How to Improve Lithium Bromide Heat Transfer in Systems

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lithium Bromide Heat Transfer Technology Background and Objectives

Lithium bromide (LiBr) absorption systems have been a cornerstone technology in industrial refrigeration and air conditioning applications since their commercial introduction in the mid-20th century. The evolution of this technology has been marked by continuous improvements in efficiency, reliability, and environmental compatibility. Initially developed as an alternative to ammonia-based absorption systems, LiBr systems gained prominence due to their lower operating pressures and non-toxic working fluid characteristics.

The fundamental principle behind LiBr absorption systems involves the strong affinity of lithium bromide solution for water vapor, enabling an absorption-based refrigeration cycle without mechanical compression. This process has historically provided significant energy advantages in applications where waste heat or low-grade thermal energy is available, such as industrial processes, solar cooling systems, and combined heating and cooling plants.

Over the decades, the technology has evolved from simple single-effect cycles to more sophisticated double and triple-effect configurations, dramatically improving coefficient of performance (COP) values from approximately 0.7 to over 1.7 in modern systems. This progression represents a significant advancement in thermal efficiency utilization.

Despite these improvements, heat transfer limitations within LiBr systems remain a critical bottleneck affecting overall system performance. The high viscosity of LiBr solutions, particularly at higher concentrations, creates boundary layer effects that impede efficient heat transfer. Additionally, crystallization risks at certain concentration-temperature combinations have historically constrained operational parameters and system design flexibility.

Current technological objectives in this field focus on several key areas: enhancing heat transfer coefficients in absorption and generation processes; mitigating crystallization risks to expand operational envelopes; reducing solution pumping power requirements; and developing more compact heat exchanger designs with improved thermal performance characteristics.

Recent research has increasingly targeted the fundamental understanding of heat and mass transfer phenomena at the molecular level, employing advanced computational fluid dynamics and experimental validation techniques. The integration of nanotechnology, surface modification approaches, and advanced materials science offers promising pathways for breakthrough improvements.

The ultimate goal of current research efforts is to develop next-generation LiBr absorption systems with significantly enhanced heat transfer capabilities, enabling higher COPs, more compact designs, and broader application potential across diverse thermal energy utilization scenarios. These advancements would position LiBr absorption technology as an increasingly viable solution for sustainable cooling applications in the context of global energy transition and decarbonization objectives.

The fundamental principle behind LiBr absorption systems involves the strong affinity of lithium bromide solution for water vapor, enabling an absorption-based refrigeration cycle without mechanical compression. This process has historically provided significant energy advantages in applications where waste heat or low-grade thermal energy is available, such as industrial processes, solar cooling systems, and combined heating and cooling plants.

Over the decades, the technology has evolved from simple single-effect cycles to more sophisticated double and triple-effect configurations, dramatically improving coefficient of performance (COP) values from approximately 0.7 to over 1.7 in modern systems. This progression represents a significant advancement in thermal efficiency utilization.

Despite these improvements, heat transfer limitations within LiBr systems remain a critical bottleneck affecting overall system performance. The high viscosity of LiBr solutions, particularly at higher concentrations, creates boundary layer effects that impede efficient heat transfer. Additionally, crystallization risks at certain concentration-temperature combinations have historically constrained operational parameters and system design flexibility.

Current technological objectives in this field focus on several key areas: enhancing heat transfer coefficients in absorption and generation processes; mitigating crystallization risks to expand operational envelopes; reducing solution pumping power requirements; and developing more compact heat exchanger designs with improved thermal performance characteristics.

Recent research has increasingly targeted the fundamental understanding of heat and mass transfer phenomena at the molecular level, employing advanced computational fluid dynamics and experimental validation techniques. The integration of nanotechnology, surface modification approaches, and advanced materials science offers promising pathways for breakthrough improvements.

The ultimate goal of current research efforts is to develop next-generation LiBr absorption systems with significantly enhanced heat transfer capabilities, enabling higher COPs, more compact designs, and broader application potential across diverse thermal energy utilization scenarios. These advancements would position LiBr absorption technology as an increasingly viable solution for sustainable cooling applications in the context of global energy transition and decarbonization objectives.

Market Analysis for LiBr Absorption Systems

The global market for Lithium Bromide (LiBr) absorption systems has been experiencing steady growth, driven primarily by increasing energy costs and growing environmental concerns. The market size was valued at approximately $1.2 billion in 2022 and is projected to reach $1.8 billion by 2028, representing a compound annual growth rate of 7.2%. This growth trajectory is supported by the rising demand for energy-efficient cooling and heating solutions across various industries.

Asia-Pacific currently dominates the LiBr absorption systems market, accounting for over 40% of the global share. This regional dominance is attributed to rapid industrialization, increasing construction activities, and supportive government policies promoting energy-efficient technologies in countries like China, Japan, and South Korea. Japan, in particular, has been a pioneer in LiBr absorption technology development and implementation.

North America and Europe follow as significant markets, with growing adoption rates driven by stringent environmental regulations and increasing focus on reducing carbon footprints. The Middle East region is emerging as a promising market due to its hot climate conditions and growing investments in sustainable cooling technologies.

