Analyzing Lithium Bromide Integration in HVAC Systems

AUG 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LiBr Absorption Technology Background and Objectives

Lithium Bromide (LiBr) absorption technology represents a significant advancement in heating, ventilation, and air conditioning (HVAC) systems, with its origins dating back to the early 20th century. The fundamental principle behind this technology leverages the hygroscopic properties of lithium bromide solution to create a refrigeration effect without conventional mechanical compression. This approach has evolved from basic absorption refrigeration concepts to sophisticated energy-efficient cooling systems that are increasingly relevant in today's sustainability-focused environment.

The evolution of LiBr absorption technology has been marked by several key developments. Initially deployed in industrial refrigeration applications in the 1930s, these systems gained prominence in the 1950s and 1960s as energy conservation became a growing concern. The oil crisis of the 1970s further accelerated research and development in this field, positioning LiBr absorption systems as viable alternatives to conventional vapor compression systems, particularly in scenarios where waste heat or low-grade thermal energy is available.

Current technological trends in LiBr absorption systems focus on enhancing coefficient of performance (COP), reducing physical footprint, minimizing crystallization risks, and improving overall system reliability. Innovations in heat exchanger design, working fluid formulations, and control systems have contributed to steady improvements in system efficiency and operational stability. Additionally, the integration of advanced materials and manufacturing techniques has addressed historical challenges related to corrosion and maintenance requirements.

The primary objective of implementing LiBr absorption technology in modern HVAC systems is to achieve sustainable cooling solutions with reduced electrical consumption and lower environmental impact. These systems aim to effectively utilize low-grade thermal energy sources such as solar heat, geothermal energy, or industrial waste heat that would otherwise be discarded. By converting these thermal resources into useful cooling capacity, LiBr systems offer a pathway to significant reductions in primary energy consumption and associated greenhouse gas emissions.

Another critical objective is to develop more compact and cost-effective LiBr absorption systems that can be deployed across diverse applications, from large commercial buildings to residential settings. Current research targets include improving part-load performance, enhancing heat and mass transfer processes, and developing more sophisticated control algorithms to optimize system operation under varying conditions. The ultimate goal is to position LiBr absorption technology as a mainstream alternative to conventional cooling systems, particularly in regions with abundant thermal resources or high electricity costs.

Looking forward, the technology roadmap for LiBr absorption systems includes further integration with renewable energy sources, development of hybrid systems that combine absorption and conventional technologies, and exploration of novel applications beyond traditional air conditioning, such as refrigeration, process cooling, and thermal energy storage solutions.

The evolution of LiBr absorption technology has been marked by several key developments. Initially deployed in industrial refrigeration applications in the 1930s, these systems gained prominence in the 1950s and 1960s as energy conservation became a growing concern. The oil crisis of the 1970s further accelerated research and development in this field, positioning LiBr absorption systems as viable alternatives to conventional vapor compression systems, particularly in scenarios where waste heat or low-grade thermal energy is available.

Current technological trends in LiBr absorption systems focus on enhancing coefficient of performance (COP), reducing physical footprint, minimizing crystallization risks, and improving overall system reliability. Innovations in heat exchanger design, working fluid formulations, and control systems have contributed to steady improvements in system efficiency and operational stability. Additionally, the integration of advanced materials and manufacturing techniques has addressed historical challenges related to corrosion and maintenance requirements.

The primary objective of implementing LiBr absorption technology in modern HVAC systems is to achieve sustainable cooling solutions with reduced electrical consumption and lower environmental impact. These systems aim to effectively utilize low-grade thermal energy sources such as solar heat, geothermal energy, or industrial waste heat that would otherwise be discarded. By converting these thermal resources into useful cooling capacity, LiBr systems offer a pathway to significant reductions in primary energy consumption and associated greenhouse gas emissions.

