Compare LS2 Engine Turbo vs Supercharger: Boost Efficiency

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LS2 Engine Forced Induction Background & Objectives

The LS2 engine, introduced by General Motors in 2005, represents a significant evolution in the LS engine family with its 6.0L displacement and aluminum block construction. This powerplant, featured prominently in vehicles like the Pontiac GTO, Chevrolet Corvette C6, and various GM trucks, delivers impressive naturally aspirated performance. However, the pursuit of increased power output has led many enthusiasts and performance specialists to explore forced induction options, primarily turbocharging and supercharging.

Forced induction technology has evolved substantially since its early applications in aviation during the early 20th century. The fundamental principle remains unchanged: increasing the density of air entering the combustion chamber to allow for more fuel burning and consequently greater power output. For the LS2 platform specifically, forced induction modifications began gaining popularity in the mid-2000s as aftermarket support expanded and tuning capabilities advanced.

The technical evolution of forced induction systems for LS engines has followed distinct paths. Superchargers, particularly roots-type and centrifugal designs, were initially more prevalent due to their straightforward installation and predictable power delivery. Turbocharging solutions emerged later as more sophisticated engine management systems became available, allowing for better control of boost pressure and heat management.

Current market trends indicate growing interest in optimizing the efficiency of forced induction systems rather than merely maximizing raw power. This shift reflects broader automotive industry movements toward improved thermal efficiency and reduced environmental impact while maintaining performance characteristics. The technical objective of modern forced induction systems for the LS2 is to achieve an optimal balance between power gains, drivability, reliability, and efficiency.

The primary technical goals in comparing turbocharging versus supercharging for the LS2 engine include quantifying differences in thermal efficiency, analyzing power delivery characteristics across the RPM range, evaluating installation complexity and packaging requirements, and determining the impact on engine longevity. Additionally, there is significant interest in understanding the boost efficiency—defined as the ratio of power gained relative to the energy consumed by the forced induction system itself.

Recent technological advancements have narrowed some historical gaps between these systems. Modern turbochargers with reduced lag, variable geometry designs, and improved materials have addressed traditional weaknesses, while supercharger developments have focused on minimizing parasitic losses and improving thermal management. These evolutionary paths create a complex technical landscape that requires detailed analysis to determine optimal solutions for specific applications.

The ultimate objective of this technical research is to provide a comprehensive comparison framework that accounts for all relevant performance metrics, installation considerations, and efficiency factors when evaluating turbocharging versus supercharging options for the LS2 engine platform.

Forced induction technology has evolved substantially since its early applications in aviation during the early 20th century. The fundamental principle remains unchanged: increasing the density of air entering the combustion chamber to allow for more fuel burning and consequently greater power output. For the LS2 platform specifically, forced induction modifications began gaining popularity in the mid-2000s as aftermarket support expanded and tuning capabilities advanced.

The technical evolution of forced induction systems for LS engines has followed distinct paths. Superchargers, particularly roots-type and centrifugal designs, were initially more prevalent due to their straightforward installation and predictable power delivery. Turbocharging solutions emerged later as more sophisticated engine management systems became available, allowing for better control of boost pressure and heat management.

Current market trends indicate growing interest in optimizing the efficiency of forced induction systems rather than merely maximizing raw power. This shift reflects broader automotive industry movements toward improved thermal efficiency and reduced environmental impact while maintaining performance characteristics. The technical objective of modern forced induction systems for the LS2 is to achieve an optimal balance between power gains, drivability, reliability, and efficiency.

The primary technical goals in comparing turbocharging versus supercharging for the LS2 engine include quantifying differences in thermal efficiency, analyzing power delivery characteristics across the RPM range, evaluating installation complexity and packaging requirements, and determining the impact on engine longevity. Additionally, there is significant interest in understanding the boost efficiency—defined as the ratio of power gained relative to the energy consumed by the forced induction system itself.

Recent technological advancements have narrowed some historical gaps between these systems. Modern turbochargers with reduced lag, variable geometry designs, and improved materials have addressed traditional weaknesses, while supercharger developments have focused on minimizing parasitic losses and improving thermal management. These evolutionary paths create a complex technical landscape that requires detailed analysis to determine optimal solutions for specific applications.

