Measure Lithium Bromide Concentration in Solutions — Criteria

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LiBr Concentration Measurement Background and Objectives

Lithium bromide (LiBr) solutions have been extensively utilized in absorption refrigeration systems since the early 20th century. The evolution of LiBr concentration measurement techniques has progressed from rudimentary density measurements to sophisticated spectroscopic methods. This technological progression has been driven by the critical need for precise concentration monitoring in absorption chillers, where even small deviations can significantly impact system efficiency and operational reliability.

The accurate measurement of LiBr concentration is fundamental to maintaining optimal performance in absorption refrigeration systems. These systems rely on the thermodynamic properties of LiBr solutions, particularly their ability to absorb water vapor at varying concentrations. The relationship between concentration and absorption efficiency follows a non-linear curve, making precise measurement essential for system control and energy optimization.

Current industry standards typically require concentration measurement accuracy within ±0.5% for effective operation. This level of precision ensures proper crystallization prevention, optimal heat transfer, and energy efficiency. However, as energy efficiency standards become more stringent globally, there is increasing pressure to improve measurement accuracy to ±0.2% or better, particularly in large industrial installations where even marginal efficiency improvements translate to substantial energy savings.

The technical objectives for LiBr concentration measurement technologies encompass several critical parameters. First, measurement accuracy must be consistently maintained across the typical operating concentration range of 45-65% by weight. Second, the measurement method should demonstrate stability under varying temperature conditions (typically 20-180°C) that occur in different parts of absorption systems. Third, the technology should offer real-time or near-real-time monitoring capabilities to enable dynamic system control.

Additionally, modern measurement solutions must address practical implementation challenges. These include resistance to corrosion from the highly corrosive nature of concentrated LiBr solutions, minimal maintenance requirements for long-term deployment, and cost-effectiveness for widespread adoption. Emerging requirements also include compatibility with digital control systems and IoT integration for remote monitoring and predictive maintenance applications.

The evolution of measurement technologies has been influenced by broader technological trends, including miniaturization of sensors, advances in materials science, and the integration of artificial intelligence for data interpretation. These developments have opened new possibilities for more accurate, reliable, and cost-effective concentration monitoring solutions that can be deployed throughout absorption refrigeration systems.

The accurate measurement of LiBr concentration is fundamental to maintaining optimal performance in absorption refrigeration systems. These systems rely on the thermodynamic properties of LiBr solutions, particularly their ability to absorb water vapor at varying concentrations. The relationship between concentration and absorption efficiency follows a non-linear curve, making precise measurement essential for system control and energy optimization.

Current industry standards typically require concentration measurement accuracy within ±0.5% for effective operation. This level of precision ensures proper crystallization prevention, optimal heat transfer, and energy efficiency. However, as energy efficiency standards become more stringent globally, there is increasing pressure to improve measurement accuracy to ±0.2% or better, particularly in large industrial installations where even marginal efficiency improvements translate to substantial energy savings.

The technical objectives for LiBr concentration measurement technologies encompass several critical parameters. First, measurement accuracy must be consistently maintained across the typical operating concentration range of 45-65% by weight. Second, the measurement method should demonstrate stability under varying temperature conditions (typically 20-180°C) that occur in different parts of absorption systems. Third, the technology should offer real-time or near-real-time monitoring capabilities to enable dynamic system control.

Additionally, modern measurement solutions must address practical implementation challenges. These include resistance to corrosion from the highly corrosive nature of concentrated LiBr solutions, minimal maintenance requirements for long-term deployment, and cost-effectiveness for widespread adoption. Emerging requirements also include compatibility with digital control systems and IoT integration for remote monitoring and predictive maintenance applications.

The evolution of measurement technologies has been influenced by broader technological trends, including miniaturization of sensors, advances in materials science, and the integration of artificial intelligence for data interpretation. These developments have opened new possibilities for more accurate, reliable, and cost-effective concentration monitoring solutions that can be deployed throughout absorption refrigeration systems.

Market Applications and Demand Analysis for LiBr Concentration Sensing

The lithium bromide (LiBr) concentration sensing market is experiencing significant growth driven by the expanding adoption of absorption refrigeration systems across various industries. The global absorption chiller market, which heavily relies on LiBr solutions, is projected to reach $2.3 billion by 2027, growing at a CAGR of 5.8% from 2022. This growth directly translates to increased demand for accurate and reliable LiBr concentration measurement technologies.

