Process Simulation Best Practices For Geothermal Lithium Plants

SEP 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Geothermal Lithium Extraction Technology Evolution and Objectives

Geothermal lithium extraction represents a significant technological advancement in the mining industry, evolving from traditional evaporation pond methods to more sophisticated direct lithium extraction (DLE) techniques. The historical trajectory began in the 1990s with initial research into geothermal brine lithium recovery, but gained substantial momentum only in the past decade as lithium demand surged for battery applications. This evolution has been characterized by a shift from conceptual research to practical implementation, with notable pilot projects emerging in the Salton Sea (USA), Clayton Valley (USA), and various sites across Germany, New Zealand, and the UK.

The technological progression has been marked by several key innovations, including advanced ion exchange materials, electrochemical separation techniques, and membrane-based extraction systems. These developments have collectively improved selectivity, reduced processing time, and enhanced recovery rates from the complex geothermal brine matrices. Process simulation capabilities have evolved in parallel, transitioning from basic mass balance calculations to sophisticated thermodynamic modeling that accounts for the unique challenges of high-temperature, high-salinity geothermal fluids.

Current objectives in geothermal lithium extraction technology center around four primary goals. First, increasing lithium recovery efficiency from the current industry average of 40-60% to a target of 80-90%, which would dramatically improve economic viability. Second, reducing energy consumption in the extraction process, particularly in the separation and concentration stages where energy intensity remains a significant challenge. Third, minimizing environmental impact through closed-loop systems that return depleted brine to geothermal reservoirs with minimal chemical alteration.

Fourth, and perhaps most critically for process simulation practices, is the development of robust predictive models that can accurately represent the complex phase behavior, chemical equilibria, and transport phenomena in geothermal lithium plants. This includes improving thermodynamic property packages for high-salinity brines, developing more accurate kinetic models for adsorption/desorption processes, and creating integrated simulation frameworks that connect subsurface reservoir dynamics with surface processing operations.

The ultimate technological objective is to establish geothermal lithium extraction as a commercially viable, environmentally sustainable alternative to traditional lithium mining methods. This requires not only advances in the core extraction technology but also significant improvements in process simulation capabilities to optimize plant design, reduce capital costs, and enable real-time operational decision-making in these complex processing environments.

The technological progression has been marked by several key innovations, including advanced ion exchange materials, electrochemical separation techniques, and membrane-based extraction systems. These developments have collectively improved selectivity, reduced processing time, and enhanced recovery rates from the complex geothermal brine matrices. Process simulation capabilities have evolved in parallel, transitioning from basic mass balance calculations to sophisticated thermodynamic modeling that accounts for the unique challenges of high-temperature, high-salinity geothermal fluids.

Current objectives in geothermal lithium extraction technology center around four primary goals. First, increasing lithium recovery efficiency from the current industry average of 40-60% to a target of 80-90%, which would dramatically improve economic viability. Second, reducing energy consumption in the extraction process, particularly in the separation and concentration stages where energy intensity remains a significant challenge. Third, minimizing environmental impact through closed-loop systems that return depleted brine to geothermal reservoirs with minimal chemical alteration.

Fourth, and perhaps most critically for process simulation practices, is the development of robust predictive models that can accurately represent the complex phase behavior, chemical equilibria, and transport phenomena in geothermal lithium plants. This includes improving thermodynamic property packages for high-salinity brines, developing more accurate kinetic models for adsorption/desorption processes, and creating integrated simulation frameworks that connect subsurface reservoir dynamics with surface processing operations.

The ultimate technological objective is to establish geothermal lithium extraction as a commercially viable, environmentally sustainable alternative to traditional lithium mining methods. This requires not only advances in the core extraction technology but also significant improvements in process simulation capabilities to optimize plant design, reduce capital costs, and enable real-time operational decision-making in these complex processing environments.

Market Analysis for Geothermal Lithium Production

The global market for lithium is experiencing unprecedented growth, driven by the rapid expansion of electric vehicle production and renewable energy storage systems. Within this context, geothermal lithium extraction represents a particularly promising segment with significant growth potential. Current market valuations place the global lithium market at approximately $7.5 billion, with projections indicating a compound annual growth rate (CAGR) of 12-15% over the next decade.

