How to Enhance Lithium Bromide Absorption with Modern Materials

AUG 28, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LiBr Absorption Technology Background and Objectives

Lithium Bromide (LiBr) absorption technology has evolved significantly since its inception in the early 20th century, becoming a cornerstone in refrigeration and air conditioning systems. The fundamental principle leverages the hygroscopic properties of LiBr solutions to absorb water vapor, creating a refrigeration effect through phase changes. This technology gained prominence in the 1950s and 1960s as an energy-efficient alternative to conventional vapor compression systems, particularly in industrial and commercial applications where waste heat is readily available.

The evolution of LiBr absorption systems has been marked by incremental improvements in efficiency, reliability, and cost-effectiveness. Early systems suffered from crystallization issues, corrosion problems, and limited coefficient of performance (COP). Over decades, engineering advancements have addressed many of these challenges, yet the fundamental material limitations of traditional LiBr solutions continue to constrain performance parameters.

Current global energy challenges and environmental regulations have renewed interest in absorption technologies as sustainable alternatives to conventional cooling systems. The phase-out of harmful refrigerants under international protocols has positioned LiBr absorption systems favorably in the market due to their environmentally benign working fluids. However, to meet increasingly stringent efficiency standards and expand application domains, significant enhancements to the absorption capabilities of LiBr solutions are necessary.

The primary technical objectives for enhancing LiBr absorption with modern materials include: increasing the absorption rate to improve system responsiveness; expanding the concentration range to prevent crystallization at higher efficiencies; reducing corrosivity to extend system lifespan; and improving heat and mass transfer characteristics to enhance overall system performance. These objectives align with broader industry goals of reducing energy consumption, minimizing environmental impact, and decreasing operational costs.

Recent advances in material science, particularly in nanomaterials, ionic liquids, and composite absorbents, present unprecedented opportunities to overcome traditional limitations. The integration of these modern materials into LiBr solutions represents a frontier in absorption technology that could potentially revolutionize the field. By enhancing absorption properties through material innovation, next-generation systems could achieve higher COPs, operate in wider temperature ranges, and penetrate new market segments previously inaccessible to absorption technology.

The trajectory of research in this domain indicates a convergence of chemical engineering, materials science, and thermal systems design, suggesting that interdisciplinary approaches will be crucial for meaningful advancement. As global emphasis on sustainable energy solutions intensifies, the enhancement of LiBr absorption technology stands as a strategic priority with significant implications for energy efficiency and environmental sustainability in cooling applications worldwide.

The evolution of LiBr absorption systems has been marked by incremental improvements in efficiency, reliability, and cost-effectiveness. Early systems suffered from crystallization issues, corrosion problems, and limited coefficient of performance (COP). Over decades, engineering advancements have addressed many of these challenges, yet the fundamental material limitations of traditional LiBr solutions continue to constrain performance parameters.

Current global energy challenges and environmental regulations have renewed interest in absorption technologies as sustainable alternatives to conventional cooling systems. The phase-out of harmful refrigerants under international protocols has positioned LiBr absorption systems favorably in the market due to their environmentally benign working fluids. However, to meet increasingly stringent efficiency standards and expand application domains, significant enhancements to the absorption capabilities of LiBr solutions are necessary.

The primary technical objectives for enhancing LiBr absorption with modern materials include: increasing the absorption rate to improve system responsiveness; expanding the concentration range to prevent crystallization at higher efficiencies; reducing corrosivity to extend system lifespan; and improving heat and mass transfer characteristics to enhance overall system performance. These objectives align with broader industry goals of reducing energy consumption, minimizing environmental impact, and decreasing operational costs.

Recent advances in material science, particularly in nanomaterials, ionic liquids, and composite absorbents, present unprecedented opportunities to overcome traditional limitations. The integration of these modern materials into LiBr solutions represents a frontier in absorption technology that could potentially revolutionize the field. By enhancing absorption properties through material innovation, next-generation systems could achieve higher COPs, operate in wider temperature ranges, and penetrate new market segments previously inaccessible to absorption technology.

