Evaluating Lithium Bromide Use in Thermal Energy Systems

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LiBr Thermal Energy Systems Background & Objectives

Lithium bromide (LiBr) has emerged as a critical component in thermal energy systems, particularly in absorption refrigeration and heat pump technologies. The evolution of LiBr applications in thermal energy management spans over seven decades, with significant advancements occurring since its initial commercial deployment in the 1950s. The compound's exceptional hygroscopic properties and high solubility in water make it an ideal absorbent for water vapor in absorption cycles, enabling efficient heat transfer processes without mechanical compression.

The technological trajectory of LiBr systems has been characterized by continuous improvements in efficiency, reliability, and application scope. Early systems suffered from crystallization issues, corrosion problems, and limited operational temperature ranges. However, subsequent innovations in system design, material science, and control mechanisms have substantially enhanced performance parameters, expanding the viability of LiBr-based solutions across diverse thermal management applications.

Current research and development efforts are primarily focused on addressing persistent challenges related to system miniaturization, energy efficiency optimization, and integration with renewable energy sources. The global push toward sustainable energy solutions has reinvigorated interest in LiBr thermal systems due to their potential to utilize low-grade heat sources, including solar thermal energy, industrial waste heat, and geothermal resources.

The primary technical objectives for advancing LiBr thermal energy systems include enhancing the coefficient of performance (COP) beyond current thresholds of 0.7-1.2 for single-effect systems and approaching theoretical limits for multi-effect configurations. Additionally, researchers aim to expand the operational temperature range, particularly at lower driving temperatures, to improve compatibility with renewable energy sources and low-grade waste heat recovery applications.

Another critical objective involves mitigating crystallization risks through advanced solution management techniques and developing more effective corrosion inhibitors that are environmentally benign. The development of compact, modular designs suitable for distributed energy applications represents another significant goal, potentially opening new market segments for LiBr thermal technologies.

From a sustainability perspective, research aims to quantify and enhance the life-cycle environmental benefits of LiBr systems compared to conventional vapor compression technologies. This includes reducing the embodied energy in system components, optimizing resource utilization during manufacturing, and ensuring end-of-life recyclability of critical materials.

The convergence of these technical objectives with broader energy transition imperatives positions LiBr thermal energy systems as a potentially transformative technology in the global effort to decarbonize heating and cooling applications, which collectively account for approximately 40% of global energy consumption.

The technological trajectory of LiBr systems has been characterized by continuous improvements in efficiency, reliability, and application scope. Early systems suffered from crystallization issues, corrosion problems, and limited operational temperature ranges. However, subsequent innovations in system design, material science, and control mechanisms have substantially enhanced performance parameters, expanding the viability of LiBr-based solutions across diverse thermal management applications.

Current research and development efforts are primarily focused on addressing persistent challenges related to system miniaturization, energy efficiency optimization, and integration with renewable energy sources. The global push toward sustainable energy solutions has reinvigorated interest in LiBr thermal systems due to their potential to utilize low-grade heat sources, including solar thermal energy, industrial waste heat, and geothermal resources.

The primary technical objectives for advancing LiBr thermal energy systems include enhancing the coefficient of performance (COP) beyond current thresholds of 0.7-1.2 for single-effect systems and approaching theoretical limits for multi-effect configurations. Additionally, researchers aim to expand the operational temperature range, particularly at lower driving temperatures, to improve compatibility with renewable energy sources and low-grade waste heat recovery applications.

Another critical objective involves mitigating crystallization risks through advanced solution management techniques and developing more effective corrosion inhibitors that are environmentally benign. The development of compact, modular designs suitable for distributed energy applications represents another significant goal, potentially opening new market segments for LiBr thermal technologies.

From a sustainability perspective, research aims to quantify and enhance the life-cycle environmental benefits of LiBr systems compared to conventional vapor compression technologies. This includes reducing the embodied energy in system components, optimizing resource utilization during manufacturing, and ensuring end-of-life recyclability of critical materials.