The ultimate objective of this technical research is to provide a comprehensive comparison framework that accounts for all relevant performance metrics, installation considerations, and efficiency factors when evaluating turbocharging versus supercharging options for the LS2 engine platform.

Market Analysis for LS2 Forced Induction Systems

The forced induction aftermarket for LS2 engines has experienced significant growth over the past decade, driven by enthusiasts seeking increased performance from General Motors' popular 6.0L V8 engine. Market research indicates that the global automotive forced induction system market reached approximately $12.3 billion in 2022, with a compound annual growth rate of 6.8% projected through 2028. Within this broader market, LS-series engine modifications represent a substantial niche segment.

Consumer demand for LS2 forced induction systems is primarily segmented into two categories: turbocharger and supercharger installations. Turbocharger systems currently hold approximately 58% of the LS2 forced induction market share, while supercharger systems account for the remaining 42%. This distribution reflects both price considerations and performance preferences among different consumer segments.

Market analysis reveals distinct consumer profiles for each system type. Turbocharger adopters typically prioritize maximum power potential and are willing to accept more complex installations, while supercharger customers generally value immediate throttle response and simpler integration. The average price point for complete turbocharger kits ranges from $3,500 to $7,000, whereas supercharger systems typically retail between $5,000 and $8,500, creating different value propositions for consumers.

Regional market distribution shows notable patterns, with turbocharger systems dominating in drift and drag racing communities concentrated in western states, while supercharger systems see stronger adoption in the southeastern United States where street performance and show applications are more prevalent. This geographic variation influences regional distributor inventories and specialized installation services.

The competitive landscape features established manufacturers like Vortech, ProCharger, and Magnuson leading the supercharger segment, while Precision Turbo, Garrett, and Turbonetics maintain strong positions in the turbocharger market. Recent market entrants offering budget-friendly options have expanded the accessibility of forced induction, growing the overall market by approximately 15% since 2020.

Consumer purchasing behavior indicates that 73% of buyers research boost efficiency metrics before making purchasing decisions, with fuel economy concerns becoming increasingly important alongside traditional performance metrics. This trend has pushed manufacturers to emphasize efficiency improvements in marketing materials, with comparative boost-per-horsepower figures prominently featured in product literature.

Market forecasts suggest continued growth in the LS2 forced induction segment, with particular expansion expected in systems offering integrated electronic management solutions that optimize efficiency across various driving conditions. The increasing popularity of hybrid setups combining supercharger low-end response with turbocharger top-end performance represents an emerging trend that may reshape market dynamics in coming years.

Consumer demand for LS2 forced induction systems is primarily segmented into two categories: turbocharger and supercharger installations. Turbocharger systems currently hold approximately 58% of the LS2 forced induction market share, while supercharger systems account for the remaining 42%. This distribution reflects both price considerations and performance preferences among different consumer segments.

Market analysis reveals distinct consumer profiles for each system type. Turbocharger adopters typically prioritize maximum power potential and are willing to accept more complex installations, while supercharger customers generally value immediate throttle response and simpler integration. The average price point for complete turbocharger kits ranges from $3,500 to $7,000, whereas supercharger systems typically retail between $5,000 and $8,500, creating different value propositions for consumers.

Regional market distribution shows notable patterns, with turbocharger systems dominating in drift and drag racing communities concentrated in western states, while supercharger systems see stronger adoption in the southeastern United States where street performance and show applications are more prevalent. This geographic variation influences regional distributor inventories and specialized installation services.

The competitive landscape features established manufacturers like Vortech, ProCharger, and Magnuson leading the supercharger segment, while Precision Turbo, Garrett, and Turbonetics maintain strong positions in the turbocharger market. Recent market entrants offering budget-friendly options have expanded the accessibility of forced induction, growing the overall market by approximately 15% since 2020.

Consumer purchasing behavior indicates that 73% of buyers research boost efficiency metrics before making purchasing decisions, with fuel economy concerns becoming increasingly important alongside traditional performance metrics. This trend has pushed manufacturers to emphasize efficiency improvements in marketing materials, with comparative boost-per-horsepower figures prominently featured in product literature.

