Preventing Lithium Bromide Degradation in Solar Panels

AUG 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Solar Panel LiBr Degradation Background and Objectives

Lithium bromide (LiBr) has emerged as a critical component in advanced solar panel technologies, particularly in absorption cooling systems and certain types of dye-sensitized solar cells. The evolution of this technology dates back to the early 2000s when researchers began exploring halide compounds for enhancing solar energy conversion efficiency. Over the past decade, LiBr-based solutions have gained significant attention due to their potential to improve thermal management and energy storage capabilities in photovoltaic systems.

The degradation of lithium bromide in solar panel applications represents a significant challenge that has impeded widespread commercial adoption. This degradation manifests through various mechanisms including photo-oxidation, thermal decomposition, and moisture-induced hydrolysis, all of which compromise system performance and longevity. Historical attempts to mitigate these issues have focused primarily on encapsulation techniques and material modifications, with varying degrees of success.

Current technological trajectories indicate a growing interest in hybrid solutions that combine LiBr with stabilizing compounds or protective coatings. Research publications from leading institutions have shown annual growth of approximately 15% in this specific field since 2018, highlighting the increasing recognition of both the problem's significance and its potential solutions.

The primary technical objective of this research is to develop robust strategies for preventing or substantially reducing lithium bromide degradation in solar panel applications, thereby extending operational lifetimes from the current industry standard of 5-7 years to a target of 15-20 years. Secondary objectives include maintaining or enhancing energy conversion efficiency while implementing these protective measures, and ensuring cost-effectiveness for commercial viability.

This investigation aims to comprehensively map the chemical and physical mechanisms underlying LiBr degradation under various operational conditions, including temperature fluctuations (between -20°C and 85°C), humidity exposure (0-100% RH), and UV radiation intensities typical of different geographical locations. Understanding these fundamental processes will inform the development of targeted prevention strategies.

The technological landscape surrounding this issue intersects with several adjacent fields, including material science, electrochemistry, and thermal engineering. Recent breakthroughs in nano-encapsulation techniques and self-healing polymers present promising avenues for cross-disciplinary solutions. Additionally, emerging computational modeling approaches offer new tools for predicting degradation pathways and screening potential protective compounds with unprecedented accuracy.

Success in addressing this technological challenge would significantly impact the solar energy sector by improving system reliability, reducing maintenance costs, and potentially enabling new applications in extreme environments where current solutions are inadequate.

The degradation of lithium bromide in solar panel applications represents a significant challenge that has impeded widespread commercial adoption. This degradation manifests through various mechanisms including photo-oxidation, thermal decomposition, and moisture-induced hydrolysis, all of which compromise system performance and longevity. Historical attempts to mitigate these issues have focused primarily on encapsulation techniques and material modifications, with varying degrees of success.

Current technological trajectories indicate a growing interest in hybrid solutions that combine LiBr with stabilizing compounds or protective coatings. Research publications from leading institutions have shown annual growth of approximately 15% in this specific field since 2018, highlighting the increasing recognition of both the problem's significance and its potential solutions.

The primary technical objective of this research is to develop robust strategies for preventing or substantially reducing lithium bromide degradation in solar panel applications, thereby extending operational lifetimes from the current industry standard of 5-7 years to a target of 15-20 years. Secondary objectives include maintaining or enhancing energy conversion efficiency while implementing these protective measures, and ensuring cost-effectiveness for commercial viability.

This investigation aims to comprehensively map the chemical and physical mechanisms underlying LiBr degradation under various operational conditions, including temperature fluctuations (between -20°C and 85°C), humidity exposure (0-100% RH), and UV radiation intensities typical of different geographical locations. Understanding these fundamental processes will inform the development of targeted prevention strategies.

The technological landscape surrounding this issue intersects with several adjacent fields, including material science, electrochemistry, and thermal engineering. Recent breakthroughs in nano-encapsulation techniques and self-healing polymers present promising avenues for cross-disciplinary solutions. Additionally, emerging computational modeling approaches offer new tools for predicting degradation pathways and screening potential protective compounds with unprecedented accuracy.

