How to Utilize Lithium Bromide in Hybrid Energy Systems

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lithium Bromide Hybrid Energy Systems Background and Objectives

Lithium bromide (LiBr) has emerged as a critical component in the evolution of hybrid energy systems over the past several decades. Initially developed for absorption refrigeration applications in the 1930s, lithium bromide's unique hygroscopic properties have positioned it as an essential material for energy conversion and storage technologies. The compound's exceptional ability to absorb water vapor makes it particularly valuable in absorption cooling systems, where it serves as an absorbent in the refrigeration cycle.

The technological trajectory of lithium bromide applications has expanded significantly beyond cooling systems. Recent advancements have demonstrated its potential in thermal energy storage, heat pumps, and integrated renewable energy systems. This evolution reflects broader industry trends toward more efficient, sustainable energy solutions that can address the intermittency challenges associated with renewable energy sources.

Current market dynamics indicate growing interest in lithium bromide-based technologies, particularly as energy efficiency and decarbonization become increasingly important global priorities. The compound's ability to enable thermal energy storage and conversion presents significant opportunities for integration with solar thermal systems, waste heat recovery applications, and district heating networks.

The primary technical objective for lithium bromide utilization in hybrid energy systems centers on maximizing energy conversion efficiency while minimizing system complexity and operational costs. Specifically, research aims to enhance the performance of LiBr-based absorption systems, improve cycle stability, reduce corrosion issues, and develop more compact system designs suitable for distributed energy applications.

Secondary objectives include the development of multi-functional energy systems that can provide both heating and cooling capabilities, integration with various renewable energy sources, and the creation of smart control systems that can optimize performance based on varying energy availability and demand patterns. These objectives align with the broader industry goal of creating more resilient, flexible energy infrastructure.

Long-term technological goals involve the development of next-generation lithium bromide formulations with enhanced thermophysical properties, novel system architectures that can operate across wider temperature ranges, and integrated energy management platforms that can coordinate multiple energy services. These advancements would position lithium bromide-based technologies as key components in the transition toward more sustainable, efficient energy systems.

The convergence of renewable energy integration challenges, increasing cooling demands in urban environments, and the push for greater energy efficiency has created a favorable environment for lithium bromide technology development. As hybrid energy systems continue to evolve, lithium bromide is expected to play an increasingly important role in bridging thermal and electrical energy domains, enabling more effective energy utilization across various sectors.

The technological trajectory of lithium bromide applications has expanded significantly beyond cooling systems. Recent advancements have demonstrated its potential in thermal energy storage, heat pumps, and integrated renewable energy systems. This evolution reflects broader industry trends toward more efficient, sustainable energy solutions that can address the intermittency challenges associated with renewable energy sources.

Current market dynamics indicate growing interest in lithium bromide-based technologies, particularly as energy efficiency and decarbonization become increasingly important global priorities. The compound's ability to enable thermal energy storage and conversion presents significant opportunities for integration with solar thermal systems, waste heat recovery applications, and district heating networks.

The primary technical objective for lithium bromide utilization in hybrid energy systems centers on maximizing energy conversion efficiency while minimizing system complexity and operational costs. Specifically, research aims to enhance the performance of LiBr-based absorption systems, improve cycle stability, reduce corrosion issues, and develop more compact system designs suitable for distributed energy applications.

Secondary objectives include the development of multi-functional energy systems that can provide both heating and cooling capabilities, integration with various renewable energy sources, and the creation of smart control systems that can optimize performance based on varying energy availability and demand patterns. These objectives align with the broader industry goal of creating more resilient, flexible energy infrastructure.

Long-term technological goals involve the development of next-generation lithium bromide formulations with enhanced thermophysical properties, novel system architectures that can operate across wider temperature ranges, and integrated energy management platforms that can coordinate multiple energy services. These advancements would position lithium bromide-based technologies as key components in the transition toward more sustainable, efficient energy systems.

