How to Calculate Lithium Bromide Solution Concentration

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LiBr Solution Concentration Measurement Background & Objectives

Lithium bromide (LiBr) solution concentration measurement has evolved significantly over the past several decades, driven by the growing importance of absorption refrigeration systems in industrial and commercial applications. The technology for measuring LiBr concentration began with simple density-based methods in the 1950s and has progressed to sophisticated digital analysis techniques in recent years. This evolution reflects the critical nature of precise concentration control in absorption chillers, where even small deviations can significantly impact system efficiency and operational stability.

The accurate measurement of LiBr solution concentration is fundamental to the proper functioning of absorption refrigeration systems, which represent a more environmentally friendly alternative to conventional vapor compression systems. These systems utilize LiBr as an absorbent for water vapor, creating a refrigeration effect without the use of harmful refrigerants that contribute to ozone depletion or global warming. The concentration of LiBr directly affects the absorption capacity and crystallization risk, making precise measurement essential for optimal system performance.

Current technological objectives in this field focus on developing more accurate, reliable, and cost-effective methods for real-time concentration monitoring. Traditional methods such as density measurement using hydrometers or pycnometers, while still in use, lack the precision required for modern high-efficiency systems. Newer approaches including electrical conductivity measurement, refractive index analysis, and ultrasonic velocity determination aim to provide more precise readings with minimal system disruption.

The integration of digital technologies and IoT capabilities represents the next frontier in LiBr concentration measurement. These advancements aim to enable continuous monitoring with automated adjustment capabilities, reducing maintenance requirements and improving overall system efficiency. Additionally, there is growing interest in developing portable and non-invasive measurement techniques that can be deployed without interrupting system operation.

Research objectives in this field include improving measurement accuracy to within ±0.1% concentration, developing sensors capable of withstanding the corrosive nature of LiBr solutions over extended periods, and creating more affordable monitoring systems to expand the accessibility of absorption cooling technology in emerging markets. There is also significant focus on integrating concentration measurement with broader system diagnostics to enable predictive maintenance and optimization.

The ultimate goal of advancements in LiBr concentration measurement technology is to support the wider adoption of absorption refrigeration systems as part of global efforts to reduce energy consumption and greenhouse gas emissions in the HVAC sector. This aligns with international sustainability initiatives and represents a critical component in the transition toward more environmentally responsible cooling technologies.

The accurate measurement of LiBr solution concentration is fundamental to the proper functioning of absorption refrigeration systems, which represent a more environmentally friendly alternative to conventional vapor compression systems. These systems utilize LiBr as an absorbent for water vapor, creating a refrigeration effect without the use of harmful refrigerants that contribute to ozone depletion or global warming. The concentration of LiBr directly affects the absorption capacity and crystallization risk, making precise measurement essential for optimal system performance.

Current technological objectives in this field focus on developing more accurate, reliable, and cost-effective methods for real-time concentration monitoring. Traditional methods such as density measurement using hydrometers or pycnometers, while still in use, lack the precision required for modern high-efficiency systems. Newer approaches including electrical conductivity measurement, refractive index analysis, and ultrasonic velocity determination aim to provide more precise readings with minimal system disruption.

The integration of digital technologies and IoT capabilities represents the next frontier in LiBr concentration measurement. These advancements aim to enable continuous monitoring with automated adjustment capabilities, reducing maintenance requirements and improving overall system efficiency. Additionally, there is growing interest in developing portable and non-invasive measurement techniques that can be deployed without interrupting system operation.

Research objectives in this field include improving measurement accuracy to within ±0.1% concentration, developing sensors capable of withstanding the corrosive nature of LiBr solutions over extended periods, and creating more affordable monitoring systems to expand the accessibility of absorption cooling technology in emerging markets. There is also significant focus on integrating concentration measurement with broader system diagnostics to enable predictive maintenance and optimization.

