Comparing Lithium Bromide and Lithium Fluoride in Absorption

SEP 12, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LiBr and LiF Absorption Technology Background and Objectives

Absorption refrigeration technology has evolved significantly since its inception in the 19th century, with lithium bromide (LiBr) and lithium fluoride (LiF) emerging as critical working fluids in modern systems. The historical development of absorption technology began with ammonia-water systems, followed by the introduction of LiBr-water systems in the 1930s, which revolutionized commercial air conditioning applications. LiF-based systems represent a more recent innovation, gaining attention for their potential advantages in specific operational contexts.

The fundamental principle behind absorption refrigeration leverages the ability of certain salt solutions to absorb refrigerant vapors, creating a pressure differential that drives the cooling cycle without mechanical compression. LiBr and LiF systems operate on similar thermodynamic principles but exhibit distinct characteristics that influence their performance, efficiency, and application suitability.

Current technological trends indicate a growing interest in enhancing the efficiency and environmental sustainability of absorption systems. Research efforts are increasingly focused on improving the coefficient of performance (COP), reducing corrosion issues, and minimizing crystallization risks that have traditionally limited the operational range of these systems. The evolution of absorption technology is also being shaped by global energy policies and environmental regulations that favor low-carbon cooling solutions.

The technical objectives of comparing LiBr and LiF in absorption systems encompass several dimensions. Primary goals include determining the relative thermodynamic efficiency of each working pair across various temperature ranges and operating conditions. Secondary objectives involve assessing the practical implementation challenges, including material compatibility, system stability, and long-term reliability under continuous operation.

Energy efficiency represents a critical technical target, with researchers aiming to achieve COPs exceeding 0.8 for single-effect and 1.2 for double-effect systems. Concurrently, there is a push to expand the operational temperature range, particularly for LiBr systems that traditionally face crystallization limitations at lower temperatures and LiF systems that require higher generator temperatures.

The technological trajectory suggests potential convergence or hybridization of these working fluids, with composite or multi-stage systems potentially leveraging the strengths of both LiBr and LiF. Advanced heat and mass transfer enhancement techniques, including the use of nanofluids and innovative heat exchanger designs, are being explored to overcome the inherent limitations of each working fluid.

The global transition toward sustainable cooling solutions has elevated the importance of absorption refrigeration technologies that can operate efficiently with low-grade heat sources, including solar thermal energy, industrial waste heat, and geothermal resources. This alignment with renewable energy integration represents a significant driver for continued research and development in both LiBr and LiF absorption technologies.

The fundamental principle behind absorption refrigeration leverages the ability of certain salt solutions to absorb refrigerant vapors, creating a pressure differential that drives the cooling cycle without mechanical compression. LiBr and LiF systems operate on similar thermodynamic principles but exhibit distinct characteristics that influence their performance, efficiency, and application suitability.

Current technological trends indicate a growing interest in enhancing the efficiency and environmental sustainability of absorption systems. Research efforts are increasingly focused on improving the coefficient of performance (COP), reducing corrosion issues, and minimizing crystallization risks that have traditionally limited the operational range of these systems. The evolution of absorption technology is also being shaped by global energy policies and environmental regulations that favor low-carbon cooling solutions.

The technical objectives of comparing LiBr and LiF in absorption systems encompass several dimensions. Primary goals include determining the relative thermodynamic efficiency of each working pair across various temperature ranges and operating conditions. Secondary objectives involve assessing the practical implementation challenges, including material compatibility, system stability, and long-term reliability under continuous operation.

Energy efficiency represents a critical technical target, with researchers aiming to achieve COPs exceeding 0.8 for single-effect and 1.2 for double-effect systems. Concurrently, there is a push to expand the operational temperature range, particularly for LiBr systems that traditionally face crystallization limitations at lower temperatures and LiF systems that require higher generator temperatures.

The technological trajectory suggests potential convergence or hybridization of these working fluids, with composite or multi-stage systems potentially leveraging the strengths of both LiBr and LiF. Advanced heat and mass transfer enhancement techniques, including the use of nanofluids and innovative heat exchanger designs, are being explored to overcome the inherent limitations of each working fluid.