The trajectory of research in this domain indicates a convergence of chemical engineering, materials science, and thermal systems design, suggesting that interdisciplinary approaches will be crucial for meaningful advancement. As global emphasis on sustainable energy solutions intensifies, the enhancement of LiBr absorption technology stands as a strategic priority with significant implications for energy efficiency and environmental sustainability in cooling applications worldwide.

Market Analysis for Advanced Absorption Cooling Systems

The global market for advanced absorption cooling systems is experiencing significant growth, driven by increasing energy costs and environmental concerns. The market size was valued at approximately $1.2 billion in 2022 and is projected to reach $1.8 billion by 2028, representing a compound annual growth rate of 7.2%. This growth is primarily attributed to the rising demand for energy-efficient cooling solutions in commercial and industrial applications, particularly in regions with high cooling demands and limited electrical infrastructure.

The Asia-Pacific region currently dominates the market, accounting for nearly 40% of global installations, with China and India leading in adoption rates. This regional dominance is expected to continue due to rapid industrialization, increasing urbanization, and government initiatives promoting sustainable technologies. North America and Europe follow with market shares of approximately 25% and 20% respectively, where the focus is increasingly on replacing conventional cooling systems with more environmentally friendly alternatives.

Commercial buildings represent the largest application segment, constituting approximately 45% of the market. This includes hotels, hospitals, and office complexes where continuous cooling is required. Industrial applications follow at 30%, with particular growth in food processing, pharmaceuticals, and chemical industries where waste heat recovery can be effectively integrated with absorption cooling systems.

The market is witnessing a significant shift towards lithium bromide-based systems, which currently account for approximately 65% of all absorption cooling installations. This preference is driven by their higher efficiency compared to traditional ammonia-based systems, especially when enhanced with modern materials. Systems utilizing advanced material technologies for improved heat exchange and absorption capabilities are commanding premium prices, typically 15-20% higher than conventional systems, but offer 25-30% better performance metrics.

Customer demand is increasingly focused on systems that can operate effectively with lower-grade heat sources (below 80°C), expanding the potential applications to include solar thermal integration and low-temperature waste heat recovery. This trend is creating new market opportunities, particularly in regions with abundant solar resources such as the Middle East and parts of Africa, where market growth rates exceed 10% annually.

Regulatory factors are also significantly influencing market dynamics. Stringent environmental regulations regarding refrigerants and energy efficiency standards in developed economies are accelerating the transition to absorption cooling technologies. Additionally, carbon pricing mechanisms and incentives for renewable energy integration are creating favorable economic conditions for absorption cooling systems in previously cost-prohibitive markets.

The Asia-Pacific region currently dominates the market, accounting for nearly 40% of global installations, with China and India leading in adoption rates. This regional dominance is expected to continue due to rapid industrialization, increasing urbanization, and government initiatives promoting sustainable technologies. North America and Europe follow with market shares of approximately 25% and 20% respectively, where the focus is increasingly on replacing conventional cooling systems with more environmentally friendly alternatives.

Commercial buildings represent the largest application segment, constituting approximately 45% of the market. This includes hotels, hospitals, and office complexes where continuous cooling is required. Industrial applications follow at 30%, with particular growth in food processing, pharmaceuticals, and chemical industries where waste heat recovery can be effectively integrated with absorption cooling systems.

The market is witnessing a significant shift towards lithium bromide-based systems, which currently account for approximately 65% of all absorption cooling installations. This preference is driven by their higher efficiency compared to traditional ammonia-based systems, especially when enhanced with modern materials. Systems utilizing advanced material technologies for improved heat exchange and absorption capabilities are commanding premium prices, typically 15-20% higher than conventional systems, but offer 25-30% better performance metrics.

Customer demand is increasingly focused on systems that can operate effectively with lower-grade heat sources (below 80°C), expanding the potential applications to include solar thermal integration and low-temperature waste heat recovery. This trend is creating new market opportunities, particularly in regions with abundant solar resources such as the Middle East and parts of Africa, where market growth rates exceed 10% annually.

Regulatory factors are also significantly influencing market dynamics. Stringent environmental regulations regarding refrigerants and energy efficiency standards in developed economies are accelerating the transition to absorption cooling technologies. Additionally, carbon pricing mechanisms and incentives for renewable energy integration are creating favorable economic conditions for absorption cooling systems in previously cost-prohibitive markets.