Geothermal lithium production specifically offers a compelling value proposition compared to traditional extraction methods. While conventional lithium mining through hard rock extraction or solar evaporation of brine accounts for over 95% of current production, geothermal extraction is positioned to capture an increasing market share due to its substantially lower environmental footprint and potential for cost optimization through process simulation advancements.

Market demand analysis reveals that battery manufacturers and automotive companies are increasingly prioritizing sustainably sourced lithium, creating a premium market segment for geothermal lithium producers. Companies like Tesla, Volkswagen Group, and LG Energy Solution have publicly committed to sourcing materials with reduced environmental impact, directly benefiting geothermal lithium operations with optimized process simulations.

Regional market assessment indicates that the Western United States, particularly the Salton Sea region in California, represents the most immediate growth opportunity for geothermal lithium production in North America. This region alone contains estimated lithium reserves sufficient to meet 40% of global demand. Similar opportunities exist in the Rhine Valley (Germany), Cornwall Basin (UK), and various locations across Chile and Argentina where geothermal resources coincide with lithium-rich brines.

Market barriers include the capital-intensive nature of geothermal plant development, with initial investment requirements ranging from $30-50 million for pilot facilities to $150-300 million for commercial-scale operations. However, advanced process simulation can significantly reduce these costs by optimizing plant design and operational parameters before physical construction begins.

Consumer and industrial demand patterns suggest that premium pricing for environmentally responsible lithium production methods could command 5-8% higher prices than conventional sources. This price differential is expected to increase as carbon taxation and environmental regulations become more stringent globally, further enhancing the economic case for geothermal lithium extraction.

Market forecasts indicate that geothermal lithium production could capture 15-20% of global lithium supply by 2030, representing a market segment worth potentially $3-4 billion annually. This growth trajectory is contingent upon continued advancement in process simulation technologies that can effectively address the unique challenges of geothermal brine processing.

Geothermal lithium production specifically offers a compelling value proposition compared to traditional extraction methods. While conventional lithium mining through hard rock extraction or solar evaporation of brine accounts for over 95% of current production, geothermal extraction is positioned to capture an increasing market share due to its substantially lower environmental footprint and potential for cost optimization through process simulation advancements.

Market demand analysis reveals that battery manufacturers and automotive companies are increasingly prioritizing sustainably sourced lithium, creating a premium market segment for geothermal lithium producers. Companies like Tesla, Volkswagen Group, and LG Energy Solution have publicly committed to sourcing materials with reduced environmental impact, directly benefiting geothermal lithium operations with optimized process simulations.

Regional market assessment indicates that the Western United States, particularly the Salton Sea region in California, represents the most immediate growth opportunity for geothermal lithium production in North America. This region alone contains estimated lithium reserves sufficient to meet 40% of global demand. Similar opportunities exist in the Rhine Valley (Germany), Cornwall Basin (UK), and various locations across Chile and Argentina where geothermal resources coincide with lithium-rich brines.

Market barriers include the capital-intensive nature of geothermal plant development, with initial investment requirements ranging from $30-50 million for pilot facilities to $150-300 million for commercial-scale operations. However, advanced process simulation can significantly reduce these costs by optimizing plant design and operational parameters before physical construction begins.

Consumer and industrial demand patterns suggest that premium pricing for environmentally responsible lithium production methods could command 5-8% higher prices than conventional sources. This price differential is expected to increase as carbon taxation and environmental regulations become more stringent globally, further enhancing the economic case for geothermal lithium extraction.

Market forecasts indicate that geothermal lithium production could capture 15-20% of global lithium supply by 2030, representing a market segment worth potentially $3-4 billion annually. This growth trajectory is contingent upon continued advancement in process simulation technologies that can effectively address the unique challenges of geothermal brine processing.

Current Process Simulation Challenges in Geothermal Lithium Extraction

Despite significant advancements in geothermal lithium extraction technologies, process simulation for these plants faces several critical challenges that impede optimal design and operation. The complexity of geothermal brine chemistry presents a fundamental obstacle, as these brines contain diverse dissolved minerals and gases with concentrations that vary significantly between reservoirs and even within the same reservoir over time. Current simulation tools struggle to accurately model these complex, multi-component systems, particularly the non-ideal behavior of highly concentrated salt solutions.

