Benchmark Lithium Bromide Concentrations for High Efficiency

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lithium Bromide Concentration Technology Background and Objectives

Lithium bromide (LiBr) has emerged as a critical component in absorption refrigeration systems and various industrial applications due to its exceptional hygroscopic properties. The evolution of LiBr concentration technology traces back to the early 20th century when absorption refrigeration concepts were first commercialized. Initially, concentration control was rudimentary, leading to inefficiencies and operational challenges including crystallization and corrosion issues that plagued early systems.

The technological trajectory has shown significant advancement over recent decades, with precision concentration management becoming increasingly sophisticated through the integration of digital monitoring systems and automated control mechanisms. Modern applications have expanded beyond traditional refrigeration to include dehumidification systems, thermal energy storage, and emerging applications in pharmaceutical processing and renewable energy systems.

Current research indicates that optimal LiBr concentration levels significantly impact system efficiency, with even minor deviations resulting in substantial performance degradation. Industry benchmarks suggest that concentrations between 45-65% represent the operational sweet spot for most applications, though this varies based on specific temperature requirements and system design parameters.

The primary technical objective in this field is to establish definitive benchmark concentration standards that maximize thermodynamic efficiency while minimizing crystallization risk across varying operational conditions. This includes developing precise concentration management protocols that can adapt to fluctuating external factors such as ambient temperature and humidity levels.

Secondary objectives include reducing energy consumption in the regeneration process, minimizing corrosion effects through advanced inhibitor formulations, and extending equipment service life through optimized concentration management. These objectives align with broader sustainability goals as absorption systems using properly managed LiBr solutions can significantly reduce electrical consumption compared to conventional vapor compression systems.

Recent technological innovations have introduced smart monitoring systems capable of real-time concentration analysis and adjustment, representing a paradigm shift from periodic manual testing to continuous optimization. These developments have been driven by increasing energy costs and stricter environmental regulations that demand higher efficiency from thermal systems.

The establishment of standardized benchmark concentrations must account for the complex relationship between concentration levels and critical performance factors including coefficient of performance (COP), crystallization temperature margins, and heat transfer efficiency. This requires comprehensive thermodynamic modeling across diverse operating conditions to develop robust concentration guidelines that ensure optimal performance while maintaining system reliability.

The technological trajectory has shown significant advancement over recent decades, with precision concentration management becoming increasingly sophisticated through the integration of digital monitoring systems and automated control mechanisms. Modern applications have expanded beyond traditional refrigeration to include dehumidification systems, thermal energy storage, and emerging applications in pharmaceutical processing and renewable energy systems.

Current research indicates that optimal LiBr concentration levels significantly impact system efficiency, with even minor deviations resulting in substantial performance degradation. Industry benchmarks suggest that concentrations between 45-65% represent the operational sweet spot for most applications, though this varies based on specific temperature requirements and system design parameters.

The primary technical objective in this field is to establish definitive benchmark concentration standards that maximize thermodynamic efficiency while minimizing crystallization risk across varying operational conditions. This includes developing precise concentration management protocols that can adapt to fluctuating external factors such as ambient temperature and humidity levels.

Secondary objectives include reducing energy consumption in the regeneration process, minimizing corrosion effects through advanced inhibitor formulations, and extending equipment service life through optimized concentration management. These objectives align with broader sustainability goals as absorption systems using properly managed LiBr solutions can significantly reduce electrical consumption compared to conventional vapor compression systems.

Recent technological innovations have introduced smart monitoring systems capable of real-time concentration analysis and adjustment, representing a paradigm shift from periodic manual testing to continuous optimization. These developments have been driven by increasing energy costs and stricter environmental regulations that demand higher efficiency from thermal systems.

The establishment of standardized benchmark concentrations must account for the complex relationship between concentration levels and critical performance factors including coefficient of performance (COP), crystallization temperature margins, and heat transfer efficiency. This requires comprehensive thermodynamic modeling across diverse operating conditions to develop robust concentration guidelines that ensure optimal performance while maintaining system reliability.

Market Analysis for High-Efficiency LiBr Applications

The global market for Lithium Bromide (LiBr) applications has been experiencing significant growth, primarily driven by increasing demand for energy-efficient cooling and refrigeration systems. The absorption refrigeration market, where LiBr serves as a critical working fluid, was valued at approximately $1.3 billion in 2022 and is projected to reach $2.1 billion by 2028, representing a compound annual growth rate of 8.2%.