Another critical objective is to develop more compact and cost-effective LiBr absorption systems that can be deployed across diverse applications, from large commercial buildings to residential settings. Current research targets include improving part-load performance, enhancing heat and mass transfer processes, and developing more sophisticated control algorithms to optimize system operation under varying conditions. The ultimate goal is to position LiBr absorption technology as a mainstream alternative to conventional cooling systems, particularly in regions with abundant thermal resources or high electricity costs.

Looking forward, the technology roadmap for LiBr absorption systems includes further integration with renewable energy sources, development of hybrid systems that combine absorption and conventional technologies, and exploration of novel applications beyond traditional air conditioning, such as refrigeration, process cooling, and thermal energy storage solutions.

Market Analysis for LiBr-based HVAC Solutions

The global market for Lithium Bromide (LiBr) based HVAC solutions has been experiencing significant growth, driven primarily by increasing demand for energy-efficient cooling systems in commercial and industrial applications. The current market size for LiBr absorption chillers is estimated at $1.2 billion, with projections indicating a compound annual growth rate of 6.8% through 2028, potentially reaching $1.7 billion by that time.

Asia-Pacific currently dominates the market landscape, accounting for approximately 45% of global installations. This regional dominance is attributed to rapid industrialization, stringent energy efficiency regulations, and substantial government incentives for green technology adoption, particularly in China, Japan, and South Korea. North America and Europe follow with market shares of 28% and 22% respectively, with growing adoption rates in both regions.

Commercial buildings represent the largest application segment, constituting 38% of the market, followed by industrial facilities at 32% and healthcare institutions at 17%. The remaining 13% is distributed across various sectors including hospitality and educational facilities. This distribution reflects the technology's particular suitability for large-scale cooling applications where waste heat is readily available.

Customer demand is increasingly driven by three key factors: energy cost reduction, environmental compliance, and operational reliability. End-users report average energy savings of 30-45% compared to conventional electric chillers, representing a compelling value proposition despite higher initial capital expenditure. The typical return on investment period ranges from 3-5 years depending on usage patterns and local energy costs.

Market barriers include high initial investment costs, which are approximately 1.5-2 times higher than conventional systems, limited awareness among potential customers, and installation complexities. Additionally, the technology faces competition from emerging alternatives such as magnetic refrigeration and advanced vapor compression systems.

The competitive landscape features established players like Carrier Corporation, Johnson Controls, and Thermax Limited dominating with a combined market share of 58%. However, several specialized manufacturers from Asia, particularly from Japan and China, are rapidly gaining market share through aggressive pricing strategies and technological innovations focused on improving system efficiency and reducing physical footprint.

Future market growth is expected to be driven by increasing adoption in data centers, pharmaceutical manufacturing, and food processing industries, where the dual benefits of cooling and heating capabilities offer significant operational advantages. Regulatory trends favoring low-GWP (Global Warming Potential) refrigerants are also expected to accelerate market expansion as LiBr systems use water as the refrigerant, offering a naturally compliant solution.

Asia-Pacific currently dominates the market landscape, accounting for approximately 45% of global installations. This regional dominance is attributed to rapid industrialization, stringent energy efficiency regulations, and substantial government incentives for green technology adoption, particularly in China, Japan, and South Korea. North America and Europe follow with market shares of 28% and 22% respectively, with growing adoption rates in both regions.

Commercial buildings represent the largest application segment, constituting 38% of the market, followed by industrial facilities at 32% and healthcare institutions at 17%. The remaining 13% is distributed across various sectors including hospitality and educational facilities. This distribution reflects the technology's particular suitability for large-scale cooling applications where waste heat is readily available.

Customer demand is increasingly driven by three key factors: energy cost reduction, environmental compliance, and operational reliability. End-users report average energy savings of 30-45% compared to conventional electric chillers, representing a compelling value proposition despite higher initial capital expenditure. The typical return on investment period ranges from 3-5 years depending on usage patterns and local energy costs.

