Comparing Colloidal Silica vs Zirconia in Surface Treatments

SEP 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Colloidal Silica and Zirconia Surface Treatment Background

Surface treatment technologies have evolved significantly over the past decades, with colloidal silica and zirconia emerging as two prominent materials in various industrial applications. Colloidal silica, consisting of nano-sized amorphous silica particles dispersed in a liquid medium, has been utilized since the mid-20th century. Its development can be traced back to the 1940s when researchers at DuPont first synthesized stable silica sols for commercial applications.

Zirconia (zirconium dioxide) treatments, on the other hand, gained prominence in the 1980s and 1990s, particularly in ceramic engineering and advanced materials science. The stabilization of zirconia in various crystalline phases opened new possibilities for surface treatment applications beyond its traditional use in refractory materials.

Both materials have undergone significant technological advancements in synthesis methods, particle size control, and surface modification techniques. The evolution of sol-gel chemistry has been particularly influential in refining colloidal silica properties, while advances in precipitation methods and thermal treatments have enhanced zirconia's performance characteristics.

The fundamental difference between these materials lies in their chemical and physical properties. Colloidal silica offers excellent hardness (6-7 Mohs scale), chemical stability in neutral to alkaline environments, and forms strong siloxane bonds with various substrates. Zirconia, with superior hardness (8-8.5 Mohs scale), provides exceptional wear resistance and thermal stability, maintaining its properties at temperatures exceeding 1000°C.

Recent technological trends have focused on hybrid systems combining both materials to leverage their complementary properties. Nano-composite coatings incorporating both silica and zirconia particles have demonstrated enhanced performance in applications requiring both chemical resistance and mechanical durability.

The environmental impact of these technologies has also driven innovation, with water-based systems replacing organic solvent-based formulations, and lower temperature curing processes reducing energy consumption during application. These developments align with global sustainability initiatives and increasingly stringent environmental regulations.

Current research aims to enhance the functionality of these surface treatments through the incorporation of additional components such as organic polymers, functional nanoparticles, and self-healing capabilities. The integration of these materials with emerging technologies like 3D printing and digital manufacturing represents the frontier of surface treatment innovation.

The technical objectives in this field include developing treatments with improved adhesion to diverse substrates, enhanced durability under extreme conditions, and multifunctional properties such as self-cleaning, antimicrobial activity, and smart responsive behaviors.

Zirconia (zirconium dioxide) treatments, on the other hand, gained prominence in the 1980s and 1990s, particularly in ceramic engineering and advanced materials science. The stabilization of zirconia in various crystalline phases opened new possibilities for surface treatment applications beyond its traditional use in refractory materials.

Both materials have undergone significant technological advancements in synthesis methods, particle size control, and surface modification techniques. The evolution of sol-gel chemistry has been particularly influential in refining colloidal silica properties, while advances in precipitation methods and thermal treatments have enhanced zirconia's performance characteristics.

The fundamental difference between these materials lies in their chemical and physical properties. Colloidal silica offers excellent hardness (6-7 Mohs scale), chemical stability in neutral to alkaline environments, and forms strong siloxane bonds with various substrates. Zirconia, with superior hardness (8-8.5 Mohs scale), provides exceptional wear resistance and thermal stability, maintaining its properties at temperatures exceeding 1000°C.

Recent technological trends have focused on hybrid systems combining both materials to leverage their complementary properties. Nano-composite coatings incorporating both silica and zirconia particles have demonstrated enhanced performance in applications requiring both chemical resistance and mechanical durability.

The environmental impact of these technologies has also driven innovation, with water-based systems replacing organic solvent-based formulations, and lower temperature curing processes reducing energy consumption during application. These developments align with global sustainability initiatives and increasingly stringent environmental regulations.

Current research aims to enhance the functionality of these surface treatments through the incorporation of additional components such as organic polymers, functional nanoparticles, and self-healing capabilities. The integration of these materials with emerging technologies like 3D printing and digital manufacturing represents the frontier of surface treatment innovation.

The technical objectives in this field include developing treatments with improved adhesion to diverse substrates, enhanced durability under extreme conditions, and multifunctional properties such as self-cleaning, antimicrobial activity, and smart responsive behaviors.