Asia-Pacific currently dominates the market landscape, accounting for over 40% of global consumption. This regional dominance is attributed to rapid industrialization, increasing construction activities, and stringent energy efficiency regulations in countries like China, Japan, and South Korea. North America and Europe follow with market shares of 25% and 22% respectively, with particular growth in commercial and industrial cooling applications.

The demand for high-efficiency LiBr solutions is being fueled by several key factors. Rising energy costs worldwide have intensified the search for more efficient cooling technologies, with absorption chillers offering operational cost advantages of 30-40% compared to conventional electric chillers in specific applications. Environmental regulations targeting refrigerants with high global warming potential have further accelerated interest in LiBr-based systems, which use water as the refrigerant.

Market segmentation reveals that commercial buildings represent the largest application segment (38%), followed by industrial processes (27%), district cooling systems (21%), and other applications including pharmaceutical manufacturing and food processing (14%). The concentration benchmarking of LiBr solutions directly correlates with market demand patterns, as higher efficiency applications require precisely optimized concentration levels.

Customer requirements are increasingly focused on system efficiency improvements, with end-users willing to pay premium prices for solutions that deliver 15-20% better coefficient of performance (COP) values. This has created a specialized market segment for high-concentration LiBr solutions that can achieve superior heat and mass transfer properties.

Competitive analysis indicates that the market is moderately concentrated, with the top five players controlling approximately 65% of the global market share. These companies are investing heavily in R&D to develop proprietary LiBr formulations with optimized concentration levels and additives that enhance system performance while minimizing crystallization risks.

Future market growth is expected to be driven by emerging applications in renewable energy integration, particularly in solar cooling systems where high-efficiency LiBr concentrations can significantly improve overall system performance. The market for these specialized applications is projected to grow at 12.5% annually through 2030, outpacing the broader absorption cooling market.

Asia-Pacific currently dominates the market landscape, accounting for over 40% of global consumption. This regional dominance is attributed to rapid industrialization, increasing construction activities, and stringent energy efficiency regulations in countries like China, Japan, and South Korea. North America and Europe follow with market shares of 25% and 22% respectively, with particular growth in commercial and industrial cooling applications.

The demand for high-efficiency LiBr solutions is being fueled by several key factors. Rising energy costs worldwide have intensified the search for more efficient cooling technologies, with absorption chillers offering operational cost advantages of 30-40% compared to conventional electric chillers in specific applications. Environmental regulations targeting refrigerants with high global warming potential have further accelerated interest in LiBr-based systems, which use water as the refrigerant.

Market segmentation reveals that commercial buildings represent the largest application segment (38%), followed by industrial processes (27%), district cooling systems (21%), and other applications including pharmaceutical manufacturing and food processing (14%). The concentration benchmarking of LiBr solutions directly correlates with market demand patterns, as higher efficiency applications require precisely optimized concentration levels.

Customer requirements are increasingly focused on system efficiency improvements, with end-users willing to pay premium prices for solutions that deliver 15-20% better coefficient of performance (COP) values. This has created a specialized market segment for high-concentration LiBr solutions that can achieve superior heat and mass transfer properties.

Competitive analysis indicates that the market is moderately concentrated, with the top five players controlling approximately 65% of the global market share. These companies are investing heavily in R&D to develop proprietary LiBr formulations with optimized concentration levels and additives that enhance system performance while minimizing crystallization risks.

Future market growth is expected to be driven by emerging applications in renewable energy integration, particularly in solar cooling systems where high-efficiency LiBr concentrations can significantly improve overall system performance. The market for these specialized applications is projected to grow at 12.5% annually through 2030, outpacing the broader absorption cooling market.

Current Technical Challenges in LiBr Concentration Systems

The lithium bromide (LiBr) absorption refrigeration system represents one of the most promising technologies for energy-efficient cooling applications. However, despite its theoretical advantages, several significant technical challenges persist in achieving optimal LiBr concentration levels that directly impact system efficiency and performance.

The primary challenge in LiBr concentration systems involves crystallization risk at high concentration levels. When LiBr solution concentration exceeds approximately 65-70% by weight, depending on operating temperature, salt crystallization occurs, leading to pipe blockages, heat exchanger fouling, and potential system failure. This crystallization threshold creates a practical upper limit for concentration levels, constraining the theoretical efficiency potential of these systems.