By application segment, the commercial building sector represents the largest market share at approximately 35%, followed by industrial applications at 30%. Healthcare facilities, educational institutions, and data centers are emerging as high-potential segments due to their continuous cooling requirements and increasing focus on operational cost reduction.

Key market drivers include rising energy costs, growing emphasis on sustainable technologies, and increasing government incentives for energy-efficient systems. The ability of LiBr absorption systems to utilize waste heat or solar energy makes them particularly attractive in regions with abundant solar resources or industries with significant waste heat generation.

Market challenges include high initial investment costs compared to conventional cooling systems, technical limitations related to crystallization and corrosion issues, and competition from alternative cooling technologies. The performance limitations of LiBr systems, particularly related to heat transfer efficiency, represent a significant barrier to wider market adoption.

Consumer trends indicate growing preference for integrated energy systems that combine heating, cooling, and power generation. There is also increasing demand for compact systems with improved efficiency and reduced maintenance requirements, particularly in urban areas with space constraints.

The competitive landscape features established players like Carrier Corporation, Trane Technologies, and Johnson Controls, alongside emerging companies focusing on technological innovations to improve system efficiency and reduce costs. Strategic partnerships between technology providers and energy service companies are becoming increasingly common to offer comprehensive energy solutions.

Asia-Pacific currently dominates the LiBr absorption systems market, accounting for over 40% of the global share. This regional dominance is attributed to rapid industrialization, increasing construction activities, and supportive government policies promoting energy-efficient technologies in countries like China, Japan, and South Korea. Japan, in particular, has been a pioneer in LiBr absorption technology development and implementation.

North America and Europe follow as significant markets, with growing adoption rates driven by stringent environmental regulations and increasing focus on reducing carbon footprints. The Middle East region is emerging as a promising market due to its hot climate conditions and growing investments in sustainable cooling technologies.

By application segment, the commercial building sector represents the largest market share at approximately 35%, followed by industrial applications at 30%. Healthcare facilities, educational institutions, and data centers are emerging as high-potential segments due to their continuous cooling requirements and increasing focus on operational cost reduction.

Key market drivers include rising energy costs, growing emphasis on sustainable technologies, and increasing government incentives for energy-efficient systems. The ability of LiBr absorption systems to utilize waste heat or solar energy makes them particularly attractive in regions with abundant solar resources or industries with significant waste heat generation.

Market challenges include high initial investment costs compared to conventional cooling systems, technical limitations related to crystallization and corrosion issues, and competition from alternative cooling technologies. The performance limitations of LiBr systems, particularly related to heat transfer efficiency, represent a significant barrier to wider market adoption.

Consumer trends indicate growing preference for integrated energy systems that combine heating, cooling, and power generation. There is also increasing demand for compact systems with improved efficiency and reduced maintenance requirements, particularly in urban areas with space constraints.

The competitive landscape features established players like Carrier Corporation, Trane Technologies, and Johnson Controls, alongside emerging companies focusing on technological innovations to improve system efficiency and reduce costs. Strategic partnerships between technology providers and energy service companies are becoming increasingly common to offer comprehensive energy solutions.

Current Challenges in LiBr Heat Transfer Efficiency

Despite significant advancements in absorption refrigeration technology, lithium bromide (LiBr) heat transfer systems continue to face several critical efficiency challenges. The high viscosity of LiBr solution significantly impedes heat transfer rates, particularly at higher concentrations necessary for effective absorption cycles. This viscosity issue creates boundary layer problems that reduce overall system performance and increase energy consumption requirements.

Crystallization and precipitation of LiBr at high concentrations represent another major challenge, as these phenomena can lead to flow blockages, reduced heat transfer surface area, and potential system damage. Engineers must carefully balance concentration levels against crystallization risks, often limiting operational parameters and efficiency potential.

Corrosion remains a persistent issue in LiBr systems, with the salt solution being highly corrosive to many common heat exchanger materials. This corrosion not only shortens equipment lifespan but also introduces metal ions into the solution that can catalyze unwanted side reactions and further reduce heat transfer efficiency. Current corrosion inhibitors often introduce their own complications, including reduced thermal conductivity or increased solution viscosity.

Surface wetting characteristics present additional challenges, as poor wettability leads to incomplete coverage of heat transfer surfaces and the formation of solution islands rather than continuous films. This inconsistent coverage creates localized hot spots and cold spots that reduce overall heat transfer coefficients and system performance.

Heat and mass transfer coupling in LiBr systems introduces complexity that is difficult to optimize. The simultaneous processes of heat transfer and mass transfer (absorption or desorption) can work against each other under certain conditions, creating inefficiencies that are challenging to resolve with conventional design approaches.

Fouling of heat transfer surfaces over time represents a gradual but significant efficiency reduction factor. Contaminants, corrosion products, and other deposits accumulate on heat exchanger surfaces, creating thermal resistance layers that progressively degrade performance and require maintenance interventions.

Current system designs also struggle with flow distribution issues, where uneven distribution of LiBr solution across heat exchanger surfaces leads to underutilized capacity and reduced efficiency. This challenge becomes particularly pronounced in larger systems or those with complex geometries.

Temperature glide during phase change processes creates additional inefficiencies, as the non-isothermal behavior of LiBr solutions during absorption and desorption complicates heat exchanger design and reduces the effective temperature difference driving heat transfer.