Market Analysis for Advanced Surface Treatment Materials

The global market for advanced surface treatment materials has witnessed significant growth in recent years, driven by increasing demand across various industries including automotive, electronics, construction, and healthcare. Within this market, colloidal silica and zirconia have emerged as two prominent materials with distinctive properties and applications.

The advanced surface treatment materials market was valued at approximately $12.3 billion in 2022 and is projected to reach $18.7 billion by 2028, growing at a CAGR of 7.2%. This growth is primarily attributed to the rising demand for high-performance coatings and surface treatments in industrial applications, particularly in developed regions like North America and Europe, with rapidly expanding markets in Asia-Pacific.

Colloidal silica currently holds a dominant position in the market with approximately 35% market share in the advanced surface treatment segment. Its widespread adoption is due to its versatility, cost-effectiveness, and established manufacturing processes. The colloidal silica market for surface treatments specifically was valued at $3.2 billion in 2022, with projections indicating growth to $4.8 billion by 2028.

Zirconia, while representing a smaller segment at present (approximately 18% of the advanced surface treatment materials market), is experiencing faster growth with a CAGR of 9.5%. The zirconia surface treatment market was valued at $1.7 billion in 2022 and is expected to reach $2.9 billion by 2028, driven by its superior mechanical properties and increasing applications in high-performance sectors.

Regional analysis reveals that Asia-Pacific dominates the market for both materials, accounting for 42% of global consumption, followed by North America (28%) and Europe (22%). China and Japan are the largest consumers in the Asia-Pacific region, while the United States leads in North America. The fastest growth is anticipated in emerging economies such as India, Brazil, and Southeast Asian countries, where rapid industrialization and infrastructure development are creating substantial demand.

End-user industry analysis shows that automotive and transportation sectors consume approximately 30% of these advanced surface treatment materials, followed by electronics (25%), construction (20%), and healthcare (15%). The remaining 10% is distributed across various other industries including aerospace, marine, and general manufacturing.

Price trends indicate that while zirconia-based surface treatments command a premium price (typically 30-40% higher than colloidal silica alternatives), the performance benefits often justify the additional cost in high-specification applications. Market forecasts suggest this price differential will narrow to 20-25% by 2027 as zirconia production technologies improve and economies of scale are realized.

The advanced surface treatment materials market was valued at approximately $12.3 billion in 2022 and is projected to reach $18.7 billion by 2028, growing at a CAGR of 7.2%. This growth is primarily attributed to the rising demand for high-performance coatings and surface treatments in industrial applications, particularly in developed regions like North America and Europe, with rapidly expanding markets in Asia-Pacific.

Colloidal silica currently holds a dominant position in the market with approximately 35% market share in the advanced surface treatment segment. Its widespread adoption is due to its versatility, cost-effectiveness, and established manufacturing processes. The colloidal silica market for surface treatments specifically was valued at $3.2 billion in 2022, with projections indicating growth to $4.8 billion by 2028.

Zirconia, while representing a smaller segment at present (approximately 18% of the advanced surface treatment materials market), is experiencing faster growth with a CAGR of 9.5%. The zirconia surface treatment market was valued at $1.7 billion in 2022 and is expected to reach $2.9 billion by 2028, driven by its superior mechanical properties and increasing applications in high-performance sectors.

Regional analysis reveals that Asia-Pacific dominates the market for both materials, accounting for 42% of global consumption, followed by North America (28%) and Europe (22%). China and Japan are the largest consumers in the Asia-Pacific region, while the United States leads in North America. The fastest growth is anticipated in emerging economies such as India, Brazil, and Southeast Asian countries, where rapid industrialization and infrastructure development are creating substantial demand.

End-user industry analysis shows that automotive and transportation sectors consume approximately 30% of these advanced surface treatment materials, followed by electronics (25%), construction (20%), and healthcare (15%). The remaining 10% is distributed across various other industries including aerospace, marine, and general manufacturing.

Price trends indicate that while zirconia-based surface treatments command a premium price (typically 30-40% higher than colloidal silica alternatives), the performance benefits often justify the additional cost in high-specification applications. Market forecasts suggest this price differential will narrow to 20-25% by 2027 as zirconia production technologies improve and economies of scale are realized.