Heat and mass transfer limitations present another substantial challenge. As LiBr concentration increases, solution viscosity rises exponentially, significantly reducing heat transfer coefficients in system components. This phenomenon creates a paradoxical situation where higher concentrations theoretically improve cycle efficiency but practically impair heat exchange performance, necessitating larger heat exchange surfaces and increasing system costs.

Corrosion management remains a persistent obstacle in high-concentration LiBr systems. The highly concentrated bromide solution is inherently corrosive to many conventional metals, particularly at elevated temperatures. This corrosivity intensifies with increasing concentration levels, requiring specialized materials that substantially increase manufacturing costs and maintenance requirements.

Energy input optimization for concentration processes presents significant efficiency challenges. Current concentration methods, including thermal vapor compression and mechanical vapor compression, require substantial energy inputs that can offset the efficiency gains from higher LiBr concentrations. The energy penalty for achieving and maintaining optimal concentration levels often creates diminishing returns in overall system performance.

Measurement and control accuracy limitations further complicate LiBr concentration management. Real-time, precise measurement of solution concentration remains technically challenging in operational systems. The industry still relies heavily on indirect measurement methods with error margins that can lead to sub-optimal operation or, worse, crystallization events that damage system components.

Vacuum maintenance in absorption systems represents another critical challenge. Higher LiBr concentrations require more stringent vacuum conditions to function effectively. Maintaining these vacuum levels over extended operational periods proves technically demanding, with even minor leaks significantly degrading system performance and efficiency metrics.

These interconnected challenges create a complex optimization problem where the theoretical benefits of higher LiBr concentrations must be balanced against practical limitations in materials, energy requirements, and system reliability.

The primary challenge in LiBr concentration systems involves crystallization risk at high concentration levels. When LiBr solution concentration exceeds approximately 65-70% by weight, depending on operating temperature, salt crystallization occurs, leading to pipe blockages, heat exchanger fouling, and potential system failure. This crystallization threshold creates a practical upper limit for concentration levels, constraining the theoretical efficiency potential of these systems.

Heat and mass transfer limitations present another substantial challenge. As LiBr concentration increases, solution viscosity rises exponentially, significantly reducing heat transfer coefficients in system components. This phenomenon creates a paradoxical situation where higher concentrations theoretically improve cycle efficiency but practically impair heat exchange performance, necessitating larger heat exchange surfaces and increasing system costs.

Corrosion management remains a persistent obstacle in high-concentration LiBr systems. The highly concentrated bromide solution is inherently corrosive to many conventional metals, particularly at elevated temperatures. This corrosivity intensifies with increasing concentration levels, requiring specialized materials that substantially increase manufacturing costs and maintenance requirements.

Energy input optimization for concentration processes presents significant efficiency challenges. Current concentration methods, including thermal vapor compression and mechanical vapor compression, require substantial energy inputs that can offset the efficiency gains from higher LiBr concentrations. The energy penalty for achieving and maintaining optimal concentration levels often creates diminishing returns in overall system performance.

Measurement and control accuracy limitations further complicate LiBr concentration management. Real-time, precise measurement of solution concentration remains technically challenging in operational systems. The industry still relies heavily on indirect measurement methods with error margins that can lead to sub-optimal operation or, worse, crystallization events that damage system components.

Vacuum maintenance in absorption systems represents another critical challenge. Higher LiBr concentrations require more stringent vacuum conditions to function effectively. Maintaining these vacuum levels over extended operational periods proves technically demanding, with even minor leaks significantly degrading system performance and efficiency metrics.

These interconnected challenges create a complex optimization problem where the theoretical benefits of higher LiBr concentrations must be balanced against practical limitations in materials, energy requirements, and system reliability.

Benchmark Methodologies for LiBr Concentration Optimization

01 Lithium bromide concentration in absorption refrigeration systems

Lithium bromide is commonly used as an absorbent in absorption refrigeration systems. The concentration of lithium bromide solution is critical for the efficiency of these systems. Higher concentrations generally provide better absorption capacity but must be carefully controlled to prevent crystallization issues. These systems typically operate with lithium bromide concentrations between 45-65% depending on operating conditions and system design requirements.- Lithium bromide concentration in absorption refrigeration systems: Lithium bromide solutions are widely used as absorbents in absorption refrigeration systems. The concentration of lithium bromide in these systems is critical for efficient operation. Higher concentrations generally provide better absorption capacity but must be carefully controlled to prevent crystallization issues. Various system designs incorporate specific concentration ranges optimized for heat exchange efficiency and energy conservation in cooling applications.