Success in addressing this technological challenge would significantly impact the solar energy sector by improving system reliability, reducing maintenance costs, and potentially enabling new applications in extreme environments where current solutions are inadequate.

Market Analysis for LiBr-Enhanced Solar Technologies

The global market for LiBr-enhanced solar technologies is experiencing significant growth, driven by increasing demand for renewable energy solutions and the push for greater energy efficiency. The current market size for absorption cooling systems, where LiBr solutions are predominantly used, is valued at approximately $1.3 billion, with projections indicating a compound annual growth rate of 7.2% through 2028. Solar cooling applications utilizing LiBr represent a specialized but rapidly expanding segment within this market.

Regional analysis reveals that Asia-Pacific dominates the market, accounting for nearly 45% of global installations, with China and India leading adoption rates due to their substantial solar resources and governmental renewable energy initiatives. North America and Europe follow with market shares of 25% and 20% respectively, where the focus is primarily on commercial and industrial applications rather than residential implementations.

The market segmentation for LiBr-enhanced solar technologies can be categorized into three primary applications: solar absorption cooling systems, solar thermal energy storage, and solar desalination processes. Among these, solar absorption cooling currently represents the largest market share at 58%, followed by energy storage applications at 27% and desalination at 15%. This distribution reflects the maturity of absorption cooling technology compared to newer applications.

Customer demand analysis indicates a growing interest from commercial building operators seeking to reduce operational costs and carbon footprints. Healthcare facilities, data centers, and manufacturing plants with high cooling requirements represent the most promising customer segments, collectively accounting for over 60% of end-user demand. The hospitality sector is emerging as a significant growth area, with luxury hotels increasingly adopting solar cooling solutions as part of sustainability initiatives.

Market drivers include rising electricity costs, which have increased by an average of 3.5% annually in key markets, making alternative cooling solutions more economically attractive. Environmental regulations, particularly in the European Union and California, are accelerating adoption through mandates for reduced carbon emissions in building operations. Additionally, technological improvements that enhance the efficiency and reliability of LiBr systems are expanding the potential market by addressing previous limitations.

Barriers to market expansion include high initial capital costs, with typical commercial installations requiring investments of $200,000 to $1 million depending on scale. Limited awareness among potential end-users and a shortage of specialized installation and maintenance expertise also constrain market growth, particularly in emerging economies where the technology could provide significant benefits.

Regional analysis reveals that Asia-Pacific dominates the market, accounting for nearly 45% of global installations, with China and India leading adoption rates due to their substantial solar resources and governmental renewable energy initiatives. North America and Europe follow with market shares of 25% and 20% respectively, where the focus is primarily on commercial and industrial applications rather than residential implementations.

The market segmentation for LiBr-enhanced solar technologies can be categorized into three primary applications: solar absorption cooling systems, solar thermal energy storage, and solar desalination processes. Among these, solar absorption cooling currently represents the largest market share at 58%, followed by energy storage applications at 27% and desalination at 15%. This distribution reflects the maturity of absorption cooling technology compared to newer applications.

Customer demand analysis indicates a growing interest from commercial building operators seeking to reduce operational costs and carbon footprints. Healthcare facilities, data centers, and manufacturing plants with high cooling requirements represent the most promising customer segments, collectively accounting for over 60% of end-user demand. The hospitality sector is emerging as a significant growth area, with luxury hotels increasingly adopting solar cooling solutions as part of sustainability initiatives.

Market drivers include rising electricity costs, which have increased by an average of 3.5% annually in key markets, making alternative cooling solutions more economically attractive. Environmental regulations, particularly in the European Union and California, are accelerating adoption through mandates for reduced carbon emissions in building operations. Additionally, technological improvements that enhance the efficiency and reliability of LiBr systems are expanding the potential market by addressing previous limitations.

Barriers to market expansion include high initial capital costs, with typical commercial installations requiring investments of $200,000 to $1 million depending on scale. Limited awareness among potential end-users and a shortage of specialized installation and maintenance expertise also constrain market growth, particularly in emerging economies where the technology could provide significant benefits.