Temperature and pressure gradients throughout extraction systems create additional modeling difficulties. As geothermal fluids move from reservoir conditions (often exceeding 200°C) to surface processing temperatures, phase changes and precipitation reactions occur that are difficult to predict with existing thermodynamic models. The kinetics of lithium adsorption and desorption processes, central to many extraction technologies, remain inadequately characterized in simulation environments.

Scaling and fouling phenomena represent another significant simulation challenge. Mineral precipitation on equipment surfaces affects heat transfer coefficients, flow characteristics, and extraction efficiency, yet these dynamic processes are poorly integrated into current simulation frameworks. The lack of comprehensive thermodynamic databases specifically tailored to geothermal lithium extraction compounds these issues, as many simulators rely on databases developed for other industries that may not accurately represent geothermal conditions.

Computational limitations further constrain simulation capabilities. The multiphysics nature of geothermal lithium extraction—involving fluid dynamics, heat transfer, chemical reactions, and mass transfer—demands significant computational resources. Current simulation approaches often require simplifications that compromise accuracy or focus on isolated subsystems rather than integrated plant operations.

Data scarcity presents an additional hurdle. Unlike established chemical processes with decades of operational data, geothermal lithium extraction has limited industrial-scale implementation history. This shortage of validation data makes it difficult to verify simulation accuracy and calibrate models appropriately. The proprietary nature of many emerging extraction technologies further restricts the availability of process data for simulation development.

Integration challenges between subsystem models also persist. Reservoir simulation, wellbore flow modeling, heat exchanger networks, and separation processes are typically simulated using different specialized tools, creating difficulties in developing cohesive plant-wide simulations. The interfaces between these subsystems often introduce significant uncertainties that propagate throughout the simulation results.

Temperature and pressure gradients throughout extraction systems create additional modeling difficulties. As geothermal fluids move from reservoir conditions (often exceeding 200°C) to surface processing temperatures, phase changes and precipitation reactions occur that are difficult to predict with existing thermodynamic models. The kinetics of lithium adsorption and desorption processes, central to many extraction technologies, remain inadequately characterized in simulation environments.

Scaling and fouling phenomena represent another significant simulation challenge. Mineral precipitation on equipment surfaces affects heat transfer coefficients, flow characteristics, and extraction efficiency, yet these dynamic processes are poorly integrated into current simulation frameworks. The lack of comprehensive thermodynamic databases specifically tailored to geothermal lithium extraction compounds these issues, as many simulators rely on databases developed for other industries that may not accurately represent geothermal conditions.

Computational limitations further constrain simulation capabilities. The multiphysics nature of geothermal lithium extraction—involving fluid dynamics, heat transfer, chemical reactions, and mass transfer—demands significant computational resources. Current simulation approaches often require simplifications that compromise accuracy or focus on isolated subsystems rather than integrated plant operations.

Data scarcity presents an additional hurdle. Unlike established chemical processes with decades of operational data, geothermal lithium extraction has limited industrial-scale implementation history. This shortage of validation data makes it difficult to verify simulation accuracy and calibrate models appropriately. The proprietary nature of many emerging extraction technologies further restricts the availability of process data for simulation development.

Integration challenges between subsystem models also persist. Reservoir simulation, wellbore flow modeling, heat exchanger networks, and separation processes are typically simulated using different specialized tools, creating difficulties in developing cohesive plant-wide simulations. The interfaces between these subsystems often introduce significant uncertainties that propagate throughout the simulation results.

State-of-the-Art Process Simulation Solutions for Geothermal Brines

01 Simulation-based business process optimization

Process simulation can be used to optimize business processes by modeling and analyzing different scenarios before implementation. This approach helps organizations identify bottlenecks, inefficiencies, and potential improvements in their workflows. Best practices include creating accurate process models, defining relevant performance metrics, and using simulation results to guide decision-making for process improvements.- Simulation-based business process optimization: Process simulation can be used to optimize business operations by modeling and analyzing workflows, resource allocation, and performance metrics. This approach allows organizations to identify bottlenecks, test different scenarios, and implement improvements before making changes to actual processes. Simulation tools can help in decision-making by providing data-driven insights about potential outcomes of process modifications.