The convergence of renewable energy integration challenges, increasing cooling demands in urban environments, and the push for greater energy efficiency has created a favorable environment for lithium bromide technology development. As hybrid energy systems continue to evolve, lithium bromide is expected to play an increasingly important role in bridging thermal and electrical energy domains, enabling more effective energy utilization across various sectors.

Market Analysis for LiBr-based Energy Solutions

The global market for Lithium Bromide (LiBr) based energy solutions is experiencing significant growth, driven by increasing demand for energy-efficient heating and cooling systems. The absorption refrigeration market, where LiBr serves as a primary working fluid, was valued at approximately $1.3 billion in 2022 and is projected to reach $2.1 billion by 2028, representing a compound annual growth rate of 8.4%. This growth trajectory is particularly pronounced in regions with ambitious decarbonization targets, including Europe, North America, and parts of Asia.

Commercial buildings represent the largest market segment for LiBr-based hybrid energy systems, accounting for roughly 42% of the total market share. This dominance stems from the substantial cooling requirements of large commercial spaces and the economic benefits of reduced electricity consumption. The industrial sector follows closely at 35%, where process cooling and waste heat recovery applications drive adoption. Residential applications currently constitute a smaller but rapidly growing segment at 15%, with the remaining 8% distributed across specialized applications.

Geographically, Asia-Pacific leads the market with approximately 38% share, bolstered by China's aggressive clean energy policies and Japan's long-standing expertise in absorption chiller technology. North America and Europe follow with 27% and 24% respectively, while the Middle East and Africa represent emerging markets with significant growth potential due to their high cooling demands and increasing focus on sustainable energy solutions.

Market drivers for LiBr-based energy solutions include rising energy costs, stringent environmental regulations, and growing awareness of sustainable building practices. The integration of these systems with renewable energy sources such as solar thermal collectors has created a particularly promising market segment, growing at nearly 12% annually. Additionally, the push toward district heating and cooling networks in urban centers has opened new application avenues for large-scale LiBr absorption systems.

Challenges constraining market expansion include high initial capital costs, which can be 1.5-2 times higher than conventional vapor compression systems, and limited awareness among potential end-users about the long-term operational benefits. Technical limitations such as crystallization risks and the need for cooling towers also present market barriers in certain applications.

The competitive landscape features established players like Carrier Corporation, Johnson Controls, and Thermax Limited dominating with approximately 45% combined market share. However, innovative startups focusing on enhanced LiBr system designs and smart control technologies are gaining traction, particularly in specialized applications and integrated renewable energy solutions.

Commercial buildings represent the largest market segment for LiBr-based hybrid energy systems, accounting for roughly 42% of the total market share. This dominance stems from the substantial cooling requirements of large commercial spaces and the economic benefits of reduced electricity consumption. The industrial sector follows closely at 35%, where process cooling and waste heat recovery applications drive adoption. Residential applications currently constitute a smaller but rapidly growing segment at 15%, with the remaining 8% distributed across specialized applications.

Geographically, Asia-Pacific leads the market with approximately 38% share, bolstered by China's aggressive clean energy policies and Japan's long-standing expertise in absorption chiller technology. North America and Europe follow with 27% and 24% respectively, while the Middle East and Africa represent emerging markets with significant growth potential due to their high cooling demands and increasing focus on sustainable energy solutions.

Market drivers for LiBr-based energy solutions include rising energy costs, stringent environmental regulations, and growing awareness of sustainable building practices. The integration of these systems with renewable energy sources such as solar thermal collectors has created a particularly promising market segment, growing at nearly 12% annually. Additionally, the push toward district heating and cooling networks in urban centers has opened new application avenues for large-scale LiBr absorption systems.

Challenges constraining market expansion include high initial capital costs, which can be 1.5-2 times higher than conventional vapor compression systems, and limited awareness among potential end-users about the long-term operational benefits. Technical limitations such as crystallization risks and the need for cooling towers also present market barriers in certain applications.

The competitive landscape features established players like Carrier Corporation, Johnson Controls, and Thermax Limited dominating with approximately 45% combined market share. However, innovative startups focusing on enhanced LiBr system designs and smart control technologies are gaining traction, particularly in specialized applications and integrated renewable energy solutions.