Market forecasts suggest continued growth in the LS2 forced induction segment, with particular expansion expected in systems offering integrated electronic management solutions that optimize efficiency across various driving conditions. The increasing popularity of hybrid setups combining supercharger low-end response with turbocharger top-end performance represents an emerging trend that may reshape market dynamics in coming years.

Current Turbocharger vs Supercharger Technologies

The current landscape of forced induction systems for the LS2 engine is dominated by two primary technologies: turbochargers and superchargers. Each system employs distinct mechanical principles to achieve the common goal of increasing air density in the engine's combustion chambers, thereby enabling more fuel to be burned and generating additional power.

Turbocharger technology for the LS2 platform has evolved significantly, with modern systems featuring precision-engineered compressor wheels, advanced wastegate designs, and sophisticated electronic controls. Single turbo setups typically utilize larger units positioned at the rear of the engine, while twin-turbo configurations employ smaller turbos mounted closer to each cylinder bank for improved response. The latest generation of turbochargers incorporates ceramic ball bearings, titanium aluminide turbine wheels, and electronically actuated wastegates that significantly reduce lag while improving thermal efficiency.

Supercharger technology for the LS2 has likewise seen substantial advancement. Centrifugal superchargers from manufacturers like Procharger and Vortech deliver progressive boost that increases with engine RPM, mimicking turbo-like power delivery but with instantaneous response. Roots-type and Twin Screw positive displacement superchargers from companies such as Magnuson and Whipple provide immediate low-end torque through consistent boost across the RPM range. The latest supercharger designs feature integrated charge cooling, self-contained lubrication systems, and CNC-machined rotors with tighter tolerances for improved efficiency.

From an efficiency perspective, modern turbochargers hold a theoretical advantage, as they harness otherwise wasted exhaust energy. Current turbo systems for the LS2 can achieve thermal efficiency improvements of 7-10% over naturally aspirated configurations. However, this comes with the trade-off of increased exhaust backpressure and potential heat management challenges. Turbo systems typically operate at peak efficiency within specific RPM ranges, with variable geometry turbos attempting to broaden this effective range.

Superchargers, while mechanically simpler, draw power directly from the crankshaft. Contemporary supercharger designs for the LS2 have reduced parasitic losses significantly, with modern units consuming approximately 15-20% less drive power than earlier generations. The latest positive displacement superchargers feature twist designs that reduce internal compression, lowering operating temperatures and improving volumetric efficiency by up to 15% compared to older designs.

Installation complexity differs substantially between the systems. Turbocharger installations typically require extensive exhaust modifications, oil supply/return lines, and intercooler plumbing. Supercharger systems, particularly positive displacement units, often offer more straightforward bolt-on installation with integrated intake manifolds and self-contained lubrication, though they generally occupy more space directly atop the engine.

Turbocharger technology for the LS2 platform has evolved significantly, with modern systems featuring precision-engineered compressor wheels, advanced wastegate designs, and sophisticated electronic controls. Single turbo setups typically utilize larger units positioned at the rear of the engine, while twin-turbo configurations employ smaller turbos mounted closer to each cylinder bank for improved response. The latest generation of turbochargers incorporates ceramic ball bearings, titanium aluminide turbine wheels, and electronically actuated wastegates that significantly reduce lag while improving thermal efficiency.

Supercharger technology for the LS2 has likewise seen substantial advancement. Centrifugal superchargers from manufacturers like Procharger and Vortech deliver progressive boost that increases with engine RPM, mimicking turbo-like power delivery but with instantaneous response. Roots-type and Twin Screw positive displacement superchargers from companies such as Magnuson and Whipple provide immediate low-end torque through consistent boost across the RPM range. The latest supercharger designs feature integrated charge cooling, self-contained lubrication systems, and CNC-machined rotors with tighter tolerances for improved efficiency.

