and sorbent technologies faces persistent issues with membrane fouling and scaling, particularly when processing complex brine solutions containing multiple ions and organic contaminants. These fouling phenomena significantly reduce separation efficiency and membrane lifespan, necessitating frequent cleaning or replacement cycles that increase operational costs.

Selectivity limitations represent another major hurdle, as current hybrid systems struggle to achieve high lithium selectivity in the presence of competing ions with similar properties, especially sodium and magnesium. The chemical similarity between these elements makes selective lithium extraction technically challenging, with most systems showing insufficient discrimination between lithium and other monovalent cations.

Energy consumption remains prohibitively high for large-scale operations, with current hybrid systems requiring substantial energy inputs for regeneration processes and maintaining optimal operating conditions. This energy intensity directly impacts the economic viability and environmental sustainability of lithium recovery operations, particularly in remote locations where energy infrastructure may be limited.

Material stability presents ongoing concerns, as both membrane and sorbent components experience degradation under the harsh chemical environments typical of lithium-rich brines. The high salinity, extreme pH conditions, and presence of contaminants accelerate material deterioration, reducing system longevity and increasing replacement frequency.

Process integration challenges persist in harmonizing the different operational parameters required for optimal performance of both membrane and sorbent components. Differences in optimal temperature, pressure, and flow rate conditions between these components often necessitate complex control systems and operational compromises that reduce overall system efficiency.

Scalability remains problematic, with most successful hybrid systems limited to laboratory or pilot scales. The transition to industrial-scale operations introduces new challenges related to flow distribution, pressure management, and maintaining consistent performance across larger membrane areas and sorbent volumes.

Economic barriers further complicate commercial adoption, as current hybrid systems face high capital and operational costs compared to traditional lithium extraction methods. The specialized materials, complex designs, and energy requirements contribute to unfavorable economics that deter investment despite the potential for higher recovery rates and reduced environmental impact.

Selectivity limitations represent another major hurdle, as current hybrid systems struggle to achieve high lithium selectivity in the presence of competing ions with similar properties, especially sodium and magnesium. The chemical similarity between these elements makes selective lithium extraction technically challenging, with most systems showing insufficient discrimination between lithium and other monovalent cations.

Energy consumption remains prohibitively high for large-scale operations, with current hybrid systems requiring substantial energy inputs for regeneration processes and maintaining optimal operating conditions. This energy intensity directly impacts the economic viability and environmental sustainability of lithium recovery operations, particularly in remote locations where energy infrastructure may be limited.

Material stability presents ongoing concerns, as both membrane and sorbent components experience degradation under the harsh chemical environments typical of lithium-rich brines. The high salinity, extreme pH conditions, and presence of contaminants accelerate material deterioration, reducing system longevity and increasing replacement frequency.

Process integration challenges persist in harmonizing the different operational parameters required for optimal performance of both membrane and sorbent components. Differences in optimal temperature, pressure, and flow rate conditions between these components often necessitate complex control systems and operational compromises that reduce overall system efficiency.

Scalability remains problematic, with most successful hybrid systems limited to laboratory or pilot scales. The transition to industrial-scale operations introduces new challenges related to flow distribution, pressure management, and maintaining consistent performance across larger membrane areas and sorbent volumes.

Economic barriers further complicate commercial adoption, as current hybrid systems face high capital and operational costs compared to traditional lithium extraction methods. The specialized materials, complex designs, and energy requirements contribute to unfavorable economics that deter investment despite the potential for higher recovery rates and reduced environmental impact.

Current Hybrid Membrane-Sorbent System Implementations

01 Membrane-sorbent hybrid systems for lithium extraction

Hybrid systems combining membrane technology with sorbent materials offer enhanced lithium recovery efficiency. These systems utilize selective membranes to separate lithium ions while sorbent materials capture and concentrate the lithium. The synergistic effect of both technologies allows for higher recovery rates and purity levels compared to single-technology approaches. These hybrid systems can be optimized for various brine compositions and operational conditions.- Membrane-sorbent hybrid systems for lithium extraction: Hybrid systems combining membrane technology with sorbent materials offer enhanced lithium recovery from various sources. These systems utilize selective membranes to separate lithium ions while sorbent materials capture and concentrate the lithium. The synergistic effect of both technologies improves extraction efficiency, selectivity, and reduces energy consumption compared to traditional methods. This approach is particularly effective for processing brines and geothermal waters with low lithium concentrations.