The HVAC industry represents the largest application segment for LiBr concentration sensing, accounting for approximately 65% of the total market. In commercial buildings and industrial facilities, absorption chillers using LiBr-water solutions are preferred for their energy efficiency and ability to utilize waste heat. The precise monitoring of LiBr concentration is critical for maintaining optimal system performance and preventing crystallization issues that can damage equipment.

Industrial process cooling applications constitute the second-largest market segment at 20%. Industries such as pharmaceuticals, food processing, and chemical manufacturing require precise temperature control in their processes, driving the adoption of absorption cooling systems and consequently the need for concentration monitoring solutions.

The renewable energy sector presents the fastest-growing application area for LiBr concentration sensing technology. Solar thermal cooling systems, which pair solar collectors with absorption chillers, are gaining traction as sustainable alternatives to conventional cooling systems. This segment is expected to grow at a CAGR of 12.3% through 2028, creating substantial demand for advanced concentration measurement solutions.

Geographically, Asia Pacific dominates the market with a 42% share, led by China, Japan, and India. The region's rapid industrialization, coupled with government initiatives promoting energy-efficient technologies, is driving market growth. North America and Europe follow with market shares of 28% and 24% respectively, with particular growth in the commercial building sector.

End-users across these markets are increasingly demanding real-time, continuous monitoring capabilities rather than periodic manual testing. This shift is evidenced by the 35% year-over-year increase in sales of automated LiBr concentration monitoring systems in 2022. Additionally, there is growing interest in non-invasive measurement techniques that can be integrated into existing systems without disrupting operations.

The market also shows strong demand for multi-parameter sensing solutions that can simultaneously measure concentration, temperature, and pressure, providing comprehensive system monitoring. This trend aligns with the broader industrial movement toward integrated monitoring systems and IoT-enabled predictive maintenance approaches.

The HVAC industry represents the largest application segment for LiBr concentration sensing, accounting for approximately 65% of the total market. In commercial buildings and industrial facilities, absorption chillers using LiBr-water solutions are preferred for their energy efficiency and ability to utilize waste heat. The precise monitoring of LiBr concentration is critical for maintaining optimal system performance and preventing crystallization issues that can damage equipment.

Industrial process cooling applications constitute the second-largest market segment at 20%. Industries such as pharmaceuticals, food processing, and chemical manufacturing require precise temperature control in their processes, driving the adoption of absorption cooling systems and consequently the need for concentration monitoring solutions.

The renewable energy sector presents the fastest-growing application area for LiBr concentration sensing technology. Solar thermal cooling systems, which pair solar collectors with absorption chillers, are gaining traction as sustainable alternatives to conventional cooling systems. This segment is expected to grow at a CAGR of 12.3% through 2028, creating substantial demand for advanced concentration measurement solutions.

Geographically, Asia Pacific dominates the market with a 42% share, led by China, Japan, and India. The region's rapid industrialization, coupled with government initiatives promoting energy-efficient technologies, is driving market growth. North America and Europe follow with market shares of 28% and 24% respectively, with particular growth in the commercial building sector.

End-users across these markets are increasingly demanding real-time, continuous monitoring capabilities rather than periodic manual testing. This shift is evidenced by the 35% year-over-year increase in sales of automated LiBr concentration monitoring systems in 2022. Additionally, there is growing interest in non-invasive measurement techniques that can be integrated into existing systems without disrupting operations.

The market also shows strong demand for multi-parameter sensing solutions that can simultaneously measure concentration, temperature, and pressure, providing comprehensive system monitoring. This trend aligns with the broader industrial movement toward integrated monitoring systems and IoT-enabled predictive maintenance approaches.

Current Technologies and Challenges in LiBr Solution Measurement

The measurement of lithium bromide (LiBr) concentration in solutions presents significant technical challenges despite its critical importance in absorption refrigeration systems, industrial processes, and energy applications. Current measurement technologies can be broadly categorized into physical property-based methods, chemical analysis techniques, and emerging sensor technologies.