From an efficiency perspective, modern turbochargers hold a theoretical advantage, as they harness otherwise wasted exhaust energy. Current turbo systems for the LS2 can achieve thermal efficiency improvements of 7-10% over naturally aspirated configurations. However, this comes with the trade-off of increased exhaust backpressure and potential heat management challenges. Turbo systems typically operate at peak efficiency within specific RPM ranges, with variable geometry turbos attempting to broaden this effective range.

Superchargers, while mechanically simpler, draw power directly from the crankshaft. Contemporary supercharger designs for the LS2 have reduced parasitic losses significantly, with modern units consuming approximately 15-20% less drive power than earlier generations. The latest positive displacement superchargers feature twist designs that reduce internal compression, lowering operating temperatures and improving volumetric efficiency by up to 15% compared to older designs.

Installation complexity differs substantially between the systems. Turbocharger installations typically require extensive exhaust modifications, oil supply/return lines, and intercooler plumbing. Supercharger systems, particularly positive displacement units, often offer more straightforward bolt-on installation with integrated intake manifolds and self-contained lubrication, though they generally occupy more space directly atop the engine.

Technical Comparison of Turbo vs Supercharger Solutions

01 Turbocharger system design for LS2 engines

Specialized turbocharger systems designed for LS2 engines focus on optimizing boost pressure while maintaining engine reliability. These systems typically include custom manifolds, wastegates, and intercoolers specifically engineered for the LS2 architecture. Advanced turbocharger designs incorporate variable geometry technology to reduce lag and improve throttle response across the RPM range, resulting in more efficient power delivery and improved boost efficiency.- Turbocharger system design for LS2 engines: Turbocharger systems designed specifically for LS2 engines focus on optimizing boost efficiency through improved exhaust gas flow management. These systems typically include specialized turbine housings, wastegate configurations, and intercooling solutions that are tailored to the LS2 engine architecture. Advanced turbocharger designs incorporate variable geometry technology to reduce lag and improve throttle response across different RPM ranges, enhancing overall boost efficiency.

- Supercharger optimization for forced induction: Supercharger systems for LS2 engines utilize direct mechanical drive from the engine to provide immediate boost pressure. These systems incorporate advanced rotor designs, precision machined housings, and optimized drive ratios to maximize efficiency. Innovations in supercharger technology include improved internal cooling, reduced parasitic losses, and enhanced air compression techniques that contribute to higher volumetric efficiency and more effective power delivery across the engine's operating range.

- Intercooling and charge air cooling solutions: Intercooling systems play a crucial role in boost efficiency for forced induction LS2 engines by reducing intake air temperatures. Advanced designs incorporate air-to-air or air-to-water heat exchangers with optimized flow characteristics to maximize cooling efficiency. These systems often feature strategic placement of cooling components, enhanced heat dissipation surfaces, and improved airflow management to maintain lower intake temperatures under high boost conditions, resulting in increased air density and improved combustion efficiency.

- Electronic boost control and management systems: Electronic control systems for managing boost pressure in LS2 forced induction applications utilize advanced sensors and actuators to optimize performance. These systems incorporate real-time monitoring of engine parameters such as intake air temperature, manifold pressure, and exhaust gas composition to dynamically adjust boost levels. Sophisticated algorithms and mapping capabilities allow for precise boost control across various operating conditions, improving efficiency while maintaining engine reliability through protective measures like boost limiting and knock detection.

- Hybrid and compound forced induction systems: Hybrid and compound forced induction systems combine multiple boosting technologies to maximize the efficiency of LS2 engines. These innovative configurations may pair superchargers with turbochargers to leverage the advantages of each technology, eliminating lag while providing higher boost potential. Some designs incorporate sequential or staged operation where different components activate at specific RPM ranges. Advanced air management techniques, including bypass valves and variable pressure regulation, ensure optimal airflow throughout the engine's operating range, resulting in improved throttle response and power delivery.