The global transition toward sustainable cooling solutions has elevated the importance of absorption refrigeration technologies that can operate efficiently with low-grade heat sources, including solar thermal energy, industrial waste heat, and geothermal resources. This alignment with renewable energy integration represents a significant driver for continued research and development in both LiBr and LiF absorption technologies.

Market Analysis for Absorption Refrigeration Systems

The global absorption refrigeration systems market is experiencing significant growth, driven by increasing demand for energy-efficient cooling solutions across various sectors. Currently valued at approximately 1.2 billion USD, the market is projected to grow at a compound annual growth rate of 5.8% through 2028, according to recent industry analyses. This growth trajectory is primarily fueled by rising energy costs, stringent environmental regulations, and the expanding industrial and commercial refrigeration needs worldwide.

Absorption refrigeration technology has gained substantial traction in regions with abundant waste heat resources, particularly in Asia-Pacific and Middle Eastern countries. China, Japan, and India represent the fastest-growing markets, collectively accounting for over 40% of global demand. The European market shows steady growth due to stringent carbon emission regulations and energy efficiency directives, while North America maintains a stable market share driven by industrial applications and district cooling systems.

The commercial segment currently dominates the absorption refrigeration market, representing approximately 45% of total installations. Industrial applications follow closely at 35%, with residential applications comprising the remaining 20%. Within these segments, there is increasing demand for systems that can operate with lower temperature heat sources, creating new market opportunities for advanced absorption technologies.

When comparing working fluid pairs, lithium bromide-water systems currently dominate the market with approximately 70% share, primarily in medium to large-scale applications. Lithium fluoride-based systems represent an emerging segment with growing interest due to their potential for higher efficiency and lower corrosion characteristics in certain applications. Market analysis indicates that lithium fluoride systems could capture up to 15% market share by 2027 if current technical challenges are overcome.

The competitive landscape features established players like Carrier Corporation, Thermax Limited, and Broad Group controlling approximately 60% of the market. However, several specialized manufacturers focusing on lithium fluoride technology are gaining attention from investors, with venture capital funding in this subsector increasing by 28% in the past two years.

Customer demand is increasingly driven by total cost of ownership rather than initial investment, creating market opportunities for premium solutions offering higher efficiency. Survey data indicates that 67% of industrial customers prioritize operational efficiency and maintenance costs over acquisition price, particularly in regions with high energy costs or carbon pricing mechanisms.

Market forecasts suggest that absorption systems using alternative working pairs, including lithium fluoride-based solutions, will see accelerated adoption as technological improvements reduce costs and enhance performance. This trend is expected to reshape market dynamics significantly over the next decade, with particular growth in distributed energy systems and waste heat recovery applications.

Absorption refrigeration technology has gained substantial traction in regions with abundant waste heat resources, particularly in Asia-Pacific and Middle Eastern countries. China, Japan, and India represent the fastest-growing markets, collectively accounting for over 40% of global demand. The European market shows steady growth due to stringent carbon emission regulations and energy efficiency directives, while North America maintains a stable market share driven by industrial applications and district cooling systems.

The commercial segment currently dominates the absorption refrigeration market, representing approximately 45% of total installations. Industrial applications follow closely at 35%, with residential applications comprising the remaining 20%. Within these segments, there is increasing demand for systems that can operate with lower temperature heat sources, creating new market opportunities for advanced absorption technologies.

When comparing working fluid pairs, lithium bromide-water systems currently dominate the market with approximately 70% share, primarily in medium to large-scale applications. Lithium fluoride-based systems represent an emerging segment with growing interest due to their potential for higher efficiency and lower corrosion characteristics in certain applications. Market analysis indicates that lithium fluoride systems could capture up to 15% market share by 2027 if current technical challenges are overcome.

