Comparing Lithium Bromide and Other Additives in Absorption

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Absorption Technology Background and Objectives

Absorption refrigeration technology has evolved significantly since its inception in the 1850s when Ferdinand Carré first developed an ammonia-water absorption system. This technology operates on the principle of using heat energy rather than mechanical energy to drive the refrigeration cycle, making it particularly valuable in applications where waste heat is available or electricity is limited. The fundamental process involves a refrigerant-absorbent pair, where the refrigerant evaporates at low pressure to create cooling, and is subsequently absorbed, pumped to high pressure, and regenerated using heat.

Lithium bromide (LiBr) emerged as a dominant working fluid in absorption systems during the mid-20th century, particularly for air conditioning applications. Its popularity stems from its excellent absorption properties when paired with water as the refrigerant, high thermal stability, and relatively low toxicity compared to alternatives. The LiBr-water system typically achieves a coefficient of performance (COP) ranging from 0.7 to 1.2 for single-effect systems, with higher values possible in multi-effect configurations.

Despite its widespread adoption, LiBr systems face several challenges, including crystallization risks at high concentrations, corrosion issues with metal components, and limited operating temperature ranges. These limitations have driven continuous research into alternative additives and working pairs. Competing technologies include ammonia-water systems, which offer lower freezing points suitable for refrigeration applications, and emerging alternatives such as ionic liquids, salt-organic solvent pairs, and metal-organic frameworks (MOFs).

The primary objectives of current research in absorption technology focus on enhancing system efficiency, expanding operational temperature ranges, reducing corrosion, and minimizing environmental impact. Specifically for LiBr and alternative additives, research aims to improve the heat and mass transfer characteristics, prevent crystallization through effective additives, and develop corrosion inhibitors that extend system lifespan without compromising performance.

Recent technological trends indicate growing interest in multi-effect and triple-effect systems that can achieve significantly higher COPs, as well as hybrid systems that combine absorption with conventional vapor compression or other technologies. Additionally, there is increasing focus on developing environmentally friendly working pairs with zero ozone depletion potential and minimal global warming impact, aligning with global sustainability goals.

The evolution of absorption technology is now being accelerated by computational fluid dynamics modeling, advanced material science, and nanotechnology, which collectively enable more precise design and optimization of absorption systems. These technological advances are expected to expand the application scope of absorption systems beyond traditional HVAC to include industrial process cooling, food preservation in remote areas, and integration with renewable energy sources.

Lithium bromide (LiBr) emerged as a dominant working fluid in absorption systems during the mid-20th century, particularly for air conditioning applications. Its popularity stems from its excellent absorption properties when paired with water as the refrigerant, high thermal stability, and relatively low toxicity compared to alternatives. The LiBr-water system typically achieves a coefficient of performance (COP) ranging from 0.7 to 1.2 for single-effect systems, with higher values possible in multi-effect configurations.

Despite its widespread adoption, LiBr systems face several challenges, including crystallization risks at high concentrations, corrosion issues with metal components, and limited operating temperature ranges. These limitations have driven continuous research into alternative additives and working pairs. Competing technologies include ammonia-water systems, which offer lower freezing points suitable for refrigeration applications, and emerging alternatives such as ionic liquids, salt-organic solvent pairs, and metal-organic frameworks (MOFs).

The primary objectives of current research in absorption technology focus on enhancing system efficiency, expanding operational temperature ranges, reducing corrosion, and minimizing environmental impact. Specifically for LiBr and alternative additives, research aims to improve the heat and mass transfer characteristics, prevent crystallization through effective additives, and develop corrosion inhibitors that extend system lifespan without compromising performance.

Recent technological trends indicate growing interest in multi-effect and triple-effect systems that can achieve significantly higher COPs, as well as hybrid systems that combine absorption with conventional vapor compression or other technologies. Additionally, there is increasing focus on developing environmentally friendly working pairs with zero ozone depletion potential and minimal global warming impact, aligning with global sustainability goals.

The evolution of absorption technology is now being accelerated by computational fluid dynamics modeling, advanced material science, and nanotechnology, which collectively enable more precise design and optimization of absorption systems. These technological advances are expected to expand the application scope of absorption systems beyond traditional HVAC to include industrial process cooling, food preservation in remote areas, and integration with renewable energy sources.