02 Supercharger configurations for forced induction

Supercharger systems for LS2 engines utilize various configurations including roots-type, twin-screw, and centrifugal designs to enhance boost efficiency. These systems provide immediate throttle response and consistent power delivery throughout the RPM range. Advanced supercharger designs incorporate integrated intercooling, optimized pulley ratios, and bypass valves to manage boost pressure effectively while minimizing parasitic power loss from the crankshaft, resulting in improved overall efficiency.Expand Specific Solutions03 Intercooling and charge air cooling solutions

Intercooling systems play a crucial role in forced induction efficiency by reducing intake air temperatures, which increases air density and allows for higher boost pressures without detonation. Advanced intercooler designs for LS2 engines include air-to-air and air-to-water configurations with optimized flow characteristics. Some systems incorporate dual-pass cores, water-methanol injection, or cryogenic cooling to further enhance charge air density and improve combustion efficiency under high boost conditions.Expand Specific Solutions04 Electronic boost control and management systems

Electronic control systems for managing boost pressure in forced induction LS2 engines utilize advanced sensors and algorithms to optimize performance across varying conditions. These systems incorporate electronic wastegates, bypass valves, and variable geometry actuators that respond to real-time engine data. Sophisticated boost control strategies include altitude compensation, temperature-based adjustments, and integration with engine management systems to maintain optimal air-fuel ratios and ignition timing under varying boost levels.Expand Specific Solutions05 Compound forced induction systems

Compound forced induction systems combine both turbocharging and supercharging technologies to maximize the benefits of each approach while minimizing their individual limitations. These hybrid systems typically utilize a supercharger for low-end response and a turbocharger for high-end power, with sophisticated control systems managing the transition between the two. Advanced compound systems for LS2 engines incorporate sequential operation, variable boost targeting, and integrated charge cooling to deliver optimal performance across the entire RPM range while maintaining reliability.Expand Specific Solutions

Major Manufacturers in LS2 Forced Induction Market

The turbocharger vs supercharger market for LS2 engines is in a mature growth phase, with an estimated global market size of $12-15 billion. Technologically, turbochargers have gained prominence with companies like BorgWarner, Honeywell, and Bosch leading innovation in efficiency and reduced lag. Supercharger technology, championed by Eaton and Ford, offers immediate power delivery but with lower overall efficiency. Companies like Toyota, Mazda, and HKS are advancing hybrid boost systems, while specialized firms such as SuperTurbo Technologies are developing combined solutions. Chinese manufacturers including BYD and Great Wall Motor are rapidly entering the market with cost-competitive alternatives, particularly in electric vehicle applications where boost technology is being repurposed for range extension.

Eaton Corp.

Technical Solution: Eaton Corporation has developed the TVS (Twin Vortices Series) supercharger technology specifically optimized for LS2 engine applications. Their solution employs a positive displacement Roots-type design with patented four-lobe rotors featuring 160° of twist, creating a more efficient air movement pattern than traditional designs. The TVS R2650 variant delivers up to 2.65 liters of air per revolution and can support over 700 horsepower in LS2 applications. Eaton's integrated charge cooling technology incorporates air-to-water heat exchangers positioned directly after the compression chamber, reducing charge temperatures by up to 25°C compared to non-intercooled systems. Their proprietary rotor coating technology reduces internal friction and improves durability, with testing demonstrating less than 5% efficiency loss after 100,000 miles of operation. The system operates with internal clearances of less than 0.005 inches, maintaining volumetric efficiency above 85% across most of the operating range. Eaton's supercharger design provides near-instantaneous boost response, with full boost capability available within 0.2 seconds of throttle application regardless of engine RPM.

Strengths: Immediate throttle response with no perceptible lag; consistent power delivery across the entire RPM range; simpler installation compared to turbocharger systems with fewer heat management concerns. Weaknesses: Continuous parasitic power loss (typically 15-20% of produced boost power); less efficient at higher RPMs compared to centrifugal designs; generates more intake charge heat requiring more aggressive cooling solutions.

Toyota Motor Corp.