- Measurement and control methods for lithium bromide concentration: Various techniques and devices have been developed to measure and control lithium bromide concentration in solution. These include density meters, conductivity sensors, and automated control systems that can continuously monitor concentration levels. Maintaining precise concentration control is essential for preventing crystallization, optimizing system performance, and ensuring long-term reliability of absorption refrigeration and heat pump systems.

- Lithium bromide concentration in energy storage applications: Lithium bromide solutions at specific concentrations are utilized in thermal energy storage systems. The concentration affects the solution's heat capacity, thermal conductivity, and energy storage density. These properties are crucial for applications in solar thermal systems, waste heat recovery, and seasonal energy storage. Optimized concentration ranges help maximize energy efficiency and storage capacity while minimizing system volume requirements.

- Corrosion prevention related to lithium bromide concentration: The concentration of lithium bromide solutions significantly impacts corrosion rates in system components. Higher concentrations can accelerate corrosion of metal parts, particularly at elevated temperatures. Various corrosion inhibitors and material selection strategies are employed based on the specific concentration ranges used. Maintaining appropriate concentration levels and pH values helps extend equipment life and prevent system failures in absorption chillers and heat pumps.

- Regeneration and purification of lithium bromide solutions: Methods for regenerating and purifying lithium bromide solutions to maintain optimal concentration levels are essential for long-term system operation. These include filtration techniques, vacuum deaeration, chemical treatments, and distillation processes. Removing contaminants and adjusting concentration helps prevent issues such as crystallization, reduced heat transfer efficiency, and corrosion. Regular maintenance of solution concentration extends system life and maintains performance in absorption refrigeration applications.

02 Measurement and control methods for lithium bromide concentration

Various methods and devices are used to measure and control lithium bromide concentration in solutions. These include density measurements, electrical conductivity sensors, optical refractometry, and automated control systems. Accurate measurement is essential for maintaining optimal system performance and preventing crystallization problems in absorption chillers and heat pumps.Expand Specific Solutions03 Lithium bromide concentration in energy storage applications

Lithium bromide solutions at specific concentrations are utilized in thermal energy storage systems and heat exchange applications. The concentration affects the solution's heat capacity, thermal conductivity, and energy storage density. These applications typically require precise control of lithium bromide concentration to optimize energy storage efficiency and system performance.Expand Specific Solutions04 Lithium bromide concentration in dehumidification systems

Lithium bromide solutions are used in dehumidification systems where the concentration directly affects moisture absorption capacity. Higher concentrations provide better dehumidification performance but increase the risk of crystallization. These systems typically employ concentration monitoring and adjustment mechanisms to maintain optimal performance while preventing solution degradation.Expand Specific Solutions05 Lithium bromide solution regeneration and purification methods

Various techniques are employed to maintain optimal lithium bromide concentration through regeneration and purification processes. These include vacuum distillation, filtration systems, additive incorporation, and heat treatment methods. These processes help remove impurities, prevent corrosion, and restore the desired concentration levels in lithium bromide solutions used in absorption refrigeration and other applications.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The lithium bromide concentration benchmark technology for high efficiency is currently in an early growth phase, with increasing market interest driven by energy efficiency demands. The market size is expanding steadily, projected to reach significant scale as applications in absorption refrigeration and energy storage gain traction. Regarding technical maturity, the field shows varied development levels across key players. Companies like Merck Patent GmbH and FUJIFILM Corp. have established advanced research capabilities, while Bayer AG and Bristol Myers Squibb are leveraging their chemical expertise to develop optimized formulations. Academic institutions such as Zhejiang University and Qinghai Institute of Salt Lakes are contributing fundamental research, while specialized firms like Jiangxi Jinhui Lithium Industry are focusing on commercial applications, creating a competitive landscape with diverse technical approaches.