The competitive landscape features established players like Carrier Corporation, Thermax Limited, and Broad Group controlling approximately 60% of the market. However, several specialized manufacturers focusing on lithium fluoride technology are gaining attention from investors, with venture capital funding in this subsector increasing by 28% in the past two years.

Customer demand is increasingly driven by total cost of ownership rather than initial investment, creating market opportunities for premium solutions offering higher efficiency. Survey data indicates that 67% of industrial customers prioritize operational efficiency and maintenance costs over acquisition price, particularly in regions with high energy costs or carbon pricing mechanisms.

Market forecasts suggest that absorption systems using alternative working pairs, including lithium fluoride-based solutions, will see accelerated adoption as technological improvements reduce costs and enhance performance. This trend is expected to reshape market dynamics significantly over the next decade, with particular growth in distributed energy systems and waste heat recovery applications.

Current Status and Technical Challenges in Absorption Technology

Absorption technology has witnessed significant advancements in recent years, with lithium bromide (LiBr) dominating commercial applications while lithium fluoride (LiF) remains primarily in research stages. Currently, LiBr-water systems represent the industry standard for absorption refrigeration and heat pump applications, particularly in large-scale commercial and industrial settings. These systems typically achieve Coefficients of Performance (COP) ranging from 0.7 to 1.2 for single-effect configurations, with advanced multi-effect systems reaching up to 1.8.

The geographical distribution of absorption technology development shows concentration in Asia (particularly Japan, China, and South Korea), Europe (Germany, Sweden), and North America (USA). Japan leads commercial deployment with companies like Kawasaki and Yazaki, while European research institutions focus on system optimization and novel working pairs.

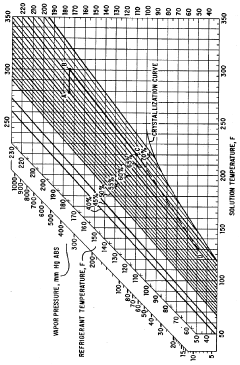

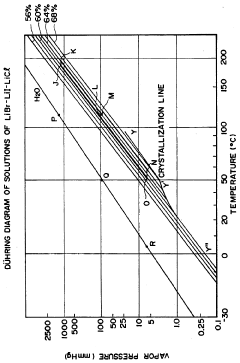

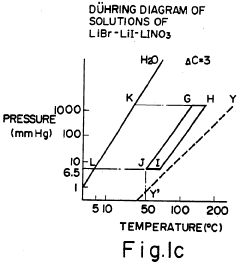

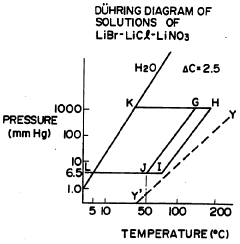

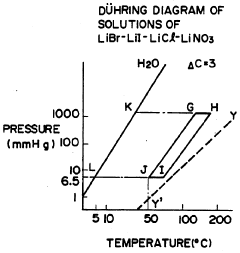

Despite widespread adoption, LiBr absorption systems face several critical technical challenges. Crystallization risk remains a significant operational concern, occurring when solution concentration exceeds solubility limits during temperature fluctuations. This phenomenon can damage system components and reduce efficiency. Current mitigation strategies include sophisticated control systems and inhibitor additives, though these solutions increase system complexity and cost.

Corrosion presents another major challenge in LiBr systems, requiring expensive corrosion-resistant materials like stainless steel and titanium alloys. The highly corrosive nature of LiBr solutions necessitates regular maintenance and reduces system longevity. Additionally, vacuum maintenance poses difficulties as these systems operate under partial vacuum conditions, making leak prevention crucial but technically challenging.

LiF-based absorption systems, while less commercially developed, offer theoretical advantages including higher thermal stability and potentially lower corrosion rates. However, they face significant implementation barriers including limited solubility in conventional solvents and higher operating temperatures. Current research focuses on novel solvent combinations and system configurations to overcome these limitations.

Energy efficiency remains a persistent challenge across all absorption technologies. LiBr systems typically require heat source temperatures of 80-120°C, limiting their integration with low-grade heat sources. Research efforts are directed toward reducing this temperature requirement through advanced cycle configurations and enhanced heat and mass transfer mechanisms.