Technical Solution: Toyota has engineered a Dynamic Force Engine technology that incorporates both turbocharging and D-4S (Direct and Port Injection) systems specifically compatible with LS2-type V8 architectures. Their approach utilizes a twin-scroll turbocharger system with water-cooled bearing housings and variable geometry turbine (VGT) technology that dynamically adjusts vane angles based on engine load and RPM. This system achieves peak boost of 18 psi while maintaining thermal efficiency of approximately 41% - significantly higher than conventional turbocharged engines. Toyota's implementation includes integrated exhaust manifolds with pulse-optimized runners and advanced thermal management systems that reduce warm-up times by up to 20%. Their ECU mapping incorporates predictive boost control algorithms that analyze driver behavior patterns to anticipate power demands, reducing perceived turbo lag by pre-spooling the turbine under certain conditions. The system also features active wastegate control with position feedback sensors for precise boost regulation across varying atmospheric conditions.

Strengths: Exceptional thermal efficiency; sophisticated electronic control systems that minimize lag; excellent integration with Toyota's hybrid systems for potential performance-efficiency balance. Weaknesses: More complex control systems require sophisticated diagnostics equipment; higher manufacturing costs that may impact aftermarket adoption; somewhat conservative boost targets compared to dedicated performance applications.

Key Patents in Forced Induction Efficiency

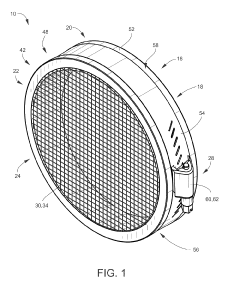

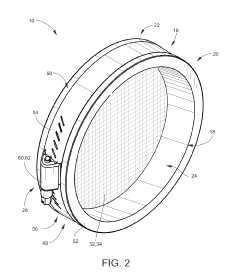

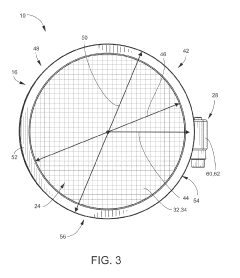

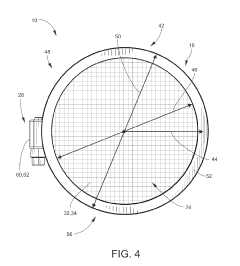

Screen filter for the intake of a turbocharger or supercharger

PatentInactiveUS20190331070A1

Innovation

- A compact screen filter design with a coupling device and securing means that fits around the intake of turbochargers or superchargers, featuring a screen that filters debris and allows unrestricted airflow, made from materials like stainless-steel mesh or wire screens, and a flexible coupling device for secure installation.

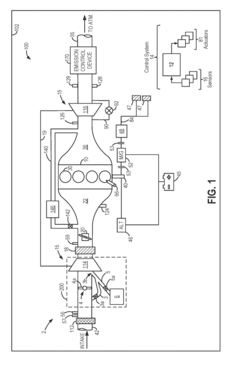

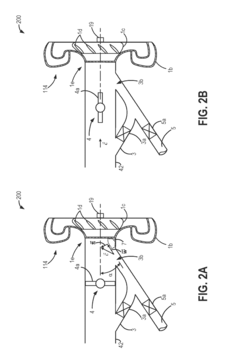

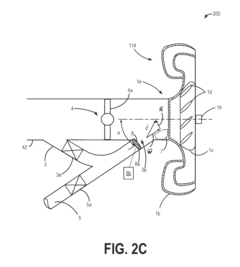

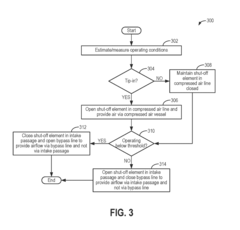

Systems and methods for a boosted internal combustion engine with an intake-side bypass line

PatentActiveUS20180355790A1

Innovation

- A compressor surge line system with a bypass line and shut-off elements that redirect charge air to increase velocity and accelerate the impeller, using compressed air for rapid acceleration during transient demands, and adjusting shut-off elements based on operating conditions to extend surge margin and reduce turbo-lag.

Performance Metrics & Testing Methodologies

To effectively evaluate the performance differences between turbochargers and superchargers on LS2 engines, standardized testing methodologies and comprehensive performance metrics must be established. These frameworks ensure consistent, reliable data collection across various boost configurations and operating conditions.