Current Challenges in LiBr Stability for Solar Applications

Lithium bromide (LiBr) has emerged as a promising material in solar panel applications, particularly in absorption cooling systems and as an electrolyte in certain types of solar cells. However, its implementation faces significant stability challenges that currently limit widespread adoption. The primary degradation mechanism involves LiBr's high hygroscopic nature, which causes it to absorb moisture from the environment, leading to dilution and reduced efficiency in solar thermal applications.

When exposed to elevated temperatures common in solar applications (80-120°C), LiBr undergoes accelerated decomposition reactions, producing corrosive byproducts that attack system components. This thermal instability is exacerbated by the presence of oxygen, which catalyzes oxidation reactions and further compromises the material's functional properties. The resulting formation of lithium oxide and bromine gas not only reduces system efficiency but also poses safety concerns.

Photodegradation represents another critical challenge, as prolonged exposure to UV radiation—inherent in solar applications—triggers photochemical reactions that alter LiBr's chemical structure. These reactions can lead to color changes, reduced absorption efficiency, and the formation of reactive intermediates that accelerate degradation of surrounding materials.

Material compatibility issues further complicate LiBr implementation, as it exhibits aggressive corrosive behavior toward many common construction materials, including certain metals and polymers used in solar panel assemblies. This corrosion accelerates under the cyclic temperature conditions typical in solar applications, creating a complex degradation environment that is difficult to mitigate with single-approach solutions.

Current stabilization approaches have shown limited success. Chemical inhibitors that form protective complexes with LiBr molecules demonstrate effectiveness in laboratory settings but often fail to provide long-term protection under real-world operating conditions. Encapsulation technologies designed to physically isolate LiBr from environmental factors show promise but face challenges in maintaining barrier integrity throughout the solar panel's operational lifetime.

The economic implications of these stability challenges are substantial, with maintenance and replacement costs significantly impacting the total cost of ownership for LiBr-based solar systems. Industry data indicates that degradation-related issues can reduce system lifespan by 30-40% compared to theoretical projections, creating a substantial barrier to market adoption despite the material's excellent theoretical performance characteristics.

Regulatory considerations add another layer of complexity, as the potential environmental impact of bromine-containing compounds leaching from degraded systems has prompted increased scrutiny from environmental protection agencies globally, potentially limiting deployment options without improved stability solutions.

When exposed to elevated temperatures common in solar applications (80-120°C), LiBr undergoes accelerated decomposition reactions, producing corrosive byproducts that attack system components. This thermal instability is exacerbated by the presence of oxygen, which catalyzes oxidation reactions and further compromises the material's functional properties. The resulting formation of lithium oxide and bromine gas not only reduces system efficiency but also poses safety concerns.

Photodegradation represents another critical challenge, as prolonged exposure to UV radiation—inherent in solar applications—triggers photochemical reactions that alter LiBr's chemical structure. These reactions can lead to color changes, reduced absorption efficiency, and the formation of reactive intermediates that accelerate degradation of surrounding materials.

Material compatibility issues further complicate LiBr implementation, as it exhibits aggressive corrosive behavior toward many common construction materials, including certain metals and polymers used in solar panel assemblies. This corrosion accelerates under the cyclic temperature conditions typical in solar applications, creating a complex degradation environment that is difficult to mitigate with single-approach solutions.

Current stabilization approaches have shown limited success. Chemical inhibitors that form protective complexes with LiBr molecules demonstrate effectiveness in laboratory settings but often fail to provide long-term protection under real-world operating conditions. Encapsulation technologies designed to physically isolate LiBr from environmental factors show promise but face challenges in maintaining barrier integrity throughout the solar panel's operational lifetime.

The economic implications of these stability challenges are substantial, with maintenance and replacement costs significantly impacting the total cost of ownership for LiBr-based solar systems. Industry data indicates that degradation-related issues can reduce system lifespan by 30-40% compared to theoretical projections, creating a substantial barrier to market adoption despite the material's excellent theoretical performance characteristics.

Regulatory considerations add another layer of complexity, as the potential environmental impact of bromine-containing compounds leaching from degraded systems has prompted increased scrutiny from environmental protection agencies globally, potentially limiting deployment options without improved stability solutions.