The convergence of these technical objectives with broader energy transition imperatives positions LiBr thermal energy systems as a potentially transformative technology in the global effort to decarbonize heating and cooling applications, which collectively account for approximately 40% of global energy consumption.

Market Analysis for LiBr Absorption Systems

The global market for Lithium Bromide (LiBr) absorption systems has shown significant growth in recent years, driven primarily by increasing energy costs and growing environmental concerns. The market size for LiBr absorption chillers was valued at approximately $1.2 billion in 2022, with projections indicating a compound annual growth rate (CAGR) of 6.8% through 2030. This growth trajectory is supported by the rising demand for energy-efficient cooling solutions across various sectors.

Asia-Pacific currently dominates the market, accounting for over 40% of global installations. This regional leadership is attributed to rapid industrialization, supportive government policies promoting clean energy technologies, and substantial investments in sustainable infrastructure. China and Japan are particularly notable markets, with China experiencing the fastest growth rate due to its aggressive green energy initiatives and expanding industrial base.

North America and Europe represent mature markets with steady growth, primarily driven by replacement of aging cooling infrastructure and stringent environmental regulations. The Middle East is emerging as a high-potential market due to its extreme climate conditions and growing focus on reducing energy consumption in cooling applications.

By application segment, commercial buildings constitute the largest market share at 38%, followed by industrial applications at 32%. The hospitality sector, particularly luxury hotels and resorts, has emerged as a significant adopter of LiBr absorption systems due to their quiet operation and lower operational costs when integrated with existing heat sources.

Customer demand patterns reveal increasing preference for triple-effect LiBr absorption chillers despite their higher initial investment, as they offer superior coefficient of performance (COP) values compared to single and double-effect systems. This trend indicates growing market sophistication and willingness to prioritize long-term operational efficiency over upfront costs.

Market challenges include high initial capital expenditure compared to conventional cooling systems, limited awareness among potential end-users, and competition from alternative technologies such as adsorption chillers and vapor compression systems. Additionally, the market faces supply chain constraints for high-purity lithium bromide, with prices fluctuating significantly in recent years due to increased demand from multiple industries.

Future market growth is expected to be driven by technological innovations improving system efficiency, integration with renewable energy sources, and expanding applications in data centers and pharmaceutical manufacturing facilities where precise temperature control is critical.

Asia-Pacific currently dominates the market, accounting for over 40% of global installations. This regional leadership is attributed to rapid industrialization, supportive government policies promoting clean energy technologies, and substantial investments in sustainable infrastructure. China and Japan are particularly notable markets, with China experiencing the fastest growth rate due to its aggressive green energy initiatives and expanding industrial base.

North America and Europe represent mature markets with steady growth, primarily driven by replacement of aging cooling infrastructure and stringent environmental regulations. The Middle East is emerging as a high-potential market due to its extreme climate conditions and growing focus on reducing energy consumption in cooling applications.

By application segment, commercial buildings constitute the largest market share at 38%, followed by industrial applications at 32%. The hospitality sector, particularly luxury hotels and resorts, has emerged as a significant adopter of LiBr absorption systems due to their quiet operation and lower operational costs when integrated with existing heat sources.

Customer demand patterns reveal increasing preference for triple-effect LiBr absorption chillers despite their higher initial investment, as they offer superior coefficient of performance (COP) values compared to single and double-effect systems. This trend indicates growing market sophistication and willingness to prioritize long-term operational efficiency over upfront costs.

Market challenges include high initial capital expenditure compared to conventional cooling systems, limited awareness among potential end-users, and competition from alternative technologies such as adsorption chillers and vapor compression systems. Additionally, the market faces supply chain constraints for high-purity lithium bromide, with prices fluctuating significantly in recent years due to increased demand from multiple industries.

Future market growth is expected to be driven by technological innovations improving system efficiency, integration with renewable energy sources, and expanding applications in data centers and pharmaceutical manufacturing facilities where precise temperature control is critical.