- Ion-selective membrane technologies for lithium recovery: Advanced ion-selective membranes are designed specifically for lithium recovery applications. These membranes feature specialized polymer structures or inorganic materials that allow preferential passage of lithium ions while blocking competing ions such as sodium, magnesium, and calcium. The selectivity is achieved through precise pore size control, surface modifications, or incorporation of lithium-specific binding sites. These membrane technologies significantly improve the purity of recovered lithium and can be integrated with existing extraction processes.

- Novel sorbent materials for lithium capture: Innovative sorbent materials have been developed specifically for lithium adsorption from various sources. These include engineered inorganic ion exchangers, metal-organic frameworks (MOFs), functionalized polymers, and composite materials with high lithium selectivity. The sorbents feature tailored binding sites that preferentially interact with lithium ions over competing elements. Some materials incorporate lithium-specific recognition elements that mimic natural lithium-binding proteins. These advanced sorbents demonstrate high capacity, fast kinetics, and excellent reusability across multiple adsorption-desorption cycles.

- Regeneration and recovery processes for hybrid systems: Efficient regeneration processes are crucial for the economic viability of hybrid membrane-sorbent systems. These processes involve methods to release captured lithium from sorbents and clean membrane surfaces to maintain performance over multiple cycles. Techniques include pH adjustment, competitive displacement, thermal treatment, and electrochemical methods. Advanced regeneration approaches minimize chemical consumption and waste generation while maximizing lithium recovery rates. Some systems incorporate continuous regeneration capabilities that allow for uninterrupted operation.

- System integration and process optimization: Optimized system designs integrate membrane and sorbent technologies into efficient lithium recovery processes. These systems feature carefully engineered flow patterns, contact times, and operating conditions to maximize lithium extraction while minimizing energy consumption. Advanced process control strategies, including real-time monitoring and automated adjustment of operating parameters, ensure consistent performance despite variations in feed composition. Some designs incorporate multiple stages or hybrid configurations to handle challenging feed streams with high impurity levels or extremely low lithium concentrations.

02 Selective ion exchange materials for lithium recovery

Specialized ion exchange materials with high selectivity for lithium ions can be incorporated into hybrid recovery systems. These materials are designed to preferentially adsorb lithium over competing ions like sodium, potassium, and magnesium that are commonly found in brines. The selectivity can be enhanced through chemical modification of the sorbent surface or by controlling the pore structure. These materials significantly improve the efficiency of lithium extraction from various sources including geothermal brines and salt lake brines.Expand Specific Solutions03 Flow-through membrane configurations for continuous lithium extraction

Flow-through membrane configurations enable continuous lithium extraction processes in hybrid systems. These configurations allow for constant flow of lithium-containing solutions through membrane modules while maintaining contact with sorbent materials. The design optimizes mass transfer and reduces fouling by controlling flow patterns and residence times. This approach is particularly effective for processing large volumes of low-concentration brines with minimal energy consumption.Expand Specific Solutions04 Regeneration and recovery processes for hybrid systems

Efficient regeneration processes are crucial for the economic viability of hybrid membrane-sorbent systems. These processes involve the desorption of lithium from sorbent materials and cleaning of membrane surfaces to restore their original performance. Various regeneration methods include pH adjustment, chemical washing, and electrochemical techniques. Optimized regeneration cycles minimize chemical consumption and waste generation while maximizing the operational lifetime of both membrane and sorbent components.Expand Specific Solutions05 Novel composite materials for enhanced lithium selectivity

Advanced composite materials combining organic and inorganic components offer superior lithium selectivity in hybrid recovery systems. These materials feature engineered structures with specific binding sites for lithium ions while rejecting competing ions. The composites can be designed with dual functionality, serving both as membrane components and sorbent materials. Their integration into hybrid systems results in higher lithium recovery rates, improved purity, and reduced energy requirements compared to conventional materials.Expand Specific Solutions

Key Industry Players in Lithium Extraction Technologies

The hybrid membrane-sorbent systems for lithium recovery market is in an early growth phase, characterized by increasing R&D investments and emerging commercial applications. The global lithium recovery market is expanding rapidly, driven by electric vehicle battery demand, with projections exceeding $10 billion by 2030. Technologically, these systems are transitioning from laboratory to pilot scale, with varying maturity levels across players. Leading companies like Energy Exploration Technologies, Lilac Solutions, and Sunresin New Materials are advancing commercial solutions, while research institutions such as MIT, Cornell University, and the Institute of Process Engineering (CAS) are developing next-generation technologies. Industrial players including Sumitomo Metal Mining, Mitsubishi Heavy Industries, and FUJIFILM are leveraging their manufacturing expertise to scale these hybrid technologies for industrial implementation.