Market Analysis of Absorption Refrigeration Systems

The global absorption refrigeration systems market has been experiencing steady growth, valued at approximately 1.2 billion USD in 2022 with projections to reach 1.8 billion USD by 2028, representing a compound annual growth rate of 6.7%. This growth is primarily driven by increasing demand for energy-efficient cooling solutions across various sectors including commercial buildings, industrial processes, and residential applications.

The market segmentation reveals distinct preferences across regions. Asia-Pacific currently dominates with nearly 40% market share, led by China and India where rapid industrialization and commercial construction create substantial demand. North America and Europe follow with approximately 25% and 20% market shares respectively, where the focus is increasingly on sustainable cooling technologies to meet stringent environmental regulations.

When examining absorption refrigeration systems by working fluid, lithium bromide-water systems hold the largest market segment at approximately 65%, particularly in commercial air conditioning and industrial process cooling applications. Ammonia-water systems account for about 30% of the market, primarily in industrial refrigeration where lower temperatures are required. Other working pairs and experimental additives constitute the remaining 5%.

The commercial sector represents the largest end-user segment (45%), followed by industrial applications (35%) and residential systems (15%). Healthcare facilities, hotels, and large office complexes are key commercial customers, while food processing, chemical manufacturing, and pharmaceutical production drive industrial demand.

Market dynamics are significantly influenced by energy costs and environmental regulations. Regions with high electricity costs show stronger adoption rates for absorption systems despite their higher initial investment compared to conventional vapor compression systems. The global push toward reducing greenhouse gas emissions has created favorable conditions for absorption refrigeration, as these systems can utilize waste heat and renewable thermal energy sources.

Customer purchasing decisions are increasingly driven by total cost of ownership rather than initial capital expenditure. The ability of absorption systems to utilize low-grade thermal energy that would otherwise be wasted presents a compelling value proposition, particularly in combined heat and power installations where system integration can achieve overall efficiencies exceeding 80%.

Recent market trends indicate growing interest in small and medium-capacity absorption chillers, expanding beyond the traditional large-scale applications. This trend is supported by technological advancements that have improved system efficiency and reduced physical footprint, making absorption refrigeration viable for a broader range of applications.

The market segmentation reveals distinct preferences across regions. Asia-Pacific currently dominates with nearly 40% market share, led by China and India where rapid industrialization and commercial construction create substantial demand. North America and Europe follow with approximately 25% and 20% market shares respectively, where the focus is increasingly on sustainable cooling technologies to meet stringent environmental regulations.

When examining absorption refrigeration systems by working fluid, lithium bromide-water systems hold the largest market segment at approximately 65%, particularly in commercial air conditioning and industrial process cooling applications. Ammonia-water systems account for about 30% of the market, primarily in industrial refrigeration where lower temperatures are required. Other working pairs and experimental additives constitute the remaining 5%.

The commercial sector represents the largest end-user segment (45%), followed by industrial applications (35%) and residential systems (15%). Healthcare facilities, hotels, and large office complexes are key commercial customers, while food processing, chemical manufacturing, and pharmaceutical production drive industrial demand.

Market dynamics are significantly influenced by energy costs and environmental regulations. Regions with high electricity costs show stronger adoption rates for absorption systems despite their higher initial investment compared to conventional vapor compression systems. The global push toward reducing greenhouse gas emissions has created favorable conditions for absorption refrigeration, as these systems can utilize waste heat and renewable thermal energy sources.

Customer purchasing decisions are increasingly driven by total cost of ownership rather than initial capital expenditure. The ability of absorption systems to utilize low-grade thermal energy that would otherwise be wasted presents a compelling value proposition, particularly in combined heat and power installations where system integration can achieve overall efficiencies exceeding 80%.

Recent market trends indicate growing interest in small and medium-capacity absorption chillers, expanding beyond the traditional large-scale applications. This trend is supported by technological advancements that have improved system efficiency and reduced physical footprint, making absorption refrigeration viable for a broader range of applications.