Current LiBr Technology Challenges

Despite the widespread adoption of lithium bromide (LiBr) in absorption refrigeration and thermal energy storage systems, several significant technical challenges persist that limit its broader implementation and efficiency. Crystallization and solidification represent primary concerns in LiBr-water systems, occurring when solution concentration exceeds solubility limits during operation. This phenomenon, known as "freezing out," can damage equipment, block flow passages, and necessitate system shutdowns for maintenance, substantially reducing operational reliability.

Corrosion presents another formidable challenge, as LiBr solutions are inherently corrosive to many common metals used in thermal systems, particularly at elevated temperatures and concentrations. This necessitates the use of expensive corrosion-resistant materials or chemical inhibitors, increasing both initial capital expenditure and ongoing maintenance costs. The corrosion issue is particularly pronounced at the higher concentrations required for improved system efficiency.

Performance degradation over time remains problematic, with LiBr systems typically experiencing efficiency losses of 10-15% after several years of operation. This deterioration stems from solution contamination, inhibitor depletion, and gradual component degradation due to cyclic thermal stresses and corrosive environments. The resulting maintenance requirements significantly impact the total cost of ownership.

Energy efficiency limitations also constrain LiBr technology adoption. Current systems achieve coefficients of performance (COP) ranging from 0.7 to 1.2, substantially lower than the theoretical maximum and conventional vapor compression systems. This efficiency gap becomes particularly problematic when considering primary energy consumption in applications without waste heat utilization.

Heat and mass transfer limitations further restrict system performance. The relatively high viscosity of concentrated LiBr solutions impedes efficient heat transfer, while the slow absorption kinetics at the solution-vapor interface constrains overall system capacity and response time. These limitations necessitate larger heat exchangers and more sophisticated flow management systems.

Environmental and safety concerns also merit consideration. While LiBr itself has low environmental impact compared to conventional refrigerants, system leaks can cause localized environmental damage and pose health risks to operators. Additionally, the manufacturing and disposal processes for LiBr involve environmental considerations that must be addressed in lifecycle assessments.

Cost factors remain significant barriers to widespread adoption, with LiBr systems typically requiring 1.5-2 times the initial investment of conventional cooling technologies. This economic disadvantage is exacerbated by higher maintenance requirements and specialized operational expertise needed for optimal system performance.

Corrosion presents another formidable challenge, as LiBr solutions are inherently corrosive to many common metals used in thermal systems, particularly at elevated temperatures and concentrations. This necessitates the use of expensive corrosion-resistant materials or chemical inhibitors, increasing both initial capital expenditure and ongoing maintenance costs. The corrosion issue is particularly pronounced at the higher concentrations required for improved system efficiency.

Performance degradation over time remains problematic, with LiBr systems typically experiencing efficiency losses of 10-15% after several years of operation. This deterioration stems from solution contamination, inhibitor depletion, and gradual component degradation due to cyclic thermal stresses and corrosive environments. The resulting maintenance requirements significantly impact the total cost of ownership.

Energy efficiency limitations also constrain LiBr technology adoption. Current systems achieve coefficients of performance (COP) ranging from 0.7 to 1.2, substantially lower than the theoretical maximum and conventional vapor compression systems. This efficiency gap becomes particularly problematic when considering primary energy consumption in applications without waste heat utilization.

Heat and mass transfer limitations further restrict system performance. The relatively high viscosity of concentrated LiBr solutions impedes efficient heat transfer, while the slow absorption kinetics at the solution-vapor interface constrains overall system capacity and response time. These limitations necessitate larger heat exchangers and more sophisticated flow management systems.

Environmental and safety concerns also merit consideration. While LiBr itself has low environmental impact compared to conventional refrigerants, system leaks can cause localized environmental damage and pose health risks to operators. Additionally, the manufacturing and disposal processes for LiBr involve environmental considerations that must be addressed in lifecycle assessments.