The ultimate goal of advancements in LiBr concentration measurement technology is to support the wider adoption of absorption refrigeration systems as part of global efforts to reduce energy consumption and greenhouse gas emissions in the HVAC sector. This aligns with international sustainability initiatives and represents a critical component in the transition toward more environmentally responsible cooling technologies.

Market Applications and Demand Analysis for LiBr Solutions

Lithium bromide (LiBr) solutions have established a significant presence across multiple industries due to their unique physicochemical properties. The global market for LiBr solutions is primarily driven by the HVAC industry, where absorption refrigeration and cooling systems represent the largest application segment. This market was valued at approximately 1.8 billion USD in 2022 and is projected to grow at a compound annual growth rate of 5.7% through 2030, reflecting increasing demand for energy-efficient cooling solutions.

The absorption refrigeration sector constitutes nearly 65% of the total LiBr solution market. This dominance stems from the growing need for sustainable cooling technologies in commercial buildings, industrial facilities, and district cooling systems. As energy costs continue to rise and environmental regulations become more stringent, absorption chillers using LiBr solutions offer an attractive alternative to conventional vapor compression systems, particularly in regions with abundant waste heat or solar thermal resources.

Dehumidification applications represent the second-largest market segment, accounting for approximately 18% of global LiBr solution consumption. These systems are increasingly deployed in pharmaceutical manufacturing, food processing, and semiconductor production facilities where precise humidity control is critical. The market for dehumidification applications is expected to grow at 6.3% annually, outpacing the overall market growth rate.

The pharmaceutical and chemical industries utilize LiBr solutions for various separation processes, catalysis, and as reagents in organic synthesis. This segment represents about 12% of the market and is characterized by high-purity requirements and specialized applications. The demand in this sector is closely tied to pharmaceutical manufacturing output and chemical production volumes.

Geographically, Asia-Pacific dominates the global LiBr solution market with a 42% share, driven by rapid industrialization, expanding HVAC infrastructure, and increasing adoption of absorption cooling technologies in China, Japan, and South Korea. North America and Europe follow with market shares of 28% and 23% respectively, where the focus on energy efficiency and carbon footprint reduction is stimulating market growth.

Market analysis indicates that end-users are increasingly demanding precise concentration measurement and control systems for LiBr solutions to optimize system performance and energy efficiency. This trend is creating new opportunities for instrumentation and control system manufacturers who can provide accurate, reliable, and cost-effective concentration measurement technologies tailored to specific applications.

The absorption refrigeration sector constitutes nearly 65% of the total LiBr solution market. This dominance stems from the growing need for sustainable cooling technologies in commercial buildings, industrial facilities, and district cooling systems. As energy costs continue to rise and environmental regulations become more stringent, absorption chillers using LiBr solutions offer an attractive alternative to conventional vapor compression systems, particularly in regions with abundant waste heat or solar thermal resources.

Dehumidification applications represent the second-largest market segment, accounting for approximately 18% of global LiBr solution consumption. These systems are increasingly deployed in pharmaceutical manufacturing, food processing, and semiconductor production facilities where precise humidity control is critical. The market for dehumidification applications is expected to grow at 6.3% annually, outpacing the overall market growth rate.

The pharmaceutical and chemical industries utilize LiBr solutions for various separation processes, catalysis, and as reagents in organic synthesis. This segment represents about 12% of the market and is characterized by high-purity requirements and specialized applications. The demand in this sector is closely tied to pharmaceutical manufacturing output and chemical production volumes.

Geographically, Asia-Pacific dominates the global LiBr solution market with a 42% share, driven by rapid industrialization, expanding HVAC infrastructure, and increasing adoption of absorption cooling technologies in China, Japan, and South Korea. North America and Europe follow with market shares of 28% and 23% respectively, where the focus on energy efficiency and carbon footprint reduction is stimulating market growth.

Market analysis indicates that end-users are increasingly demanding precise concentration measurement and control systems for LiBr solutions to optimize system performance and energy efficiency. This trend is creating new opportunities for instrumentation and control system manufacturers who can provide accurate, reliable, and cost-effective concentration measurement technologies tailored to specific applications.