Density measurement remains one of the most widely implemented approaches, utilizing hydrometers, vibrating tube densitometers, and Coriolis flow meters. These methods leverage the direct correlation between LiBr concentration and solution density. However, they face limitations in accuracy when temperature fluctuations occur, typically requiring temperature compensation algorithms to maintain measurement integrity.

Refractive index measurement offers another physical property-based approach, employing refractometers to detect changes in light propagation through LiBr solutions. While providing non-invasive measurement capabilities, these systems require precise optical alignment and regular calibration to account for contamination effects that can distort readings.

Electrical conductivity methods utilize the relationship between ionic concentration and electrical properties, offering real-time monitoring capabilities. The challenge lies in distinguishing LiBr-specific conductivity from other ionic species that may be present in solution, particularly in industrial applications where solution purity cannot be guaranteed.

Spectroscopic techniques, including infrared and Raman spectroscopy, have gained traction for their ability to provide molecular-specific measurements. These methods can differentiate between LiBr and potential contaminants but require sophisticated equipment and expertise for proper implementation and data interpretation.

Titration and chemical analysis methods deliver high accuracy but remain primarily laboratory-based techniques unsuitable for continuous monitoring applications. The time delay between sampling and result reporting represents a significant limitation for process control applications.

Emerging technologies include miniaturized sensors based on microelectromechanical systems (MEMS), which show promise for in-situ monitoring but currently face challenges in long-term stability and drift compensation. Similarly, ion-selective electrodes specifically designed for lithium or bromide detection offer potential for continuous measurement but struggle with interference from competing ions in complex solutions.

The primary technical challenges across all measurement technologies include achieving sufficient accuracy (typically ±0.5% concentration) across wide concentration ranges (30-70% LiBr), maintaining measurement stability under varying temperature conditions (often 20-200°C), and ensuring sensor longevity in the corrosive environment that concentrated LiBr solutions present. Additionally, response time requirements for process control applications often necessitate measurement updates within seconds to minutes, further constraining technology selection.

Density measurement remains one of the most widely implemented approaches, utilizing hydrometers, vibrating tube densitometers, and Coriolis flow meters. These methods leverage the direct correlation between LiBr concentration and solution density. However, they face limitations in accuracy when temperature fluctuations occur, typically requiring temperature compensation algorithms to maintain measurement integrity.

Refractive index measurement offers another physical property-based approach, employing refractometers to detect changes in light propagation through LiBr solutions. While providing non-invasive measurement capabilities, these systems require precise optical alignment and regular calibration to account for contamination effects that can distort readings.

Electrical conductivity methods utilize the relationship between ionic concentration and electrical properties, offering real-time monitoring capabilities. The challenge lies in distinguishing LiBr-specific conductivity from other ionic species that may be present in solution, particularly in industrial applications where solution purity cannot be guaranteed.

Spectroscopic techniques, including infrared and Raman spectroscopy, have gained traction for their ability to provide molecular-specific measurements. These methods can differentiate between LiBr and potential contaminants but require sophisticated equipment and expertise for proper implementation and data interpretation.

Titration and chemical analysis methods deliver high accuracy but remain primarily laboratory-based techniques unsuitable for continuous monitoring applications. The time delay between sampling and result reporting represents a significant limitation for process control applications.

Emerging technologies include miniaturized sensors based on microelectromechanical systems (MEMS), which show promise for in-situ monitoring but currently face challenges in long-term stability and drift compensation. Similarly, ion-selective electrodes specifically designed for lithium or bromide detection offer potential for continuous measurement but struggle with interference from competing ions in complex solutions.

The primary technical challenges across all measurement technologies include achieving sufficient accuracy (typically ±0.5% concentration) across wide concentration ranges (30-70% LiBr), maintaining measurement stability under varying temperature conditions (often 20-200°C), and ensuring sensor longevity in the corrosive environment that concentrated LiBr solutions present. Additionally, response time requirements for process control applications often necessitate measurement updates within seconds to minutes, further constraining technology selection.