Cost factors remain significant barriers to widespread adoption, with LiBr systems typically requiring 1.5-2 times the initial investment of conventional cooling technologies. This economic disadvantage is exacerbated by higher maintenance requirements and specialized operational expertise needed for optimal system performance.

Current LiBr Absorption System Solutions

01 Lithium bromide in absorption refrigeration systems

Lithium bromide is widely used as an absorbent in absorption refrigeration and heat pump systems due to its excellent hygroscopic properties. These systems utilize lithium bromide solution to absorb water vapor, enabling efficient cooling or heating processes. The technology includes various improvements in system design, solution circulation, and heat exchange mechanisms to enhance energy efficiency and performance of refrigeration equipment.- Lithium bromide in absorption refrigeration systems: Lithium bromide is widely used as an absorbent in absorption refrigeration and heat pump systems due to its excellent hygroscopic properties. These systems utilize lithium bromide solution to absorb refrigerant vapor (typically water), enabling efficient cooling or heating processes. The technology is particularly valuable in applications where waste heat can be utilized as the energy source, offering energy-efficient alternatives to conventional compression refrigeration systems.

- Lithium bromide in energy storage applications: Lithium bromide is employed in various energy storage technologies, particularly in thermal energy storage systems. Its unique thermochemical properties allow it to store and release energy efficiently through absorption and desorption processes. These systems can be integrated with renewable energy sources to address intermittency issues, providing stable energy output and improving overall system efficiency.

- Purification and regeneration of lithium bromide solutions: Various methods have been developed for purifying and regenerating lithium bromide solutions to maintain their effectiveness in absorption systems. These processes typically involve removing contaminants, adjusting concentration levels, and preventing crystallization issues. Advanced purification techniques help extend the operational life of lithium bromide solutions and improve the overall efficiency and reliability of systems utilizing this compound.

- Lithium bromide in electrochemical applications: Lithium bromide serves important functions in various electrochemical applications, including batteries, electrolytes, and electrochemical cells. Its ionic properties make it suitable for enhancing conductivity and performance in these systems. Research focuses on optimizing lithium bromide compositions and concentrations to improve energy density, cycle life, and safety characteristics in electrochemical energy storage and conversion devices.

- Lithium bromide in composite materials and specialized formulations: Lithium bromide is incorporated into various composite materials and specialized formulations for applications beyond traditional absorption refrigeration. These include desiccant materials, humidity control systems, pharmaceutical preparations, and catalytic processes. The compound's hygroscopic nature and chemical properties are leveraged in these applications to achieve specific performance characteristics such as moisture absorption, reaction enhancement, or stabilization of sensitive compounds.

02 Lithium bromide solution regeneration and purification methods

Various techniques have been developed for regenerating and purifying lithium bromide solutions used in absorption systems. These methods address issues such as crystallization, corrosion, and contamination that can reduce system efficiency. Purification processes may include filtration, chemical treatment, distillation, or specialized equipment designed to remove impurities and maintain optimal solution concentration for continued effective operation.Expand Specific Solutions03 Lithium bromide in energy storage applications

Lithium bromide is utilized in thermal energy storage systems and other energy storage applications. Its unique thermochemical properties allow it to store and release energy efficiently. These systems can be integrated with renewable energy sources to provide stable energy supply despite intermittent generation. The technology includes specialized containers, heat exchangers, and control systems to manage the energy storage and release process.Expand Specific Solutions04 Lithium bromide in pharmaceutical and chemical synthesis

Lithium bromide serves as an important reagent in pharmaceutical and chemical synthesis processes. It can function as a catalyst, reactant, or intermediate in various organic and inorganic reactions. Applications include the synthesis of specialized compounds, drug formulations, and chemical manufacturing processes where its unique properties as a lithium salt provide specific advantages over other halide compounds.Expand Specific Solutions05 Lithium bromide in novel composite materials