Current State and Challenges of Absorption Additives

The absorption refrigeration and heat pump industry has witnessed significant technological advancements over the past decades, with lithium bromide (LiBr) emerging as the dominant working fluid in commercial applications. Currently, LiBr-water solutions represent approximately 70% of the global absorption system market due to their excellent thermal properties and relatively low cost compared to alternatives.

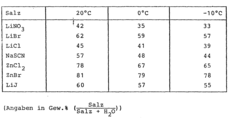

Despite its widespread adoption, LiBr systems face several critical challenges that limit their broader application. Crystallization risk remains a primary concern, occurring when the solution concentration exceeds solubility limits during operation, leading to system blockages and efficiency losses. This phenomenon typically manifests at temperatures below 5°C, restricting LiBr systems' application in colder climates.

Corrosion presents another significant challenge, as LiBr solutions are highly corrosive to many common metals used in heat exchange equipment. Industry data indicates that corrosion-related maintenance accounts for approximately 25-30% of total system lifetime costs. Current mitigation strategies include corrosion inhibitors like lithium molybdate and lithium nitrate, though these additives can impact system performance and add complexity.

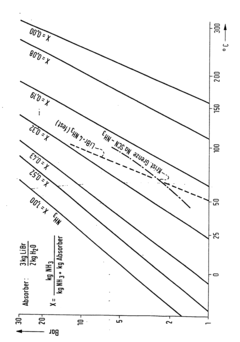

Alternative absorption pairs have emerged to address LiBr limitations. Ammonia-water systems offer superior low-temperature performance without crystallization risks, enabling operation at temperatures as low as -60°C. However, they require higher generator temperatures and present toxicity concerns. Water-salt systems utilizing calcium chloride or lithium chloride show promise for specific applications but generally demonstrate lower coefficients of performance (COP) than traditional LiBr systems.

Recent innovations include ionic liquids as absorption working fluids, with compounds like [EMIM][BF4] and [BMIM][BF4] showing promising thermodynamic properties. These materials offer negligible vapor pressure, high thermal stability, and customizable molecular structures. However, their high viscosity and production costs (5-20 times that of conventional working fluids) currently limit commercial viability.

Nanofluids represent another frontier, with research demonstrating that nano-additives can enhance heat and mass transfer in absorption systems. Preliminary studies show efficiency improvements of 5-15% when incorporating nanoparticles like TiO2, SiO2, and carbon nanotubes into conventional working fluids, though long-term stability remains problematic.

The geographical distribution of absorption technology development shows concentration in Asia (particularly Japan and China), Europe, and North America, with different regions focusing on specific applications based on climate conditions and energy infrastructure. This regional specialization has led to divergent technological approaches that complicate standardization efforts.

Despite its widespread adoption, LiBr systems face several critical challenges that limit their broader application. Crystallization risk remains a primary concern, occurring when the solution concentration exceeds solubility limits during operation, leading to system blockages and efficiency losses. This phenomenon typically manifests at temperatures below 5°C, restricting LiBr systems' application in colder climates.

Corrosion presents another significant challenge, as LiBr solutions are highly corrosive to many common metals used in heat exchange equipment. Industry data indicates that corrosion-related maintenance accounts for approximately 25-30% of total system lifetime costs. Current mitigation strategies include corrosion inhibitors like lithium molybdate and lithium nitrate, though these additives can impact system performance and add complexity.

Alternative absorption pairs have emerged to address LiBr limitations. Ammonia-water systems offer superior low-temperature performance without crystallization risks, enabling operation at temperatures as low as -60°C. However, they require higher generator temperatures and present toxicity concerns. Water-salt systems utilizing calcium chloride or lithium chloride show promise for specific applications but generally demonstrate lower coefficients of performance (COP) than traditional LiBr systems.

Recent innovations include ionic liquids as absorption working fluids, with compounds like [EMIM][BF4] and [BMIM][BF4] showing promising thermodynamic properties. These materials offer negligible vapor pressure, high thermal stability, and customizable molecular structures. However, their high viscosity and production costs (5-20 times that of conventional working fluids) currently limit commercial viability.