Existing Methodologies for LiBr Concentration Determination

01 Optical measurement methods for lithium bromide concentration

Optical measurement techniques utilize light properties to determine lithium bromide concentration in solutions. These methods include spectrophotometry, refractive index measurement, and optical density analysis. The techniques offer advantages of real-time monitoring without sample extraction and can be integrated into absorption refrigeration systems for continuous concentration monitoring. Some implementations use specific wavelengths of light to enhance measurement accuracy based on the absorption characteristics of lithium bromide solutions.- Optical measurement methods for lithium bromide concentration: Optical measurement techniques utilize light properties to determine lithium bromide concentration in solutions. These methods include spectrophotometry, refractive index measurement, and optical density analysis. The techniques provide non-invasive, real-time monitoring capabilities and can be integrated into automated control systems for absorption refrigeration units. These optical approaches offer advantages in terms of accuracy and response time compared to traditional methods.

- Electrochemical sensors for lithium bromide solutions: Electrochemical sensors measure lithium bromide concentration by analyzing electrical properties of the solution. These sensors utilize conductivity, impedance, or potentiometric principles to determine concentration levels. The sensors can be designed for continuous monitoring in absorption refrigeration systems, providing real-time data for system optimization. Some designs incorporate temperature compensation mechanisms to ensure accurate readings across varying operating conditions.

- Density-based measurement systems: Density measurement systems determine lithium bromide concentration by analyzing the relationship between solution density and concentration. These systems may use vibrating tube densitometers, hydrometer principles, or pressure differential techniques. The density approach provides reliable concentration data that can be used for controlling absorption refrigeration cycles. Some systems incorporate automatic temperature compensation to account for density variations with temperature changes.

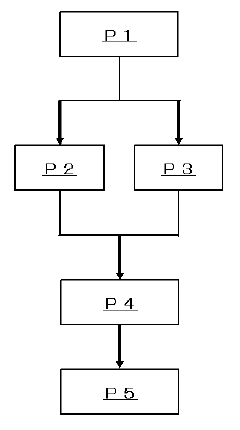

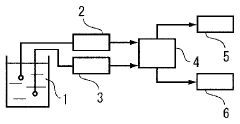

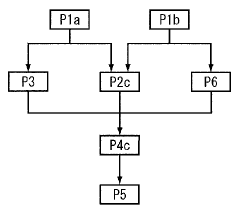

- Integrated monitoring systems for absorption refrigeration units: Integrated monitoring systems combine multiple measurement techniques and sensors to provide comprehensive analysis of lithium bromide solutions in absorption refrigeration units. These systems may incorporate concentration measurement alongside temperature, pressure, and flow monitoring. The integrated approach enables better control of the absorption cycle, improved energy efficiency, and early detection of potential issues such as crystallization. Some systems include automated adjustment mechanisms based on concentration readings.

- Portable and handheld concentration measurement devices: Portable devices for measuring lithium bromide concentration provide flexibility for maintenance and field testing applications. These compact instruments may utilize various measurement principles including electrical conductivity, optical methods, or density analysis. The portable nature allows technicians to perform spot checks throughout absorption refrigeration systems without the need for permanent sensor installation. Some devices include digital displays, data logging capabilities, and wireless connectivity for easy documentation of measurements.

02 Electrochemical sensors for lithium bromide concentration measurement

Electrochemical sensors determine lithium bromide concentration by measuring electrical properties such as conductivity, impedance, or potential difference. These sensors typically consist of electrodes immersed in the solution, with the electrical response correlating to concentration levels. Some designs incorporate temperature compensation mechanisms to ensure accurate readings across varying operating conditions. These sensors are particularly useful in absorption refrigeration systems where continuous monitoring is required for optimal performance.Expand Specific Solutions03 Integrated monitoring systems for absorption refrigeration units

Specialized monitoring systems designed specifically for absorption refrigeration units incorporate lithium bromide concentration measurement as a critical parameter. These integrated systems often combine multiple sensor types with data processing capabilities to provide comprehensive monitoring of system performance. The systems may include automated control mechanisms that adjust operating parameters based on concentration measurements to maintain optimal efficiency. Some designs feature remote monitoring capabilities and alert systems for concentration deviations.Expand Specific Solutions04 Density and specific gravity measurement techniques

Methods based on density or specific gravity measurements provide an indirect approach to determining lithium bromide concentration. These techniques utilize the correlation between solution density and concentration, often employing hydrometers, densitometers, or vibrating tube density meters. Some implementations incorporate temperature compensation algorithms to account for density variations with temperature. These methods are valued for their simplicity and reliability in industrial applications where precise concentration control is necessary.Expand Specific Solutions05 Automated sampling and analysis systems