Market barriers include high initial investment costs, which are approximately 1.5-2 times higher than conventional systems, limited awareness among potential customers, and installation complexities. Additionally, the technology faces competition from emerging alternatives such as magnetic refrigeration and advanced vapor compression systems.

The competitive landscape features established players like Carrier Corporation, Johnson Controls, and Thermax Limited dominating with a combined market share of 58%. However, several specialized manufacturers from Asia, particularly from Japan and China, are rapidly gaining market share through aggressive pricing strategies and technological innovations focused on improving system efficiency and reducing physical footprint.

Future market growth is expected to be driven by increasing adoption in data centers, pharmaceutical manufacturing, and food processing industries, where the dual benefits of cooling and heating capabilities offer significant operational advantages. Regulatory trends favoring low-GWP (Global Warming Potential) refrigerants are also expected to accelerate market expansion as LiBr systems use water as the refrigerant, offering a naturally compliant solution.

Current State and Technical Challenges of LiBr Systems

Lithium Bromide (LiBr) absorption systems have established a significant presence in the HVAC industry, particularly in large-scale commercial and industrial cooling applications. Currently, these systems represent approximately 5% of the global commercial cooling market, with higher adoption rates in regions facing electricity constraints or prioritizing energy efficiency. The technology has matured considerably over the past three decades, with thermal coefficients of performance (COP) typically ranging from 0.7 to 1.2 for single-effect systems and up to 1.8 for advanced double-effect configurations.

Despite their established presence, LiBr absorption systems face several critical technical challenges that limit wider adoption. Crystallization risk remains one of the most significant operational concerns, occurring when LiBr concentration exceeds solubility limits (typically above 65% concentration), leading to system blockages and performance degradation. Current mitigation strategies include sophisticated control algorithms and dilution cycles, but these solutions often compromise system efficiency.

Corrosion presents another persistent challenge, as LiBr solutions are inherently corrosive to many conventional metals used in HVAC systems. Industry standard materials include stainless steel, titanium alloys, and specialized coatings, which significantly increase system costs. Recent developments in corrosion inhibitors have shown promise, with compounds containing molybdate and nitrate demonstrating up to 70% reduction in corrosion rates, though long-term stability remains questionable.

Energy efficiency limitations also constrain market expansion. While absorption chillers eliminate compressor electricity demand, they require substantial thermal energy input. This dependency on high-grade heat sources (typically 80-120°C for single-effect systems) restricts applications to settings with abundant waste heat or solar thermal resources. The integration with renewable energy sources remains technically challenging due to intermittency issues and temperature matching requirements.

Size and weight considerations present practical implementation barriers. Current LiBr systems typically require 2-3 times the physical footprint of equivalent vapor compression systems, limiting their application in space-constrained environments. The technology also demands specialized maintenance expertise, which is often scarce in many markets, further hampering widespread adoption.

Geographically, LiBr absorption technology development is concentrated in specific regions. Japan leads with approximately 40% of global patents in this field, followed by the United States (25%), China (20%), and Germany (10%). This concentration reflects both historical expertise and current market demands, with Asian markets showing the fastest growth trajectory due to industrial expansion and district cooling initiatives.

Recent technological innovations have focused on enhancing system stability and reducing size constraints. Vacuum maintenance systems have improved, extending reliable operation periods between service interventions from typically 1-2 years to 3-5 years. However, the fundamental thermodynamic limitations of the absorption cycle continue to present efficiency barriers that require breakthrough innovations to overcome.

Despite their established presence, LiBr absorption systems face several critical technical challenges that limit wider adoption. Crystallization risk remains one of the most significant operational concerns, occurring when LiBr concentration exceeds solubility limits (typically above 65% concentration), leading to system blockages and performance degradation. Current mitigation strategies include sophisticated control algorithms and dilution cycles, but these solutions often compromise system efficiency.