Nanofluids represent another frontier, with research demonstrating that nano-additives can enhance heat and mass transfer in absorption systems. Preliminary studies show efficiency improvements of 5-15% when incorporating nanoparticles like TiO2, SiO2, and carbon nanotubes into conventional working fluids, though long-term stability remains problematic.

The geographical distribution of absorption technology development shows concentration in Asia (particularly Japan and China), Europe, and North America, with different regions focusing on specific applications based on climate conditions and energy infrastructure. This regional specialization has led to divergent technological approaches that complicate standardization efforts.

Comparative Analysis of LiBr and Alternative Additives

01 Lithium bromide in absorption refrigeration systems

Lithium bromide is widely used as an absorbent in absorption refrigeration and heat pump systems due to its excellent absorption properties. These systems often incorporate lithium bromide solution with various additives to enhance performance, prevent crystallization, and reduce corrosion. The combination of lithium bromide with water as a working pair is particularly effective for air conditioning and industrial cooling applications.- Lithium bromide in absorption refrigeration systems: Lithium bromide is widely used as an absorbent in absorption refrigeration and heat pump systems due to its excellent absorption properties for water vapor. These systems typically include a generator, condenser, evaporator, and absorber. The addition of specific additives to lithium bromide solutions can enhance performance by reducing crystallization risks, improving heat transfer, and preventing corrosion of metal components in the system.

- Corrosion inhibitors for lithium bromide solutions: Various additives are used as corrosion inhibitors in lithium bromide solutions to protect metal components in absorption systems. These inhibitors include molybdate compounds, chromate salts, nitrates, and organic compounds that form protective films on metal surfaces. The effectiveness of these inhibitors depends on concentration, temperature, and the specific metals being protected, with some formulations providing synergistic effects when multiple inhibitors are combined.

- Lithium bromide in energy storage applications: Lithium bromide, combined with specific additives, is utilized in thermal energy storage systems and battery technologies. In thermal storage applications, lithium bromide solutions with stabilizers can store and release thermal energy through absorption and desorption processes. In battery applications, lithium bromide serves as an electrolyte component, with additives improving conductivity, stability, and cycle life of the energy storage systems.

- Performance enhancers for lithium bromide working fluids: Specific additives are incorporated into lithium bromide solutions to enhance their thermodynamic and transport properties. These include surfactants that reduce surface tension and improve heat and mass transfer, viscosity modifiers that optimize flow characteristics, and solubility enhancers that increase the working concentration range. These performance enhancers can significantly improve the coefficient of performance in absorption systems and extend operational parameters.

- Crystallization inhibitors and stabilizers for lithium bromide solutions: Crystallization inhibitors are critical additives for lithium bromide solutions to prevent solidification during operation or shutdown periods. These include ethylene glycol, alcohols, and certain salts that modify the crystallization point of the solution. Stabilizers are also added to prevent degradation of the solution under high temperatures and to maintain consistent performance over extended operational periods, thereby increasing system reliability and reducing maintenance requirements.

02 Corrosion inhibitors for lithium bromide systems

Various additives are used as corrosion inhibitors in lithium bromide solutions to protect metal components in absorption systems. These inhibitors include molybdate compounds, chromate salts, nitrates, and organic compounds that form protective films on metal surfaces. The addition of these corrosion inhibitors significantly extends the service life of absorption refrigeration equipment by preventing degradation of heat exchanger surfaces and other critical components.Expand Specific Solutions03 Lithium bromide in battery technologies

Lithium bromide serves as an electrolyte additive in various battery technologies, particularly in lithium-ion and lithium-metal batteries. When combined with other salts and solvents, it can enhance battery performance by improving ionic conductivity, forming stable solid electrolyte interphase layers, and extending cycle life. These formulations help address challenges in energy density, safety, and longevity of rechargeable battery systems.Expand Specific Solutions04 Crystallization inhibitors for lithium bromide solutions

To prevent crystallization in lithium bromide absorption systems, various additives such as lithium iodide, lithium nitrate, and organic compounds are incorporated into the solution. These additives effectively lower the crystallization temperature, allowing the system to operate at higher concentrations or lower temperatures without the risk of solid formation. This improves system efficiency and reliability by preventing blockages and maintaining continuous operation.Expand Specific Solutions05 Lithium bromide in energy storage applications