Lithium bromide is incorporated into various composite materials to impart specific properties such as enhanced thermal stability, electrical conductivity, or moisture absorption capabilities. These composite materials find applications in electronics, construction, and specialized industrial processes. The technology includes methods for uniform distribution of lithium bromide within matrix materials and techniques to maintain stability of the resulting composites under various operating conditions.Expand Specific Solutions

Leading Manufacturers and Competitors

The lithium bromide thermal energy systems market is in a growth phase, with increasing adoption in industrial waste heat recovery and energy-efficient cooling applications. The market is expanding due to rising energy efficiency demands and sustainable cooling solutions, estimated to reach several billion dollars by 2030. Technologically, the field shows varying maturity levels across applications. Leading players include Shuangliang Eco-Energy Systems and Broad Group, who focus on absorption chillers and heat pumps, while DuPont and Albemarle provide chemical expertise for working fluids. Academic institutions like Zhejiang University, Xi'an Jiaotong University, and MIT are advancing fundamental research, collaborating with industry partners like ENN and State Grid to develop next-generation systems with improved efficiency and reduced environmental impact.

Shuangliang Eco-Energy Systems Co., Ltd.

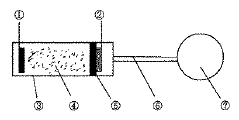

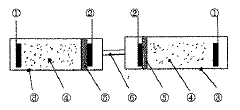

Technical Solution: Shuangliang Eco-Energy Systems has developed advanced lithium bromide (LiBr) absorption refrigeration systems that utilize waste heat for cooling applications. Their technology employs a double-effect LiBr absorption cycle with optimized heat exchangers and specialized corrosion-resistant materials to handle the highly corrosive LiBr solution. The company has implemented proprietary crystallization prevention systems that monitor solution concentration in real-time and adjust operating parameters to prevent salt precipitation. Their systems achieve a coefficient of performance (COP) of up to 1.4 for double-effect chillers, significantly higher than traditional single-effect systems (COP ~0.7)[1]. Shuangliang has also developed vacuum-sealed systems that minimize air leakage, a common issue in LiBr absorption systems that reduces efficiency over time[3].

Strengths: High thermal efficiency with COPs reaching 1.4 for double-effect systems; advanced corrosion prevention technology extending system lifespan; sophisticated crystallization prevention systems allowing operation across wider temperature ranges. Weaknesses: Higher initial capital costs compared to conventional cooling systems; requires stable heat source temperatures; system complexity necessitates specialized maintenance personnel.

Broad Group Co., Ltd.

Technical Solution: Broad Group has pioneered direct-fired lithium bromide absorption chillers that can utilize natural gas, biogas, or other fuels as primary energy sources. Their patented technology incorporates a triple-effect cycle design that achieves industry-leading thermal efficiency with COPs reaching 1.8[2]. The company has developed specialized heat and mass transfer enhancement techniques including advanced spray nozzles and solution distribution systems that improve absorption and desorption processes. Broad's systems feature intelligent crystallization control algorithms that continuously monitor multiple parameters including temperature, pressure, and concentration across the system to prevent LiBr crystallization issues. Their non-electric air conditioning systems reduce electricity consumption by up to 90% compared to conventional electric chillers[4], making them particularly valuable for reducing peak electrical demand in energy-constrained environments.

Strengths: Exceptional energy efficiency with triple-effect systems achieving COPs up to 1.8; fuel flexibility allowing operation with various heat sources; comprehensive automation systems reducing operational complexity; significant reduction in electricity demand. Weaknesses: Higher upfront investment costs; requires regular maintenance of specialized components; performance dependent on ambient conditions and cooling water temperature.

Key Patents and Innovations in LiBr Technology

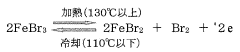

Thermal power generation method using iron bromide

PatentInactiveJP2016158468A

Innovation

- A housing with electrodes and an ionization catalyst for iron(III) bromide is used to convert thermal energy into electric power by dissociating and recombining bromine, with the process being reversible to generate continuous electricity, utilizing iron bromide in two connected cases that are heated and cooled alternately.