Corrosion presents another persistent challenge, as LiBr solutions are inherently corrosive to many conventional metals used in HVAC systems. Industry standard materials include stainless steel, titanium alloys, and specialized coatings, which significantly increase system costs. Recent developments in corrosion inhibitors have shown promise, with compounds containing molybdate and nitrate demonstrating up to 70% reduction in corrosion rates, though long-term stability remains questionable.

Energy efficiency limitations also constrain market expansion. While absorption chillers eliminate compressor electricity demand, they require substantial thermal energy input. This dependency on high-grade heat sources (typically 80-120°C for single-effect systems) restricts applications to settings with abundant waste heat or solar thermal resources. The integration with renewable energy sources remains technically challenging due to intermittency issues and temperature matching requirements.

Size and weight considerations present practical implementation barriers. Current LiBr systems typically require 2-3 times the physical footprint of equivalent vapor compression systems, limiting their application in space-constrained environments. The technology also demands specialized maintenance expertise, which is often scarce in many markets, further hampering widespread adoption.

Geographically, LiBr absorption technology development is concentrated in specific regions. Japan leads with approximately 40% of global patents in this field, followed by the United States (25%), China (20%), and Germany (10%). This concentration reflects both historical expertise and current market demands, with Asian markets showing the fastest growth trajectory due to industrial expansion and district cooling initiatives.

Recent technological innovations have focused on enhancing system stability and reducing size constraints. Vacuum maintenance systems have improved, extending reliable operation periods between service interventions from typically 1-2 years to 3-5 years. However, the fundamental thermodynamic limitations of the absorption cycle continue to present efficiency barriers that require breakthrough innovations to overcome.

Current LiBr Integration Solutions for HVAC Systems

01 Lithium bromide in absorption refrigeration systems

Lithium bromide is widely used as an absorbent in absorption refrigeration and heat pump systems due to its excellent hygroscopic properties. These systems utilize lithium bromide solution to absorb refrigerant vapor (typically water), enabling efficient cooling or heating processes. The technology is particularly valuable in applications where waste heat can be utilized as the energy source, offering energy-efficient alternatives to conventional compression refrigeration systems.- Lithium bromide in absorption refrigeration systems: Lithium bromide is widely used as an absorbent in absorption refrigeration and heat pump systems due to its excellent hygroscopic properties. These systems utilize lithium bromide solution to absorb water vapor, creating a cooling effect. The technology is energy-efficient and environmentally friendly compared to conventional refrigeration systems, making it suitable for air conditioning and industrial cooling applications.

- Lithium bromide in energy storage applications: Lithium bromide is employed in thermal energy storage systems and heat transformation processes. Its ability to store and release thermal energy through absorption and desorption processes makes it valuable for energy conservation. These systems can store excess heat during off-peak hours and release it when needed, improving energy efficiency in buildings and industrial processes.

- Purification and regeneration of lithium bromide solutions: Various methods have been developed for purifying and regenerating lithium bromide solutions to maintain their efficiency in absorption systems. These processes remove contaminants and restore the concentration of the solution, extending its useful life. Techniques include filtration, crystallization, vacuum distillation, and chemical treatment to remove impurities that can reduce performance or cause corrosion in absorption systems.

- Lithium bromide in battery technologies: Lithium bromide is utilized in advanced battery technologies as an electrolyte component or additive. It can enhance the performance, stability, and safety of various battery systems. The compound contributes to improved ionic conductivity, reduced dendrite formation, and extended cycle life in rechargeable batteries, making it valuable for energy storage applications in portable electronics and electric vehicles.

- Corrosion inhibition in lithium bromide systems: Corrosion inhibitors are added to lithium bromide solutions to protect metal components in absorption systems. These additives form protective films on metal surfaces or neutralize corrosive species in the solution. Various organic and inorganic compounds have been developed as effective inhibitors, significantly extending the service life of equipment and reducing maintenance costs in lithium bromide-based absorption refrigeration systems.