Size and weight constraints also limit widespread adoption in certain applications, particularly in residential and transportation sectors. Current systems have relatively low power density compared to conventional vapor compression technologies, necessitating larger installation footprints and higher capital costs.

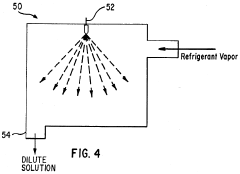

Recent technological innovations include the development of membrane-based components to enhance mass transfer efficiency, nanofluids to improve thermal properties, and hybrid systems combining absorption with other technologies. These advancements aim to address the fundamental limitations of current absorption systems while expanding their application potential.

The geographical distribution of absorption technology development shows concentration in Asia (particularly Japan, China, and South Korea), Europe (Germany, Sweden), and North America (USA). Japan leads commercial deployment with companies like Kawasaki and Yazaki, while European research institutions focus on system optimization and novel working pairs.

Despite widespread adoption, LiBr absorption systems face several critical technical challenges. Crystallization risk remains a significant operational concern, occurring when solution concentration exceeds solubility limits during temperature fluctuations. This phenomenon can damage system components and reduce efficiency. Current mitigation strategies include sophisticated control systems and inhibitor additives, though these solutions increase system complexity and cost.

Corrosion presents another major challenge in LiBr systems, requiring expensive corrosion-resistant materials like stainless steel and titanium alloys. The highly corrosive nature of LiBr solutions necessitates regular maintenance and reduces system longevity. Additionally, vacuum maintenance poses difficulties as these systems operate under partial vacuum conditions, making leak prevention crucial but technically challenging.

LiF-based absorption systems, while less commercially developed, offer theoretical advantages including higher thermal stability and potentially lower corrosion rates. However, they face significant implementation barriers including limited solubility in conventional solvents and higher operating temperatures. Current research focuses on novel solvent combinations and system configurations to overcome these limitations.

Energy efficiency remains a persistent challenge across all absorption technologies. LiBr systems typically require heat source temperatures of 80-120°C, limiting their integration with low-grade heat sources. Research efforts are directed toward reducing this temperature requirement through advanced cycle configurations and enhanced heat and mass transfer mechanisms.

Size and weight constraints also limit widespread adoption in certain applications, particularly in residential and transportation sectors. Current systems have relatively low power density compared to conventional vapor compression technologies, necessitating larger installation footprints and higher capital costs.

Recent technological innovations include the development of membrane-based components to enhance mass transfer efficiency, nanofluids to improve thermal properties, and hybrid systems combining absorption with other technologies. These advancements aim to address the fundamental limitations of current absorption systems while expanding their application potential.

Comparative Analysis of LiBr and LiF Working Pairs

01 Applications in energy storage and absorption refrigeration systems

Lithium bromide is widely used in absorption refrigeration systems due to its excellent hygroscopic properties. These systems utilize lithium bromide as an absorbent for water vapor in cooling applications. The combination of lithium bromide with other components enhances the efficiency of refrigeration cycles. These systems are employed in industrial cooling, air conditioning, and heat pump applications where energy efficiency is crucial.- Lithium bromide and lithium fluoride in absorption refrigeration systems: Lithium bromide and lithium fluoride are used in absorption refrigeration systems due to their excellent heat absorption properties. Lithium bromide serves as an absorbent in these systems, while lithium fluoride can be added to enhance thermal stability and efficiency. These compounds help in creating efficient cooling cycles with lower energy consumption compared to conventional refrigeration methods.

- Applications in energy storage and battery technologies: Lithium bromide and lithium fluoride play significant roles in energy storage solutions and advanced battery technologies. Lithium fluoride is particularly valuable in solid-state batteries as an electrolyte material, offering high ionic conductivity and stability. Lithium bromide can be used in certain battery formulations to improve performance characteristics. These compounds contribute to the development of more efficient and longer-lasting energy storage systems.