- Security and risk management in process simulation: Process simulation can be applied to security and risk management by modeling potential threats, vulnerabilities, and their impacts. These simulations help organizations develop robust security protocols, test response strategies, and identify weaknesses in existing systems. By simulating various security scenarios, organizations can better prepare for and mitigate risks in their operational processes.

- Integration of data analytics with process simulation: Combining data analytics with process simulation enhances the accuracy and relevance of simulation models. By incorporating real-time data, historical patterns, and predictive analytics, organizations can create more dynamic and responsive simulations. This integration allows for continuous improvement of processes based on actual performance data and helps in making more informed decisions about process changes.

- Software development and testing through simulation: Process simulation is valuable in software development and testing environments, allowing developers to model application behavior, test performance under various conditions, and identify potential issues before deployment. Simulation-based testing can reduce development time, improve code quality, and ensure better user experiences by identifying and addressing problems early in the development lifecycle.

- Collaborative and cloud-based process simulation: Modern process simulation best practices include collaborative approaches that leverage cloud technologies to enable multiple stakeholders to participate in simulation development, testing, and analysis. Cloud-based simulation platforms provide accessibility, scalability, and real-time collaboration capabilities, allowing teams to work together regardless of location. These collaborative environments enhance knowledge sharing and improve the overall quality of process simulations.

02 Data management and integration for simulation models

Effective process simulation requires proper data management and integration practices. This includes collecting accurate input data, maintaining data consistency across different simulation models, and integrating simulation data with enterprise systems. Best practices involve establishing data governance frameworks, implementing data validation procedures, and ensuring seamless data flow between simulation tools and other business applications.Expand Specific Solutions03 Security and compliance in simulation environments

Process simulation often involves sensitive business data and must comply with various regulations. Best practices include implementing robust security measures to protect simulation models and data, ensuring compliance with industry standards, and establishing access controls for simulation environments. This approach helps organizations maintain data integrity while meeting regulatory requirements during simulation activities.Expand Specific Solutions04 Collaborative simulation and knowledge sharing

Collaborative approaches to process simulation enable organizations to leverage collective expertise and improve simulation outcomes. Best practices include establishing platforms for sharing simulation models, creating standardized documentation procedures, and implementing collaborative workflows for model development and validation. This facilitates knowledge transfer and ensures consistency in simulation practices across the organization.Expand Specific Solutions05 Performance measurement and continuous improvement

Effective process simulation requires ongoing performance measurement and continuous improvement of simulation models. Best practices include establishing key performance indicators for simulation accuracy, conducting regular validation of simulation results against real-world outcomes, and implementing feedback loops to refine simulation models. This approach ensures that simulation tools continue to provide valuable insights for business decision-making.Expand Specific Solutions

Leading Companies and Research Institutions in Geothermal Lithium

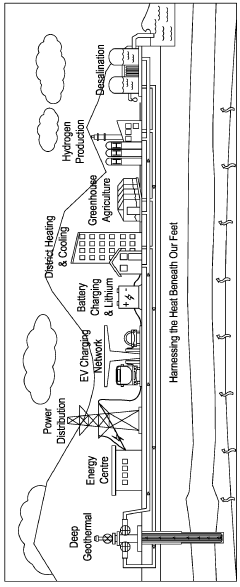

The geothermal lithium extraction industry is currently in an early growth phase, characterized by rapid technological development and increasing market interest due to the global push for sustainable battery materials. The market size is projected to expand significantly as demand for lithium in electric vehicle batteries continues to surge, with estimates suggesting a compound annual growth rate exceeding 20% through 2030. From a technological maturity perspective, companies like Vulcan Energy Resources are pioneering zero-carbon lithium extraction methods, while established players such as LG Chem and Siemens are leveraging their industrial process expertise to develop optimized simulation models. Research institutions including Central South University and the Institute of Process Engineering (Chinese Academy of Sciences) are advancing fundamental understanding of geothermal lithium extraction processes, while specialized firms like CeraPhi Energy are developing innovative closed-loop geothermal systems specifically designed for lithium recovery.