02 Lithium bromide in energy storage applications

Lithium bromide is employed in various energy storage technologies, particularly in thermal energy storage systems. Its unique thermochemical properties allow it to store and release energy efficiently through absorption and desorption processes. These systems can be integrated with renewable energy sources to address intermittency issues, providing stable energy output and improving overall system efficiency.Expand Specific Solutions03 Purification and regeneration of lithium bromide solutions

Various methods have been developed for purifying and regenerating lithium bromide solutions to maintain their effectiveness in absorption systems. These techniques include filtration processes, chemical treatments, and specialized regeneration cycles that remove contaminants and restore the solution's absorption capacity. Proper purification extends the operational life of lithium bromide solutions and ensures consistent performance in absorption systems.Expand Specific Solutions04 Lithium bromide in pharmaceutical and chemical applications

Lithium bromide serves as an important reagent in pharmaceutical synthesis and various chemical processes. It functions as a catalyst, reactant, or intermediate in the production of specialized chemicals and pharmaceutical compounds. Its unique chemical properties make it valuable for specific reactions where other halide salts may be less effective, particularly in organic synthesis applications.Expand Specific Solutions05 Enhanced lithium bromide systems with additives

Research has focused on improving lithium bromide solutions through the addition of various additives that enhance performance characteristics. These additives can improve heat transfer properties, reduce corrosion, prevent crystallization, and enhance absorption efficiency. Modified lithium bromide solutions demonstrate superior performance in absorption refrigeration systems, with increased coefficient of performance and extended equipment lifespan.Expand Specific Solutions

Key Industry Players in LiBr HVAC Market

The lithium bromide HVAC systems market is in a growth phase, with increasing adoption driven by energy efficiency demands and sustainability goals. The global market size is projected to expand significantly as commercial and industrial sectors seek lower-carbon cooling solutions. Technologically, the field shows varying maturity levels, with established players like Johnson Controls-Hitachi, Toshiba, and Honeywell leading commercial implementation, while specialized manufacturers such as Shuangliang Eco-Energy Systems and Broad Group are advancing absorption chiller technologies. DuPont contributes through materials innovation, while academic institutions including Zhejiang University and Xi'an Jiaotong University are driving fundamental research. The integration of lithium bromide systems with renewable energy sources represents the frontier of development, with collaboration between industry and research institutions accelerating technological advancement.

Shuangliang Eco-Energy Systems Co., Ltd.

Technical Solution: Shuangliang has developed comprehensive lithium bromide absorption refrigeration systems specifically optimized for HVAC applications. Their technology utilizes a patented high-efficiency heat exchanger design that improves heat transfer coefficients by up to 25% compared to conventional systems. The company's lithium bromide solution incorporates proprietary corrosion inhibitors that extend system lifespan while maintaining thermal efficiency. Shuangliang's systems feature advanced crystallization prevention through precise solution concentration control and intelligent temperature management algorithms. Their direct-fired double-effect chillers achieve COP values of 1.2-1.4, while their waste-heat recovery models can effectively utilize low-grade thermal energy (85-95°C) with minimal performance degradation. The company has also pioneered vacuum maintenance technology that reduces non-condensable gas accumulation, maintaining optimal system performance over extended operational periods.

Strengths: Excellent heat exchanger efficiency; robust crystallization prevention; effective utilization of low-grade waste heat; comprehensive domestic service network in China. Weaknesses: Less international market presence compared to global competitors; higher maintenance requirements than electric chillers; performance sensitivity to cooling water temperature fluctuations.

Broad Group Co., Ltd.

Technical Solution: Broad Group has pioneered advanced lithium bromide absorption chillers that utilize waste heat or direct-fired natural gas for cooling applications. Their patented technology incorporates high-efficiency heat exchangers and specialized corrosion-resistant materials to extend system lifespan. The company's non-electric chillers achieve Coefficient of Performance (COP) values up to 1.41 for double-effect systems, significantly higher than conventional single-effect systems. Broad's lithium bromide solution features proprietary crystallization prevention mechanisms and automated vacuum maintenance systems that ensure stable operation across varying load conditions. Their modular design approach allows for scalable installations from 16 to 6,000 refrigeration tons, making them suitable for diverse commercial and industrial applications.