Automated systems for lithium bromide concentration measurement incorporate sampling mechanisms, analysis equipment, and data processing capabilities. These systems extract samples from the main process, perform concentration analysis using various methods, and provide feedback for process control. Some designs include self-cleaning features to prevent salt deposition and ensure measurement accuracy over extended periods. Advanced systems may incorporate machine learning algorithms to improve measurement accuracy and predict concentration trends based on operating conditions.Expand Specific Solutions

Key Industry Players in Chemical Concentration Sensing Technology

The lithium bromide concentration measurement market is in a growth phase, driven by increasing applications in absorption refrigeration systems and energy storage solutions. The market size is expanding due to rising demand in HVAC systems, particularly in commercial and industrial sectors. Technologically, the field shows moderate maturity with established methods like titration and spectroscopy, but innovation continues in sensor-based real-time monitoring. Key players include Carrier Corp. focusing on HVAC applications, Albemarle Corp. and BYD developing lithium compounds, SciAps offering portable analytical instruments, and METAWATER specializing in water treatment solutions. Hach Co. and Organo Corp. contribute significant advancements in water quality testing technologies, while research institutions like Vanderbilt University and Oxford University Innovation drive fundamental measurement innovations.

Carrier Corp.

Technical Solution: Carrier Corporation has developed an integrated lithium bromide concentration monitoring system specifically for their absorption chiller product line. Their technology combines refractive index measurement with electrical conductivity analysis to provide redundant verification of solution concentration. The system features inline sensors that continuously monitor lithium bromide concentration without interrupting chiller operation, with measurement accuracy of ±0.5% across the operational range of 45-65%. Carrier's proprietary algorithms compensate for temperature effects and detect the presence of contaminants that might affect readings. Their SMART Service tool interfaces with these sensors to provide technicians with real-time concentration data and historical trends, enabling predictive maintenance before concentration issues affect chiller performance. The system includes automatic alerts when concentrations approach operational limits and can integrate with building automation systems for remote monitoring capabilities.

Strengths: Seamless integration with existing absorption chiller systems; continuous monitoring without operational interruption; dual measurement methodology for increased reliability; comprehensive data analysis tools. Weaknesses: Primarily designed for Carrier equipment; requires professional installation; higher cost compared to portable testing solutions; periodic sensor cleaning needed in some applications.

SciAps, Inc.

Technical Solution: SciAps has developed portable X-ray fluorescence (XRF) analyzers specifically calibrated for lithium bromide concentration measurement in absorption chiller solutions. Their handheld devices utilize advanced silicon drift detectors and proprietary algorithms to provide rapid, non-destructive analysis of lithium and bromide content simultaneously. The technology can measure concentrations from 5-70% with accuracy of ±1% in under 30 seconds per sample. SciAps' analyzers incorporate automatic matrix correction to account for solution density variations and potential interfering elements. Their Z-series analyzers feature GPS tagging of measurements, allowing facility managers to track concentration variations across multiple sampling points. The devices include Bluetooth connectivity for immediate data transfer to central monitoring systems and cloud storage for historical trend analysis of lithium bromide concentration in critical cooling systems.

Strengths: Rapid analysis time; non-destructive testing; simultaneous multi-element analysis capability; highly portable for field use; minimal sample preparation required. Weaknesses: Higher initial equipment cost; requires periodic factory calibration; limited accuracy at very low concentrations; regulatory considerations for X-ray generating devices.

Critical Patents and Research in LiBr Concentration Measurement

Lithium bromide concentration measuring method and system for lithium bromide water solution, and lithium bromide leakage detecting method

PatentInactiveJP2006258345A

Innovation

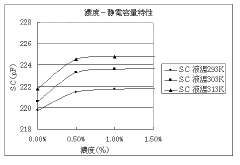

- A method and system using capacitance and temperature measurements, along with optional pH measurement, to determine lithium bromide concentration in real-time without sampling, utilizing capacitance and temperature relationships to calculate concentration accurately.