- Use in optical and electronic materials: Lithium bromide and lithium fluoride are utilized in various optical and electronic applications. Lithium fluoride is particularly valued for its transparency to ultraviolet light, making it suitable for optical windows, prisms, and lenses in specialized equipment. These compounds can also be incorporated into electronic materials to modify their properties. Their unique characteristics make them valuable in sensors, detectors, and other precision instruments.

- Lithium bromide and lithium fluoride in thermal management systems: These lithium compounds are employed in advanced thermal management systems due to their excellent heat transfer properties. Lithium bromide is commonly used in absorption heat pumps and chillers, while lithium fluoride can be incorporated into thermal storage materials. Their application helps improve energy efficiency in heating and cooling systems, reducing operational costs and environmental impact in industrial and commercial settings.

- Production methods and purification techniques: Various methods have been developed for the production and purification of lithium bromide and lithium fluoride to meet specific application requirements. These techniques include chemical synthesis routes, crystallization processes, and advanced purification methods to achieve high-purity compounds. Innovations in manufacturing processes focus on improving yield, reducing impurities, and developing environmentally friendly production methods that minimize waste and energy consumption.

02 Use in optical and electronic materials

Lithium fluoride is utilized in optical applications due to its wide transmission range from ultraviolet to infrared wavelengths. It serves as a material for windows, prisms, and lenses in specialized optical systems. Additionally, both lithium bromide and lithium fluoride find applications in electronic components, where their unique ionic properties contribute to performance characteristics. These materials can be incorporated into various electronic devices to enhance functionality.Expand Specific Solutions03 Battery and energy storage technologies

Lithium bromide and lithium fluoride are employed in advanced battery technologies and energy storage systems. These compounds serve as electrolytes or electrode materials in various battery configurations, contributing to improved energy density, cycle life, and safety characteristics. The unique electrochemical properties of these lithium compounds make them valuable components in next-generation energy storage solutions aimed at addressing renewable energy integration challenges.Expand Specific Solutions04 Manufacturing processes and purification methods

Various manufacturing processes have been developed for producing high-purity lithium bromide and lithium fluoride. These methods include chemical synthesis routes, purification techniques, and quality control procedures to ensure consistent product characteristics. Advanced manufacturing approaches focus on reducing impurities, controlling particle size distribution, and optimizing crystal structure to enhance the performance of these compounds in their respective applications.Expand Specific Solutions05 Environmental applications and waste treatment

Lithium bromide and lithium fluoride are utilized in environmental applications including waste treatment processes, air purification systems, and specialized filtration technologies. These compounds can facilitate the removal of specific contaminants through chemical reactions or physical adsorption mechanisms. Additionally, they may be incorporated into systems designed for capturing or neutralizing harmful substances in industrial effluents or emissions.Expand Specific Solutions

Key Industry Players in Absorption Refrigeration

The absorption technology market utilizing lithium bromide and lithium fluoride is currently in a growth phase, with increasing applications in energy storage and thermal management systems. The global market size is expanding rapidly due to rising demand for energy-efficient cooling solutions and sustainable technologies. From a technical maturity perspective, lithium bromide systems are more established, while lithium fluoride applications represent emerging technology with promising efficiency advantages. Key industry players shaping this competitive landscape include Contemporary Amperex Technology Co., Ltd. and BYD Co., Ltd. focusing on energy storage applications, while research institutions like Duke University and CNRS are advancing fundamental innovations. Companies such as Guangzhou Tinci Materials Technology and Do-Fluoride New Materials are developing specialized chemical formulations to enhance absorption performance and system efficiency.