Strengths: Superior energy efficiency with high COP values; excellent waste heat utilization; modular scalability for various project sizes; advanced corrosion protection technology. Weaknesses: Higher initial capital costs compared to conventional systems; requires specialized maintenance expertise; performance dependent on stable heat source availability.

Critical Patents and Technical Literature on LiBr Absorption

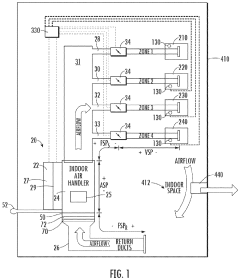

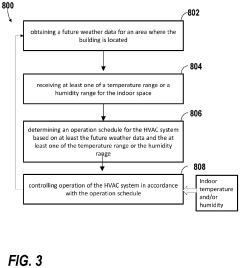

Heating, ventilation, and air conditioning system control leveraging future weather

PatentPendingUS20230358430A1

Innovation

- A method and apparatus that utilize future weather data to determine and implement an operation schedule for the HVAC system, adjusting components such as the blower, vent fans, and refrigerant flow to optimize energy usage and indoor air quality based on predicted weather patterns and user-set temperature and humidity ranges.

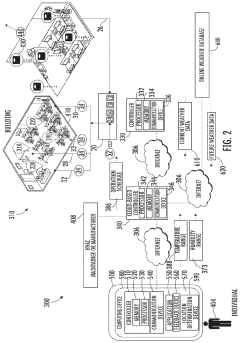

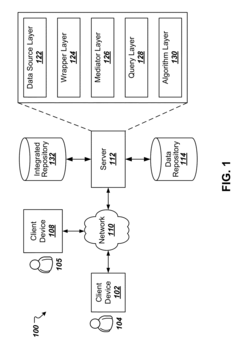

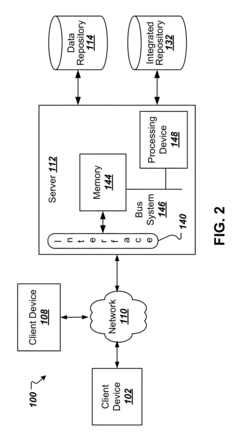

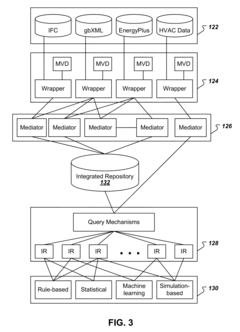

Integrated information framework for automated performance analysis of heating, ventilation, and air conditioning (HVAC) systems

PatentActiveUS9429960B2

Innovation

- An information integration system that acquires, integrates, and manages data from heterogeneous models and sensors, providing a query mechanism to support multiple performance analysis algorithms, facilitating energy savings and proactive maintenance by converting and storing HVAC system information, and transmitting relevant data for algorithm execution.

Energy Efficiency and Performance Metrics

The integration of lithium bromide in HVAC systems presents significant opportunities for enhancing energy efficiency metrics across various applications. When evaluating these systems, Coefficient of Performance (COP) typically ranges from 0.7 to 1.2 for single-effect and 1.2 to 1.5 for double-effect lithium bromide absorption chillers, compared to 2.5-3.5 for conventional vapor compression systems. However, when considering primary energy utilization, especially when waste heat or renewable thermal energy sources are leveraged, the effective efficiency can increase substantially.

Performance analysis reveals that lithium bromide absorption systems can achieve up to 30-45% reduction in electrical energy consumption compared to conventional systems, though this comes with increased thermal energy requirements. The energy utilization factor (EUF), which considers both electrical and thermal inputs, provides a more comprehensive efficiency metric, typically ranging from 1.3 to 1.8 for well-designed lithium bromide systems.