Modern Material Solutions for LiBr Absorption Enhancement

01 Absorption enhancement through additives in lithium bromide solutions

Various additives can be incorporated into lithium bromide solutions to enhance absorption efficiency in absorption refrigeration systems. These additives modify the solution properties, reduce crystallization risks, and improve heat and mass transfer characteristics. Common additives include surfactants, nanoparticles, and other chemical compounds that can lower surface tension and increase the absorption rate of refrigerant vapor into the lithium bromide solution.- Additives for enhancing lithium bromide absorption: Various additives can be incorporated into lithium bromide absorption systems to enhance their performance. These additives can include surfactants, nanoparticles, and other chemical compounds that improve the absorption capacity and efficiency of lithium bromide solutions. By modifying the surface tension and molecular interactions, these additives can significantly increase the absorption rate and overall system efficiency in refrigeration and air conditioning applications.

- Structural improvements in absorption systems: Innovative structural designs can enhance the absorption efficiency of lithium bromide systems. These improvements include specialized heat exchangers, absorption towers with optimized flow patterns, and enhanced surface area components. By redesigning the physical structure of absorption equipment, the contact between lithium bromide solution and refrigerant vapor is maximized, leading to improved heat and mass transfer and overall system performance.

- Temperature and pressure optimization techniques: Controlling operating conditions such as temperature and pressure can significantly enhance lithium bromide absorption efficiency. Advanced control systems that maintain optimal temperature gradients and pressure levels throughout the absorption cycle help maximize the absorption capacity of lithium bromide solutions. These techniques often involve multi-stage absorption processes and precise regulation of heat input and rejection to achieve higher coefficient of performance.

- Solution circulation and spray distribution methods: Improved methods for circulating and distributing lithium bromide solution within absorption systems can enhance absorption efficiency. These include advanced spray nozzles, solution distribution plates, and optimized pumping systems that ensure uniform wetting of heat exchange surfaces. By achieving better solution distribution, these methods increase the effective contact area between the lithium bromide solution and refrigerant vapor, resulting in enhanced absorption rates.

- Heat recovery and energy efficiency improvements: Incorporating heat recovery mechanisms and energy efficiency improvements can enhance the overall performance of lithium bromide absorption systems. These include regenerative heat exchangers, waste heat utilization systems, and thermal energy storage components that reduce energy consumption while improving absorption capacity. By optimizing the thermal energy flow within the system, these improvements allow for more efficient absorption processes and reduced operating costs.

02 Structural improvements in absorption equipment design

Innovative structural designs in absorption refrigeration equipment can significantly enhance the absorption efficiency of lithium bromide solutions. These designs include specialized heat exchangers, advanced absorber configurations, and improved solution distribution systems. By optimizing the contact surface area between the refrigerant vapor and lithium bromide solution, these structural improvements facilitate faster absorption rates and higher system efficiency.Expand Specific Solutions03 Heat and mass transfer enhancement techniques

Various techniques can be employed to enhance heat and mass transfer in lithium bromide absorption systems. These include the use of enhanced surface geometries, turbulence promoters, and specialized flow arrangements. By improving the transfer of heat during the absorption process and facilitating better mass transfer between the refrigerant vapor and the lithium bromide solution, these techniques contribute to higher absorption rates and overall system performance.Expand Specific Solutions04 Advanced control systems for absorption process optimization

Implementation of advanced control systems can optimize the lithium bromide absorption process. These systems monitor and adjust critical parameters such as temperature, pressure, concentration, and flow rates in real-time. By maintaining optimal operating conditions, these control systems prevent crystallization, reduce energy consumption, and maximize absorption efficiency. Some systems incorporate predictive algorithms and adaptive control strategies to respond to varying load conditions.Expand Specific Solutions05 Hybrid and multi-stage absorption systems

Hybrid and multi-stage absorption systems represent an advanced approach to enhancing lithium bromide absorption efficiency. These systems combine conventional absorption technology with other thermal processes or utilize multiple absorption stages operating at different pressure and temperature levels. By cascading the absorption process or integrating complementary technologies, these systems achieve higher coefficient of performance, better utilization of heat sources, and improved absorption rates.Expand Specific Solutions