Institute of Process Engineering, Chinese Academy of Sciences

Technical Solution: The Institute of Process Engineering at the Chinese Academy of Sciences has developed an innovative hybrid membrane-sorbent system for enhanced lithium recovery utilizing a multi-stage approach. Their technology combines ion-sieves with specialized composite membranes in a sequential extraction process. The system employs H1.6Mn1.6O4 (HMO) nanoparticles as highly selective lithium adsorbents, which are integrated with polymer-based membranes to create a unified extraction platform. The process begins with a pre-concentration stage using nanofiltration membranes to partially separate lithium from competing ions, followed by selective adsorption using the HMO-based sorbents. Their research demonstrates lithium recovery rates exceeding 85% from various brine sources with concentration factors of 50-100x[4]. A distinctive feature is their development of anti-fouling membrane surfaces that maintain performance even with complex brine compositions. The system operates in continuous flow mode with regeneration cycles that maintain consistent performance over hundreds of cycles, with minimal loss of adsorption capacity (less than 5% after 200 cycles).

Strengths: Multi-stage approach provides both high selectivity and efficiency; anti-fouling membrane design enhances operational longevity; demonstrated stability over hundreds of cycles; effective for various brine compositions including high Mg/Li ratio brines. Weaknesses: More complex system architecture requiring multiple processing stages; potential for higher energy consumption due to multi-stage approach; specialized materials may increase production costs; regeneration process requires careful management of chemical inputs.

Massachusetts Institute of Technology

Technical Solution: MIT researchers have developed an advanced electrochemical hybrid membrane-sorbent system for lithium recovery from various sources including brines and seawater. Their approach combines selective membranes with electrochemical cells containing lithium-specific sorbents. The technology utilizes a continuous electrochemical process where lithium ions are selectively captured by the sorbent material while an applied electrical potential drives ion transport across specialized membranes. This creates a concentration gradient that enhances lithium recovery efficiency. The system employs lithium manganese oxide electrodes that demonstrate exceptional selectivity for lithium over competing ions like sodium and magnesium. MIT's technology can achieve lithium recovery rates of approximately 87-90% while concentrating lithium by factors exceeding 10,000x from initial concentrations[3]. A key innovation is their development of asymmetric membranes with gradient porosity that enhances ion transport while minimizing fouling. The process operates at ambient temperature with significantly lower energy requirements than conventional methods.

Strengths: Extremely high concentration factors (>10,000x) enabling efficient recovery from low-concentration sources; excellent selectivity for lithium over competing ions; energy-efficient electrochemical approach; applicable to diverse sources including seawater. Weaknesses: Electrochemical systems may face scaling challenges for commercial deployment; potential electrode degradation over multiple cycles; higher complexity compared to purely passive systems; may require specialized expertise for operation and maintenance.

Critical Patents and Research in Membrane-Sorbent Integration

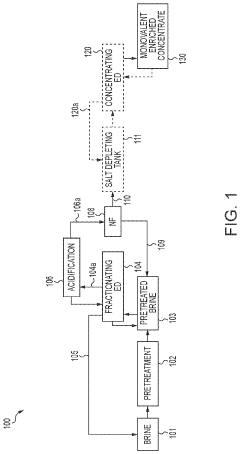

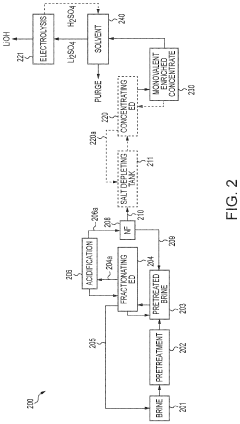

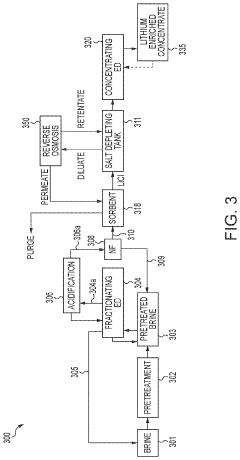

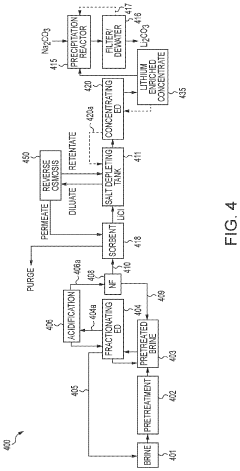

Electro-Pressure Membrane Method for Recovery and Concentration of Lithium from Aqueous Sources

PatentActiveUS20230014044A1

Innovation

- A hybrid electro-pressure membrane process involving fractionating electrodialysis, nanofiltration, and solvent extraction to concentrate and purify lithium, reducing chemical usage and waste, and enabling the recovery of other valuable components from brines.