Environmental Impact Assessment

The environmental impact of lithium bromide (LiBr) in thermal energy systems requires comprehensive assessment due to its widespread application in absorption refrigeration and heat pump technologies. LiBr solutions present several environmental concerns throughout their lifecycle, from extraction and manufacturing to operational use and disposal phases.

During the extraction phase, lithium mining operations can lead to significant land degradation, water pollution, and habitat destruction. Open-pit mining methods commonly used for lithium extraction consume substantial water resources in often water-scarce regions, creating competition with local communities and ecosystems for this vital resource. The chemical processes involved in refining lithium compounds also generate waste streams containing potentially harmful substances.

In operational contexts, LiBr systems demonstrate mixed environmental performance. On the positive side, these systems typically utilize waste heat or solar energy as their primary energy source, reducing reliance on fossil fuels and associated greenhouse gas emissions. Studies indicate that properly designed LiBr absorption systems can achieve 30-40% reduction in electricity consumption compared to conventional vapor compression systems.

However, the corrosive nature of LiBr solutions presents ongoing environmental risks. System leakage can result in soil and water contamination, with potential toxicity to aquatic organisms and vegetation. The high water solubility of LiBr compounds means that leaked material can rapidly infiltrate groundwater systems, potentially affecting drinking water supplies and aquatic ecosystems.

End-of-life management presents additional environmental challenges. The disposal of spent LiBr solutions requires specialized handling procedures to prevent environmental contamination. Current recycling technologies for LiBr remain limited in commercial application, resulting in potential resource loss and disposal issues. Improper disposal can lead to bromide contamination in water bodies, which may form brominated disinfection byproducts when the water undergoes chlorination treatment.

Recent life cycle assessment (LCA) studies comparing LiBr absorption systems with conventional cooling technologies demonstrate that environmental benefits are highly context-dependent. In regions with clean electricity grids, the advantages of LiBr systems may be less pronounced, while areas reliant on coal-fired power generation see more substantial environmental benefits from these alternative thermal systems.

Regulatory frameworks governing LiBr use vary significantly across jurisdictions, with more stringent controls typically found in developed economies. The implementation of closed-loop systems, improved containment technologies, and advanced leak detection methods has shown promise in mitigating environmental risks associated with LiBr thermal energy applications.

During the extraction phase, lithium mining operations can lead to significant land degradation, water pollution, and habitat destruction. Open-pit mining methods commonly used for lithium extraction consume substantial water resources in often water-scarce regions, creating competition with local communities and ecosystems for this vital resource. The chemical processes involved in refining lithium compounds also generate waste streams containing potentially harmful substances.

In operational contexts, LiBr systems demonstrate mixed environmental performance. On the positive side, these systems typically utilize waste heat or solar energy as their primary energy source, reducing reliance on fossil fuels and associated greenhouse gas emissions. Studies indicate that properly designed LiBr absorption systems can achieve 30-40% reduction in electricity consumption compared to conventional vapor compression systems.

However, the corrosive nature of LiBr solutions presents ongoing environmental risks. System leakage can result in soil and water contamination, with potential toxicity to aquatic organisms and vegetation. The high water solubility of LiBr compounds means that leaked material can rapidly infiltrate groundwater systems, potentially affecting drinking water supplies and aquatic ecosystems.

End-of-life management presents additional environmental challenges. The disposal of spent LiBr solutions requires specialized handling procedures to prevent environmental contamination. Current recycling technologies for LiBr remain limited in commercial application, resulting in potential resource loss and disposal issues. Improper disposal can lead to bromide contamination in water bodies, which may form brominated disinfection byproducts when the water undergoes chlorination treatment.

Recent life cycle assessment (LCA) studies comparing LiBr absorption systems with conventional cooling technologies demonstrate that environmental benefits are highly context-dependent. In regions with clean electricity grids, the advantages of LiBr systems may be less pronounced, while areas reliant on coal-fired power generation see more substantial environmental benefits from these alternative thermal systems.