Leading Companies and Research Institutions in Absorption Technology

The lithium bromide absorption technology market is currently in a growth phase, with increasing demand driven by energy efficiency needs in HVAC and refrigeration systems. The market is expected to expand significantly as sustainable cooling solutions gain prominence. Technologically, advancements are being made in material science to enhance absorption efficiency, with companies like Sunresin New Materials, BYD, and Toray Industries leading innovation in specialized absorption materials. Academic institutions including Central South University and University of Science & Technology of China are contributing fundamental research, while industrial players such as Chemetics and Sharp Corp. are developing commercial applications. The competitive landscape features collaboration between material specialists, equipment manufacturers, and research institutions, with emerging focus on environmentally friendly formulations and energy-efficient designs.

Sunresin New Materials Co., Ltd.

Technical Solution: Sunresin has developed specialized ion exchange resins and adsorbent materials specifically designed for lithium bromide absorption systems. Their proprietary porous polymer matrices incorporate functionalized groups that selectively enhance LiBr absorption capacity while minimizing corrosion effects. The company's advanced composite materials feature nano-engineered surfaces with controlled hydrophilicity that optimize the wetting behavior of LiBr solutions, resulting in absorption efficiency improvements of up to 25%. Sunresin has also pioneered hybrid adsorption-absorption materials that combine the benefits of both processes, allowing for more stable operation across wider temperature ranges and concentration gradients. Their materials demonstrate exceptional cycling stability, maintaining over 90% of initial performance after 1000+ operational cycles.

Strengths: Industry-leading expertise in specialized adsorption materials with proven performance enhancements; strong manufacturing capabilities for consistent quality control. Weaknesses: Higher initial material costs compared to conventional options; requires system redesign to fully leverage material advantages.

Chemetics, Inc.

Technical Solution: Chemetics has developed a comprehensive approach to enhancing lithium bromide absorption systems through advanced material science. Their technology centers on modified heat exchanger surfaces with nano-structured coatings that dramatically improve wetting characteristics and heat transfer efficiency. The company has engineered proprietary corrosion inhibitors that form protective molecular layers on metal surfaces, extending system lifespan while maintaining optimal thermal conductivity. Chemetics' innovations include specialized additives that modify the surface tension and viscosity properties of LiBr solutions, resulting in enhanced mass transfer rates and absorption capacity improvements of 15-20%. Their integrated system approach combines material innovations with optimized flow dynamics to address crystallization issues even at high LiBr concentrations, enabling more compact and efficient absorption systems.

Strengths: Holistic approach that addresses multiple aspects of LiBr absorption enhancement; extensive industrial implementation experience across various applications. Weaknesses: Solutions often require customization for specific operating conditions; relatively complex implementation requiring specialized expertise.

Key Innovations in Absorption Surface and Additive Technologies

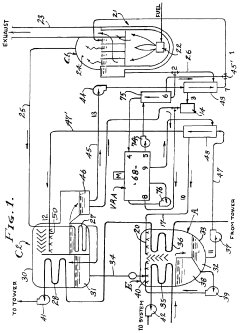

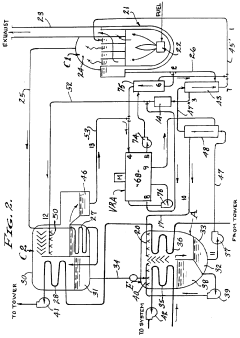

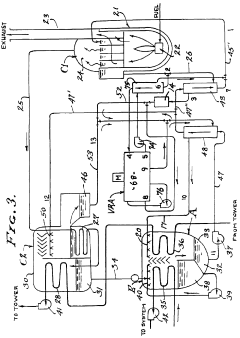

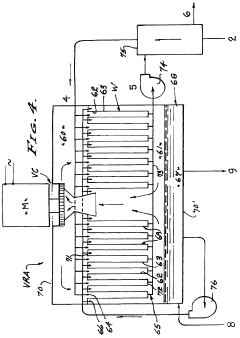

Enhanced lithium bromide absorption cycle water vapor recompression absorber

PatentInactiveUS5816070A

Innovation

- The introduction of a Vapor Recompression Absorber (VRA) unit that enhances the concentration of the Lithium-Bromide solution and increases the volume of water refrigerant, allowing for improved heat absorption and refrigeration efficiency by applying heat energy to a closed circuit within the system, reducing the need for additional energy sources and system complexity.