Current Concentration Calculation Methods and Limitations

The determination of lithium bromide (LiBr) solution concentration is critical for absorption refrigeration systems, heat pumps, and various industrial applications. Currently, several methods are employed to calculate LiBr concentration, each with distinct advantages and limitations.

Density measurement represents one of the most traditional approaches, utilizing hydrometers or digital density meters to correlate solution density with concentration. While this method offers simplicity and relatively low equipment costs, it suffers from temperature sensitivity issues. Density measurements must be precisely temperature-compensated, as even small temperature variations can lead to significant concentration calculation errors. Additionally, contamination in industrial systems can alter density readings, reducing measurement accuracy over time.

Refractive index measurement provides another common approach, employing refractometers to determine concentration based on light refraction properties. This technique offers rapid results and requires minimal sample volumes. However, refractive index measurements are highly sensitive to temperature fluctuations and solution impurities. The presence of corrosion inhibitors or other additives in industrial LiBr solutions can significantly skew readings, necessitating frequent calibration.

Electrical conductivity measurement utilizes the relationship between ionic concentration and electrical conductivity. While this method enables continuous online monitoring, it exhibits pronounced non-linearity at high concentrations (above 50%) and requires complex temperature compensation algorithms. Furthermore, trace metal contamination from system components can dramatically alter conductivity readings, leading to erroneous concentration calculations.

Titration methods, particularly argentometric titration for bromide content determination, provide high accuracy but are labor-intensive and time-consuming. These methods are primarily suitable for laboratory settings rather than field applications or continuous monitoring. The requirement for skilled technicians and specialized reagents further limits widespread implementation.

Ultrasonic velocity measurement represents a newer approach, correlating sound wave propagation speed through the solution with concentration. This non-invasive technique allows for online monitoring without sample extraction. However, the technology remains relatively expensive, requires complex calibration procedures, and can be affected by entrained gases or particulates in industrial systems.

Mass spectrometry and chromatographic methods deliver exceptional accuracy but involve prohibitively expensive equipment and specialized expertise. These approaches are generally restricted to research applications rather than routine industrial monitoring.

A significant limitation across all current methods is the challenge of accurately measuring concentration at extreme temperatures, particularly near crystallization points or at elevated temperatures where solution properties become highly non-linear. Furthermore, most techniques struggle with real-time monitoring capabilities essential for optimizing absorption system performance and preventing crystallization incidents.

Density measurement represents one of the most traditional approaches, utilizing hydrometers or digital density meters to correlate solution density with concentration. While this method offers simplicity and relatively low equipment costs, it suffers from temperature sensitivity issues. Density measurements must be precisely temperature-compensated, as even small temperature variations can lead to significant concentration calculation errors. Additionally, contamination in industrial systems can alter density readings, reducing measurement accuracy over time.

Refractive index measurement provides another common approach, employing refractometers to determine concentration based on light refraction properties. This technique offers rapid results and requires minimal sample volumes. However, refractive index measurements are highly sensitive to temperature fluctuations and solution impurities. The presence of corrosion inhibitors or other additives in industrial LiBr solutions can significantly skew readings, necessitating frequent calibration.

Electrical conductivity measurement utilizes the relationship between ionic concentration and electrical conductivity. While this method enables continuous online monitoring, it exhibits pronounced non-linearity at high concentrations (above 50%) and requires complex temperature compensation algorithms. Furthermore, trace metal contamination from system components can dramatically alter conductivity readings, leading to erroneous concentration calculations.

Titration methods, particularly argentometric titration for bromide content determination, provide high accuracy but are labor-intensive and time-consuming. These methods are primarily suitable for laboratory settings rather than field applications or continuous monitoring. The requirement for skilled technicians and specialized reagents further limits widespread implementation.

Ultrasonic velocity measurement represents a newer approach, correlating sound wave propagation speed through the solution with concentration. This non-invasive technique allows for online monitoring without sample extraction. However, the technology remains relatively expensive, requires complex calibration procedures, and can be affected by entrained gases or particulates in industrial systems.