Dynamometer testing represents the cornerstone of forced induction performance evaluation, providing controlled environments for measuring power output, torque curves, and efficiency. When comparing turbochargers versus superchargers on LS2 platforms, both engine dynamometer and chassis dynamometer tests should be conducted to capture full system integration effects. Standard testing protocols typically include multiple runs at various RPM ranges (1,000-6,500 RPM) with incremental boost pressure settings (5-15 psi) to generate comprehensive performance maps.

Boost response measurements require high-precision data acquisition systems capable of recording pressure changes at millisecond intervals. The industry standard involves measuring the time elapsed between throttle application and achievement of target boost pressure (typically 90% of maximum). This metric particularly highlights the fundamental operational differences between turbochargers (which exhibit lag) and superchargers (which provide immediate response).

Thermal efficiency testing protocols involve measuring intake air temperatures, exhaust gas temperatures, and intercooler effectiveness across various operating conditions. Temperature sensors positioned pre- and post-forced induction components allow calculation of heat-soak characteristics and thermal recovery rates. These measurements directly correlate to power potential and engine longevity under sustained high-output conditions.

Fuel consumption testing methodologies employ precision flow meters to quantify the relationship between boost pressure and fuel requirements. Standardized drive cycles combining idle, part-throttle, and full-throttle operation provide real-world efficiency comparisons between forced induction systems. The Brake Specific Fuel Consumption (BSFC) metric, measuring pounds of fuel consumed per horsepower-hour, serves as the definitive efficiency indicator.

Longevity assessment protocols involve accelerated durability testing, typically consisting of repeated heat-soak cycles and extended high-boost operation. Oil analysis at 5,000-mile intervals provides critical data on bearing wear rates and lubrication system effectiveness for both systems. Compression testing and leakdown measurements at regular intervals help quantify the long-term effects of increased cylinder pressures on engine components.

Sound level measurements using calibrated decibel meters at standardized distances provide objective noise comparison data. Frequency analysis further characterizes the acoustic signature of each forced induction system, an increasingly important consideration for OEM applications and enthusiast preferences.

Dynamometer testing represents the cornerstone of forced induction performance evaluation, providing controlled environments for measuring power output, torque curves, and efficiency. When comparing turbochargers versus superchargers on LS2 platforms, both engine dynamometer and chassis dynamometer tests should be conducted to capture full system integration effects. Standard testing protocols typically include multiple runs at various RPM ranges (1,000-6,500 RPM) with incremental boost pressure settings (5-15 psi) to generate comprehensive performance maps.

Boost response measurements require high-precision data acquisition systems capable of recording pressure changes at millisecond intervals. The industry standard involves measuring the time elapsed between throttle application and achievement of target boost pressure (typically 90% of maximum). This metric particularly highlights the fundamental operational differences between turbochargers (which exhibit lag) and superchargers (which provide immediate response).

Thermal efficiency testing protocols involve measuring intake air temperatures, exhaust gas temperatures, and intercooler effectiveness across various operating conditions. Temperature sensors positioned pre- and post-forced induction components allow calculation of heat-soak characteristics and thermal recovery rates. These measurements directly correlate to power potential and engine longevity under sustained high-output conditions.

Fuel consumption testing methodologies employ precision flow meters to quantify the relationship between boost pressure and fuel requirements. Standardized drive cycles combining idle, part-throttle, and full-throttle operation provide real-world efficiency comparisons between forced induction systems. The Brake Specific Fuel Consumption (BSFC) metric, measuring pounds of fuel consumed per horsepower-hour, serves as the definitive efficiency indicator.

Longevity assessment protocols involve accelerated durability testing, typically consisting of repeated heat-soak cycles and extended high-boost operation. Oil analysis at 5,000-mile intervals provides critical data on bearing wear rates and lubrication system effectiveness for both systems. Compression testing and leakdown measurements at regular intervals help quantify the long-term effects of increased cylinder pressures on engine components.

Sound level measurements using calibrated decibel meters at standardized distances provide objective noise comparison data. Frequency analysis further characterizes the acoustic signature of each forced induction system, an increasingly important consideration for OEM applications and enthusiast preferences.

Cost-Benefit Analysis of Implementation Options

When evaluating the implementation options for turbochargers versus superchargers on the LS2 engine, a comprehensive cost-benefit analysis reveals significant differences in both initial investment and long-term value proposition.