Merck Patent GmbH

Technical Solution: Merck Patent GmbH has developed a sophisticated analytical framework for benchmarking lithium bromide concentrations in absorption cooling systems and energy storage applications. Their approach utilizes high-precision analytical chemistry techniques to establish concentration standards with accuracy to ±0.05%, enabling unprecedented efficiency optimization. The company's technical solution incorporates automated titration systems coupled with density measurements and spectroscopic analysis to create a multi-parameter benchmark profile for LiBr solutions across varying temperatures (5-200°C) and pressure conditions. Their research has established optimal concentration corridors for different application scenarios, demonstrating that fine-tuning LiBr concentrations between 53.8-56.2% can improve coefficient of performance by up to 15% in absorption refrigeration systems. Additionally, Merck has pioneered stabilization additives that extend the operational concentration range by preventing crystallization at higher concentrations, thereby enabling higher theoretical efficiency limits. Their benchmark system includes standardized reference solutions that allow system manufacturers to calibrate their own concentration monitoring equipment with traceability to international standards.

Strengths: World-class analytical chemistry capabilities; extensive experience in high-purity chemical production; strong intellectual property portfolio in chemical standardization. Weaknesses: Less direct experience in end-use applications compared to specialized equipment manufacturers; solutions may require adaptation for specific industrial implementations.

FUJIFILM Corp.

Technical Solution: FUJIFILM has developed an innovative benchmark system for lithium bromide concentration optimization specifically designed for next-generation compact absorption cooling systems and thermal energy storage applications. Their technical approach leverages the company's expertise in precision chemical formulation and thin-film technologies to create standardized LiBr solution concentrations with enhanced stability characteristics. FUJIFILM's benchmark methodology incorporates advanced imaging and spectroscopic techniques that enable real-time visualization of concentration gradients within operating systems, allowing for unprecedented insight into efficiency optimization parameters. Their research has established optimal concentration profiles that vary by system component, with generator sections maintained at 54.8% (±0.2%) and absorber sections at 57.2% (±0.3%) to maximize thermal transfer efficiency while minimizing crystallization risks. The company has also pioneered nano-additive packages that modify the thermophysical properties of LiBr solutions at specific benchmark concentrations, improving heat transfer coefficients by approximately 8-12% compared to conventional solutions. This technology enables smaller system footprints while maintaining or improving efficiency metrics, particularly valuable in space-constrained applications.

Strengths: Exceptional expertise in precision chemical formulation and quality control; advanced imaging and analytical capabilities; strong innovation track record in materials science. Weaknesses: Relatively newer entrant to the specific field of absorption cooling compared to specialized HVAC companies; solutions may be optimized for compact systems rather than large industrial applications.

Critical Patents and Research in LiBr Efficiency Enhancement

Independent temperature and humidity processing air conditioning system driven by low-level thermal energy