Mass spectrometry and chromatographic methods deliver exceptional accuracy but involve prohibitively expensive equipment and specialized expertise. These approaches are generally restricted to research applications rather than routine industrial monitoring.

A significant limitation across all current methods is the challenge of accurately measuring concentration at extreme temperatures, particularly near crystallization points or at elevated temperatures where solution properties become highly non-linear. Furthermore, most techniques struggle with real-time monitoring capabilities essential for optimizing absorption system performance and preventing crystallization incidents.

Established Protocols for LiBr Concentration Determination

01 Lithium bromide solution concentration in absorption refrigeration systems

Lithium bromide solutions are widely used as absorbents in absorption refrigeration systems. The concentration of lithium bromide solution is a critical parameter that affects the efficiency and performance of these systems. Optimal concentration ranges typically fall between 45-65% depending on operating conditions. Higher concentrations improve absorption capacity but risk crystallization issues, while lower concentrations may reduce system efficiency.- Lithium bromide solution concentration in absorption refrigeration systems: Lithium bromide solutions are widely used as absorbents in absorption refrigeration systems. The concentration of lithium bromide solution is a critical parameter that affects the efficiency and performance of these systems. Optimal concentration ranges typically fall between 45-65% depending on operating conditions. Proper concentration management prevents crystallization issues while maximizing cooling capacity.

- Methods for measuring and controlling lithium bromide concentration: Various techniques are employed to measure and control the concentration of lithium bromide solutions in industrial applications. These include density measurements, electrical conductivity testing, refractive index analysis, and automated monitoring systems. Maintaining precise concentration control is essential for system efficiency and preventing operational issues such as crystallization or corrosion.

- Lithium bromide solution regeneration and purification: Regeneration and purification processes are essential for maintaining optimal lithium bromide solution concentration in absorption systems. These processes involve removing contaminants, adjusting concentration levels, and restoring the solution's absorption properties. Methods include filtration, distillation, ion exchange, and chemical treatment to remove impurities that can affect solution performance.

- Additives for lithium bromide solutions to enhance performance: Various additives are incorporated into lithium bromide solutions to improve performance characteristics. These additives can prevent crystallization, reduce corrosion, enhance heat transfer properties, and improve solution stability at different concentration levels. Common additives include corrosion inhibitors, surfactants, and stabilizing agents that allow for higher working concentrations without operational issues.

- Equipment design for handling lithium bromide solutions of varying concentrations: Specialized equipment designs accommodate the handling of lithium bromide solutions at different concentration levels. These designs address challenges such as corrosion resistance, crystallization prevention, and efficient heat transfer. Equipment includes specially designed heat exchangers, pumps, valves, and monitoring systems that can operate reliably with high-concentration lithium bromide solutions under various operating conditions.

02 Methods for measuring and controlling lithium bromide concentration

Various techniques are employed to measure and control the concentration of lithium bromide solutions in industrial applications. These include density measurements, electrical conductivity testing, refractive index analysis, and automated monitoring systems. Maintaining precise concentration control is essential for preventing crystallization, optimizing system performance, and ensuring long-term operational stability in absorption chillers and heat pumps.Expand Specific Solutions03 Lithium bromide solution regeneration and purification techniques

Regeneration and purification of lithium bromide solutions are necessary to maintain optimal performance in absorption systems. These processes involve removing contaminants, adjusting concentration levels, and preventing degradation. Techniques include filtration, distillation, ion exchange, and chemical treatment methods that help extend the useful life of the solution and maintain system efficiency.Expand Specific Solutions04 Additives for improving lithium bromide solution properties

Various additives are incorporated into lithium bromide solutions to enhance performance characteristics. These additives can prevent corrosion, inhibit crystallization, improve heat transfer, and increase solution stability. Common additives include corrosion inhibitors, surfactants, and stabilizing agents that allow for higher concentration operation without crystallization issues, thereby improving overall system efficiency.Expand Specific Solutions05 Equipment design for handling lithium bromide solutions