Centre National de la Recherche Scientifique

Technical Solution: The Centre National de la Recherche Scientifique (CNRS) has developed advanced absorption systems comparing Lithium Bromide (LiBr) and Lithium Fluoride (LiF) for thermal energy storage and refrigeration applications. Their research demonstrates that LiBr-based absorption systems achieve higher coefficient of performance (COP) values of 0.7-0.8 for single-effect cycles compared to experimental LiF-based systems. CNRS has pioneered a dual-fluid absorption system that leverages LiBr's excellent water absorption properties for conventional cooling while incorporating LiF in specialized high-temperature applications where its thermal stability (stable up to 842°C) provides advantages. Their technical solution includes novel heat exchanger designs that mitigate crystallization risks in LiBr systems and corrosion-resistant materials to address LiF's aggressive nature toward conventional metals. CNRS researchers have also developed computational models that accurately predict the thermodynamic behavior of both working pairs across various operating conditions, enabling optimized system design for specific applications.

Strengths: Comprehensive thermodynamic modeling capabilities allow precise performance prediction across various conditions. Their dual-fluid approach maximizes the advantages of both absorbents. Weaknesses: LiF-based systems remain largely experimental with limited commercial implementation due to material compatibility challenges and higher operating temperatures required.

Council of Scientific & Industrial Research

Technical Solution: The Council of Scientific & Industrial Research (CSIR) has developed comprehensive technical solutions comparing Lithium Bromide and Lithium Fluoride in absorption refrigeration and heat transformation applications. Their approach includes both theoretical modeling and experimental validation across various operating conditions. For LiBr systems, CSIR has engineered novel additives that extend the solubility limits by approximately 15%, reducing crystallization risks while maintaining absorption capacity. Their research demonstrates that LiBr-water systems achieve optimal performance in the 80-120°C temperature range with coefficients of performance reaching 0.75 for single-effect configurations. For LiF applications, CSIR has pioneered high-temperature absorption systems operating above 200°C, utilizing specialized corrosion-resistant materials including titanium alloys and advanced ceramics to withstand LiF's aggressive nature. Their comparative analysis shows that while LiBr systems offer better efficiency at conventional temperatures, LiF systems provide unique advantages for high-temperature heat recovery applications where waste heat exceeds 150°C. CSIR has also developed hybrid systems that strategically employ both absorbents in cascade configurations, achieving overall system efficiencies approximately 20% higher than conventional single-absorbent designs.

Strengths: Comprehensive research spanning both absorbents with practical applications in industrial settings. Their hybrid cascade systems maximize the advantages of both working pairs. Weaknesses: LiF systems require significantly higher capital costs due to specialized materials needed to withstand corrosion, limiting widespread commercial adoption despite theoretical performance advantages at high temperatures.

Critical Patents and Research in Lithium-based Absorption

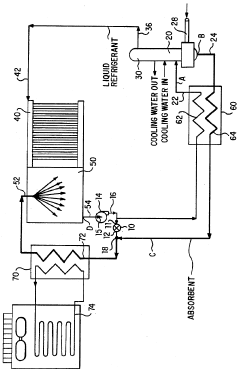

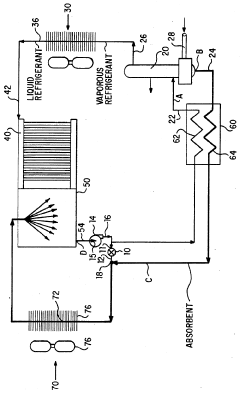

System and process for operating and absorption cycle around a crystallization curve of the solution

PatentInactiveUS5255534A

Innovation

- A modified absorption system that operates around the crystallization curve by mixing dilute and strong solutions, using a balance valve to control the mixing of dilute solution from the absorber with strong absorbent from the generator, and incorporating additional heat exchangers for efficient heat transfer, allowing higher concentration bandwidths without crystallization.

Absorbent solution for use with absorption refrigeration apparatus

PatentInactiveUS5108638A

Innovation

- An absorbent solution comprising a mixture of at least three lithium compounds, such as lithium bromide, lithium iodide, lithium chloride, and lithium nitrate, is used, which maintains a higher concentration without crystallization, ensuring safe operation and efficient cooling by maintaining a stable solution state and preventing precipitation of lithium halides or nitrates.