Crystallization and precipitation of LiBr at high concentrations represent another major challenge, as these phenomena can lead to flow blockages, reduced heat transfer surface area, and potential system damage. Engineers must carefully balance concentration levels against crystallization risks, often limiting operational parameters and efficiency potential.

Corrosion remains a persistent issue in LiBr systems, with the salt solution being highly corrosive to many common heat exchanger materials. This corrosion not only shortens equipment lifespan but also introduces metal ions into the solution that can catalyze unwanted side reactions and further reduce heat transfer efficiency. Current corrosion inhibitors often introduce their own complications, including reduced thermal conductivity or increased solution viscosity.

Surface wetting characteristics present additional challenges, as poor wettability leads to incomplete coverage of heat transfer surfaces and the formation of solution islands rather than continuous films. This inconsistent coverage creates localized hot spots and cold spots that reduce overall heat transfer coefficients and system performance.

Heat and mass transfer coupling in LiBr systems introduces complexity that is difficult to optimize. The simultaneous processes of heat transfer and mass transfer (absorption or desorption) can work against each other under certain conditions, creating inefficiencies that are challenging to resolve with conventional design approaches.

Fouling of heat transfer surfaces over time represents a gradual but significant efficiency reduction factor. Contaminants, corrosion products, and other deposits accumulate on heat exchanger surfaces, creating thermal resistance layers that progressively degrade performance and require maintenance interventions.

Current system designs also struggle with flow distribution issues, where uneven distribution of LiBr solution across heat exchanger surfaces leads to underutilized capacity and reduced efficiency. This challenge becomes particularly pronounced in larger systems or those with complex geometries.

Temperature glide during phase change processes creates additional inefficiencies, as the non-isothermal behavior of LiBr solutions during absorption and desorption complicates heat exchanger design and reduces the effective temperature difference driving heat transfer.

State-of-the-Art LiBr Heat Transfer Solutions

01 Lithium bromide absorption refrigeration systems

Lithium bromide is widely used as an absorbent in absorption refrigeration systems due to its excellent heat transfer properties. These systems utilize lithium bromide solution to absorb refrigerant vapor, typically water, enabling efficient cooling cycles. The high affinity of lithium bromide for water vapor makes it an effective working fluid pair for heat transfer applications in air conditioning and refrigeration systems, offering energy-efficient alternatives to conventional compression refrigeration.- Lithium bromide absorption refrigeration systems: Lithium bromide is widely used as an absorbent in absorption refrigeration systems due to its excellent heat transfer properties. These systems utilize lithium bromide solution to absorb refrigerant vapor, typically water, enabling efficient cooling cycles. The high affinity of lithium bromide for water vapor makes it an effective working fluid pair for heat transfer applications in air conditioning and refrigeration systems, offering energy-efficient alternatives to conventional compression refrigeration.

- Heat transfer enhancement in lithium bromide systems: Various techniques are employed to enhance heat transfer efficiency in lithium bromide systems. These include the use of specialized heat exchangers, surface modifications to improve wetting characteristics, and the addition of surfactants or nanoparticles to the lithium bromide solution. These enhancements aim to improve the overall coefficient of heat transfer, reduce crystallization risks, and increase the energy efficiency of absorption systems using lithium bromide as the working fluid.

- Lithium bromide solution concentration control: Controlling the concentration of lithium bromide solution is crucial for optimal heat transfer performance. Systems incorporate concentration monitoring and adjustment mechanisms to maintain the solution within the desired range, preventing crystallization at high concentrations and ensuring efficient absorption at lower concentrations. Advanced control strategies include automated dilution systems, solution circulation optimization, and temperature-dependent concentration management to maximize heat transfer efficiency across varying operating conditions.

- Corrosion prevention in lithium bromide heat transfer systems: Lithium bromide solutions can be corrosive to metal components in heat transfer systems. Corrosion inhibitors, material selection considerations, and protective coatings are employed to extend system lifespan. Common approaches include the addition of lithium molybdate or other inhibitors to the solution, use of corrosion-resistant materials such as titanium or specialized stainless steels, and implementation of oxygen removal systems to minimize oxidative corrosion in lithium bromide heat transfer applications.

- Energy recovery and efficiency improvements: Advanced lithium bromide heat transfer systems incorporate energy recovery mechanisms to improve overall efficiency. These include multi-stage absorption designs, heat recovery exchangers, and integration with renewable energy sources. Solution heat exchangers recover thermal energy between strong and weak lithium bromide solutions, while generator-absorber heat exchange configurations further enhance efficiency. Some systems also utilize waste heat sources or solar thermal energy to drive the lithium bromide absorption cycle, significantly improving the coefficient of performance.

