Lithium Bromide Test Cases: How to Ensure System Robustness

AUG 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LiBr Testing Background and Objectives

Lithium bromide (LiBr) has emerged as a critical component in absorption refrigeration systems, particularly in industrial cooling applications and HVAC systems for large commercial buildings. The evolution of LiBr technology dates back to the mid-20th century, with significant advancements occurring in the 1970s and 1980s as energy efficiency concerns drove innovation in alternative cooling technologies. The trajectory of development has consistently focused on improving system efficiency, reducing corrosion issues, and enhancing overall reliability.

The primary objective of LiBr testing protocols is to ensure system robustness under various operational conditions, including temperature fluctuations, pressure variations, and extended operational cycles. These tests aim to validate the system's ability to maintain stable absorption-refrigeration processes while preventing crystallization, which remains one of the most significant technical challenges in LiBr-based systems.

Current technological trends in LiBr systems include the integration of advanced materials for heat exchangers, implementation of sophisticated control algorithms for crystallization prevention, and development of hybrid systems that combine LiBr absorption with conventional vapor compression technologies. These innovations seek to address historical limitations while expanding the application scope of LiBr-based cooling solutions.

Market demands have increasingly pushed for more rigorous testing methodologies as LiBr systems are deployed in critical infrastructure where system failure could result in significant operational disruptions and financial losses. The testing objectives must therefore align with industry standards such as ASHRAE 181 and ISO 16358, which provide frameworks for performance evaluation but require supplementation with specialized robustness testing protocols.

From a technical perspective, LiBr testing must address several key parameters: solution concentration stability, corrosion resistance of system components, thermal cycling endurance, vacuum integrity maintenance, and crystallization prevention mechanisms. Each of these factors contributes to the overall system reliability and operational lifespan, making comprehensive testing essential for quality assurance.

The expected outcomes of robust LiBr testing include the establishment of performance boundaries, identification of failure modes, determination of maintenance intervals, and validation of design improvements. These outcomes support both immediate quality control objectives and longer-term research and development goals aimed at advancing the technology's capabilities and applications.

As global energy efficiency regulations become more stringent, the importance of reliable LiBr systems continues to grow, particularly in regions with high cooling demands and limited electrical infrastructure. This technological context underscores the critical nature of developing standardized, comprehensive testing methodologies that can ensure system robustness across diverse operational environments and use cases.

The primary objective of LiBr testing protocols is to ensure system robustness under various operational conditions, including temperature fluctuations, pressure variations, and extended operational cycles. These tests aim to validate the system's ability to maintain stable absorption-refrigeration processes while preventing crystallization, which remains one of the most significant technical challenges in LiBr-based systems.

Current technological trends in LiBr systems include the integration of advanced materials for heat exchangers, implementation of sophisticated control algorithms for crystallization prevention, and development of hybrid systems that combine LiBr absorption with conventional vapor compression technologies. These innovations seek to address historical limitations while expanding the application scope of LiBr-based cooling solutions.

Market demands have increasingly pushed for more rigorous testing methodologies as LiBr systems are deployed in critical infrastructure where system failure could result in significant operational disruptions and financial losses. The testing objectives must therefore align with industry standards such as ASHRAE 181 and ISO 16358, which provide frameworks for performance evaluation but require supplementation with specialized robustness testing protocols.

From a technical perspective, LiBr testing must address several key parameters: solution concentration stability, corrosion resistance of system components, thermal cycling endurance, vacuum integrity maintenance, and crystallization prevention mechanisms. Each of these factors contributes to the overall system reliability and operational lifespan, making comprehensive testing essential for quality assurance.

The expected outcomes of robust LiBr testing include the establishment of performance boundaries, identification of failure modes, determination of maintenance intervals, and validation of design improvements. These outcomes support both immediate quality control objectives and longer-term research and development goals aimed at advancing the technology's capabilities and applications.

As global energy efficiency regulations become more stringent, the importance of reliable LiBr systems continues to grow, particularly in regions with high cooling demands and limited electrical infrastructure. This technological context underscores the critical nature of developing standardized, comprehensive testing methodologies that can ensure system robustness across diverse operational environments and use cases.

Market Requirements for LiBr System Reliability

The reliability of Lithium Bromide (LiBr) absorption systems has become a critical market requirement as these systems gain wider adoption in industrial cooling, HVAC applications, and renewable energy integration. Market analysis indicates that end-users across various sectors are demanding increasingly robust LiBr systems that can maintain consistent performance under diverse operating conditions while minimizing maintenance requirements and downtime.