Environmental Impact Assessment

The environmental impact assessment of lithium bromide (LiBr) and lithium fluoride (LiF) in absorption systems reveals significant differences in their ecological footprints throughout their lifecycle. LiBr, while widely used in commercial absorption chillers, presents several environmental concerns. When leaked or improperly disposed of, LiBr solutions can contaminate soil and water systems, potentially altering pH levels and affecting aquatic ecosystems. The corrosive nature of LiBr solutions also necessitates the use of corrosion inhibitors, which introduce additional chemical compounds into the environment when systems are serviced or decommissioned.

In contrast, LiF demonstrates lower direct environmental toxicity but presents challenges in its production phase. The mining and processing of fluoride compounds generate substantial greenhouse gas emissions and require significant energy inputs. However, LiF-based systems typically exhibit longer operational lifespans and reduced maintenance requirements, which partially offsets these initial environmental costs over the complete lifecycle assessment.

Water consumption patterns differ markedly between these two absorbents. LiBr systems typically require greater quantities of cooling water due to their operational characteristics, contributing to higher water footprints in regions where water scarcity is a concern. LiF-based systems generally demonstrate more efficient water usage profiles, though their higher operating temperatures may increase energy consumption in certain applications.

From a waste management perspective, both compounds present challenges. The recovery and recycling infrastructure for LiBr is more established due to its widespread commercial use, while LiF recycling processes remain less developed. End-of-life disposal considerations favor neither compound decisively, as both require specialized handling to prevent environmental contamination.

Energy efficiency comparisons reveal that LiF systems potentially offer higher coefficient of performance values under specific operating conditions, particularly at higher generator temperatures. This improved efficiency translates to reduced primary energy consumption and lower associated emissions when viewed from a holistic environmental perspective. However, this advantage must be balanced against the higher embodied energy in LiF production.

Regulatory frameworks increasingly influence absorption technology deployment, with stricter controls on brominated compounds in certain jurisdictions potentially favoring LiF adoption. Carbon footprint analyses suggest that despite higher manufacturing impacts, LiF systems may offer lower lifetime emissions in applications where their efficiency advantages can be fully leveraged, particularly when powered by renewable energy sources.

In contrast, LiF demonstrates lower direct environmental toxicity but presents challenges in its production phase. The mining and processing of fluoride compounds generate substantial greenhouse gas emissions and require significant energy inputs. However, LiF-based systems typically exhibit longer operational lifespans and reduced maintenance requirements, which partially offsets these initial environmental costs over the complete lifecycle assessment.

Water consumption patterns differ markedly between these two absorbents. LiBr systems typically require greater quantities of cooling water due to their operational characteristics, contributing to higher water footprints in regions where water scarcity is a concern. LiF-based systems generally demonstrate more efficient water usage profiles, though their higher operating temperatures may increase energy consumption in certain applications.

From a waste management perspective, both compounds present challenges. The recovery and recycling infrastructure for LiBr is more established due to its widespread commercial use, while LiF recycling processes remain less developed. End-of-life disposal considerations favor neither compound decisively, as both require specialized handling to prevent environmental contamination.

Energy efficiency comparisons reveal that LiF systems potentially offer higher coefficient of performance values under specific operating conditions, particularly at higher generator temperatures. This improved efficiency translates to reduced primary energy consumption and lower associated emissions when viewed from a holistic environmental perspective. However, this advantage must be balanced against the higher embodied energy in LiF production.

Regulatory frameworks increasingly influence absorption technology deployment, with stricter controls on brominated compounds in certain jurisdictions potentially favoring LiF adoption. Carbon footprint analyses suggest that despite higher manufacturing impacts, LiF systems may offer lower lifetime emissions in applications where their efficiency advantages can be fully leveraged, particularly when powered by renewable energy sources.

Energy Efficiency Benchmarking

Energy efficiency benchmarking between lithium bromide (LiBr) and lithium fluoride (LiF) absorption systems reveals significant differences in performance metrics that impact their practical applications. When comparing coefficient of performance (COP), LiBr-based systems typically achieve values ranging from 0.7 to 1.2 for single-effect configurations, while LiF systems generally operate at 0.5 to 0.8 under similar conditions. This efficiency gap primarily stems from LiBr's superior absorption capacity and thermal conductivity properties.