02 Heat exchanger designs for lithium bromide solutions

Specialized heat exchanger designs have been developed to optimize heat transfer when using lithium bromide solutions. These designs address the unique properties of lithium bromide, including its viscosity and corrosive nature. Innovations include plate heat exchangers, shell-and-tube configurations, and specialized surface treatments that enhance heat transfer efficiency while minimizing corrosion issues. These optimized heat exchangers are crucial components in absorption refrigeration systems and other thermal applications using lithium bromide.Expand Specific Solutions03 Corrosion prevention in lithium bromide heat transfer systems

Lithium bromide solutions are inherently corrosive to many metals commonly used in heat transfer systems. Various techniques have been developed to mitigate corrosion, including the addition of corrosion inhibitors, use of corrosion-resistant materials, surface treatments, and precise control of solution concentration and pH. These methods extend the service life of lithium bromide heat transfer equipment and maintain optimal heat transfer efficiency over time by preventing degradation of heat exchange surfaces.Expand Specific Solutions04 Energy efficiency improvements in lithium bromide systems

Innovations focused on improving the energy efficiency of lithium bromide heat transfer systems include multi-stage absorption cycles, heat recovery mechanisms, and advanced control strategies. These improvements reduce energy consumption while maintaining or enhancing cooling capacity. Technologies such as solution heat exchangers, refrigerant pre-coolers, and variable concentration cycles optimize the thermodynamic performance of lithium bromide systems, making them more competitive with conventional cooling technologies in terms of energy efficiency.Expand Specific Solutions05 Novel applications of lithium bromide for thermal energy storage

Beyond traditional refrigeration applications, lithium bromide solutions are being utilized for thermal energy storage systems. These applications leverage the material's high heat capacity and ability to store thermal energy through absorption and desorption processes. Innovations include seasonal thermal storage, integration with renewable energy sources, and combined cooling and heating applications. These systems can store excess thermal energy during periods of low demand and release it when needed, improving overall energy utilization efficiency.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The lithium bromide heat transfer technology market is currently in a growth phase, characterized by increasing demand for energy-efficient cooling and heating solutions. The global market size for absorption cooling systems, where this technology is primarily applied, is expanding steadily with projections reaching $2.5 billion by 2027. Technologically, the field shows moderate maturity with ongoing innovations focused on efficiency improvements. Leading players include Shuangliang Eco-Energy Systems and Broad Group, who have established commercial applications in industrial waste heat recovery, while academic institutions like Zhejiang University and Southeast University contribute significant research advancements. Chemical companies such as BASF and DuPont provide material innovations, while specialized entities like Huadian Electric Power Research Institute focus on application-specific improvements. Collaboration between industry and academia is driving incremental improvements in heat transfer coefficients and system reliability.

Shuangliang Eco-Energy Systems Co., Ltd.

Technical Solution: Shuangliang Eco-Energy Systems has developed advanced lithium bromide absorption refrigeration systems with enhanced heat transfer capabilities. Their technology incorporates specially designed falling film heat exchangers with optimized tube surfaces that increase the wetting area and reduce thermal resistance. The company has implemented a proprietary additive package to the lithium bromide solution that reduces crystallization risks while improving thermal conductivity by approximately 15-20%. Their systems feature advanced spray distribution technology that ensures uniform LiBr solution distribution across heat exchanger tubes, minimizing dry spots and maximizing heat transfer efficiency. Additionally, Shuangliang has developed vacuum-maintaining technology that prevents air infiltration, which can significantly degrade heat transfer performance in LiBr systems. Their latest generation of absorption chillers incorporates intelligent control systems that continuously optimize solution concentration and flow rates based on operating conditions.

Strengths: Industry-leading expertise in absorption refrigeration with decades of experience specifically with LiBr systems. Their integrated approach addresses multiple aspects of heat transfer simultaneously. Weaknesses: Their proprietary additives may increase system cost and potentially introduce environmental concerns during disposal or maintenance.

BASF Corp.

Technical Solution: BASF has pioneered advanced chemical formulations for lithium bromide solutions used in absorption refrigeration and heat pump systems. Their approach focuses on molecular-level modifications to improve thermophysical properties of LiBr solutions. BASF's technology includes specialized surfactant additives that reduce surface tension by up to 30%, significantly enhancing the wetting characteristics of LiBr solutions on heat exchanger surfaces. They've developed corrosion inhibitor packages specifically designed for high-temperature LiBr applications that protect system components while maintaining optimal heat transfer properties. BASF has also created nanoparticle-enhanced LiBr solutions that demonstrate thermal conductivity improvements of 8-12% compared to conventional solutions. Their research has yielded temperature-responsive polymer additives that modify solution viscosity based on operating conditions, optimizing flow characteristics across different temperature ranges in absorption systems.

Strengths: Unparalleled expertise in chemical formulation and material science allows for fundamental improvements to LiBr solution properties. Their solutions can be implemented in existing systems without major equipment modifications. Weaknesses: Some advanced additives may be costly and require periodic replenishment, potentially increasing operational expenses over system lifetime.