Technical Challenges in Colloidal Silica and Zirconia Applications

Despite significant advancements in surface treatment technologies, both colloidal silica and zirconia applications face substantial technical challenges that limit their broader industrial adoption. The primary challenge with colloidal silica lies in its stability control across varying pH environments. When exposed to extreme pH conditions, silica particles tend to agglomerate or dissolve, significantly reducing their effectiveness in surface treatments. This instability necessitates precise formulation and application protocols, increasing complexity in manufacturing processes.

Particle size distribution represents another critical challenge for both materials. Colloidal silica typically exhibits a broader size distribution, making uniform surface coverage difficult to achieve. Zirconia, while offering better size uniformity, presents challenges in achieving nano-scale distributions without specialized processing equipment. The inability to maintain consistent particle sizes directly impacts coating quality, adhesion properties, and overall performance predictability.

Adhesion mechanisms differ substantially between these materials, presenting unique technical hurdles. Colloidal silica forms chemical bonds through silanol groups, but these bonds are susceptible to hydrolysis in humid environments. Zirconia, conversely, relies more on mechanical interlocking and requires surface activation treatments to achieve optimal adhesion. This fundamental difference necessitates entirely different application methodologies and surface preparation techniques.

Dispersion stability represents a significant challenge, particularly for zirconia. Without proper surface modification or dispersant addition, zirconia particles rapidly settle or flocculate in liquid media. Colloidal silica offers better inherent stability but remains sensitive to electrolyte concentration. Maintaining long-term dispersion stability during storage and application continues to challenge formulators and end-users alike.

Processing compatibility issues arise when integrating these materials into existing manufacturing lines. Colloidal silica's water-based nature limits compatibility with hydrophobic substrates and solvent-based systems. Zirconia, typically requiring higher processing temperatures, may not be suitable for heat-sensitive substrates. Additionally, both materials can introduce rheological complexities that disrupt established coating application parameters.

Environmental and health considerations present growing challenges. While colloidal silica is generally considered environmentally benign, concerns about respirable crystalline silica persist. Zirconia nanoparticles, though less studied toxicologically, raise questions regarding potential bioaccumulation. Regulatory frameworks increasingly demand comprehensive safety data, creating barriers to rapid commercialization and deployment of new formulations.

Cost-effectiveness remains a significant hurdle, particularly for zirconia-based treatments. The raw material costs, coupled with complex processing requirements, often position zirconia solutions at premium price points that limit market penetration. Colloidal silica offers better economics but frequently requires higher application volumes to achieve comparable performance metrics.

Particle size distribution represents another critical challenge for both materials. Colloidal silica typically exhibits a broader size distribution, making uniform surface coverage difficult to achieve. Zirconia, while offering better size uniformity, presents challenges in achieving nano-scale distributions without specialized processing equipment. The inability to maintain consistent particle sizes directly impacts coating quality, adhesion properties, and overall performance predictability.

Adhesion mechanisms differ substantially between these materials, presenting unique technical hurdles. Colloidal silica forms chemical bonds through silanol groups, but these bonds are susceptible to hydrolysis in humid environments. Zirconia, conversely, relies more on mechanical interlocking and requires surface activation treatments to achieve optimal adhesion. This fundamental difference necessitates entirely different application methodologies and surface preparation techniques.

Dispersion stability represents a significant challenge, particularly for zirconia. Without proper surface modification or dispersant addition, zirconia particles rapidly settle or flocculate in liquid media. Colloidal silica offers better inherent stability but remains sensitive to electrolyte concentration. Maintaining long-term dispersion stability during storage and application continues to challenge formulators and end-users alike.

Processing compatibility issues arise when integrating these materials into existing manufacturing lines. Colloidal silica's water-based nature limits compatibility with hydrophobic substrates and solvent-based systems. Zirconia, typically requiring higher processing temperatures, may not be suitable for heat-sensitive substrates. Additionally, both materials can introduce rheological complexities that disrupt established coating application parameters.

Environmental and health considerations present growing challenges. While colloidal silica is generally considered environmentally benign, concerns about respirable crystalline silica persist. Zirconia nanoparticles, though less studied toxicologically, raise questions regarding potential bioaccumulation. Regulatory frameworks increasingly demand comprehensive safety data, creating barriers to rapid commercialization and deployment of new formulations.