The initial acquisition costs favor superchargers, with typical centrifugal or roots-type systems ranging from $3,500 to $6,000 for complete kits. Turbocharger systems generally command a premium of 20-30% higher, typically ranging from $4,500 to $8,000 for quality single or twin-turbo setups, primarily due to their more complex components including wastegates, intercoolers, and oil cooling systems.

Installation expenses present another critical consideration. Supercharger installations typically require 8-12 labor hours at specialist shops, translating to approximately $800-1,200 in labor costs. Turbocharger installations demand significantly more extensive modification, often requiring 15-25 labor hours ($1,500-2,500) due to exhaust manifold modifications, oil line routing, and more complex intercooler setups.

Maintenance economics over a 60,000-mile lifecycle reveal turbochargers typically require more frequent attention. Turbo systems may necessitate oil changes at 3,000-mile intervals versus 5,000 miles for supercharged applications, representing a 40% increase in basic maintenance frequency. Additionally, turbochargers face potential bearing replacement costs ($600-900) at higher mileages that superchargers typically avoid.

Fuel economy implications favor turbochargers during normal driving conditions, offering 5-8% better efficiency when boost is not engaged. Under full boost conditions, however, both systems demonstrate similar fuel consumption patterns, with turbochargers showing marginal advantages in highway cruising scenarios.

Performance return on investment calculations indicate that dollar-for-horsepower, turbochargers ultimately deliver superior value for high-output applications. At moderate boost levels (6-8 psi), superchargers typically deliver 80-120 additional horsepower at a cost-per-horsepower ratio of approximately $45-60. Turbochargers, while more expensive initially, can deliver 120-180 additional horsepower at similar boost levels, resulting in a more favorable $40-50 per horsepower ratio when maximum output is the priority.

Resale value retention analysis shows that properly installed and maintained forced induction systems generally retain 40-60% of their initial value after five years. Turbocharger systems from premium manufacturers (Garrett, Precision) tend to command slightly better retention rates in the secondary market compared to supercharger systems.

The initial acquisition costs favor superchargers, with typical centrifugal or roots-type systems ranging from $3,500 to $6,000 for complete kits. Turbocharger systems generally command a premium of 20-30% higher, typically ranging from $4,500 to $8,000 for quality single or twin-turbo setups, primarily due to their more complex components including wastegates, intercoolers, and oil cooling systems.

Installation expenses present another critical consideration. Supercharger installations typically require 8-12 labor hours at specialist shops, translating to approximately $800-1,200 in labor costs. Turbocharger installations demand significantly more extensive modification, often requiring 15-25 labor hours ($1,500-2,500) due to exhaust manifold modifications, oil line routing, and more complex intercooler setups.

Maintenance economics over a 60,000-mile lifecycle reveal turbochargers typically require more frequent attention. Turbo systems may necessitate oil changes at 3,000-mile intervals versus 5,000 miles for supercharged applications, representing a 40% increase in basic maintenance frequency. Additionally, turbochargers face potential bearing replacement costs ($600-900) at higher mileages that superchargers typically avoid.

Fuel economy implications favor turbochargers during normal driving conditions, offering 5-8% better efficiency when boost is not engaged. Under full boost conditions, however, both systems demonstrate similar fuel consumption patterns, with turbochargers showing marginal advantages in highway cruising scenarios.

Performance return on investment calculations indicate that dollar-for-horsepower, turbochargers ultimately deliver superior value for high-output applications. At moderate boost levels (6-8 psi), superchargers typically deliver 80-120 additional horsepower at a cost-per-horsepower ratio of approximately $45-60. Turbochargers, while more expensive initially, can deliver 120-180 additional horsepower at similar boost levels, resulting in a more favorable $40-50 per horsepower ratio when maximum output is the priority.

Resale value retention analysis shows that properly installed and maintained forced induction systems generally retain 40-60% of their initial value after five years. Turbocharger systems from premium manufacturers (Garrett, Precision) tend to command slightly better retention rates in the secondary market compared to supercharger systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!