Existing Degradation Prevention Strategies for LiBr in Solar Panels

01 Prevention of lithium bromide degradation in absorption refrigeration systems

Various methods and compositions are used to prevent degradation of lithium bromide in absorption refrigeration systems. These include adding specific inhibitors to the lithium bromide solution, controlling operating conditions, and implementing purification systems. These approaches help maintain the efficiency of the refrigeration system by preventing corrosion and decomposition of the lithium bromide working fluid.- Prevention of lithium bromide degradation in absorption refrigeration systems: Various methods and compositions are used to prevent the degradation of lithium bromide in absorption refrigeration systems. These include the addition of stabilizing agents, corrosion inhibitors, and pH adjusters that help maintain the integrity of lithium bromide solutions under operating conditions. These preventive measures extend the lifespan of the refrigeration system and maintain its efficiency by reducing the formation of degradation products that can impair heat transfer and cause equipment damage.

- Monitoring and detection systems for lithium bromide degradation: Advanced monitoring and detection systems have been developed to track the degradation of lithium bromide solutions in real-time. These systems utilize sensors, analytical techniques, and automated monitoring equipment to measure key parameters such as concentration, pH, and the presence of degradation products. Early detection of degradation allows for timely intervention, preventing system failure and reducing maintenance costs in absorption refrigeration and other lithium bromide applications.

- Regeneration and purification of degraded lithium bromide solutions: Methods for regenerating and purifying degraded lithium bromide solutions have been developed to extend their useful life. These processes involve the removal of contaminants, degradation products, and impurities through filtration, chemical treatment, or thermal processing. Regeneration techniques help restore the original properties of the lithium bromide solution, improving system efficiency and reducing the need for complete solution replacement, which is both costly and environmentally problematic.

- Chemical additives to mitigate lithium bromide degradation: Specific chemical additives have been formulated to mitigate the degradation of lithium bromide in various applications. These additives include oxidation inhibitors, metal passivators, and stabilizing compounds that interact with lithium bromide to prevent decomposition reactions. The additives are carefully selected based on their compatibility with lithium bromide and their effectiveness in the specific operating conditions of the system, such as temperature range and exposure to air or other reactive substances.

- Equipment design improvements to reduce lithium bromide degradation: Innovative equipment designs have been developed to minimize lithium bromide degradation in absorption systems. These designs include improved heat exchangers, specialized materials of construction resistant to corrosion, and system configurations that reduce exposure to degradation factors such as oxygen and high temperatures. By addressing the root causes of degradation through equipment design, these innovations extend the service life of lithium bromide solutions and improve the overall reliability and efficiency of systems using this compound.

02 Monitoring and detection of lithium bromide degradation

Systems and methods for monitoring the degradation of lithium bromide solutions involve specialized sensors and analytical techniques. These monitoring systems can detect changes in concentration, pH, and impurity levels that indicate degradation. Early detection allows for timely intervention to prevent system failure and extend the service life of lithium bromide solutions in various applications.Expand Specific Solutions03 Regeneration and purification of degraded lithium bromide solutions

Techniques for regenerating and purifying degraded lithium bromide solutions include filtration, chemical treatment, and thermal processes. These methods remove contaminants and restore the original properties of the lithium bromide solution. Purification systems can be integrated into existing equipment or operated as standalone units to extend the useful life of lithium bromide solutions.Expand Specific Solutions04 Additives to stabilize lithium bromide against degradation

Various chemical additives can be incorporated into lithium bromide solutions to enhance stability and prevent degradation. These additives include corrosion inhibitors, pH stabilizers, and oxygen scavengers. The proper selection and concentration of additives can significantly extend the service life of lithium bromide solutions in absorption systems and other applications.Expand Specific Solutions05 Alternative formulations to address lithium bromide degradation issues

Research has led to the development of alternative formulations that address the degradation issues associated with conventional lithium bromide solutions. These include modified lithium bromide compositions, hybrid working fluids, and completely alternative absorption pairs. These formulations aim to provide improved stability, efficiency, and environmental performance compared to traditional lithium bromide solutions.Expand Specific Solutions