Lithium bromide, combined with other additives, is utilized in thermal energy storage systems and advanced energy conversion technologies. These formulations can store and release thermal energy efficiently, making them suitable for solar thermal applications, waste heat recovery, and grid-scale energy storage. The addition of specific compounds enhances the thermal stability, energy density, and cycle efficiency of these storage systems.Expand Specific Solutions

Key Industry Players in Absorption Technology

The absorption technology market, particularly focusing on lithium bromide and other additives, is in a growth phase with increasing applications in HVAC systems and industrial cooling. The global market size is expanding steadily, driven by energy efficiency demands and sustainable cooling solutions. Technologically, lithium bromide remains dominant but faces competition from alternative additives. Leading players like DuPont, Evonik Operations, and China Petroleum & Chemical Corp. have established strong positions through R&D investments, while companies such as Kaneka Corp. and Sunresin New Materials are advancing material innovations. Research institutions including KIST Corp. and Georgia Tech Research Corp. are contributing to technological advancements, pushing the absorption technology toward greater efficiency and reduced environmental impact.

DuPont de Nemours, Inc.

Technical Solution: DuPont has developed advanced absorption systems utilizing lithium bromide as the primary working fluid, with proprietary additives to enhance performance. Their technology incorporates corrosion inhibitors that extend system lifespan by up to 40% compared to standard LiBr solutions. DuPont's approach focuses on multi-effect absorption chillers where their enhanced LiBr solution achieves coefficient of performance (COP) values of 1.2-1.5, significantly higher than conventional single-effect systems. The company has also pioneered hybrid absorption systems that combine lithium bromide with organic additives to reduce crystallization risks at high concentrations, allowing operation at higher temperatures and improving thermal efficiency by approximately 15-20%. Their research has demonstrated that specific surfactant additives can reduce surface tension by up to 30%, enhancing heat and mass transfer in absorption processes.

Strengths: Superior corrosion resistance properties, higher thermal efficiency, and reduced crystallization risk. Weaknesses: Higher initial cost compared to conventional systems, requires specialized maintenance protocols, and performance advantages diminish in smaller-scale applications.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed proprietary absorption refrigeration systems using modified lithium bromide solutions enhanced with specific ionic additives. Their technology incorporates lithium bromide as the absorbent and water as the refrigerant, but with critical improvements through carefully selected additives that enhance thermal stability and reduce corrosion. Sinopec's approach includes the addition of lithium nitrate and lithium molybdate in precise concentrations (typically 0.1-0.5% by weight) to inhibit corrosion of copper and steel components. Their research has shown that these additives can reduce corrosion rates by up to 85% compared to standard LiBr solutions. Additionally, Sinopec has pioneered the use of specific surfactants that reduce surface tension at the vapor-liquid interface, improving heat and mass transfer coefficients by approximately 25-30% and thereby enhancing overall system efficiency.

Strengths: Excellent corrosion inhibition properties, improved thermal stability at high temperatures, and enhanced heat transfer characteristics. Weaknesses: Requires precise additive concentration control, higher manufacturing costs, and potential environmental concerns with some additives.

Technical Innovations in Absorption Working Fluids

Ionic compounds in lithium bromide/water absorption cycle systems

PatentInactiveEP2414476A1

Innovation

- Incorporating specific ionic compounds such as pyridazinium, pyrimidinium, and their derivatives into the lithium bromide/water solutions to suppress crystallization, allowing for wider operating ranges and improved energy efficiency.

Use of an aqueous bromide lithium solution as an absorber component for a working fluid composition

PatentInactiveEP0012856A1

Innovation

- Employing almost saturated or supersaturated aqueous salt solutions, such as LiBr or NaSCN, to prevent crystallization of ammoniates and extend the solution field, allowing operation within safe temperature ranges while maintaining favorable thermodynamic properties, and using water to maintain solution stability without exceeding saturation limits.

Environmental Impact and Sustainability Assessment

The environmental impact of absorption refrigeration systems is significantly influenced by the choice of working fluids and additives. Lithium bromide (LiBr), as the predominant absorbent in commercial absorption systems, presents several environmental considerations that must be evaluated against alternative additives.