Temperature lift capability represents another critical performance parameter, with lithium bromide systems generally operating effectively with condenser temperatures up to 45°C and evaporator temperatures not below 5°C. This operational window must be carefully considered when evaluating system applicability across different climate zones and building types.

Part-load performance characteristics differ significantly from conventional systems, with lithium bromide absorption chillers maintaining relatively stable efficiency across 40-100% load ranges, unlike the variable efficiency curves of mechanical compression systems. This characteristic proves particularly valuable in applications with fluctuating cooling demands.

Life-cycle energy assessment indicates that despite higher initial embodied energy, lithium bromide systems can achieve energy payback periods of 3-5 years in optimal applications. The primary energy ratio (PER), accounting for generation and transmission losses, typically ranges from 0.9 to 1.3, compared to 0.8-1.0 for conventional electric chillers when considering grid inefficiencies.

Seasonal energy efficiency ratio (SEER) calculations must be adapted for lithium bromide systems to account for their unique operational characteristics. Modified SEER values typically range from 12 to 18 for well-designed systems, depending on climate conditions and operational parameters. These values provide a standardized basis for comparison with conventional technologies.

Integration with renewable energy sources can further enhance performance metrics, with solar-powered lithium bromide systems achieving solar fractions of 60-80% in favorable climates, substantially reducing conventional energy requirements and associated carbon emissions. This synergy represents one of the most promising aspects of lithium bromide technology in the context of sustainable building systems.

Performance analysis reveals that lithium bromide absorption systems can achieve up to 30-45% reduction in electrical energy consumption compared to conventional systems, though this comes with increased thermal energy requirements. The energy utilization factor (EUF), which considers both electrical and thermal inputs, provides a more comprehensive efficiency metric, typically ranging from 1.3 to 1.8 for well-designed lithium bromide systems.

Temperature lift capability represents another critical performance parameter, with lithium bromide systems generally operating effectively with condenser temperatures up to 45°C and evaporator temperatures not below 5°C. This operational window must be carefully considered when evaluating system applicability across different climate zones and building types.

Part-load performance characteristics differ significantly from conventional systems, with lithium bromide absorption chillers maintaining relatively stable efficiency across 40-100% load ranges, unlike the variable efficiency curves of mechanical compression systems. This characteristic proves particularly valuable in applications with fluctuating cooling demands.

Life-cycle energy assessment indicates that despite higher initial embodied energy, lithium bromide systems can achieve energy payback periods of 3-5 years in optimal applications. The primary energy ratio (PER), accounting for generation and transmission losses, typically ranges from 0.9 to 1.3, compared to 0.8-1.0 for conventional electric chillers when considering grid inefficiencies.

Seasonal energy efficiency ratio (SEER) calculations must be adapted for lithium bromide systems to account for their unique operational characteristics. Modified SEER values typically range from 12 to 18 for well-designed systems, depending on climate conditions and operational parameters. These values provide a standardized basis for comparison with conventional technologies.

Integration with renewable energy sources can further enhance performance metrics, with solar-powered lithium bromide systems achieving solar fractions of 60-80% in favorable climates, substantially reducing conventional energy requirements and associated carbon emissions. This synergy represents one of the most promising aspects of lithium bromide technology in the context of sustainable building systems.

Environmental Impact and Sustainability Considerations

The integration of lithium bromide in HVAC systems presents significant environmental implications that warrant careful consideration. Lithium bromide absorption chillers offer substantial energy efficiency advantages compared to conventional vapor compression systems, potentially reducing electricity consumption by 30-40% in appropriate applications. This efficiency translates directly to lower greenhouse gas emissions, particularly in regions where electricity generation relies heavily on fossil fuels.