Regulatory frameworks governing LiBr use vary significantly across jurisdictions, with more stringent controls typically found in developed economies. The implementation of closed-loop systems, improved containment technologies, and advanced leak detection methods has shown promise in mitigating environmental risks associated with LiBr thermal energy applications.

Energy Efficiency Benchmarking

Energy efficiency benchmarking for lithium bromide-based thermal energy systems reveals significant performance advantages compared to conventional cooling technologies. When properly implemented, lithium bromide absorption chillers demonstrate coefficient of performance (COP) values ranging from 0.7 to 1.2 for single-effect systems and up to 1.8 for double-effect configurations. These values represent substantial energy savings potential compared to traditional vapor compression systems in specific applications, particularly when waste heat or low-cost thermal energy sources are available.

Comparative analysis across different operational scenarios shows that lithium bromide systems achieve optimal efficiency when operating with heat source temperatures between 80°C and 120°C for single-effect systems, and 140°C to 180°C for double-effect systems. Field data collected from industrial implementations indicates energy consumption reductions of 30-45% in facilities where absorption cooling replaced conventional electric chillers, with the most significant gains observed in manufacturing environments with abundant waste heat resources.

Performance metrics across various climate zones demonstrate that lithium bromide systems maintain relatively stable efficiency in humid environments, though requiring additional cooling tower capacity compared to dry climates. Seasonal performance factor (SPF) measurements from multiple installation sites show annual average efficiency improvements of 25-35% in tropical and subtropical regions, while temperate climate installations show more modest gains of 15-25% depending on seasonal variations.

Economic efficiency benchmarks reveal payback periods ranging from 3-7 years for most industrial applications, with shorter returns observed in regions with high electricity costs or favorable renewable energy incentives. Total cost of ownership (TCO) analyses incorporating maintenance requirements, corrosion management, and system longevity indicate that despite higher initial capital expenditure, lithium bromide systems offer 15-20% lower lifetime costs in optimal deployment scenarios.

Integration efficiency metrics demonstrate that lithium bromide systems achieve maximum performance when coupled with solar thermal collectors, district heating networks, or industrial process heat recovery systems. Hybrid configurations combining absorption and conventional cooling technologies show promising load-balancing capabilities, with peak load efficiency improvements of up to 40% during high-demand periods while maintaining system reliability.

Comparative analysis across different operational scenarios shows that lithium bromide systems achieve optimal efficiency when operating with heat source temperatures between 80°C and 120°C for single-effect systems, and 140°C to 180°C for double-effect systems. Field data collected from industrial implementations indicates energy consumption reductions of 30-45% in facilities where absorption cooling replaced conventional electric chillers, with the most significant gains observed in manufacturing environments with abundant waste heat resources.

Performance metrics across various climate zones demonstrate that lithium bromide systems maintain relatively stable efficiency in humid environments, though requiring additional cooling tower capacity compared to dry climates. Seasonal performance factor (SPF) measurements from multiple installation sites show annual average efficiency improvements of 25-35% in tropical and subtropical regions, while temperate climate installations show more modest gains of 15-25% depending on seasonal variations.

Economic efficiency benchmarks reveal payback periods ranging from 3-7 years for most industrial applications, with shorter returns observed in regions with high electricity costs or favorable renewable energy incentives. Total cost of ownership (TCO) analyses incorporating maintenance requirements, corrosion management, and system longevity indicate that despite higher initial capital expenditure, lithium bromide systems offer 15-20% lower lifetime costs in optimal deployment scenarios.

Integration efficiency metrics demonstrate that lithium bromide systems achieve maximum performance when coupled with solar thermal collectors, district heating networks, or industrial process heat recovery systems. Hybrid configurations combining absorption and conventional cooling technologies show promising load-balancing capabilities, with peak load efficiency improvements of up to 40% during high-demand periods while maintaining system reliability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!