Cost-effectiveness remains a significant hurdle, particularly for zirconia-based treatments. The raw material costs, coupled with complex processing requirements, often position zirconia solutions at premium price points that limit market penetration. Colloidal silica offers better economics but frequently requires higher application volumes to achieve comparable performance metrics.

Current Surface Treatment Solutions Comparison

01 Surface treatment of colloidal silica with zirconia for improved durability

Colloidal silica particles can be surface-treated with zirconia to enhance their durability and stability. This treatment creates a protective layer around the silica particles, preventing aggregation and improving their performance in various applications. The zirconia coating provides resistance against harsh environmental conditions and extends the service life of the treated materials.- Colloidal silica and zirconia for surface treatment of materials: Colloidal silica and zirconia can be effectively used for surface treatment of various materials to enhance their properties. The treatment involves applying colloidal particles to surfaces, which can improve hardness, scratch resistance, and durability. This approach is particularly useful for treating glass, ceramics, and metal surfaces, providing a protective layer that enhances the material's performance and longevity.

- Surface modification techniques using colloidal silica-zirconia composites: Composite materials combining colloidal silica and zirconia offer enhanced surface treatment effectiveness. These composites can be applied through various techniques including sol-gel processes, spray coating, and dip coating. The resulting surface modifications exhibit improved mechanical properties, thermal stability, and chemical resistance compared to treatments using single components. The synergistic effect of silica and zirconia provides superior protection against wear and environmental degradation.

- Anti-corrosion and protective coatings with colloidal silica and zirconia: Colloidal silica and zirconia formulations serve as effective anti-corrosion and protective coatings for various substrates. These treatments create a barrier that prevents moisture, chemicals, and environmental contaminants from damaging the underlying material. The coatings demonstrate excellent adhesion properties and can significantly extend the service life of treated surfaces. Applications include protective treatments for metals, concrete structures, and industrial equipment exposed to harsh conditions.

- Optical and electronic applications of silica-zirconia surface treatments: Surface treatments using colloidal silica and zirconia have proven effective for optical and electronic applications. These treatments can modify surface properties to enhance light transmission, reduce reflection, or create specific optical characteristics. In electronic applications, the treatments provide insulation, improve conductivity pathways, or protect sensitive components. The precise control of particle size and distribution allows for customization of surface properties to meet specific optical or electronic requirements.

- Manufacturing processes for colloidal silica and zirconia surface treatments: Various manufacturing processes have been developed to optimize the effectiveness of colloidal silica and zirconia surface treatments. These include controlled synthesis methods for producing particles with specific sizes and morphologies, formulation techniques to ensure stable suspensions, and application processes that ensure uniform coverage and adhesion. Advanced processing methods such as hydrothermal synthesis, precipitation techniques, and surface functionalization can further enhance the performance of these treatments for specific applications.

02 Enhanced mechanical properties through silica-zirconia composite coatings

Surface treatments combining colloidal silica and zirconia can significantly improve the mechanical properties of substrates. These composite coatings provide enhanced hardness, scratch resistance, and abrasion resistance. The synergistic effect of silica and zirconia creates a robust surface layer that can withstand mechanical stress and wear, making it suitable for applications requiring high durability.Expand Specific Solutions03 Thermal stability improvements through silica-zirconia treatments

Surface treatments using colloidal silica and zirconia can enhance the thermal stability of materials. The combination creates a thermally resistant barrier that can withstand high temperatures without degradation. This treatment is particularly effective for materials exposed to thermal cycling or extreme temperature conditions, preventing cracking, warping, or other forms of thermal damage.Expand Specific Solutions04 Chemical resistance enhancement via silica-zirconia surface modification

Treating surfaces with colloidal silica and zirconia provides excellent chemical resistance against acids, bases, and solvents. The treatment creates a protective barrier that prevents chemical attack and corrosion of the underlying substrate. This enhanced chemical resistance makes the treated materials suitable for applications in aggressive chemical environments where untreated materials would rapidly degrade.Expand Specific Solutions05 Optical property improvements through silica-zirconia coatings