Technical Challenges in LiBr Hybrid Energy Integration

The integration of Lithium Bromide (LiBr) into hybrid energy systems presents several significant technical challenges that must be addressed for successful implementation. One primary obstacle is the corrosive nature of LiBr solutions, which can severely damage system components, particularly those made from common metals. This necessitates the use of specialized corrosion-resistant materials and protective coatings, substantially increasing system costs and maintenance requirements.

Temperature management represents another critical challenge. LiBr absorption systems operate optimally within specific temperature ranges, and maintaining these conditions across varied operational scenarios in hybrid systems proves difficult. Performance degradation occurs when temperatures deviate from optimal ranges, reducing overall system efficiency and reliability, especially in environments with fluctuating ambient conditions.

Crystallization risk poses a persistent technical hurdle in LiBr systems. When solution concentrations exceed solubility limits due to temperature fluctuations or improper operation, LiBr can crystallize, blocking flow paths and damaging critical components. This phenomenon, known as "crystallization fouling," requires sophisticated control systems and preventive measures that add complexity to system design.

Energy density limitations also constrain LiBr applications in hybrid systems. Compared to other energy storage technologies, LiBr-based thermal storage systems typically exhibit lower energy density, necessitating larger installation footprints and potentially limiting their applicability in space-constrained environments.

System integration complexity presents formidable engineering challenges. Synchronizing LiBr absorption cycles with other energy technologies (such as photovoltaics, wind generation, or conventional HVAC systems) requires advanced control algorithms and sophisticated system architecture. The disparate operating parameters and response times between these technologies create significant control and optimization difficulties.

Heat rejection requirements constitute another substantial technical barrier. LiBr absorption systems generate considerable waste heat that must be efficiently dissipated, often requiring cooling towers or other heat rejection equipment that increase water consumption, system footprint, and operational costs.

Vacuum maintenance in absorption chillers presents ongoing technical difficulties. Many LiBr systems operate under partial vacuum conditions that must be meticulously maintained to ensure proper functionality. Air leakage into these systems can dramatically reduce performance and necessitate complex purging mechanisms and regular maintenance procedures.

Finally, part-load performance optimization remains challenging. Hybrid energy systems frequently operate under varying load conditions, but LiBr absorption technologies typically demonstrate reduced efficiency at partial loads, requiring sophisticated modulation strategies and potentially supplementary systems to maintain overall performance across operational ranges.

Temperature management represents another critical challenge. LiBr absorption systems operate optimally within specific temperature ranges, and maintaining these conditions across varied operational scenarios in hybrid systems proves difficult. Performance degradation occurs when temperatures deviate from optimal ranges, reducing overall system efficiency and reliability, especially in environments with fluctuating ambient conditions.

Crystallization risk poses a persistent technical hurdle in LiBr systems. When solution concentrations exceed solubility limits due to temperature fluctuations or improper operation, LiBr can crystallize, blocking flow paths and damaging critical components. This phenomenon, known as "crystallization fouling," requires sophisticated control systems and preventive measures that add complexity to system design.

Energy density limitations also constrain LiBr applications in hybrid systems. Compared to other energy storage technologies, LiBr-based thermal storage systems typically exhibit lower energy density, necessitating larger installation footprints and potentially limiting their applicability in space-constrained environments.

System integration complexity presents formidable engineering challenges. Synchronizing LiBr absorption cycles with other energy technologies (such as photovoltaics, wind generation, or conventional HVAC systems) requires advanced control algorithms and sophisticated system architecture. The disparate operating parameters and response times between these technologies create significant control and optimization difficulties.

Heat rejection requirements constitute another substantial technical barrier. LiBr absorption systems generate considerable waste heat that must be efficiently dissipated, often requiring cooling towers or other heat rejection equipment that increase water consumption, system footprint, and operational costs.