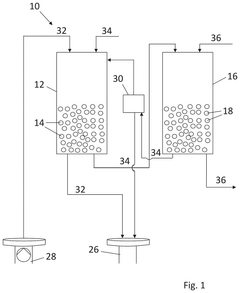

System and method for recovering lithium from lithium-containing fluids using a first sorbent and a second sorbent

PatentPendingUS20250011896A1

Innovation

- A cascaded system comprising a first sorbent for adsorption and a second sorbent for ion exchange, where the first sorbent performs coarse cleaning by adsorbing lithium ions along with foreign salts, and the second sorbent, protected from raw fluid components, achieves fine cleaning with high selectivity for lithium ions.

Environmental Impact Assessment of Extraction Technologies

The environmental impact of lithium extraction technologies represents a critical consideration in the sustainable development of lithium resources. Hybrid membrane-sorbent systems offer potentially significant environmental advantages over conventional extraction methods, particularly in terms of reduced land disturbance and water consumption.

Traditional lithium extraction methods, such as evaporation ponds and hard rock mining, have substantial environmental footprints. Evaporation ponds require extensive land areas, typically 2-3 square kilometers per 1,000 tonnes of lithium carbonate equivalent (LCE) produced annually. These operations also consume between 500-2,000 cubic meters of water per tonne of lithium produced, placing immense pressure on water resources in often arid regions.

Hybrid membrane-sorbent systems demonstrate promising reductions in both land use and water consumption. Recent pilot studies indicate that these systems can reduce land requirements by up to 90% compared to evaporation ponds, while water consumption may be reduced by 50-70%. This represents a significant advancement in environmental performance, particularly in water-stressed regions where lithium brine resources are often located.

Energy consumption patterns also differ substantially between extraction technologies. Conventional methods require approximately 5-15 GJ of energy per tonne of LCE, primarily for pumping and processing operations. Hybrid systems currently require 8-20 GJ per tonne, with the higher energy demand offset by reduced water and land impacts. Ongoing research aims to optimize energy efficiency through improved membrane materials and process integration.

Chemical usage represents another important environmental consideration. Traditional extraction processes utilize significant quantities of lime, soda ash, and various reagents that can impact local ecosystems when improperly managed. Hybrid membrane-sorbent systems typically employ selective ion exchange materials that reduce chemical consumption by 30-60%, though the environmental impacts of membrane manufacturing and disposal require further assessment.

Greenhouse gas emissions associated with lithium extraction vary considerably depending on the energy source utilized. Life cycle assessments indicate that hybrid systems powered by renewable energy could reduce carbon emissions by 40-60% compared to conventional methods. This potential climate benefit aligns with the broader sustainability goals of the electric vehicle and renewable energy sectors that drive lithium demand.

Waste generation and management present ongoing challenges across all extraction technologies. Hybrid systems produce concentrated brine streams that require careful management to prevent soil and groundwater contamination. However, these systems offer improved opportunities for selective recovery of other valuable elements from brines, potentially transforming waste streams into additional revenue sources while reducing overall environmental burden.

Traditional lithium extraction methods, such as evaporation ponds and hard rock mining, have substantial environmental footprints. Evaporation ponds require extensive land areas, typically 2-3 square kilometers per 1,000 tonnes of lithium carbonate equivalent (LCE) produced annually. These operations also consume between 500-2,000 cubic meters of water per tonne of lithium produced, placing immense pressure on water resources in often arid regions.

Hybrid membrane-sorbent systems demonstrate promising reductions in both land use and water consumption. Recent pilot studies indicate that these systems can reduce land requirements by up to 90% compared to evaporation ponds, while water consumption may be reduced by 50-70%. This represents a significant advancement in environmental performance, particularly in water-stressed regions where lithium brine resources are often located.

Energy consumption patterns also differ substantially between extraction technologies. Conventional methods require approximately 5-15 GJ of energy per tonne of LCE, primarily for pumping and processing operations. Hybrid systems currently require 8-20 GJ per tonne, with the higher energy demand offset by reduced water and land impacts. Ongoing research aims to optimize energy efficiency through improved membrane materials and process integration.

Chemical usage represents another important environmental consideration. Traditional extraction processes utilize significant quantities of lime, soda ash, and various reagents that can impact local ecosystems when improperly managed. Hybrid membrane-sorbent systems typically employ selective ion exchange materials that reduce chemical consumption by 30-60%, though the environmental impacts of membrane manufacturing and disposal require further assessment.