Specialized equipment designs are essential for handling lithium bromide solutions at various concentrations. These designs address challenges related to corrosion resistance, heat transfer efficiency, crystallization prevention, and solution distribution. Equipment components include specialized heat exchangers, pumps, spray nozzles, and monitoring systems that are optimized for the specific properties of lithium bromide solutions at different concentration levels.Expand Specific Solutions

Leading Manufacturers and Research Institutions in LiBr Technology

The lithium bromide solution concentration calculation market is in a growth phase, driven by increasing applications in absorption refrigeration systems and energy storage. The market size is expanding due to rising demand in HVAC, industrial cooling, and pharmaceutical sectors. Technologically, the field shows moderate maturity with established analytical methods, but innovation continues in precision measurement techniques. Key players include Albemarle Corp., which leads in lithium compound development, alongside pharmaceutical companies like Novartis AG, Bayer AG, and Eli Lilly & Co. that require precise concentration calculations for formulations. Academic institutions such as Sichuan University and Hunan University contribute research advancements, while companies like BYD Co. utilize this technology in battery applications.

Albemarle Corp.

Technical Solution: Albemarle Corporation has developed advanced titration-based methods for calculating lithium bromide solution concentration with high precision. Their approach combines traditional volumetric analysis with proprietary automated systems that can detect concentration levels as low as 0.01%. The company employs a dual-verification system where conductivity measurements are cross-referenced with density readings to ensure accuracy across varying temperature conditions. For industrial applications, Albemarle has implemented inline monitoring systems using near-infrared spectroscopy that provides real-time concentration data without interrupting absorption refrigeration cycles. Their technology includes temperature compensation algorithms that automatically adjust readings based on solution temperature, eliminating a common source of measurement error in lithium bromide concentration calculations.

Strengths: High precision measurement capability with error margins below 0.5%; automated systems reduce human error; real-time monitoring capabilities for industrial applications. Weaknesses: Proprietary equipment requirements increase implementation costs; requires periodic calibration against reference standards; more complex than simple density-based methods.

Guangdong Bangpu Recycling Technology Co., Ltd.

Technical Solution: Guangdong Bangpu has pioneered a multi-parameter approach to lithium bromide concentration measurement specifically designed for recycling applications. Their technology combines electrical conductivity measurements with refractive index analysis to determine LiBr concentrations in recovered solutions. The company has developed portable digital refractometers calibrated specifically for lithium bromide that can provide readings with ±0.5% accuracy. For industrial-scale operations, they employ an integrated system that uses density measurements (via precision hydrometers or digital density meters) correlated with temperature readings through proprietary algorithms. This system automatically compensates for the presence of common contaminants found in recovered lithium bromide solutions. Their method includes spectrophotometric verification for solutions where high purity is required, allowing detection of trace impurities that might affect concentration calculations.

Strengths: Specialized for recycling applications where solution purity varies; multi-parameter approach increases accuracy in contaminated solutions; portable options available for field testing. Weaknesses: Requires more sophisticated equipment than basic methods; accuracy decreases with higher levels of solution contamination; calibration needs to be frequently updated for different recovery sources.

Key Scientific Principles Behind LiBr Concentration Measurement

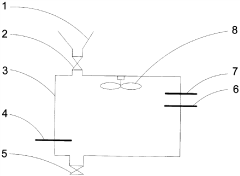

Lithium bromide aqueous solution concentration measuring device

PatentInactiveCN218036715U

Innovation

- A device including a liquid inlet tank, a liquid inlet valve, a container, a solution thermometer, a liquid drain valve, an air thermometer, an air hygrometer and a fan is designed. The fan blows air to bring the surface of the lithium bromide aqueous solution into contact with the air hygrometer and thermometer. Platinum resistive and capacitive sensors measure the concentration of aqueous lithium bromide solutions.