Vacuum maintenance in absorption chillers presents ongoing technical difficulties. Many LiBr systems operate under partial vacuum conditions that must be meticulously maintained to ensure proper functionality. Air leakage into these systems can dramatically reduce performance and necessitate complex purging mechanisms and regular maintenance procedures.

Finally, part-load performance optimization remains challenging. Hybrid energy systems frequently operate under varying load conditions, but LiBr absorption technologies typically demonstrate reduced efficiency at partial loads, requiring sophisticated modulation strategies and potentially supplementary systems to maintain overall performance across operational ranges.

Current LiBr Hybrid Energy System Configurations

01 Lithium bromide in absorption refrigeration systems

Lithium bromide is widely used as an absorbent in absorption refrigeration and heat pump systems due to its excellent hygroscopic properties. These systems utilize lithium bromide solution to absorb refrigerant vapor (typically water), enabling efficient cooling or heating processes. The technology is particularly valuable in applications where waste heat can be utilized as the energy source, offering energy-efficient alternatives to conventional compression refrigeration systems.- Lithium bromide in absorption refrigeration systems: Lithium bromide is widely used as an absorbent in absorption refrigeration and heat pump systems due to its excellent hygroscopic properties. These systems utilize lithium bromide solution to absorb water vapor, enabling efficient cooling or heating processes. The technology includes various improvements in system design, solution circulation, and heat exchange mechanisms to enhance energy efficiency and performance of air conditioning and refrigeration equipment.

- Lithium bromide in energy storage applications: Lithium bromide is utilized in thermal energy storage systems and battery technologies. In thermal storage applications, it serves as a phase change material or component in heat storage solutions. The compound's properties allow for efficient energy absorption, storage, and release in various temperature conditions. These technologies contribute to improved energy management in renewable energy systems and grid stabilization applications.

- Purification and recovery processes for lithium bromide: Various methods have been developed for the purification, regeneration, and recovery of lithium bromide from used solutions. These processes include filtration techniques, chemical treatments, and crystallization methods to remove impurities and restore the original properties of the compound. The purification technologies aim to extend the service life of lithium bromide solutions and reduce operational costs in industrial applications.

- Lithium bromide in pharmaceutical and chemical synthesis: Lithium bromide serves as a reagent or catalyst in pharmaceutical manufacturing and chemical synthesis processes. It is used in the preparation of various organic compounds, drug intermediates, and active pharmaceutical ingredients. The compound's properties enable specific chemical transformations, selective reactions, and improved yields in synthetic pathways for producing high-value chemical products.

- Lithium bromide in dehumidification and drying systems: Lithium bromide solutions are employed in industrial dehumidification and drying systems due to their strong hygroscopic properties. These systems utilize the compound's ability to absorb moisture from air or other gases, enabling efficient humidity control in various industrial processes. The technology includes specialized equipment designs, solution management methods, and regeneration techniques to maintain optimal dehumidification performance.

02 Lithium bromide in energy storage applications

Lithium bromide is employed in various energy storage technologies, particularly in thermal energy storage systems. Its unique thermochemical properties allow it to store and release energy efficiently through absorption and desorption processes. These systems can be integrated with renewable energy sources to address intermittency issues, providing stable energy output and improving overall system efficiency.Expand Specific Solutions03 Purification and regeneration of lithium bromide solutions

Various methods have been developed for purifying and regenerating lithium bromide solutions to maintain their effectiveness in absorption systems. These processes typically involve removing contaminants, adjusting concentration levels, and restoring the solution's absorption capacity. Purification techniques may include filtration, crystallization, ion exchange, and chemical treatment to extend the service life of lithium bromide solutions and improve system performance.Expand Specific Solutions04 Lithium bromide in pharmaceutical and chemical applications

Lithium bromide serves as an important compound in pharmaceutical formulations and chemical synthesis processes. In pharmaceuticals, it may be used for its sedative properties or as a precursor in drug synthesis. In chemical applications, it functions as a catalyst, reagent, or intermediate in various reactions. Its high solubility and ionic properties make it valuable for specific chemical transformations and processes.Expand Specific Solutions05 Lithium bromide in advanced material development