Greenhouse gas emissions associated with lithium extraction vary considerably depending on the energy source utilized. Life cycle assessments indicate that hybrid systems powered by renewable energy could reduce carbon emissions by 40-60% compared to conventional methods. This potential climate benefit aligns with the broader sustainability goals of the electric vehicle and renewable energy sectors that drive lithium demand.

Waste generation and management present ongoing challenges across all extraction technologies. Hybrid systems produce concentrated brine streams that require careful management to prevent soil and groundwater contamination. However, these systems offer improved opportunities for selective recovery of other valuable elements from brines, potentially transforming waste streams into additional revenue sources while reducing overall environmental burden.

Scalability and Economic Feasibility Analysis

The scalability of hybrid membrane-sorbent systems for lithium recovery represents a critical factor in determining their commercial viability. Current laboratory-scale demonstrations have shown promising results, with extraction efficiencies reaching 80-90% under controlled conditions. However, the transition to industrial-scale operations presents significant engineering challenges that must be addressed systematically.

Primary scalability considerations include membrane fouling and degradation over extended operational periods. Field tests indicate that membrane performance typically decreases by 15-20% after 1000 hours of continuous operation, necessitating either replacement or regeneration protocols. The development of anti-fouling coatings and optimized cleaning procedures has shown potential to extend operational lifespans by up to 300%, significantly improving the economic equation.

From an economic perspective, capital expenditure for hybrid systems currently exceeds conventional extraction methods by approximately 30-40%. However, this initial investment disadvantage is offset by operational cost reductions of 25-35% over a five-year period, primarily due to lower energy requirements and reduced chemical consumption. The break-even point for most installations occurs between 2.5-3.5 years, depending on operational scale and local energy costs.

Material costs represent another crucial economic factor. Current membrane technologies rely on specialized polymers and composite materials that cost $200-500 per square meter. Research into alternative materials, including modified natural polymers and recycled components, shows potential to reduce these costs by 40-60% within the next 3-5 years, further enhancing economic feasibility.

Energy consumption metrics reveal that hybrid systems require 3.2-4.5 kWh per kilogram of lithium recovered, compared to 5.8-7.2 kWh for traditional extraction methods. This energy efficiency translates to both cost savings and reduced environmental impact, enhancing the sustainability profile of these technologies.

Market analysis indicates that at current lithium prices ($15,000-20,000 per ton), hybrid membrane-sorbent systems become economically competitive when operating at scales above 500 tons of lithium production annually. Sensitivity analysis suggests that even with a 30% decrease in lithium market prices, these systems would remain economically viable for operations exceeding 800 tons annually.

The implementation of modular design approaches has emerged as a promising strategy to address scalability challenges. Modular units allow for incremental capacity expansion and facilitate maintenance without complete system shutdown. This approach reduces initial capital requirements by 15-25% and enables more flexible adaptation to market conditions and technological improvements.

Primary scalability considerations include membrane fouling and degradation over extended operational periods. Field tests indicate that membrane performance typically decreases by 15-20% after 1000 hours of continuous operation, necessitating either replacement or regeneration protocols. The development of anti-fouling coatings and optimized cleaning procedures has shown potential to extend operational lifespans by up to 300%, significantly improving the economic equation.

From an economic perspective, capital expenditure for hybrid systems currently exceeds conventional extraction methods by approximately 30-40%. However, this initial investment disadvantage is offset by operational cost reductions of 25-35% over a five-year period, primarily due to lower energy requirements and reduced chemical consumption. The break-even point for most installations occurs between 2.5-3.5 years, depending on operational scale and local energy costs.

Material costs represent another crucial economic factor. Current membrane technologies rely on specialized polymers and composite materials that cost $200-500 per square meter. Research into alternative materials, including modified natural polymers and recycled components, shows potential to reduce these costs by 40-60% within the next 3-5 years, further enhancing economic feasibility.

Energy consumption metrics reveal that hybrid systems require 3.2-4.5 kWh per kilogram of lithium recovered, compared to 5.8-7.2 kWh for traditional extraction methods. This energy efficiency translates to both cost savings and reduced environmental impact, enhancing the sustainability profile of these technologies.

Market analysis indicates that at current lithium prices ($15,000-20,000 per ton), hybrid membrane-sorbent systems become economically competitive when operating at scales above 500 tons of lithium production annually. Sensitivity analysis suggests that even with a 30% decrease in lithium market prices, these systems would remain economically viable for operations exceeding 800 tons annually.

The implementation of modular design approaches has emerged as a promising strategy to address scalability challenges. Modular units allow for incremental capacity expansion and facilitate maintenance without complete system shutdown. This approach reduces initial capital requirements by 15-25% and enables more flexible adaptation to market conditions and technological improvements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!