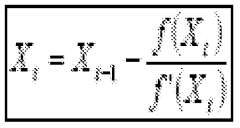

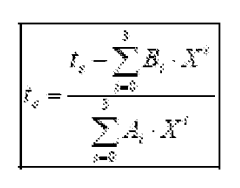

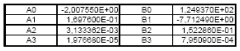

Method for calculating and adjusting the concentration of absorbing fluid in an absorption air conditioning device, and absorption air conditioning device for implementing said method

PatentWO2009044034A1

Innovation

- A method that calculates the concentration of absorbent fluid by measuring refrigerant vapor pressure and solution temperature, using a formula to determine concentration and adjusting pressure drop in the pipe connecting the desorber to the condenser with a butterfly valve to manage crystallization risk, thereby controlling desorption and condensation processes.

Environmental Impact and Safety Considerations of LiBr Solutions

The environmental impact of lithium bromide (LiBr) solutions extends across their entire lifecycle, from production to disposal. During manufacturing, significant energy consumption and resource extraction contribute to carbon emissions and habitat disruption. The mining of lithium and bromine compounds often involves land degradation, water consumption, and potential contamination of local ecosystems, particularly in sensitive areas where these elements are extracted.

When LiBr solutions are used in absorption refrigeration systems, their environmental footprint depends largely on operational efficiency and containment integrity. Properly maintained systems with accurate concentration calculations minimize energy consumption and reduce the risk of leaks. However, improper disposal or accidental releases can lead to soil and water contamination, as LiBr is highly water-soluble and can persist in aquatic environments.

From a safety perspective, LiBr solutions present several significant hazards that require careful management. The corrosive nature of these solutions, particularly at higher concentrations, poses risks to equipment integrity and human health. Direct contact can cause severe skin irritation, eye damage, and respiratory issues if vapors are inhaled. Workers handling these solutions must employ appropriate personal protective equipment, including chemical-resistant gloves, eye protection, and respiratory safeguards when necessary.

Accurate concentration calculation is directly linked to safety management, as improper concentrations can lead to system inefficiencies, equipment damage, or increased accident risk. Facilities using LiBr systems should implement comprehensive safety protocols, including regular concentration monitoring, leak detection systems, and emergency response procedures for spills or exposure incidents.

Regulatory frameworks governing LiBr solution handling vary globally but generally include requirements for proper storage, transportation, and disposal. Many jurisdictions classify concentrated LiBr solutions as hazardous materials, necessitating specialized handling procedures and documentation. Companies must remain compliant with these regulations while implementing best practices that often exceed minimum requirements.

Future sustainability considerations for LiBr systems include developing closed-loop recycling processes, improving concentration monitoring technologies to prevent waste, and researching alternative absorption pairs with reduced environmental and safety impacts while maintaining thermal efficiency.

When LiBr solutions are used in absorption refrigeration systems, their environmental footprint depends largely on operational efficiency and containment integrity. Properly maintained systems with accurate concentration calculations minimize energy consumption and reduce the risk of leaks. However, improper disposal or accidental releases can lead to soil and water contamination, as LiBr is highly water-soluble and can persist in aquatic environments.

From a safety perspective, LiBr solutions present several significant hazards that require careful management. The corrosive nature of these solutions, particularly at higher concentrations, poses risks to equipment integrity and human health. Direct contact can cause severe skin irritation, eye damage, and respiratory issues if vapors are inhaled. Workers handling these solutions must employ appropriate personal protective equipment, including chemical-resistant gloves, eye protection, and respiratory safeguards when necessary.

Accurate concentration calculation is directly linked to safety management, as improper concentrations can lead to system inefficiencies, equipment damage, or increased accident risk. Facilities using LiBr systems should implement comprehensive safety protocols, including regular concentration monitoring, leak detection systems, and emergency response procedures for spills or exposure incidents.

Regulatory frameworks governing LiBr solution handling vary globally but generally include requirements for proper storage, transportation, and disposal. Many jurisdictions classify concentrated LiBr solutions as hazardous materials, necessitating specialized handling procedures and documentation. Companies must remain compliant with these regulations while implementing best practices that often exceed minimum requirements.