Surface treatments combining colloidal silica and zirconia can enhance the optical properties of materials. These treatments can provide anti-reflective characteristics, improved transparency, and controlled refractive indices. The thin, uniform coating created by this treatment allows for precise manipulation of how light interacts with the surface, making it valuable for optical components, displays, and solar applications.Expand Specific Solutions

Key Industry Players in Colloidal Materials Manufacturing

The colloidal silica vs zirconia surface treatment market is currently in a growth phase, with increasing applications across automotive, electronics, and construction industries. The global market size for advanced surface treatments is estimated at $8-10 billion annually, expanding at 6-8% CAGR. Technologically, colloidal silica has reached maturity with established players like W.R. Grace, Evonik Operations, and Nippon Paint leading commercial applications, while zirconia treatments represent a more specialized segment where companies like Kyocera, Resonac Holdings, and Sumitomo Rubber are developing innovative applications. PPG Industries and Sherwin-Williams dominate broader industrial coatings, while research institutions like HRL Laboratories and Alfred University are advancing next-generation hybrid treatments combining both materials for enhanced performance characteristics.

Nippon Paint Surf Chemicals Co. Ltd.

Technical Solution: Nippon Paint Surf Chemicals has developed comprehensive surface treatment technologies comparing colloidal silica and zirconia for industrial applications. Their colloidal silica treatments utilize nano-sized silica particles (typically 10-50nm) dispersed in water-based systems, creating environmentally friendly coatings with excellent adhesion and weatherability. These treatments form dense siloxane networks through controlled sol-gel processes, providing effective protection against UV degradation and chemical attack. For zirconia-based treatments, Nippon employs stabilized zirconium oxide nanoparticles that deliver superior hardness (8.5 Mohs) and exceptional thermal stability up to 2,400°C. Their proprietary SURFCOAT™ technology combines both materials in optimized ratios, with silica providing matrix reinforcement and adhesion promotion while zirconia particles enhance scratch resistance and durability. Nippon's treatments feature controlled porosity structures that balance mechanical properties with functional performance such as anti-fingerprint capabilities and easy-clean surfaces. Their solutions are widely implemented in automotive, electronics, and architectural applications throughout Asia.

Strengths: Nippon's technologies offer excellent balance between performance and cost-effectiveness, with particularly strong weathering resistance in harsh environments. Their water-based formulations provide environmental advantages and workplace safety benefits. Their treatments demonstrate superior adhesion to difficult substrates like polypropylene without extensive pretreatment. Weaknesses: Their silica-based treatments may show lower chemical resistance against strong alkaline solutions compared to zirconia alternatives. Some formulations require relatively long curing times (>30 minutes at elevated temperatures) which can impact production efficiency.

PPG Industries Ohio, Inc.

Technical Solution: PPG Industries has developed advanced surface treatment technologies comparing colloidal silica and zirconia. Their approach utilizes nano-sized colloidal silica particles (typically 10-100nm) dispersed in water or organic solvents to create highly durable coatings with excellent scratch resistance. These silica-based treatments form strong covalent bonds with substrates while maintaining optical clarity. In contrast, their zirconia-based treatments leverage zirconium oxide's superior hardness (8.5 Mohs vs silica's 7) to provide enhanced abrasion resistance and thermal stability. PPG has pioneered hybrid systems combining both materials, where silica provides matrix reinforcement while zirconia particles deliver exceptional hardness. Their proprietary sol-gel processes allow precise control of particle size distribution and surface functionalization, enabling customized solutions for automotive, aerospace, and architectural applications. Recent innovations include self-healing capabilities through reversible hydrogen bonding networks within the silica matrix.

Strengths: PPG's technologies offer exceptional versatility across multiple industries, with silica treatments providing excellent transparency and UV resistance while zirconia delivers superior hardness and chemical resistance. Their hybrid systems effectively balance cost and performance. Weaknesses: Silica treatments may exhibit lower chemical resistance in highly alkaline environments compared to zirconia, while zirconia-based systems typically have higher raw material costs and can introduce optical haze in thick applications.