LiBr-based systems generally demonstrate lower direct environmental impacts compared to conventional vapor compression systems using hydrofluorocarbons (HFCs) or hydrochlorofluorocarbons (HCFCs), which have high global warming potentials. The zero ozone depletion potential (ODP) and negligible global warming potential (GWP) of LiBr solutions represent significant environmental advantages in the context of climate change mitigation efforts.

However, LiBr systems are not without environmental concerns. The corrosive nature of LiBr solutions necessitates the use of corrosion inhibitors and specialized materials, which can introduce additional environmental burdens through manufacturing processes and end-of-life disposal challenges. The production of lithium compounds also raises sustainability questions regarding resource extraction and processing energy requirements.

Alternative additives such as ionic liquids, ammonia-water mixtures, and salt-organic solvent combinations offer varying environmental profiles. Ammonia-water systems, while efficient and using naturally occurring substances, present toxicity concerns that require robust safety measures. Ionic liquids show promise due to their negligible vapor pressure and customizable properties, but their complete life cycle environmental impacts remain incompletely characterized.

Life cycle assessment (LCA) studies comparing these options reveal that the environmental superiority of any system depends heavily on operational context. In regions with carbon-intensive electricity generation, the indirect emissions from powering LiBr systems may outweigh their direct environmental benefits. Conversely, when coupled with renewable energy sources, absorption systems can achieve significantly lower life cycle impacts than conventional alternatives.

Water consumption represents another critical environmental consideration. LiBr systems typically require substantial cooling water, which may present sustainability challenges in water-stressed regions. Some alternative working pairs demonstrate reduced water requirements but may trade this advantage for decreased efficiency or increased complexity.

Emerging research on novel additives and hybrid systems suggests pathways toward improved environmental performance. Bio-based absorbents derived from renewable resources show potential for reducing the embodied carbon of absorption systems. Additionally, waste heat recovery applications of absorption technology can substantially improve the overall resource efficiency of industrial processes and energy systems.

The sustainability assessment of absorption refrigeration must ultimately consider not only the environmental impacts of the working fluids themselves but also their enabling role in utilizing low-grade thermal energy that might otherwise be wasted, potentially offering system-level environmental benefits that transcend component-level comparisons.

LiBr-based systems generally demonstrate lower direct environmental impacts compared to conventional vapor compression systems using hydrofluorocarbons (HFCs) or hydrochlorofluorocarbons (HCFCs), which have high global warming potentials. The zero ozone depletion potential (ODP) and negligible global warming potential (GWP) of LiBr solutions represent significant environmental advantages in the context of climate change mitigation efforts.

However, LiBr systems are not without environmental concerns. The corrosive nature of LiBr solutions necessitates the use of corrosion inhibitors and specialized materials, which can introduce additional environmental burdens through manufacturing processes and end-of-life disposal challenges. The production of lithium compounds also raises sustainability questions regarding resource extraction and processing energy requirements.

Alternative additives such as ionic liquids, ammonia-water mixtures, and salt-organic solvent combinations offer varying environmental profiles. Ammonia-water systems, while efficient and using naturally occurring substances, present toxicity concerns that require robust safety measures. Ionic liquids show promise due to their negligible vapor pressure and customizable properties, but their complete life cycle environmental impacts remain incompletely characterized.

Life cycle assessment (LCA) studies comparing these options reveal that the environmental superiority of any system depends heavily on operational context. In regions with carbon-intensive electricity generation, the indirect emissions from powering LiBr systems may outweigh their direct environmental benefits. Conversely, when coupled with renewable energy sources, absorption systems can achieve significantly lower life cycle impacts than conventional alternatives.

Water consumption represents another critical environmental consideration. LiBr systems typically require substantial cooling water, which may present sustainability challenges in water-stressed regions. Some alternative working pairs demonstrate reduced water requirements but may trade this advantage for decreased efficiency or increased complexity.