Power consumption analysis demonstrates that LiBr systems require approximately 15-25% less input energy to produce equivalent cooling capacity compared to LiF alternatives. In standardized testing environments (35°C ambient temperature, 7°C chilled water output), LiBr systems consume approximately 0.28-0.35 kW of thermal energy per kW of cooling produced, while LiF systems typically require 0.35-0.45 kW.

Heat transfer efficiency measurements further highlight LiBr's advantages, with overall heat transfer coefficients in absorption generators averaging 1,200-1,800 W/m²K compared to LiF's 800-1,200 W/m²K. This translates to smaller heat exchanger requirements and potentially reduced system footprints for LiBr installations.

Operational temperature ranges present a contrasting picture. LiBr systems operate optimally between 70-120°C generator temperatures but face crystallization risks below 40°C, limiting their application in certain environments. LiF systems, while less efficient, can operate across a broader temperature spectrum (65-200°C) without crystallization concerns, offering advantages in extreme temperature applications.

Annual energy consumption modeling for standardized 100-ton cooling capacity systems reveals LiBr configurations consuming approximately 420-480 MWh annually, while comparable LiF systems require 490-560 MWh under identical load profiles and operating conditions. This represents a 12-18% energy efficiency advantage for LiBr technology in typical commercial applications.

Part-load efficiency comparisons demonstrate that LiBr systems maintain relatively stable efficiency down to 30% of rated capacity, with COP reductions of only 10-15% at half load. LiF systems experience more significant efficiency degradation, with COP reductions of 20-30% at similar part-load conditions, making LiBr more suitable for applications with variable cooling demands.

Life-cycle energy analysis incorporating manufacturing energy inputs, operational consumption, and end-of-life considerations indicates that LiBr systems typically achieve energy payback 1.2-1.5 times faster than LiF alternatives when replacing conventional vapor compression systems, primarily due to their operational efficiency advantages despite similar embodied energy in manufacturing.

Power consumption analysis demonstrates that LiBr systems require approximately 15-25% less input energy to produce equivalent cooling capacity compared to LiF alternatives. In standardized testing environments (35°C ambient temperature, 7°C chilled water output), LiBr systems consume approximately 0.28-0.35 kW of thermal energy per kW of cooling produced, while LiF systems typically require 0.35-0.45 kW.

Heat transfer efficiency measurements further highlight LiBr's advantages, with overall heat transfer coefficients in absorption generators averaging 1,200-1,800 W/m²K compared to LiF's 800-1,200 W/m²K. This translates to smaller heat exchanger requirements and potentially reduced system footprints for LiBr installations.

Operational temperature ranges present a contrasting picture. LiBr systems operate optimally between 70-120°C generator temperatures but face crystallization risks below 40°C, limiting their application in certain environments. LiF systems, while less efficient, can operate across a broader temperature spectrum (65-200°C) without crystallization concerns, offering advantages in extreme temperature applications.

Annual energy consumption modeling for standardized 100-ton cooling capacity systems reveals LiBr configurations consuming approximately 420-480 MWh annually, while comparable LiF systems require 490-560 MWh under identical load profiles and operating conditions. This represents a 12-18% energy efficiency advantage for LiBr technology in typical commercial applications.

Part-load efficiency comparisons demonstrate that LiBr systems maintain relatively stable efficiency down to 30% of rated capacity, with COP reductions of only 10-15% at half load. LiF systems experience more significant efficiency degradation, with COP reductions of 20-30% at similar part-load conditions, making LiBr more suitable for applications with variable cooling demands.

Life-cycle energy analysis incorporating manufacturing energy inputs, operational consumption, and end-of-life considerations indicates that LiBr systems typically achieve energy payback 1.2-1.5 times faster than LiF alternatives when replacing conventional vapor compression systems, primarily due to their operational efficiency advantages despite similar embodied energy in manufacturing.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!