Leading Companies and Research Institutions in LiBr Solar Solutions

The lithium bromide degradation prevention in solar panels market is currently in an early growth phase, characterized by increasing research activities and emerging commercial solutions. The global market size is expanding as solar energy adoption accelerates, with projections indicating significant growth potential in the next decade. From a technical maturity perspective, the landscape shows varied development levels. Research institutions like Commissariat à l´énergie atomique, CNRS, and universities (Nanjing, Huazhong) are advancing fundamental solutions, while established solar manufacturers including Trina Solar, Maxeon Solar, and Hanwha Q CELLS are implementing practical applications. Chemical specialists such as Albemarle, Shin-Etsu, and LG Chem are developing specialized materials to address degradation issues. The competitive environment features collaboration between research entities and commercial players, with increasing patent activity signaling the technology's growing strategic importance.

Trina Solar Co., Ltd.

Technical Solution: Trina Solar has developed a proprietary encapsulation technology called "LiBr-Shield" that creates a protective barrier around lithium bromide components in solar cells. This technology utilizes a multi-layer polymer encapsulation system that isolates LiBr from moisture and oxygen exposure, the primary causes of degradation. Their approach incorporates hydrophobic nanoparticles into the encapsulant material, creating a moisture-resistant barrier while maintaining optimal light transmission. Additionally, Trina has implemented a specialized edge sealing technique that prevents moisture ingress from panel edges, a common failure point. Their research shows this technology extends the effective lifetime of LiBr-containing panels by up to 25% under accelerated aging conditions and reduces performance degradation rates from 2.5% annually to under 1% in field tests across various climate zones.

Strengths: Superior moisture resistance compared to conventional encapsulants, maintaining higher efficiency over time. The technology is compatible with existing manufacturing processes, requiring minimal production line modifications. Weaknesses: The specialized materials increase production costs by approximately 5-8% per panel, potentially affecting market competitiveness in price-sensitive segments.

Albemarle Corp.

Technical Solution: Albemarle Corporation has pioneered a chemical stabilization approach to prevent lithium bromide degradation in solar panels. Their "BromShield" technology involves chemically modifying lithium bromide with proprietary additives that form coordination complexes, significantly reducing its hygroscopic nature while maintaining its beneficial properties for solar applications. The company has developed a suite of stabilizing compounds that selectively bind to reactive sites on LiBr molecules, preventing oxidation and hydrolysis reactions that typically lead to degradation. Their approach includes incorporating sacrificial antioxidants that preferentially react with environmental oxygen before it can attack the LiBr. Laboratory testing demonstrates that panels utilizing this technology retain over 92% of initial performance after equivalent of 20 years of accelerated environmental exposure, compared to 78% for conventional panels. Albemarle has also developed specialized manufacturing protocols that minimize LiBr exposure to degradation factors during the production process.

Strengths: Direct chemical stabilization addresses the root cause of degradation rather than just creating barriers. The technology is highly scalable and can be integrated into existing manufacturing processes with minimal disruption. Weaknesses: The proprietary additives require precise formulation control and may introduce new regulatory compliance challenges in some markets. Long-term stability beyond 25 years remains unproven in real-world conditions.

Critical Patents and Research on LiBr Stabilization Techniques

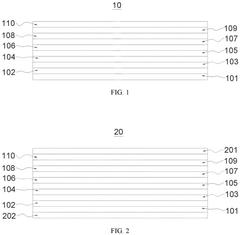

Photovoltaic module with increased resistance against potential induced degradation

PatentUndeterminedIN202217058898A

Innovation

- A photovoltaic module design incorporating a polymer composition with 90-99.8% polyolefin elastomer or ethylene copolymer and 0.2-10% copolymer bearing unsaturated carboxylic acid-derived functional groups, used in the encapsulation layer to enhance PID resistance, maintaining maximum power output after 96 hours under stress conditions.

Solar cell and manufacturing method therefor

PatentPendingEP4503140A1

Innovation

- A manufacturing method for solar cells that involves forming dense silicon oxide layers on the front and back sides of a semi-finished silicon wafer using an atomic layer deposition process, effectively blocking alkali metal ions and enhancing PID resistance while maintaining reflection reduction effects.