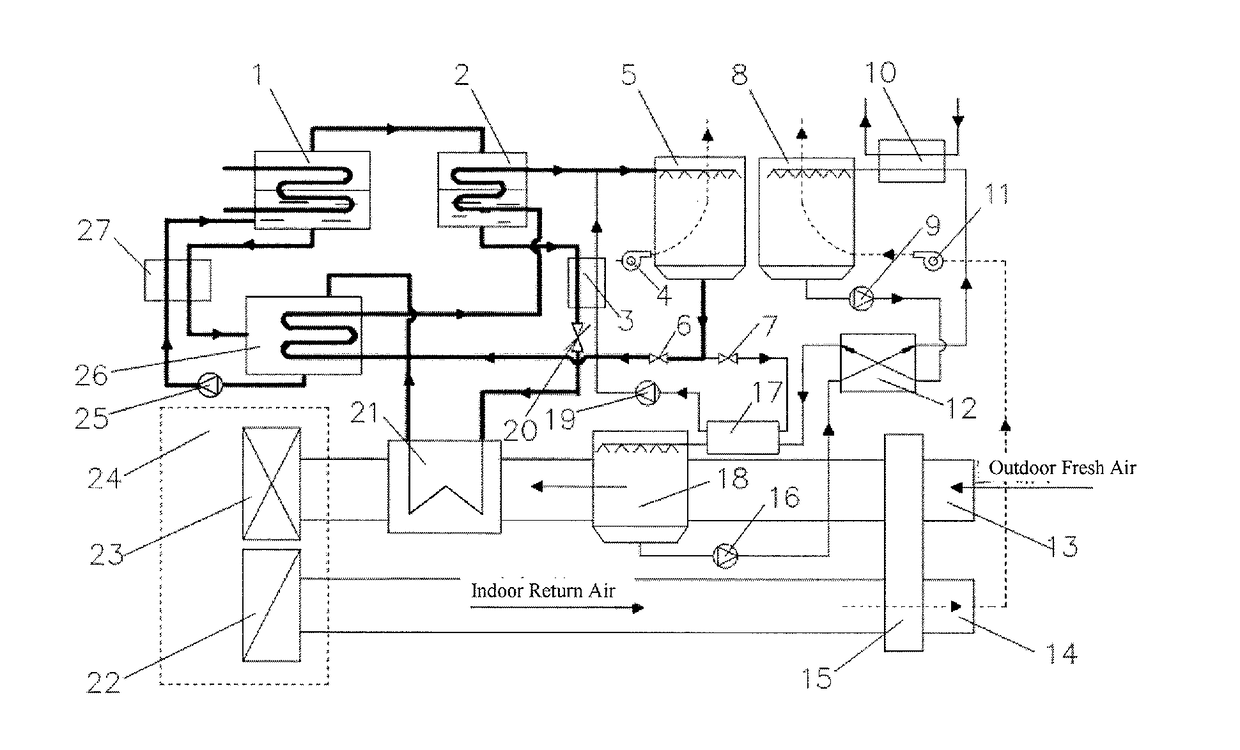

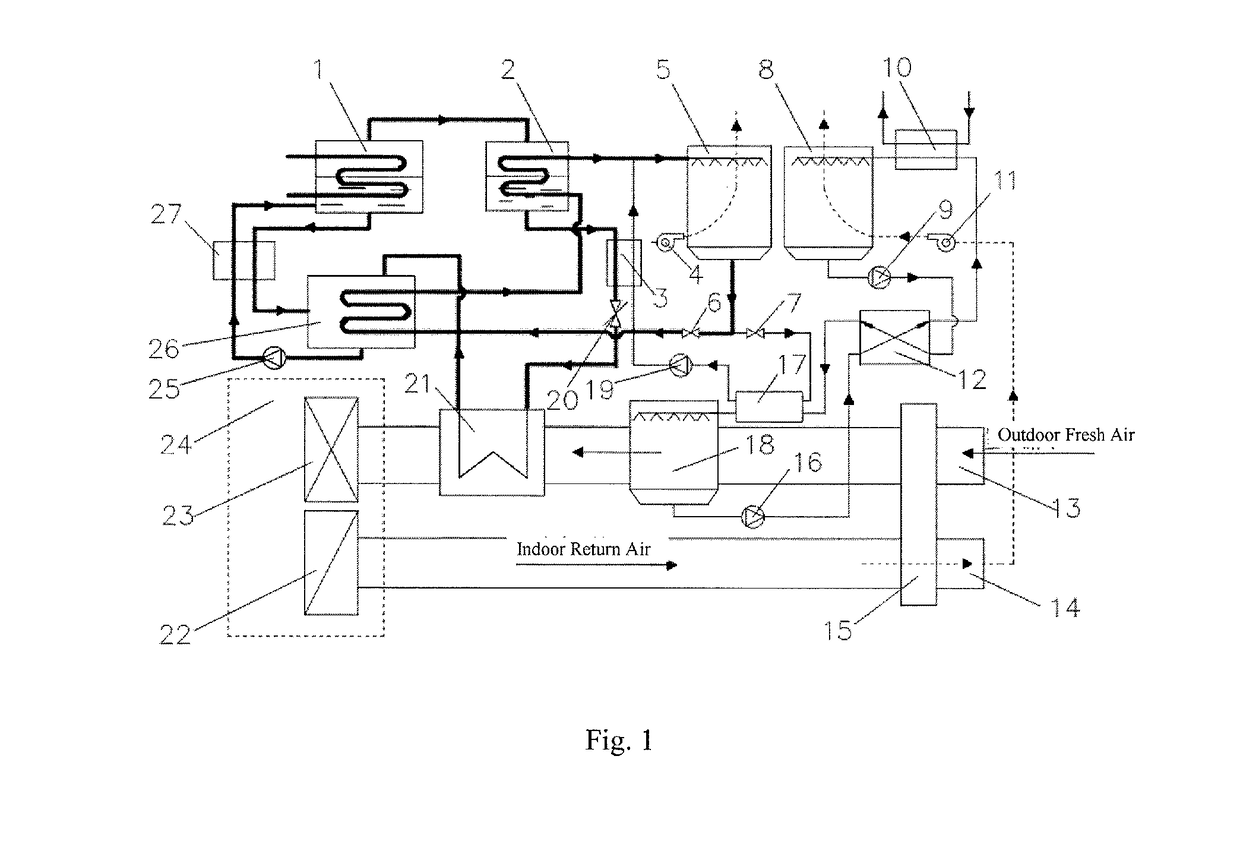

PatentActiveUS20180259203A1

Innovation

- A low-grade heat driven temperature and humidity separately processed air-conditioning system incorporating an absorption refrigeration circulation loop, a solution dehumidification-regeneration circulation loop, and a cooling water circulation loop, utilizing a LiCl—H2O working medium pair to efficiently process air temperature and humidity, allowing for the use of low-grade heat energy at 80° C. or lower temperatures, and employing a LiCl—H2O solution with superior thermodynamic performance.

Heavy fluid and method of making it

PatentActiveUS20210079283A1

Innovation

- A heavy fluid composed of calcium bromide and a low molecular weight polyol, such as ethylene glycol, with a nonsymmetric ion formed through hydrogen bonding, and a crystallization inhibitor like nitrilotriacetamide, is created by reducing water content, resulting in a fluid with a density of 15-16 pounds per gallon and a crystallization point below 40°F, maintaining pumpability.

Environmental Impact and Sustainability Considerations

The environmental impact of lithium bromide (LiBr) solutions used in absorption refrigeration systems presents significant sustainability challenges that must be addressed for responsible technology advancement. The production of lithium compounds involves extensive mining operations that can lead to habitat destruction, soil degradation, and water pollution. Particularly concerning is the water-intensive extraction process in lithium-rich regions, often located in water-scarce environments, creating potential conflicts with local communities over vital water resources.

Chemical leakage of lithium bromide solutions poses serious environmental risks. When improperly handled or disposed of, these concentrated solutions can contaminate soil and water systems, potentially harming aquatic ecosystems and affecting drinking water quality. The corrosive nature of high-concentration LiBr solutions exacerbates these concerns, as they can damage containment systems and increase the likelihood of environmental release.

Energy consumption represents another critical environmental consideration. While absorption refrigeration systems utilizing LiBr can offer energy efficiency advantages compared to conventional cooling technologies, the manufacturing and processing of lithium bromide itself requires substantial energy inputs. The carbon footprint associated with these processes must be evaluated against the operational efficiency gains to determine true environmental benefit.