Lithium bromide is utilized in the development of advanced materials with specialized properties. These applications include the synthesis of lithium-containing compounds, preparation of electrolytes for batteries and electrochemical devices, and development of functional materials with specific optical, electrical, or thermal characteristics. The compound's unique properties contribute to innovations in material science and technology development.Expand Specific Solutions

Leading Companies and Research Institutions in LiBr Technology

The lithium bromide hybrid energy systems market is in a growth phase, characterized by increasing adoption across industrial and commercial sectors. The market size is expanding due to rising demand for energy-efficient heating and cooling solutions, with projections showing significant growth potential. Technologically, the field is moderately mature but evolving rapidly. Leading players like Broad Group and Shuangliang Eco-Energy Systems have established strong positions in absorption chiller technology, while DuPont and BASF contribute advanced materials expertise. Research institutions including MIT, Zhejiang University, and Fudan University are driving innovation through collaborative projects with industry leaders like Hitachi and Tesla, focusing on improving system efficiency and integration capabilities. The competitive landscape features a mix of specialized equipment manufacturers and diversified energy solution providers working to enhance lithium bromide applications in renewable energy systems.

Huadian Electric Power Research Institute Co., Ltd.

Technical Solution: Huadian has developed an innovative Combined Cooling, Heating and Power (CCHP) system that integrates lithium bromide absorption chillers with conventional power generation. Their approach utilizes waste heat from gas turbines or other power generation equipment to drive LiBr absorption refrigeration cycles, significantly improving overall energy utilization efficiency. The system incorporates a multi-stage heat recovery design that extracts thermal energy at different temperature levels, directing high-temperature heat to power generation and medium-temperature heat to LiBr absorption chillers. Huadian's proprietary control system optimizes the distribution of thermal energy based on real-time demand for electricity, heating, and cooling, achieving total system efficiencies exceeding 80%. Their latest innovation includes a variable concentration LiBr solution system that can adapt to fluctuating heat source temperatures, making it particularly suitable for integration with renewable energy sources like solar thermal and biomass. The technology has been successfully deployed in district energy systems, industrial parks, and large commercial complexes across China, demonstrating energy savings of 30-40% compared to conventional separated production of cooling, heating, and power.

Strengths: Exceptional primary energy utilization efficiency (>80%); reduced carbon emissions through waste heat recovery; flexible operation modes that can prioritize electricity or thermal output based on demand. Weaknesses: Complex system integration requiring sophisticated controls; higher initial capital costs compared to conventional systems; performance dependent on base load operation of power generation equipment.

Hitachi Ltd.

Technical Solution: Hitachi has developed an innovative hybrid energy system utilizing lithium bromide absorption technology integrated with their H-Vision energy management platform. Their approach combines LiBr absorption chillers with conventional electric chillers, heat pumps, and renewable energy sources in a comprehensive energy solution. Hitachi's system employs a triple-effect absorption cycle that achieves coefficient of performance (COP) values up to 1.7, significantly higher than conventional double-effect systems. The company has engineered specialized heat exchangers with enhanced surface treatments that minimize corrosion issues common in LiBr systems while improving heat transfer efficiency. Their hybrid control system employs predictive analytics to forecast building loads and energy prices, dynamically switching between absorption cooling (powered by waste heat or renewable thermal energy) and conventional electric cooling based on real-time efficiency and cost parameters. This integration extends to thermal storage systems that store excess heat for later use in the LiBr absorption process during peak demand periods.

Strengths: Superior energy efficiency with triple-effect technology; comprehensive integration with building management systems; reduced maintenance requirements through corrosion-resistant materials and automated crystallization prevention. Weaknesses: Higher initial investment costs compared to standard cooling systems; requires specialized technical expertise for installation and commissioning; optimal performance dependent on consistent heat source availability.