Lithium bromide aqueous solution concentration measuring device

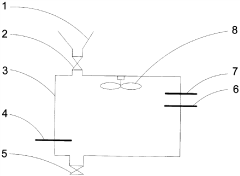

PatentInactiveCN218036715U

Innovation

- A device including a liquid inlet tank, a liquid inlet valve, a container, a solution thermometer, a liquid drain valve, an air thermometer, an air hygrometer and a fan is designed. The fan blows air to bring the surface of the lithium bromide aqueous solution into contact with the air hygrometer and thermometer. Platinum resistive and capacitive sensors measure the concentration of aqueous lithium bromide solutions.

Accuracy and Calibration Standards for LiBr Measurement Systems

Accurate measurement of lithium bromide (LiBr) concentration in solutions requires adherence to stringent calibration standards and precision metrics. Industry standards typically demand measurement accuracy within ±0.5% for absorption refrigeration systems, where LiBr serves as the primary working fluid. This level of precision is critical as even minor concentration deviations can significantly impact system efficiency and operational stability.

Calibration of LiBr measurement systems must follow traceable standards, preferably those established by national metrology institutes such as NIST (USA), PTB (Germany), or NIM (China). These calibration protocols typically involve multi-point verification using certified reference materials with known LiBr concentrations ranging from 30% to 65% by weight, covering the operational range of most absorption refrigeration systems.

Temperature compensation represents a crucial aspect of accuracy standards, as LiBr solution properties exhibit significant temperature dependence. Measurement systems must maintain accuracy across operational temperature ranges (typically 20°C to 200°C) with documented temperature coefficients and compensation algorithms. The industry standard requires temperature-compensated measurements to maintain the same ±0.5% accuracy across the entire operational temperature range.

Repeatability and reproducibility metrics form another cornerstone of LiBr measurement standards. High-quality measurement systems should demonstrate repeatability within ±0.2% under identical conditions and reproducibility within ±0.3% across different operators, instruments, and laboratories. These metrics should be validated through statistical analysis of multiple measurement series following ISO 5725 guidelines.

Long-term stability and drift characteristics must be quantified and documented for all LiBr concentration measurement systems. Acceptable drift is typically specified as less than 0.1% per month, with recalibration intervals determined based on stability testing. Systems should incorporate drift compensation mechanisms or alert operators when measurements exceed established drift thresholds.

Cross-sensitivity to common contaminants presents a significant challenge for LiBr measurement accuracy. Calibration standards must address potential interference from corrosion inhibitors, antifoaming agents, and metal ions commonly present in industrial LiBr solutions. Measurement systems should either compensate for these interferences or demonstrate immunity within specified concentration ranges.

Documentation requirements for calibration include comprehensive uncertainty budgets following GUM (Guide to the Expression of Uncertainty in Measurement) principles, with all contributing factors quantified and combined to establish measurement confidence intervals. Calibration certificates must include traceability information, environmental conditions during calibration, and the expanded uncertainty with a defined coverage factor.

Calibration of LiBr measurement systems must follow traceable standards, preferably those established by national metrology institutes such as NIST (USA), PTB (Germany), or NIM (China). These calibration protocols typically involve multi-point verification using certified reference materials with known LiBr concentrations ranging from 30% to 65% by weight, covering the operational range of most absorption refrigeration systems.

Temperature compensation represents a crucial aspect of accuracy standards, as LiBr solution properties exhibit significant temperature dependence. Measurement systems must maintain accuracy across operational temperature ranges (typically 20°C to 200°C) with documented temperature coefficients and compensation algorithms. The industry standard requires temperature-compensated measurements to maintain the same ±0.5% accuracy across the entire operational temperature range.

Repeatability and reproducibility metrics form another cornerstone of LiBr measurement standards. High-quality measurement systems should demonstrate repeatability within ±0.2% under identical conditions and reproducibility within ±0.3% across different operators, instruments, and laboratories. These metrics should be validated through statistical analysis of multiple measurement series following ISO 5725 guidelines.

Long-term stability and drift characteristics must be quantified and documented for all LiBr concentration measurement systems. Acceptable drift is typically specified as less than 0.1% per month, with recalibration intervals determined based on stability testing. Systems should incorporate drift compensation mechanisms or alert operators when measurements exceed established drift thresholds.