Vulcan Energie Ressourcen GmbH

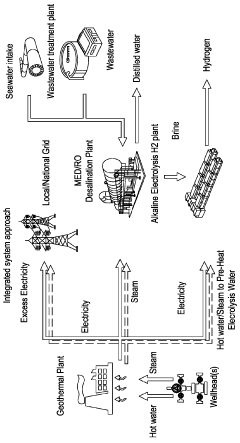

Technical Solution: Vulcan Energy has developed a proprietary Direct Lithium Extraction (DLE) process simulation framework specifically for geothermal brines in the Upper Rhine Valley. Their Zero Carbon Lithium™ project integrates advanced process simulation tools to model the extraction of lithium from geothermal brines while simultaneously producing renewable geothermal energy. The simulation incorporates multi-physics modeling that accounts for brine chemistry variations, temperature gradients, and extraction kinetics. Their process simulation best practices include real-time monitoring systems that feed operational data back into simulation models, creating a digital twin of the entire plant that optimizes both lithium recovery rates and energy efficiency. Vulcan's simulation framework also incorporates environmental impact assessments, ensuring their zero-carbon commitment is maintained throughout the process.

Strengths: Dual-purpose simulation that optimizes both lithium extraction and renewable energy production; zero-carbon approach gives competitive advantage in European markets. Weaknesses: Limited to specific brine chemistry of the Upper Rhine Valley; relatively new technology with limited long-term operational data to validate simulation accuracy.

Honeywell International Technologies Ltd.

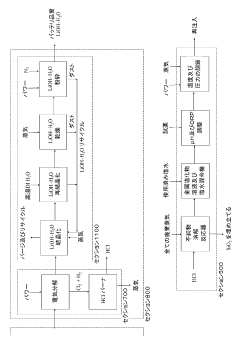

Technical Solution: Honeywell has developed the UniSim® Design Suite, a comprehensive process simulation platform that has been adapted for geothermal lithium extraction operations. Their solution incorporates specialized thermodynamic models calibrated specifically for high-temperature geothermal brines containing lithium and other minerals. The simulation platform enables dynamic modeling of the entire extraction process, from wellhead to final lithium product, accounting for variations in brine composition, temperature fluctuations, and equipment performance. Honeywell's best practices include integration of advanced control strategies within the simulation environment, allowing operators to test automated responses to process disturbances before implementation. Their digital twin approach connects real-time plant data with simulation models to continuously optimize operations, predict maintenance needs, and maximize lithium recovery while minimizing energy consumption and chemical usage.

Strengths: Extensive experience in industrial process simulation across multiple industries; robust software platform with proven reliability; comprehensive technical support infrastructure. Weaknesses: Generic solution that requires significant customization for specific geothermal lithium applications; higher implementation and licensing costs compared to specialized solutions.

Critical Patents and Technical Literature in Lithium Extraction Simulation

Improvements in geothermal energy extraction

PatentPendingGB2618133A

Innovation

- A holistic system and method for recommending design parameters for geothermal energy capture installations, including simulation and calculation tools to assess and rank technical specifications based on well-specific characteristics, external factors, and user priorities, enabling a whole-system design for maximizing energy extraction efficiency across the lifecycle of geothermal projects.

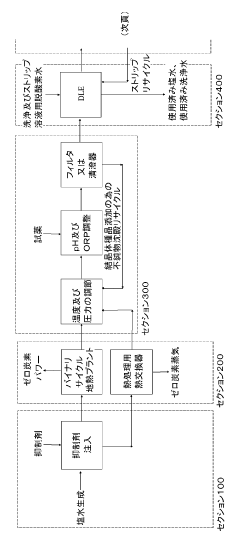

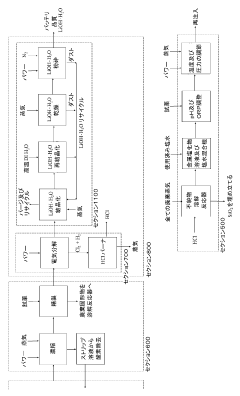

Systems and Processes for Direct Lithium Extraction and Production of Low Carbon Intensity Lithium Chemicals from Geothermal Brine

PatentInactiveJP2023525640A

Innovation

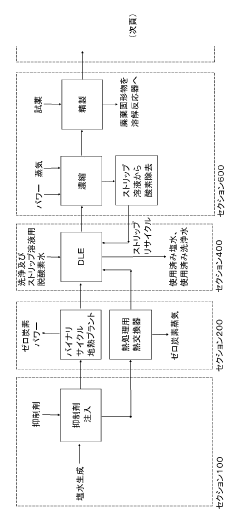

- Integration of direct lithium extraction with binary cycle geothermal plants to produce battery-quality lithium chemicals while utilizing carbon-free energy sources.