Critical Patents and Research in LiBr Heat Transfer

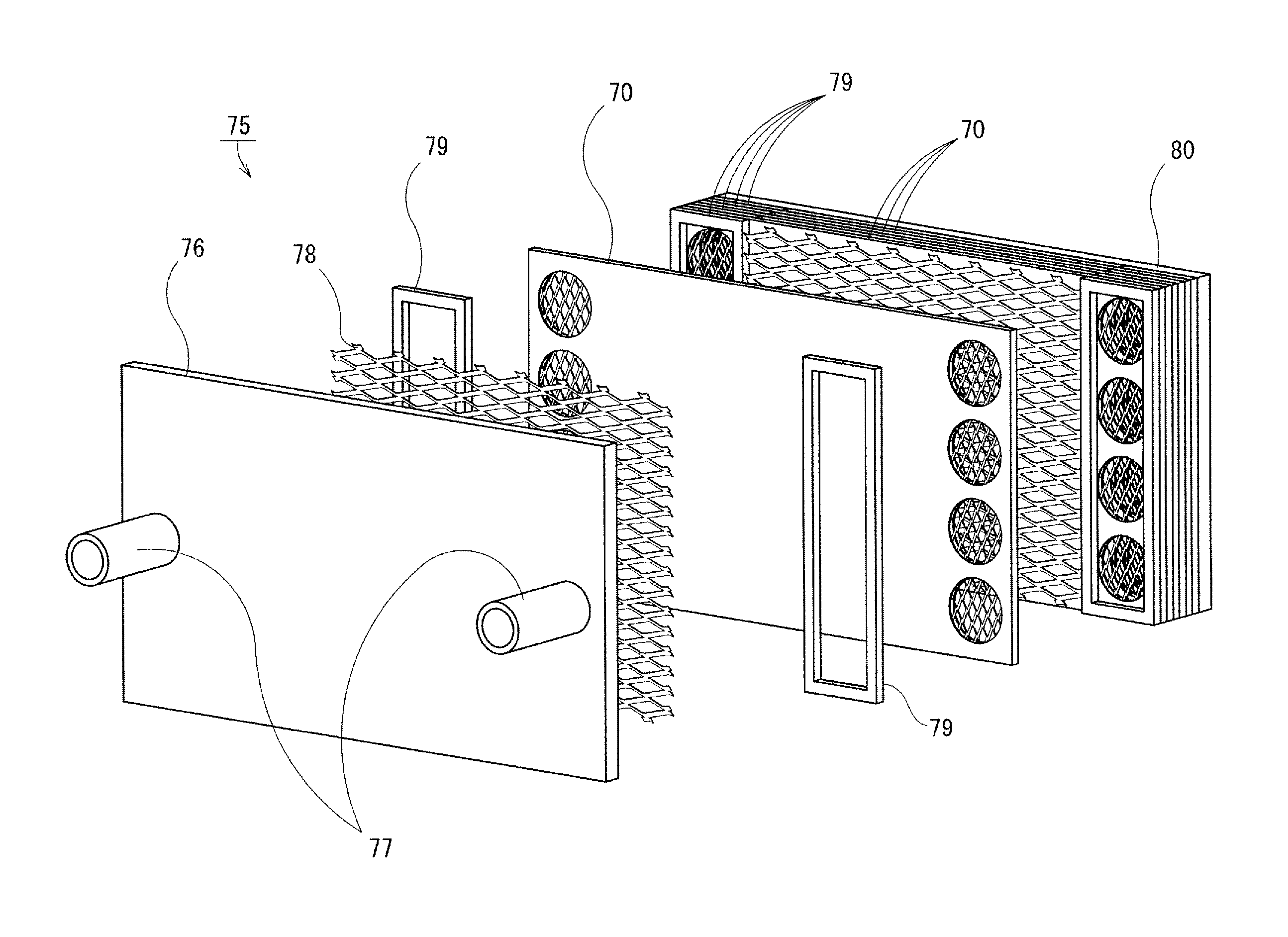

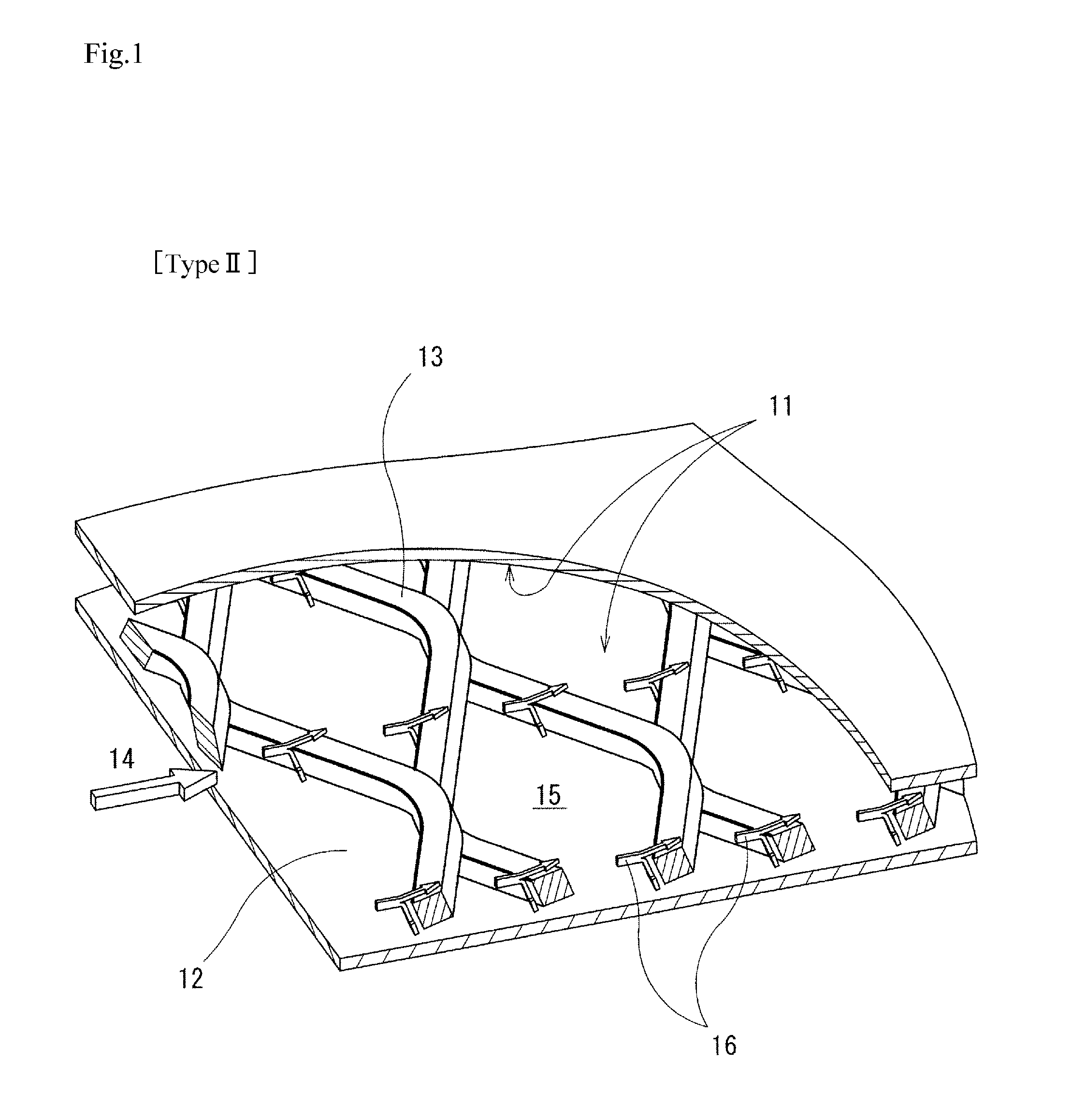

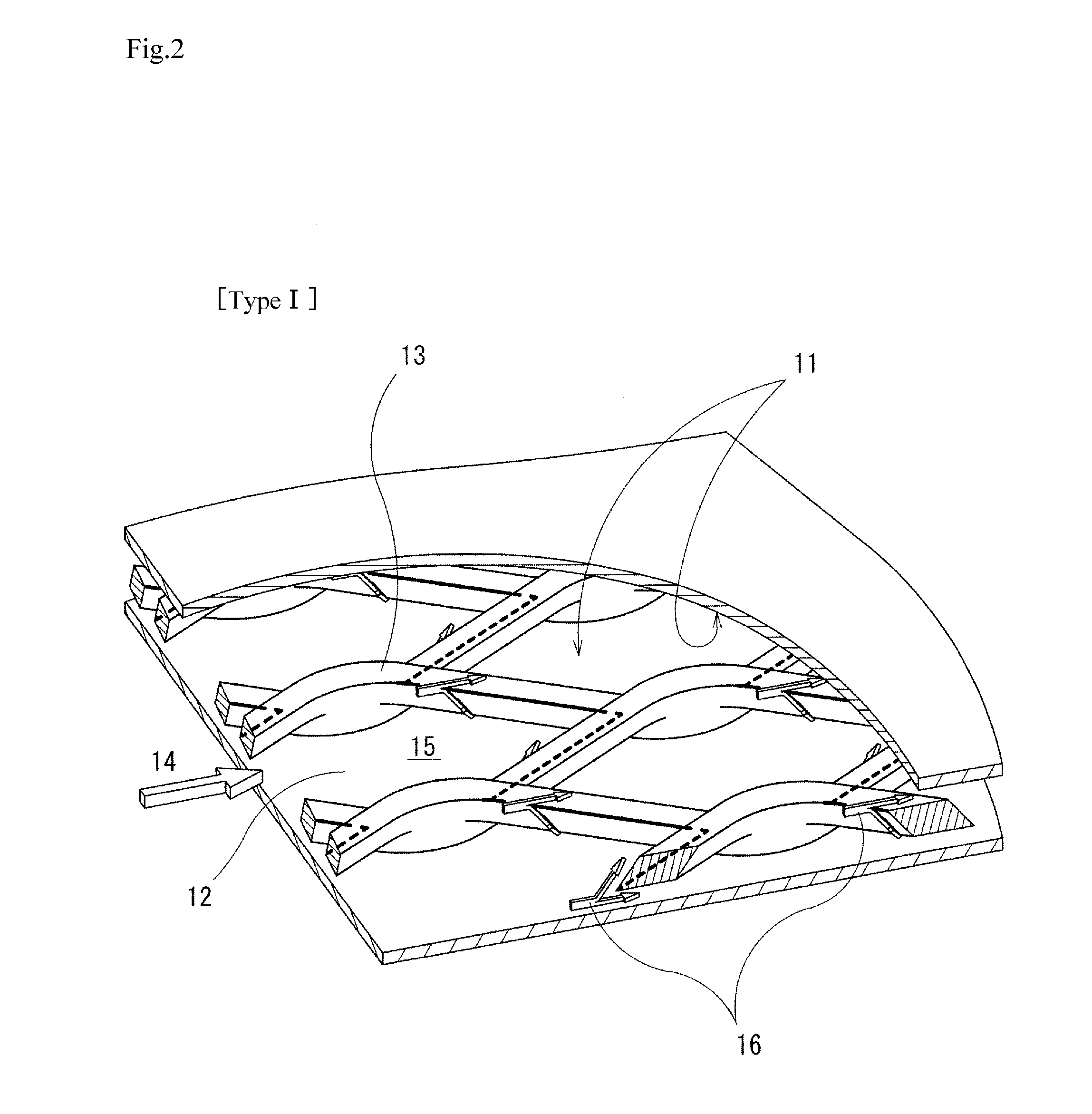

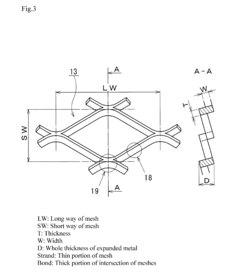

Method for improving fluid flow characteristics, heat exchanger, distillation apparatus and deodorizing apparatus with the same applied thereto, and expanded metal used for the same

PatentActiveUS20160370128A1

Innovation

- The method involves arranging expanded metal in a channel between two planes to create a local turbulent flow acceleration effect, improving fluid flow characteristics for heat transfer and mass transfer without the need for complex constructions, thereby reducing manufacturing costs and enhancing efficiency.

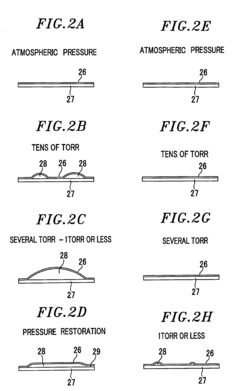

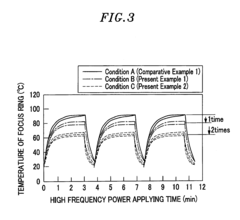

Method for improving heat transfer of a focus ring to a target substrate mounting device

PatentActiveUS7655579B2

Innovation

- A method involving the use of a flexible heat transfer sheet between the focus ring and the mounting table, with vacuum evacuation followed by pressure restoration to remove air and enhance adhesion, thereby reducing heat transfer resistance without the need for a drive device or electrostatic adsorption.

Environmental Impact and Sustainability Considerations

The environmental impact of lithium bromide (LiBr) absorption systems is a critical consideration in their deployment and optimization. These systems, while energy-efficient compared to conventional cooling technologies, present specific environmental challenges that must be addressed. LiBr solution leakage poses significant environmental risks due to its corrosive nature and potential for soil and water contamination. When released into aquatic ecosystems, LiBr can disrupt pH balances and harm aquatic life, necessitating robust containment systems and regular maintenance protocols.