Future sustainability considerations for LiBr systems include developing closed-loop recycling processes, improving concentration monitoring technologies to prevent waste, and researching alternative absorption pairs with reduced environmental and safety impacts while maintaining thermal efficiency.

Standardization and Quality Control in LiBr Concentration Testing

Standardization of lithium bromide (LiBr) concentration testing procedures is essential for ensuring accurate and reliable measurements across different applications, particularly in absorption refrigeration systems. The establishment of industry-wide standards has significantly improved the consistency of concentration calculations and quality control processes. Organizations such as ASHRAE (American Society of Heating, Refrigerating and Air-Conditioning Engineers) and ASTM International have developed comprehensive guidelines that specify acceptable testing methodologies and equipment calibration requirements.

Quality control in LiBr concentration testing involves multiple layers of verification to minimize measurement errors. Regular calibration of testing equipment using certified reference materials is fundamental to maintaining accuracy. These reference materials, typically prepared by national metrology institutes, provide known concentration values against which instruments can be calibrated. The frequency of calibration should follow manufacturer recommendations, generally ranging from monthly to quarterly depending on usage intensity.

Statistical process control (SPC) techniques have been increasingly implemented in LiBr concentration testing environments. Control charts tracking measurement variations over time help identify systematic errors and drift in testing equipment. Establishing upper and lower control limits based on historical data enables technicians to quickly recognize when a process is moving out of specification, allowing for prompt corrective action.

Proficiency testing programs, where multiple laboratories analyze identical samples and compare results, have become standard practice in industries relying on precise LiBr concentration measurements. These interlaboratory comparisons help identify methodological inconsistencies and provide valuable feedback for continuous improvement. Participation in such programs is often required for laboratory accreditation under ISO/IEC 17025 standards.

Documentation practices play a crucial role in quality control systems for LiBr concentration testing. Comprehensive records of testing procedures, equipment maintenance, calibration history, and measurement uncertainties should be maintained. Modern laboratory information management systems (LIMS) facilitate this documentation process while enabling trend analysis and automated flagging of anomalous results.

Training and certification of personnel conducting LiBr concentration tests represent another critical aspect of quality control. Technicians should demonstrate proficiency in both theoretical understanding of measurement principles and practical execution of testing protocols. Regular competency assessments help ensure that human factors do not compromise measurement quality, particularly when manual titration methods are employed alongside automated systems.

Quality control in LiBr concentration testing involves multiple layers of verification to minimize measurement errors. Regular calibration of testing equipment using certified reference materials is fundamental to maintaining accuracy. These reference materials, typically prepared by national metrology institutes, provide known concentration values against which instruments can be calibrated. The frequency of calibration should follow manufacturer recommendations, generally ranging from monthly to quarterly depending on usage intensity.

Statistical process control (SPC) techniques have been increasingly implemented in LiBr concentration testing environments. Control charts tracking measurement variations over time help identify systematic errors and drift in testing equipment. Establishing upper and lower control limits based on historical data enables technicians to quickly recognize when a process is moving out of specification, allowing for prompt corrective action.

Proficiency testing programs, where multiple laboratories analyze identical samples and compare results, have become standard practice in industries relying on precise LiBr concentration measurements. These interlaboratory comparisons help identify methodological inconsistencies and provide valuable feedback for continuous improvement. Participation in such programs is often required for laboratory accreditation under ISO/IEC 17025 standards.

Documentation practices play a crucial role in quality control systems for LiBr concentration testing. Comprehensive records of testing procedures, equipment maintenance, calibration history, and measurement uncertainties should be maintained. Modern laboratory information management systems (LIMS) facilitate this documentation process while enabling trend analysis and automated flagging of anomalous results.

Training and certification of personnel conducting LiBr concentration tests represent another critical aspect of quality control. Technicians should demonstrate proficiency in both theoretical understanding of measurement principles and practical execution of testing protocols. Regular competency assessments help ensure that human factors do not compromise measurement quality, particularly when manual titration methods are employed alongside automated systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!