Cross-sensitivity to common contaminants presents a significant challenge for LiBr measurement accuracy. Calibration standards must address potential interference from corrosion inhibitors, antifoaming agents, and metal ions commonly present in industrial LiBr solutions. Measurement systems should either compensate for these interferences or demonstrate immunity within specified concentration ranges.

Documentation requirements for calibration include comprehensive uncertainty budgets following GUM (Guide to the Expression of Uncertainty in Measurement) principles, with all contributing factors quantified and combined to establish measurement confidence intervals. Calibration certificates must include traceability information, environmental conditions during calibration, and the expanded uncertainty with a defined coverage factor.

Environmental Impact and Safety Considerations of LiBr Handling

The handling of Lithium Bromide (LiBr) solutions presents significant environmental and safety challenges that must be carefully addressed in measurement and industrial applications. LiBr is highly hygroscopic and corrosive, posing risks to both equipment and personnel during concentration measurement procedures. When released into the environment, LiBr can disrupt aquatic ecosystems by altering pH levels and increasing salinity, potentially harming sensitive aquatic organisms and vegetation.

Workplace safety considerations are paramount when handling LiBr solutions. Direct skin contact can cause severe irritation and chemical burns, while inhalation of LiBr dust or aerosols may lead to respiratory tract irritation. Proper personal protective equipment (PPE) including chemical-resistant gloves, safety goggles, and appropriate respiratory protection must be employed during all measurement and handling operations.

Environmental management protocols for LiBr require specialized disposal procedures. The compound should never be discharged directly into sewage systems or water bodies. Instead, neutralization processes or professional hazardous waste management services should be utilized to ensure proper containment and disposal. Spill response procedures must be established, with appropriate containment materials readily available in areas where LiBr is handled or measured.

The corrosive nature of LiBr solutions also necessitates careful material selection for measurement equipment. Stainless steel components may experience stress corrosion cracking when exposed to LiBr, while certain polymers and elastomers can degrade upon prolonged contact. This corrosivity factor must be considered when designing or selecting concentration measurement systems to ensure long-term reliability and safety.

Regulatory compliance represents another critical aspect of LiBr handling. Various jurisdictions impose specific requirements for the storage, handling, and disposal of LiBr under hazardous materials regulations. Organizations must maintain current Safety Data Sheets (SDS) and ensure all personnel are properly trained in safe handling procedures and emergency response protocols specific to LiBr.

When implementing concentration measurement systems for LiBr solutions, engineering controls such as closed sampling systems, adequate ventilation, and splash guards should be incorporated to minimize exposure risks. Regular maintenance and calibration of measurement equipment are essential not only for accuracy but also for preventing leaks or equipment failures that could result in environmental releases or safety incidents.

Workplace safety considerations are paramount when handling LiBr solutions. Direct skin contact can cause severe irritation and chemical burns, while inhalation of LiBr dust or aerosols may lead to respiratory tract irritation. Proper personal protective equipment (PPE) including chemical-resistant gloves, safety goggles, and appropriate respiratory protection must be employed during all measurement and handling operations.

Environmental management protocols for LiBr require specialized disposal procedures. The compound should never be discharged directly into sewage systems or water bodies. Instead, neutralization processes or professional hazardous waste management services should be utilized to ensure proper containment and disposal. Spill response procedures must be established, with appropriate containment materials readily available in areas where LiBr is handled or measured.

The corrosive nature of LiBr solutions also necessitates careful material selection for measurement equipment. Stainless steel components may experience stress corrosion cracking when exposed to LiBr, while certain polymers and elastomers can degrade upon prolonged contact. This corrosivity factor must be considered when designing or selecting concentration measurement systems to ensure long-term reliability and safety.

Regulatory compliance represents another critical aspect of LiBr handling. Various jurisdictions impose specific requirements for the storage, handling, and disposal of LiBr under hazardous materials regulations. Organizations must maintain current Safety Data Sheets (SDS) and ensure all personnel are properly trained in safe handling procedures and emergency response protocols specific to LiBr.

When implementing concentration measurement systems for LiBr solutions, engineering controls such as closed sampling systems, adequate ventilation, and splash guards should be incorporated to minimize exposure risks. Regular maintenance and calibration of measurement equipment are essential not only for accuracy but also for preventing leaks or equipment failures that could result in environmental releases or safety incidents.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!