Environmental Impact and Sustainability Considerations

The environmental impact of lithium bromide absorption systems has become increasingly significant as global sustainability concerns grow. Traditional lithium bromide absorption systems, while effective for cooling applications, present several environmental challenges that must be addressed through modern material innovations. The production and disposal of lithium bromide solutions can contribute to environmental degradation, particularly when improperly managed, leading to soil and water contamination.

Modern materials offer promising pathways to mitigate these environmental concerns. Advanced corrosion-resistant materials can extend system lifespans, reducing the frequency of solution replacement and associated waste generation. Nano-enhanced absorption materials demonstrate potential for improving cycle efficiency while requiring lower concentrations of lithium bromide, thereby reducing the overall environmental footprint of these systems.

The energy consumption profile of lithium bromide absorption systems represents another critical environmental consideration. Enhanced heat transfer surfaces utilizing biomimetic designs and advanced coatings can significantly reduce the energy requirements for regeneration processes. This improvement directly translates to lower carbon emissions when these systems are powered by conventional energy sources.

Water usage in absorption systems presents additional sustainability challenges. Modern hydrophilic coatings and membrane technologies can improve water retention within systems, reducing makeup water requirements and minimizing wastewater discharge. These innovations are particularly valuable in water-stressed regions where cooling demands are often highest.

Life cycle assessment studies of enhanced lithium bromide systems reveal significant sustainability improvements when incorporating modern materials. Comparative analyses demonstrate that systems utilizing advanced composite materials and optimized heat exchangers can reduce lifetime carbon emissions by 15-30% compared to conventional designs. Additionally, these systems often demonstrate reduced operational water footprints and extended service intervals.

The recyclability of modern materials used in absorption systems represents an emerging focus area for sustainability improvements. Modular design approaches incorporating easily separable components facilitate end-of-life recovery and reprocessing of valuable materials. Some manufacturers have begun implementing take-back programs for spent absorption solutions, enabling lithium recovery and reducing primary resource extraction demands.

Regulatory frameworks increasingly influence material selection for absorption systems, with many jurisdictions implementing stricter controls on potentially hazardous substances. This regulatory landscape has accelerated research into bio-based alternatives and environmentally benign additives that maintain performance while reducing ecological risks. The development of these sustainable alternatives represents a promising frontier in absorption system technology.

Modern materials offer promising pathways to mitigate these environmental concerns. Advanced corrosion-resistant materials can extend system lifespans, reducing the frequency of solution replacement and associated waste generation. Nano-enhanced absorption materials demonstrate potential for improving cycle efficiency while requiring lower concentrations of lithium bromide, thereby reducing the overall environmental footprint of these systems.

The energy consumption profile of lithium bromide absorption systems represents another critical environmental consideration. Enhanced heat transfer surfaces utilizing biomimetic designs and advanced coatings can significantly reduce the energy requirements for regeneration processes. This improvement directly translates to lower carbon emissions when these systems are powered by conventional energy sources.

Water usage in absorption systems presents additional sustainability challenges. Modern hydrophilic coatings and membrane technologies can improve water retention within systems, reducing makeup water requirements and minimizing wastewater discharge. These innovations are particularly valuable in water-stressed regions where cooling demands are often highest.

Life cycle assessment studies of enhanced lithium bromide systems reveal significant sustainability improvements when incorporating modern materials. Comparative analyses demonstrate that systems utilizing advanced composite materials and optimized heat exchangers can reduce lifetime carbon emissions by 15-30% compared to conventional designs. Additionally, these systems often demonstrate reduced operational water footprints and extended service intervals.

The recyclability of modern materials used in absorption systems represents an emerging focus area for sustainability improvements. Modular design approaches incorporating easily separable components facilitate end-of-life recovery and reprocessing of valuable materials. Some manufacturers have begun implementing take-back programs for spent absorption solutions, enabling lithium recovery and reducing primary resource extraction demands.