Energy consumption represents another environmental dimension of LiBr systems. Although they utilize waste heat or renewable thermal energy sources, the auxiliary equipment still requires electrical power. Improving heat transfer efficiency directly reduces this energy demand, lowering the carbon footprint associated with system operation. Research indicates that a 10-15% improvement in heat transfer efficiency can translate to a 7-12% reduction in overall energy consumption, yielding substantial environmental benefits over the system's operational lifetime.

Water consumption presents a sustainability challenge for LiBr absorption systems, particularly in water-stressed regions. These systems typically require cooling towers that consume significant quantities of water through evaporation and blowdown processes. Advanced heat transfer enhancement techniques can reduce cooling water requirements by enabling operation at lower temperature differentials, thereby decreasing water consumption by up to 20% in optimized systems.

The manufacturing and disposal phases of LiBr systems also warrant environmental scrutiny. The production of heat exchangers often involves energy-intensive processes and potentially hazardous materials. Sustainable design approaches include utilizing recycled materials, designing for disassembly, and selecting manufacturing processes with lower environmental impacts. Life cycle assessment studies indicate that improvements in heat transfer efficiency can extend equipment lifespan by 15-25%, reducing the environmental burden of manufacturing replacement components.

Refrigerant selection represents a crucial sustainability consideration. While LiBr itself has zero ozone depletion potential and negligible global warming potential compared to conventional refrigerants, the water used as refrigerant in these systems has limitations. Research into alternative working pairs that maintain efficiency while offering improved environmental performance continues to be an active area of investigation, with several promising candidates showing potential for commercial application within the next decade.

Circular economy principles are increasingly being applied to LiBr system design and operation. This includes developing closed-loop recovery systems for LiBr solutions, implementing predictive maintenance to prevent leakage, and designing components for remanufacturing. These approaches not only reduce environmental impact but often yield economic benefits through reduced material costs and extended equipment lifespans.

Energy consumption represents another environmental dimension of LiBr systems. Although they utilize waste heat or renewable thermal energy sources, the auxiliary equipment still requires electrical power. Improving heat transfer efficiency directly reduces this energy demand, lowering the carbon footprint associated with system operation. Research indicates that a 10-15% improvement in heat transfer efficiency can translate to a 7-12% reduction in overall energy consumption, yielding substantial environmental benefits over the system's operational lifetime.