- Sequential combination of direct lithium extraction, lithium chloride concentration purification, and lithium battery chemistry treatment circuits powered by geothermal electricity and heat.

- Closed-loop system design that prevents release of non-condensable gases to the atmosphere, resulting in low carbon intensity lithium production.

Environmental Impact Assessment of Geothermal Lithium Production

The environmental impact assessment of geothermal lithium production requires comprehensive analysis of both positive and negative effects on ecosystems, water resources, air quality, and local communities. Geothermal lithium extraction offers significant environmental advantages over traditional mining methods, primarily through reduced land disturbance and lower carbon emissions. The closed-loop direct lithium extraction (DLE) systems integrated with geothermal power plants can potentially achieve near-zero carbon lithium production when powered by the renewable geothermal energy they harness.

Water usage represents a critical environmental consideration in geothermal lithium operations. While these facilities generally consume less freshwater than conventional evaporative ponds used in salt flat mining, the management of geothermal brines requires careful monitoring. The potential for groundwater contamination through improper handling of process chemicals or brine reinjection must be thoroughly assessed through hydrogeological modeling and continuous monitoring systems.

Air quality impacts from geothermal lithium plants are primarily associated with potential emissions during drilling operations and non-condensable gases released from geothermal fluids. These may include hydrogen sulfide, carbon dioxide, methane, and trace amounts of mercury or arsenic depending on the geological formation. Advanced process simulation tools can predict these emissions and inform the design of appropriate abatement systems to minimize atmospheric pollution.

Land use considerations for geothermal lithium facilities are substantially more favorable than open-pit mining or evaporation pond operations. The surface footprint is primarily limited to wellheads, pipelines, and processing facilities. However, access roads and transmission infrastructure may fragment habitats in previously undisturbed areas, requiring careful planning and mitigation measures to protect biodiversity and sensitive ecosystems.

Waste management presents another significant environmental challenge. Process simulations must account for the handling and disposal of spent sorbents, filter media, and chemical reagents used in lithium extraction. Additionally, the management of precipitated solids from brine processing requires proper characterization to prevent the release of potentially harmful elements concentrated during extraction processes.

Seismic activity induced by geothermal fluid injection represents a site-specific risk that must be evaluated through geological assessment and continuous monitoring. Process simulation models should incorporate geomechanical parameters to predict potential subsurface pressure changes and inform safe operating parameters for brine reinjection to minimize induced seismicity risks.

Water usage represents a critical environmental consideration in geothermal lithium operations. While these facilities generally consume less freshwater than conventional evaporative ponds used in salt flat mining, the management of geothermal brines requires careful monitoring. The potential for groundwater contamination through improper handling of process chemicals or brine reinjection must be thoroughly assessed through hydrogeological modeling and continuous monitoring systems.

Air quality impacts from geothermal lithium plants are primarily associated with potential emissions during drilling operations and non-condensable gases released from geothermal fluids. These may include hydrogen sulfide, carbon dioxide, methane, and trace amounts of mercury or arsenic depending on the geological formation. Advanced process simulation tools can predict these emissions and inform the design of appropriate abatement systems to minimize atmospheric pollution.

Land use considerations for geothermal lithium facilities are substantially more favorable than open-pit mining or evaporation pond operations. The surface footprint is primarily limited to wellheads, pipelines, and processing facilities. However, access roads and transmission infrastructure may fragment habitats in previously undisturbed areas, requiring careful planning and mitigation measures to protect biodiversity and sensitive ecosystems.