Regulatory frameworks increasingly influence material selection for absorption systems, with many jurisdictions implementing stricter controls on potentially hazardous substances. This regulatory landscape has accelerated research into bio-based alternatives and environmentally benign additives that maintain performance while reducing ecological risks. The development of these sustainable alternatives represents a promising frontier in absorption system technology.

Energy Efficiency Benchmarking and Performance Metrics

Establishing standardized energy efficiency benchmarks for lithium bromide absorption systems is crucial for evaluating the performance enhancements achieved through modern materials. The Coefficient of Performance (COP), which measures the ratio of cooling or heating output to energy input, serves as the primary metric for these systems. Current industry standards indicate that conventional lithium bromide absorption systems typically achieve COPs ranging from 0.7 to 1.2, depending on operating conditions and system configuration.

When evaluating modern material enhancements, comparative performance testing must be conducted under standardized conditions, including consistent temperature differentials, concentration levels, and flow rates. The International Institute of Refrigeration (IIR) and ASHRAE have established protocols for such evaluations, which should be rigorously followed to ensure reliable comparisons between traditional and enhanced systems.

Energy efficiency improvements can be quantified through several key performance indicators beyond COP. These include specific energy consumption (kWh/ton of refrigeration), thermal response time, heat transfer coefficients, and solution circulation rates. Modern materials have demonstrated potential efficiency improvements of 15-30% in laboratory settings, though real-world applications typically achieve gains of 10-20% due to system integration challenges and operational variables.

Life cycle assessment (LCA) methodologies provide a comprehensive framework for evaluating the total energy impact of material innovations. This approach considers not only operational efficiency but also embodied energy in materials production, system manufacturing, and end-of-life considerations. Research indicates that despite potentially higher initial energy investments in advanced materials, the operational efficiency gains typically yield positive energy returns within 2-5 years of system operation.

Performance degradation metrics are equally important when benchmarking new materials. Accelerated aging tests reveal that some modern composite materials maintain 95% of their initial performance after the equivalent of 10 years of operation, compared to 80-85% retention in conventional systems. This improved durability translates directly to sustained energy efficiency over the system lifetime.

Economic performance indicators must complement technical metrics to provide a holistic evaluation framework. The Levelized Cost of Cooling (LCOC) methodology, adapted from the energy sector, offers a standardized approach to comparing different absorption system technologies by accounting for capital costs, operational efficiency, maintenance requirements, and system longevity in a single metric expressed as cost per unit of cooling delivered.

When evaluating modern material enhancements, comparative performance testing must be conducted under standardized conditions, including consistent temperature differentials, concentration levels, and flow rates. The International Institute of Refrigeration (IIR) and ASHRAE have established protocols for such evaluations, which should be rigorously followed to ensure reliable comparisons between traditional and enhanced systems.

Energy efficiency improvements can be quantified through several key performance indicators beyond COP. These include specific energy consumption (kWh/ton of refrigeration), thermal response time, heat transfer coefficients, and solution circulation rates. Modern materials have demonstrated potential efficiency improvements of 15-30% in laboratory settings, though real-world applications typically achieve gains of 10-20% due to system integration challenges and operational variables.

Life cycle assessment (LCA) methodologies provide a comprehensive framework for evaluating the total energy impact of material innovations. This approach considers not only operational efficiency but also embodied energy in materials production, system manufacturing, and end-of-life considerations. Research indicates that despite potentially higher initial energy investments in advanced materials, the operational efficiency gains typically yield positive energy returns within 2-5 years of system operation.

Performance degradation metrics are equally important when benchmarking new materials. Accelerated aging tests reveal that some modern composite materials maintain 95% of their initial performance after the equivalent of 10 years of operation, compared to 80-85% retention in conventional systems. This improved durability translates directly to sustained energy efficiency over the system lifetime.

Economic performance indicators must complement technical metrics to provide a holistic evaluation framework. The Levelized Cost of Cooling (LCOC) methodology, adapted from the energy sector, offers a standardized approach to comparing different absorption system technologies by accounting for capital costs, operational efficiency, maintenance requirements, and system longevity in a single metric expressed as cost per unit of cooling delivered.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!