Key Patents and Innovations in Lithium Bromide Energy Storage

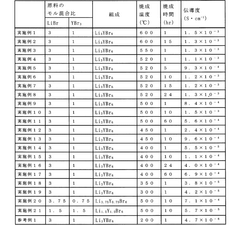

Method for producing halide

PatentWO2020136955A1

Innovation

- A method involving the firing of a mixed material comprising LiBr and YBr3 at temperatures between 200°C and 650°C in an inert gas atmosphere, allowing for the production of bromides with improved ionic conductivity without the need for vacuum sealed tubes or planetary ball mills, and optionally incorporating other elements like Na, K, Ca, or fluorine to enhance properties.

Environmental Impact Assessment of LiBr Energy Technologies

The environmental impact of lithium bromide (LiBr) technologies in hybrid energy systems requires comprehensive assessment across multiple dimensions. LiBr absorption systems, while offering significant energy efficiency benefits, present several environmental considerations that must be evaluated when implementing these technologies at scale.

The primary environmental advantage of LiBr-based absorption cooling systems is their potential to reduce electricity consumption and associated greenhouse gas emissions. When integrated with renewable energy sources or waste heat recovery systems, these technologies can significantly decrease carbon footprints compared to conventional vapor compression cooling systems. Studies indicate potential CO2 emission reductions of 30-50% depending on the energy source utilized.

However, LiBr solution presents certain environmental risks that require careful management. The corrosive nature of concentrated LiBr solutions can lead to equipment degradation and potential leakage if proper materials and maintenance protocols are not employed. Such leakages could contaminate soil and water systems, affecting local ecosystems. The toxicity profile of LiBr, while lower than some alternative working fluids, still necessitates proper handling and disposal procedures.

Water consumption represents another significant environmental consideration. LiBr absorption systems typically require cooling towers that consume substantial amounts of water through evaporation and blowdown processes. In water-stressed regions, this consumption pattern may create additional environmental pressure and compete with other essential water needs.

Life cycle assessment (LCA) studies of LiBr energy technologies reveal complex environmental trade-offs. While operational emissions are typically lower than conventional systems, the manufacturing and disposal phases may present higher environmental burdens due to material extraction and processing requirements. The production of high-purity LiBr involves energy-intensive processes and chemical treatments that generate their own environmental footprints.

End-of-life management presents additional challenges. Recovery and recycling protocols for LiBr solutions are not yet standardized across the industry, potentially leading to improper disposal practices. Developing closed-loop recycling systems for LiBr would significantly improve the overall environmental profile of these technologies.

Regulatory frameworks governing LiBr technologies vary considerably across regions, creating inconsistent environmental protection standards. More harmonized approaches to regulation, coupled with industry best practices, would help mitigate potential environmental risks while maximizing the benefits of these promising energy technologies.

The primary environmental advantage of LiBr-based absorption cooling systems is their potential to reduce electricity consumption and associated greenhouse gas emissions. When integrated with renewable energy sources or waste heat recovery systems, these technologies can significantly decrease carbon footprints compared to conventional vapor compression cooling systems. Studies indicate potential CO2 emission reductions of 30-50% depending on the energy source utilized.

However, LiBr solution presents certain environmental risks that require careful management. The corrosive nature of concentrated LiBr solutions can lead to equipment degradation and potential leakage if proper materials and maintenance protocols are not employed. Such leakages could contaminate soil and water systems, affecting local ecosystems. The toxicity profile of LiBr, while lower than some alternative working fluids, still necessitates proper handling and disposal procedures.

Water consumption represents another significant environmental consideration. LiBr absorption systems typically require cooling towers that consume substantial amounts of water through evaporation and blowdown processes. In water-stressed regions, this consumption pattern may create additional environmental pressure and compete with other essential water needs.

Life cycle assessment (LCA) studies of LiBr energy technologies reveal complex environmental trade-offs. While operational emissions are typically lower than conventional systems, the manufacturing and disposal phases may present higher environmental burdens due to material extraction and processing requirements. The production of high-purity LiBr involves energy-intensive processes and chemical treatments that generate their own environmental footprints.

End-of-life management presents additional challenges. Recovery and recycling protocols for LiBr solutions are not yet standardized across the industry, potentially leading to improper disposal practices. Developing closed-loop recycling systems for LiBr would significantly improve the overall environmental profile of these technologies.