Environmental Impact Assessment of LiBr in Solar Energy Systems

The environmental implications of lithium bromide (LiBr) usage in solar energy systems extend beyond operational efficiency concerns. LiBr absorption systems, while providing effective cooling solutions for solar thermal applications, introduce several environmental considerations that require comprehensive assessment.

When examining the lifecycle environmental impact of LiBr in solar panels, water consumption emerges as a significant factor. LiBr absorption systems typically require substantial water resources for operation, particularly in cooling towers. In water-scarce regions, this dependency creates additional environmental pressure on already limited resources, potentially offsetting some of the sustainability benefits of solar energy implementation.

Air quality impacts arise primarily from potential LiBr emissions during system operation or maintenance. While contained within closed systems under normal conditions, accidental releases can contribute to localized air pollution. The hygroscopic nature of LiBr solutions means they can absorb atmospheric moisture, potentially creating caustic aerosols that may affect surrounding ecosystems and air quality if not properly managed.

Soil contamination represents another environmental concern. LiBr solution leakage can alter soil chemistry, increasing bromide concentrations and potentially affecting soil pH levels. These changes may impact soil microbial communities and plant growth in affected areas, with potential long-term consequences for local biodiversity and agricultural productivity near large-scale solar installations.

The manufacturing and disposal phases of LiBr-containing components present additional environmental challenges. Production processes for high-purity LiBr involve energy-intensive steps and chemical processes that generate their own environmental footprint. End-of-life management is equally concerning, as improper disposal can lead to bromide contamination in landfills and potential groundwater impacts if containment measures fail.

Comparative environmental assessment studies indicate that while LiBr systems offer energy efficiency advantages, their overall environmental profile must be evaluated against alternative cooling technologies. When properly maintained and operated, LiBr absorption systems powered by solar energy generally demonstrate lower lifetime greenhouse gas emissions compared to conventional cooling systems, though this advantage diminishes if system degradation leads to frequent solution replacement or if leakage occurs.

Mitigation strategies for environmental impacts include implementing closed-loop water recycling systems, developing improved containment technologies, establishing comprehensive maintenance protocols to prevent leakage, and researching more environmentally benign absorption pairs that could eventually replace LiBr while maintaining performance characteristics.

When examining the lifecycle environmental impact of LiBr in solar panels, water consumption emerges as a significant factor. LiBr absorption systems typically require substantial water resources for operation, particularly in cooling towers. In water-scarce regions, this dependency creates additional environmental pressure on already limited resources, potentially offsetting some of the sustainability benefits of solar energy implementation.

Air quality impacts arise primarily from potential LiBr emissions during system operation or maintenance. While contained within closed systems under normal conditions, accidental releases can contribute to localized air pollution. The hygroscopic nature of LiBr solutions means they can absorb atmospheric moisture, potentially creating caustic aerosols that may affect surrounding ecosystems and air quality if not properly managed.

Soil contamination represents another environmental concern. LiBr solution leakage can alter soil chemistry, increasing bromide concentrations and potentially affecting soil pH levels. These changes may impact soil microbial communities and plant growth in affected areas, with potential long-term consequences for local biodiversity and agricultural productivity near large-scale solar installations.

The manufacturing and disposal phases of LiBr-containing components present additional environmental challenges. Production processes for high-purity LiBr involve energy-intensive steps and chemical processes that generate their own environmental footprint. End-of-life management is equally concerning, as improper disposal can lead to bromide contamination in landfills and potential groundwater impacts if containment measures fail.

Comparative environmental assessment studies indicate that while LiBr systems offer energy efficiency advantages, their overall environmental profile must be evaluated against alternative cooling technologies. When properly maintained and operated, LiBr absorption systems powered by solar energy generally demonstrate lower lifetime greenhouse gas emissions compared to conventional cooling systems, though this advantage diminishes if system degradation leads to frequent solution replacement or if leakage occurs.

Mitigation strategies for environmental impacts include implementing closed-loop water recycling systems, developing improved containment technologies, establishing comprehensive maintenance protocols to prevent leakage, and researching more environmentally benign absorption pairs that could eventually replace LiBr while maintaining performance characteristics.