However, the environmental profile of lithium bromide systems extends beyond operational efficiency. The extraction and processing of lithium compounds carry ecological consequences, including water depletion in lithium-rich regions, habitat disruption, and energy-intensive refinement processes. These upstream impacts must be factored into comprehensive environmental assessments of lithium bromide HVAC technologies.

Corrosion concerns represent another environmental consideration. Lithium bromide solutions are highly corrosive, necessitating specialized materials and regular maintenance to prevent leakage. System failures resulting in solution release could potentially contaminate soil and water systems, though modern containment designs have significantly mitigated these risks through improved sealing technologies and corrosion-resistant materials.

From a lifecycle perspective, lithium bromide systems demonstrate promising sustainability metrics. The extended operational lifespan of absorption chillers—typically 20-25 years compared to 15-20 years for conventional systems—reduces embodied carbon and resource consumption associated with equipment manufacturing and replacement. Additionally, lithium bromide solutions can be regenerated and recycled, minimizing waste generation throughout the system lifecycle.

Water consumption patterns represent both a challenge and opportunity. While lithium bromide systems typically require cooling towers that consume significant quantities of water, they can be engineered to utilize reclaimed water sources, potentially alleviating pressure on freshwater resources in water-stressed regions. Advanced designs incorporating closed-loop cooling configurations have demonstrated water consumption reductions of up to 80% compared to traditional open-loop systems.

Regulatory frameworks increasingly recognize the sustainability advantages of lithium bromide systems. Many jurisdictions now offer incentives for absorption chiller installations through green building certification programs, carbon offset mechanisms, and energy efficiency subsidies. These policy instruments accelerate adoption while ensuring proper environmental safeguards are maintained throughout system deployment and operation.

Looking forward, research into alternative absorbents with lower environmental footprints shows promise for further enhancing the sustainability profile of absorption cooling technologies. Innovations in manufacturing processes and material science continue to reduce the environmental impact of lithium bromide production while improving system performance and reliability.

However, the environmental profile of lithium bromide systems extends beyond operational efficiency. The extraction and processing of lithium compounds carry ecological consequences, including water depletion in lithium-rich regions, habitat disruption, and energy-intensive refinement processes. These upstream impacts must be factored into comprehensive environmental assessments of lithium bromide HVAC technologies.

Corrosion concerns represent another environmental consideration. Lithium bromide solutions are highly corrosive, necessitating specialized materials and regular maintenance to prevent leakage. System failures resulting in solution release could potentially contaminate soil and water systems, though modern containment designs have significantly mitigated these risks through improved sealing technologies and corrosion-resistant materials.

From a lifecycle perspective, lithium bromide systems demonstrate promising sustainability metrics. The extended operational lifespan of absorption chillers—typically 20-25 years compared to 15-20 years for conventional systems—reduces embodied carbon and resource consumption associated with equipment manufacturing and replacement. Additionally, lithium bromide solutions can be regenerated and recycled, minimizing waste generation throughout the system lifecycle.

Water consumption patterns represent both a challenge and opportunity. While lithium bromide systems typically require cooling towers that consume significant quantities of water, they can be engineered to utilize reclaimed water sources, potentially alleviating pressure on freshwater resources in water-stressed regions. Advanced designs incorporating closed-loop cooling configurations have demonstrated water consumption reductions of up to 80% compared to traditional open-loop systems.

Regulatory frameworks increasingly recognize the sustainability advantages of lithium bromide systems. Many jurisdictions now offer incentives for absorption chiller installations through green building certification programs, carbon offset mechanisms, and energy efficiency subsidies. These policy instruments accelerate adoption while ensuring proper environmental safeguards are maintained throughout system deployment and operation.

Looking forward, research into alternative absorbents with lower environmental footprints shows promise for further enhancing the sustainability profile of absorption cooling technologies. Innovations in manufacturing processes and material science continue to reduce the environmental impact of lithium bromide production while improving system performance and reliability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!