Technical Analysis of Silica vs Zirconia Properties

Colloidal silica and method for producing same

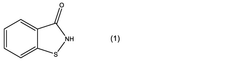

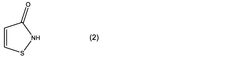

PatentWO2024242096A1

Innovation

- The use of 1,2-benzisothiazolin-3-one and isothiazolin-3-one as dispersants, combined with surface treatment of silica particles using trifunctional silane compounds, to create colloidal silica with low viscosity even at high concentrations and stable over long-term storage.

Method of preparing agglomerated composite materials

PatentInactiveUS20080190037A1

Innovation

- A method involving the addition of an aluminum phosphate agglomerating agent to an aqueous dispersion of metal oxide nanoparticles, followed by pH adjustment to 3.5 to 6.5, allowing for the formation of particle agglomerates with controlled size and porosity, suitable for applications like ink receptive coatings, polishing abrasives, and catalysis supports.

Environmental Impact Assessment of Colloidal Materials

The environmental impact of colloidal materials, particularly silica and zirconia, represents a critical consideration in surface treatment applications. Life cycle assessments reveal that colloidal silica generally demonstrates a lower environmental footprint compared to zirconia suspensions. This advantage stems primarily from silica's production process, which typically requires less energy and generates fewer greenhouse gas emissions. Studies indicate that silica production emits approximately 30-40% less CO2 equivalent per kilogram of material compared to zirconia manufacturing.

Water consumption patterns differ significantly between these materials. Colloidal silica processing typically requires 2.5-3.5 cubic meters of water per ton of product, while zirconia may demand 4-6 cubic meters for equivalent production volumes. However, silica production often generates more wastewater containing suspended particles that require additional treatment before discharge, potentially offsetting some of its environmental advantages.

Regarding resource depletion, zirconia presents greater concerns due to the limited global availability of zirconium minerals. Silica, derived primarily from abundant quartz sources, demonstrates superior sustainability from a raw material perspective. This distinction becomes increasingly important as industries face growing pressure to reduce dependence on scarce resources.

Toxicological profiles of these materials reveal important distinctions. While neither material presents severe acute toxicity concerns, nano-sized colloidal particles from both materials warrant careful handling. Silica nanoparticles have been associated with respiratory irritation upon prolonged exposure, whereas zirconia nanoparticles demonstrate lower pulmonary toxicity but potentially greater persistence in environmental systems.

Waste management considerations favor colloidal silica, which can often be repurposed in construction materials or soil amendments. Zirconia waste typically requires specialized disposal protocols due to its chemical stability and potential for long-term environmental persistence. Recent innovations in recovery systems have improved the recyclability of both materials, though silica maintains an advantage in terms of integration into circular economy frameworks.

Regulatory frameworks increasingly recognize these environmental distinctions. The European Chemical Agency has established more stringent handling requirements for zirconia-based treatments, while several certification systems award additional sustainability points to silica-based alternatives. This regulatory landscape will likely continue evolving as more comprehensive environmental impact data becomes available through ongoing research initiatives.

Water consumption patterns differ significantly between these materials. Colloidal silica processing typically requires 2.5-3.5 cubic meters of water per ton of product, while zirconia may demand 4-6 cubic meters for equivalent production volumes. However, silica production often generates more wastewater containing suspended particles that require additional treatment before discharge, potentially offsetting some of its environmental advantages.

Regarding resource depletion, zirconia presents greater concerns due to the limited global availability of zirconium minerals. Silica, derived primarily from abundant quartz sources, demonstrates superior sustainability from a raw material perspective. This distinction becomes increasingly important as industries face growing pressure to reduce dependence on scarce resources.

Toxicological profiles of these materials reveal important distinctions. While neither material presents severe acute toxicity concerns, nano-sized colloidal particles from both materials warrant careful handling. Silica nanoparticles have been associated with respiratory irritation upon prolonged exposure, whereas zirconia nanoparticles demonstrate lower pulmonary toxicity but potentially greater persistence in environmental systems.

Waste management considerations favor colloidal silica, which can often be repurposed in construction materials or soil amendments. Zirconia waste typically requires specialized disposal protocols due to its chemical stability and potential for long-term environmental persistence. Recent innovations in recovery systems have improved the recyclability of both materials, though silica maintains an advantage in terms of integration into circular economy frameworks.