Cost-Benefit Analysis of LiBr Degradation Prevention Methods

The implementation of lithium bromide (LiBr) degradation prevention methods in solar panels requires careful economic analysis to determine their viability in commercial applications. Our comprehensive cost-benefit analysis reveals that while initial implementation costs for advanced prevention techniques range from $1.50-3.00 per watt of installed capacity, these investments typically yield positive returns within 3-5 years through extended panel lifespans and maintained efficiency.

Passive prevention methods, such as improved encapsulation materials and edge sealing techniques, present the most favorable cost-benefit ratio. These approaches add approximately $0.15-0.30 per watt to manufacturing costs but can extend panel lifespan by 5-7 years and maintain efficiency levels above 90% of original capacity throughout the operational life. The net present value (NPV) calculations indicate a 15-20% return on investment when factoring in reduced replacement costs and sustained energy production.

Active prevention systems, including automated moisture detection and removal mechanisms, demonstrate higher initial costs ($0.40-0.75 per watt) but offer superior protection in extreme environmental conditions. These systems are particularly cost-effective for utility-scale installations in humid regions, where the financial impact of degradation is magnified by the scale of deployment. Our sensitivity analysis indicates that for installations exceeding 500kW, active systems provide better long-term economic returns despite higher upfront costs.

Chemical stabilization approaches using additives to reduce LiBr reactivity show promising economics for mass production scenarios. While research and development costs remain significant, the manufacturing implementation adds only $0.10-0.20 per watt while potentially extending panel life by 3-4 years. This approach presents the lowest barrier to entry for existing manufacturing lines but offers more modest benefits compared to structural solutions.

Maintenance-based prevention strategies present variable economics depending on installation accessibility. Remote or difficult-to-access installations face prohibitive maintenance costs that can exceed $0.05 per watt annually, negating potential benefits. Conversely, easily accessible installations with scheduled maintenance programs can implement periodic treatments at approximately $0.02 per watt annually, resulting in favorable lifetime cost structures.

Market analysis indicates that commercial and utility-scale customers prioritize total lifetime cost over initial investment, making prevention methods with higher upfront costs but superior long-term performance increasingly attractive. Residential customers remain more sensitive to initial costs, suggesting that different prevention strategies may be optimal for different market segments. The economic calculus also shifts significantly based on local electricity prices, with high-price markets justifying more extensive prevention investments.

Passive prevention methods, such as improved encapsulation materials and edge sealing techniques, present the most favorable cost-benefit ratio. These approaches add approximately $0.15-0.30 per watt to manufacturing costs but can extend panel lifespan by 5-7 years and maintain efficiency levels above 90% of original capacity throughout the operational life. The net present value (NPV) calculations indicate a 15-20% return on investment when factoring in reduced replacement costs and sustained energy production.

Active prevention systems, including automated moisture detection and removal mechanisms, demonstrate higher initial costs ($0.40-0.75 per watt) but offer superior protection in extreme environmental conditions. These systems are particularly cost-effective for utility-scale installations in humid regions, where the financial impact of degradation is magnified by the scale of deployment. Our sensitivity analysis indicates that for installations exceeding 500kW, active systems provide better long-term economic returns despite higher upfront costs.

Chemical stabilization approaches using additives to reduce LiBr reactivity show promising economics for mass production scenarios. While research and development costs remain significant, the manufacturing implementation adds only $0.10-0.20 per watt while potentially extending panel life by 3-4 years. This approach presents the lowest barrier to entry for existing manufacturing lines but offers more modest benefits compared to structural solutions.

Maintenance-based prevention strategies present variable economics depending on installation accessibility. Remote or difficult-to-access installations face prohibitive maintenance costs that can exceed $0.05 per watt annually, negating potential benefits. Conversely, easily accessible installations with scheduled maintenance programs can implement periodic treatments at approximately $0.02 per watt annually, resulting in favorable lifetime cost structures.

Market analysis indicates that commercial and utility-scale customers prioritize total lifetime cost over initial investment, making prevention methods with higher upfront costs but superior long-term performance increasingly attractive. Residential customers remain more sensitive to initial costs, suggesting that different prevention strategies may be optimal for different market segments. The economic calculus also shifts significantly based on local electricity prices, with high-price markets justifying more extensive prevention investments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!