Emerging research on novel additives and hybrid systems suggests pathways toward improved environmental performance. Bio-based absorbents derived from renewable resources show potential for reducing the embodied carbon of absorption systems. Additionally, waste heat recovery applications of absorption technology can substantially improve the overall resource efficiency of industrial processes and energy systems.

The sustainability assessment of absorption refrigeration must ultimately consider not only the environmental impacts of the working fluids themselves but also their enabling role in utilizing low-grade thermal energy that might otherwise be wasted, potentially offering system-level environmental benefits that transcend component-level comparisons.

Economic Feasibility of Different Absorption Systems

The economic feasibility of absorption systems varies significantly depending on the working fluid pairs and additives used, with lithium bromide (LiBr) systems often serving as the industry benchmark. When comparing LiBr with alternative additives in absorption systems, capital expenditure represents a critical consideration. LiBr-water systems typically require higher initial investment due to specialized corrosion-resistant materials and vacuum-tight construction, whereas systems using alternatives like ammonia-water may utilize less expensive carbon steel components but demand higher pressure ratings.

Operational costs reveal distinct advantages for LiBr systems in certain applications. These systems generally achieve higher coefficients of performance (COP) ranging from 0.7-1.2 for single-effect configurations, translating to lower energy consumption compared to some alternatives. However, LiBr systems often necessitate cooling towers for heat rejection, increasing water consumption costs and treatment expenses that may not be as significant with other working pairs.

Maintenance economics also differ substantially across absorption technologies. LiBr systems face recurring costs related to corrosion inhibitors and vacuum maintenance, while ammonia-based systems require regular rectification column maintenance and safety monitoring systems. The crystallization risk in LiBr systems can lead to unplanned downtime costs that must be factored into long-term economic analyses.

Life-cycle cost assessment indicates that LiBr systems typically offer 15-20 year operational lifespans when properly maintained, comparable to alternative systems. However, the replacement costs for specialized components in LiBr systems often exceed those of alternative technologies, creating higher lifetime ownership costs despite potentially lower energy consumption.

Market analysis demonstrates that LiBr dominates in large-capacity commercial and industrial cooling applications (>100 kW), where its higher efficiency justifies the increased capital expenditure. Alternative working pairs show better economic performance in small to medium capacity applications and in regions with limited water availability or where specialized maintenance expertise for LiBr systems is scarce.

Payback period calculations reveal that LiBr systems typically achieve return on investment within 3-7 years in applications with high cooling loads and extended annual operating hours, particularly when replacing conventional electric chillers. Alternative absorption systems may offer faster payback in specific niche applications, such as waste heat recovery in industrial processes or in regions with extremely high electricity costs.

Operational costs reveal distinct advantages for LiBr systems in certain applications. These systems generally achieve higher coefficients of performance (COP) ranging from 0.7-1.2 for single-effect configurations, translating to lower energy consumption compared to some alternatives. However, LiBr systems often necessitate cooling towers for heat rejection, increasing water consumption costs and treatment expenses that may not be as significant with other working pairs.

Maintenance economics also differ substantially across absorption technologies. LiBr systems face recurring costs related to corrosion inhibitors and vacuum maintenance, while ammonia-based systems require regular rectification column maintenance and safety monitoring systems. The crystallization risk in LiBr systems can lead to unplanned downtime costs that must be factored into long-term economic analyses.

Life-cycle cost assessment indicates that LiBr systems typically offer 15-20 year operational lifespans when properly maintained, comparable to alternative systems. However, the replacement costs for specialized components in LiBr systems often exceed those of alternative technologies, creating higher lifetime ownership costs despite potentially lower energy consumption.

Market analysis demonstrates that LiBr dominates in large-capacity commercial and industrial cooling applications (>100 kW), where its higher efficiency justifies the increased capital expenditure. Alternative working pairs show better economic performance in small to medium capacity applications and in regions with limited water availability or where specialized maintenance expertise for LiBr systems is scarce.

Payback period calculations reveal that LiBr systems typically achieve return on investment within 3-7 years in applications with high cooling loads and extended annual operating hours, particularly when replacing conventional electric chillers. Alternative absorption systems may offer faster payback in specific niche applications, such as waste heat recovery in industrial processes or in regions with extremely high electricity costs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!