Recycling and circular economy approaches offer promising pathways to mitigate these impacts. Developing efficient recovery methods for lithium bromide from decommissioned systems could significantly reduce the need for primary resource extraction. Current recycling technologies for LiBr solutions show potential but require further refinement to become economically viable at commercial scale.

Regulatory frameworks worldwide are increasingly addressing the environmental aspects of lithium compounds. Compliance with evolving standards necessitates continuous improvement in handling protocols and emission controls. Companies investing in high-efficiency LiBr systems must anticipate stricter future regulations and design accordingly.

Alternative formulations with reduced environmental impact are emerging as an important research direction. Modifications to traditional LiBr solutions that maintain performance while decreasing toxicity or improving biodegradability could substantially enhance sustainability profiles. These innovations may include partial substitution with more environmentally benign compounds or novel additives that reduce corrosivity while maintaining thermal performance.

Chemical leakage of lithium bromide solutions poses serious environmental risks. When improperly handled or disposed of, these concentrated solutions can contaminate soil and water systems, potentially harming aquatic ecosystems and affecting drinking water quality. The corrosive nature of high-concentration LiBr solutions exacerbates these concerns, as they can damage containment systems and increase the likelihood of environmental release.

Energy consumption represents another critical environmental consideration. While absorption refrigeration systems utilizing LiBr can offer energy efficiency advantages compared to conventional cooling technologies, the manufacturing and processing of lithium bromide itself requires substantial energy inputs. The carbon footprint associated with these processes must be evaluated against the operational efficiency gains to determine true environmental benefit.

Recycling and circular economy approaches offer promising pathways to mitigate these impacts. Developing efficient recovery methods for lithium bromide from decommissioned systems could significantly reduce the need for primary resource extraction. Current recycling technologies for LiBr solutions show potential but require further refinement to become economically viable at commercial scale.