Regulatory frameworks governing LiBr technologies vary considerably across regions, creating inconsistent environmental protection standards. More harmonized approaches to regulation, coupled with industry best practices, would help mitigate potential environmental risks while maximizing the benefits of these promising energy technologies.

Cost-Benefit Analysis of Lithium Bromide Implementation

The implementation of lithium bromide in hybrid energy systems requires careful financial assessment to determine its economic viability. Initial capital expenditure for lithium bromide absorption systems is significantly higher than conventional cooling technologies, with costs ranging from $1,500 to $2,500 per refrigeration ton. However, this investment must be evaluated against long-term operational savings, particularly in energy consumption where these systems can reduce electricity usage by 30-50% compared to traditional vapor compression systems.

Maintenance costs for lithium bromide systems present a mixed financial picture. While the absence of mechanical compressors reduces certain maintenance expenses, the corrosive nature of lithium bromide solutions necessitates specialized materials and regular system monitoring, adding approximately 5-8% to annual operational costs. The typical service life of 15-20 years for these systems provides a substantial timeframe for return on investment calculations.

Energy efficiency gains represent the most compelling economic benefit. In hybrid configurations where lithium bromide absorption chillers utilize waste heat from other system components, overall system efficiency can increase by 25-40%. This translates to annual energy cost reductions of $0.15-0.25 per square foot in commercial applications, with higher savings in regions with elevated electricity rates.

Environmental compliance considerations also factor into the cost-benefit equation. As carbon pricing mechanisms become more prevalent globally, the reduced carbon footprint of lithium bromide systems (typically 20-30% lower than conventional alternatives) may translate to quantifiable financial benefits through carbon credit systems or avoided carbon taxes, estimated at $5-15 per ton of CO₂ equivalent.

Integration complexity with existing infrastructure introduces additional costs that vary significantly based on facility design. Retrofitting existing buildings for lithium bromide systems typically adds 15-25% to base installation costs, while new construction integration can be more cost-effective. These integration expenses must be factored into comprehensive financial models.

The payback period for lithium bromide implementation in hybrid energy systems typically ranges from 4-8 years depending on energy prices, system utilization rates, and available incentives. Government subsidies and clean energy incentives can significantly improve this timeline, with some jurisdictions offering rebates covering 10-30% of initial capital costs for energy-efficient cooling technologies.

Maintenance costs for lithium bromide systems present a mixed financial picture. While the absence of mechanical compressors reduces certain maintenance expenses, the corrosive nature of lithium bromide solutions necessitates specialized materials and regular system monitoring, adding approximately 5-8% to annual operational costs. The typical service life of 15-20 years for these systems provides a substantial timeframe for return on investment calculations.

Energy efficiency gains represent the most compelling economic benefit. In hybrid configurations where lithium bromide absorption chillers utilize waste heat from other system components, overall system efficiency can increase by 25-40%. This translates to annual energy cost reductions of $0.15-0.25 per square foot in commercial applications, with higher savings in regions with elevated electricity rates.

Environmental compliance considerations also factor into the cost-benefit equation. As carbon pricing mechanisms become more prevalent globally, the reduced carbon footprint of lithium bromide systems (typically 20-30% lower than conventional alternatives) may translate to quantifiable financial benefits through carbon credit systems or avoided carbon taxes, estimated at $5-15 per ton of CO₂ equivalent.

Integration complexity with existing infrastructure introduces additional costs that vary significantly based on facility design. Retrofitting existing buildings for lithium bromide systems typically adds 15-25% to base installation costs, while new construction integration can be more cost-effective. These integration expenses must be factored into comprehensive financial models.

The payback period for lithium bromide implementation in hybrid energy systems typically ranges from 4-8 years depending on energy prices, system utilization rates, and available incentives. Government subsidies and clean energy incentives can significantly improve this timeline, with some jurisdictions offering rebates covering 10-30% of initial capital costs for energy-efficient cooling technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!