Waste management presents another significant environmental challenge. Process simulations must account for the handling and disposal of spent sorbents, filter media, and chemical reagents used in lithium extraction. Additionally, the management of precipitated solids from brine processing requires proper characterization to prevent the release of potentially harmful elements concentrated during extraction processes.

Seismic activity induced by geothermal fluid injection represents a site-specific risk that must be evaluated through geological assessment and continuous monitoring. Process simulation models should incorporate geomechanical parameters to predict potential subsurface pressure changes and inform safe operating parameters for brine reinjection to minimize induced seismicity risks.

Techno-Economic Analysis of Simulation-Optimized Lithium Plants

The techno-economic analysis of simulation-optimized lithium plants represents a critical framework for evaluating the financial viability and operational efficiency of geothermal lithium extraction facilities. This analysis integrates process simulation data with economic modeling to provide comprehensive insights into investment decisions and operational strategies.

Process simulation tools such as Aspen Plus, HYSYS, and gPROMS enable detailed modeling of lithium extraction processes from geothermal brines, capturing complex thermodynamic behaviors, reaction kinetics, and mass transfer phenomena. These simulations generate valuable data on energy consumption, material flows, and equipment sizing that form the foundation of economic assessments.

Capital expenditure (CAPEX) modeling incorporates equipment costs, installation factors, and indirect expenses derived from simulation outputs. The accuracy of these estimates significantly improves when simulation data informs equipment specifications and material requirements. Industry benchmarks suggest that simulation-optimized designs can reduce CAPEX by 15-25% compared to conventional approaches through right-sizing of equipment and process intensification.

Operating expenditure (OPEX) calculations benefit substantially from simulation data on energy consumption, chemical usage, and maintenance requirements. Sensitivity analyses performed on simulation models reveal that energy costs typically represent 30-45% of total OPEX for geothermal lithium plants, highlighting the importance of energy optimization in process design.

Revenue projections based on simulation-predicted recovery rates and product purity provide realistic financial forecasts. Market analysis indicates that high-purity lithium products (99.5%+ LCE) command premium prices, making simulation-guided purification steps economically significant.

Risk assessment methodologies incorporate simulation-based scenario analyses to evaluate process robustness under varying conditions. Monte Carlo simulations integrated with process models can quantify uncertainties in technical and economic parameters, providing probability distributions for key financial metrics like NPV and IRR.

Optimization algorithms coupled with process simulations enable identification of economically optimal operating conditions. Multi-objective optimization approaches balance competing factors such as recovery rates, energy consumption, and environmental impact to maximize economic returns while meeting sustainability goals.

Process simulation tools such as Aspen Plus, HYSYS, and gPROMS enable detailed modeling of lithium extraction processes from geothermal brines, capturing complex thermodynamic behaviors, reaction kinetics, and mass transfer phenomena. These simulations generate valuable data on energy consumption, material flows, and equipment sizing that form the foundation of economic assessments.

Capital expenditure (CAPEX) modeling incorporates equipment costs, installation factors, and indirect expenses derived from simulation outputs. The accuracy of these estimates significantly improves when simulation data informs equipment specifications and material requirements. Industry benchmarks suggest that simulation-optimized designs can reduce CAPEX by 15-25% compared to conventional approaches through right-sizing of equipment and process intensification.

Operating expenditure (OPEX) calculations benefit substantially from simulation data on energy consumption, chemical usage, and maintenance requirements. Sensitivity analyses performed on simulation models reveal that energy costs typically represent 30-45% of total OPEX for geothermal lithium plants, highlighting the importance of energy optimization in process design.

Revenue projections based on simulation-predicted recovery rates and product purity provide realistic financial forecasts. Market analysis indicates that high-purity lithium products (99.5%+ LCE) command premium prices, making simulation-guided purification steps economically significant.

Risk assessment methodologies incorporate simulation-based scenario analyses to evaluate process robustness under varying conditions. Monte Carlo simulations integrated with process models can quantify uncertainties in technical and economic parameters, providing probability distributions for key financial metrics like NPV and IRR.

Optimization algorithms coupled with process simulations enable identification of economically optimal operating conditions. Multi-objective optimization approaches balance competing factors such as recovery rates, energy consumption, and environmental impact to maximize economic returns while meeting sustainability goals.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!