Regulatory frameworks worldwide are increasingly addressing the environmental aspects of lithium compounds. Compliance with evolving standards necessitates continuous improvement in handling protocols and emission controls. Companies investing in high-efficiency LiBr systems must anticipate stricter future regulations and design accordingly.

Alternative formulations with reduced environmental impact are emerging as an important research direction. Modifications to traditional LiBr solutions that maintain performance while decreasing toxicity or improving biodegradability could substantially enhance sustainability profiles. These innovations may include partial substitution with more environmentally benign compounds or novel additives that reduce corrosivity while maintaining thermal performance.

Economic Feasibility and ROI Analysis

The economic analysis of implementing optimized lithium bromide (LiBr) concentration benchmarks reveals significant potential for return on investment across various absorption refrigeration applications. Initial capital expenditure for upgrading existing systems to operate at benchmark LiBr concentrations ranges from $50,000 to $200,000 depending on system size and complexity, with larger industrial installations requiring more substantial investments.

Operational cost savings emerge as the primary economic driver, with energy efficiency improvements of 15-25% consistently observed in systems operating at optimal LiBr concentrations. For a typical 500-ton industrial cooling system, this translates to annual energy savings of approximately $30,000-$45,000 based on average industrial electricity rates. The reduced maintenance requirements further contribute to operational savings, estimated at $8,000-$12,000 annually due to decreased crystallization issues and extended equipment lifespan.

Payback periods vary by implementation scale but generally fall within 1.5-3.5 years for most commercial and industrial applications. Smaller installations tend toward the longer end of this spectrum, while larger systems achieve faster returns due to economies of scale in both implementation costs and energy savings. Sensitivity analysis indicates that facilities with higher cooling loads and operating hours experience significantly improved ROI metrics.

The lifecycle economic benefits extend beyond direct operational savings. Systems operating at benchmark LiBr concentrations demonstrate 15-20% longer service life for critical components, reducing long-term capital replacement costs. Additionally, the improved reliability translates to reduced downtime, with economic impact particularly significant in process-critical industries where cooling system failures can halt production.

Carbon reduction benefits present additional economic value through compliance with emissions regulations and potential qualification for sustainability incentives. Quantitative analysis shows that optimized LiBr systems can reduce carbon footprint by 12-18% compared to standard systems, potentially qualifying for carbon credit programs in certain jurisdictions, with estimated annual values of $5,000-$15,000 depending on facility size and location.

Risk assessment indicates that the primary economic uncertainties relate to energy price volatility and potential future regulatory changes. However, scenario modeling across various energy price projections consistently demonstrates positive ROI even under conservative assumptions, suggesting that benchmark LiBr concentration implementation represents a financially sound investment strategy with manageable downside risk.

Operational cost savings emerge as the primary economic driver, with energy efficiency improvements of 15-25% consistently observed in systems operating at optimal LiBr concentrations. For a typical 500-ton industrial cooling system, this translates to annual energy savings of approximately $30,000-$45,000 based on average industrial electricity rates. The reduced maintenance requirements further contribute to operational savings, estimated at $8,000-$12,000 annually due to decreased crystallization issues and extended equipment lifespan.

Payback periods vary by implementation scale but generally fall within 1.5-3.5 years for most commercial and industrial applications. Smaller installations tend toward the longer end of this spectrum, while larger systems achieve faster returns due to economies of scale in both implementation costs and energy savings. Sensitivity analysis indicates that facilities with higher cooling loads and operating hours experience significantly improved ROI metrics.

The lifecycle economic benefits extend beyond direct operational savings. Systems operating at benchmark LiBr concentrations demonstrate 15-20% longer service life for critical components, reducing long-term capital replacement costs. Additionally, the improved reliability translates to reduced downtime, with economic impact particularly significant in process-critical industries where cooling system failures can halt production.

Carbon reduction benefits present additional economic value through compliance with emissions regulations and potential qualification for sustainability incentives. Quantitative analysis shows that optimized LiBr systems can reduce carbon footprint by 12-18% compared to standard systems, potentially qualifying for carbon credit programs in certain jurisdictions, with estimated annual values of $5,000-$15,000 depending on facility size and location.

Risk assessment indicates that the primary economic uncertainties relate to energy price volatility and potential future regulatory changes. However, scenario modeling across various energy price projections consistently demonstrates positive ROI even under conservative assumptions, suggesting that benchmark LiBr concentration implementation represents a financially sound investment strategy with manageable downside risk.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!