Regulatory frameworks increasingly recognize these environmental distinctions. The European Chemical Agency has established more stringent handling requirements for zirconia-based treatments, while several certification systems award additional sustainability points to silica-based alternatives. This regulatory landscape will likely continue evolving as more comprehensive environmental impact data becomes available through ongoing research initiatives.

Cost-Benefit Analysis of Silica vs Zirconia Implementations

When evaluating the economic feasibility of implementing colloidal silica versus zirconia in surface treatments, initial acquisition costs represent a significant factor. Colloidal silica typically presents a lower upfront investment, with market prices ranging from $2-5 per kilogram for industrial-grade materials, while zirconia compounds generally command $8-15 per kilogram. This substantial price differential can significantly impact project budgets, particularly for large-scale applications.

Beyond raw material costs, processing requirements introduce additional economic considerations. Colloidal silica applications generally require less specialized equipment and can often be integrated into existing production lines with minimal modifications. Conversely, zirconia implementations frequently necessitate more sophisticated application systems and potentially higher-temperature processing environments, translating to increased capital expenditure and energy consumption.

Durability metrics reveal important long-term economic implications. While colloidal silica treatments may require more frequent reapplication in high-wear environments, zirconia coatings demonstrate superior longevity under extreme conditions. Industry case studies indicate that zirconia-treated surfaces in high-temperature industrial applications can maintain integrity 2-3 times longer than silica alternatives, potentially offsetting higher initial costs through extended maintenance intervals.

Environmental compliance costs also factor into the comprehensive economic assessment. Silica processing generally produces fewer hazardous byproducts and requires less intensive waste management protocols. Regulatory compliance for silica typically involves standard dust control measures, whereas zirconia processing may trigger additional environmental monitoring requirements in certain jurisdictions, potentially adding 5-10% to operational costs.

Labor efficiency presents another critical cost variable. Silica applications generally require less specialized training and can be completed more rapidly, reducing labor costs by approximately 15-20% compared to zirconia implementations. However, this advantage may be counterbalanced by the increased frequency of maintenance interventions required for silica-treated surfaces in demanding environments.

Return on investment timelines differ significantly between these technologies. Analysis of implementation data across various industries indicates that silica treatments typically achieve ROI within 6-18 months, depending on application specifics. Zirconia implementations, while requiring larger initial investments, demonstrate superior long-term value in high-stress applications, with ROI typically realized within 18-36 months but delivering substantially longer service life and reduced lifetime maintenance costs.

Beyond raw material costs, processing requirements introduce additional economic considerations. Colloidal silica applications generally require less specialized equipment and can often be integrated into existing production lines with minimal modifications. Conversely, zirconia implementations frequently necessitate more sophisticated application systems and potentially higher-temperature processing environments, translating to increased capital expenditure and energy consumption.

Durability metrics reveal important long-term economic implications. While colloidal silica treatments may require more frequent reapplication in high-wear environments, zirconia coatings demonstrate superior longevity under extreme conditions. Industry case studies indicate that zirconia-treated surfaces in high-temperature industrial applications can maintain integrity 2-3 times longer than silica alternatives, potentially offsetting higher initial costs through extended maintenance intervals.

Environmental compliance costs also factor into the comprehensive economic assessment. Silica processing generally produces fewer hazardous byproducts and requires less intensive waste management protocols. Regulatory compliance for silica typically involves standard dust control measures, whereas zirconia processing may trigger additional environmental monitoring requirements in certain jurisdictions, potentially adding 5-10% to operational costs.

Labor efficiency presents another critical cost variable. Silica applications generally require less specialized training and can be completed more rapidly, reducing labor costs by approximately 15-20% compared to zirconia implementations. However, this advantage may be counterbalanced by the increased frequency of maintenance interventions required for silica-treated surfaces in demanding environments.

Return on investment timelines differ significantly between these technologies. Analysis of implementation data across various industries indicates that silica treatments typically achieve ROI within 6-18 months, depending on application specifics. Zirconia implementations, while requiring larger initial investments, demonstrate superior long-term value in high-stress applications, with ROI typically realized within 18-36 months but delivering substantially longer service life and reduced lifetime maintenance costs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!