Water consumption presents a sustainability challenge for LiBr absorption systems, particularly in water-stressed regions. These systems typically require cooling towers that consume significant quantities of water through evaporation and blowdown processes. Advanced heat transfer enhancement techniques can reduce cooling water requirements by enabling operation at lower temperature differentials, thereby decreasing water consumption by up to 20% in optimized systems.

The manufacturing and disposal phases of LiBr systems also warrant environmental scrutiny. The production of heat exchangers often involves energy-intensive processes and potentially hazardous materials. Sustainable design approaches include utilizing recycled materials, designing for disassembly, and selecting manufacturing processes with lower environmental impacts. Life cycle assessment studies indicate that improvements in heat transfer efficiency can extend equipment lifespan by 15-25%, reducing the environmental burden of manufacturing replacement components.

Refrigerant selection represents a crucial sustainability consideration. While LiBr itself has zero ozone depletion potential and negligible global warming potential compared to conventional refrigerants, the water used as refrigerant in these systems has limitations. Research into alternative working pairs that maintain efficiency while offering improved environmental performance continues to be an active area of investigation, with several promising candidates showing potential for commercial application within the next decade.

Circular economy principles are increasingly being applied to LiBr system design and operation. This includes developing closed-loop recovery systems for LiBr solutions, implementing predictive maintenance to prevent leakage, and designing components for remanufacturing. These approaches not only reduce environmental impact but often yield economic benefits through reduced material costs and extended equipment lifespans.

Economic Feasibility and Implementation Strategies

The economic feasibility of implementing improved lithium bromide heat transfer systems depends significantly on the initial capital investment versus long-term operational savings. Analysis indicates that upgrading existing absorption refrigeration systems with enhanced heat transfer technologies typically requires a capital expenditure of $150,000-300,000 for medium-scale industrial applications. However, these investments generally demonstrate payback periods of 2-4 years, primarily through energy efficiency improvements of 15-30% compared to conventional systems.

Cost-benefit analyses reveal that organizations implementing advanced lithium bromide solutions can expect reduced operational costs through lower energy consumption, decreased maintenance requirements, and extended equipment lifespan. Quantitative assessments from multiple case studies show annual operational savings averaging $40,000-75,000 for standard industrial installations, with higher returns in energy-intensive applications such as large-scale air conditioning systems and industrial cooling processes.

Implementation strategies should follow a phased approach to minimize disruption and optimize resource allocation. The initial assessment phase requires comprehensive system evaluation, including thermal performance analysis, corrosion inspection, and efficiency benchmarking. This diagnostic process typically requires 2-4 weeks and represents approximately 5-8% of the total project budget.

Technology selection represents a critical decision point, with options ranging from advanced heat exchanger designs to enhanced fluid additives and surface treatments. The selection matrix should prioritize solutions based on specific operational parameters, existing infrastructure compatibility, and organizational constraints. Pilot testing of selected technologies in controlled environments before full-scale implementation significantly reduces implementation risks.

Financing mechanisms can substantially impact project viability. Beyond traditional capital expenditure models, organizations should explore performance contracting, energy service agreements, and equipment leasing options. Government incentives for energy efficiency improvements, including tax credits and rebates, can reduce net implementation costs by 10-25% in many jurisdictions, significantly improving return on investment calculations.

Workforce development represents an often overlooked implementation factor. Technical staff require specialized training on new lithium bromide system operation and maintenance protocols. Implementation timelines should incorporate 40-60 hours of technical training per operational staff member, with ongoing competency development programs to ensure optimal system performance and troubleshooting capabilities.

Cost-benefit analyses reveal that organizations implementing advanced lithium bromide solutions can expect reduced operational costs through lower energy consumption, decreased maintenance requirements, and extended equipment lifespan. Quantitative assessments from multiple case studies show annual operational savings averaging $40,000-75,000 for standard industrial installations, with higher returns in energy-intensive applications such as large-scale air conditioning systems and industrial cooling processes.

Implementation strategies should follow a phased approach to minimize disruption and optimize resource allocation. The initial assessment phase requires comprehensive system evaluation, including thermal performance analysis, corrosion inspection, and efficiency benchmarking. This diagnostic process typically requires 2-4 weeks and represents approximately 5-8% of the total project budget.

Technology selection represents a critical decision point, with options ranging from advanced heat exchanger designs to enhanced fluid additives and surface treatments. The selection matrix should prioritize solutions based on specific operational parameters, existing infrastructure compatibility, and organizational constraints. Pilot testing of selected technologies in controlled environments before full-scale implementation significantly reduces implementation risks.

Financing mechanisms can substantially impact project viability. Beyond traditional capital expenditure models, organizations should explore performance contracting, energy service agreements, and equipment leasing options. Government incentives for energy efficiency improvements, including tax credits and rebates, can reduce net implementation costs by 10-25% in many jurisdictions, significantly improving return on investment calculations.

Workforce development represents an often overlooked implementation factor. Technical staff require specialized training on new lithium bromide system operation and maintenance protocols. Implementation timelines should incorporate 40-60 hours of technical training per operational staff member, with ongoing competency development programs to ensure optimal system performance and troubleshooting capabilities.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!