Primary market drivers for enhanced LiBr system reliability include the growing implementation in mission-critical facilities such as data centers, healthcare institutions, and manufacturing plants where cooling system failures can result in significant financial losses and operational disruptions. These sectors require absorption systems capable of maintaining 99.9% uptime with minimal intervention, creating strong market pressure for improved reliability testing protocols.

Energy efficiency regulations and sustainability initiatives worldwide have accelerated market demand for absorption cooling technologies as alternatives to conventional vapor compression systems. However, adoption rates remain constrained by concerns regarding system robustness, particularly in regions with variable climate conditions or limited technical support infrastructure. Market research shows that addressing reliability concerns could potentially expand the addressable market for LiBr systems by 30-40% in emerging economies.

Customer feedback analysis reveals specific reliability requirements focusing on corrosion resistance, crystallization prevention, vacuum integrity maintenance, and component longevity. Industrial users particularly emphasize the need for systems that can withstand operational fluctuations, including variable heat source temperatures and cooling load profiles without performance degradation or increased maintenance frequency.

The service and maintenance ecosystem surrounding LiBr systems represents another significant market consideration. Current market data indicates maintenance costs typically account for 15-20% of total lifecycle expenses for absorption systems. Customers are increasingly seeking solutions with extended service intervals, simplified maintenance procedures, and comprehensive monitoring capabilities to reduce these ongoing costs.

Market segmentation analysis shows varying reliability requirements across different applications. While industrial process cooling applications prioritize continuous operation capabilities and resistance to harsh environmental conditions, commercial building applications emphasize quiet operation, minimal maintenance requirements, and integration with building management systems for predictive maintenance.

Competitive benchmarking indicates that manufacturers who can demonstrate superior reliability through comprehensive test data and field performance metrics gain significant market advantage. The market increasingly values standardized testing protocols and certification programs that can objectively validate system robustness claims and provide customers with comparable reliability metrics across different product offerings.

Primary market drivers for enhanced LiBr system reliability include the growing implementation in mission-critical facilities such as data centers, healthcare institutions, and manufacturing plants where cooling system failures can result in significant financial losses and operational disruptions. These sectors require absorption systems capable of maintaining 99.9% uptime with minimal intervention, creating strong market pressure for improved reliability testing protocols.

Energy efficiency regulations and sustainability initiatives worldwide have accelerated market demand for absorption cooling technologies as alternatives to conventional vapor compression systems. However, adoption rates remain constrained by concerns regarding system robustness, particularly in regions with variable climate conditions or limited technical support infrastructure. Market research shows that addressing reliability concerns could potentially expand the addressable market for LiBr systems by 30-40% in emerging economies.

Customer feedback analysis reveals specific reliability requirements focusing on corrosion resistance, crystallization prevention, vacuum integrity maintenance, and component longevity. Industrial users particularly emphasize the need for systems that can withstand operational fluctuations, including variable heat source temperatures and cooling load profiles without performance degradation or increased maintenance frequency.

The service and maintenance ecosystem surrounding LiBr systems represents another significant market consideration. Current market data indicates maintenance costs typically account for 15-20% of total lifecycle expenses for absorption systems. Customers are increasingly seeking solutions with extended service intervals, simplified maintenance procedures, and comprehensive monitoring capabilities to reduce these ongoing costs.

Market segmentation analysis shows varying reliability requirements across different applications. While industrial process cooling applications prioritize continuous operation capabilities and resistance to harsh environmental conditions, commercial building applications emphasize quiet operation, minimal maintenance requirements, and integration with building management systems for predictive maintenance.

Competitive benchmarking indicates that manufacturers who can demonstrate superior reliability through comprehensive test data and field performance metrics gain significant market advantage. The market increasingly values standardized testing protocols and certification programs that can objectively validate system robustness claims and provide customers with comparable reliability metrics across different product offerings.

Current Testing Challenges and Limitations

The current testing methodologies for Lithium Bromide (LiBr) absorption systems face significant challenges that impede comprehensive system robustness verification. Traditional testing approaches often rely on simplified conditions that fail to replicate the complex operational environments these systems encounter in real-world applications. This disconnect between testing and actual usage scenarios creates vulnerabilities that may only become apparent after deployment.

One major limitation is the inadequate simulation of thermal cycling effects. LiBr absorption systems typically experience numerous heating and cooling cycles throughout their operational lifetime, yet current testing protocols rarely subject systems to sufficient cycle counts to reveal potential material degradation or component failure patterns that emerge over extended use periods.

Corrosion testing represents another critical gap in current methodologies. The highly corrosive nature of LiBr solutions demands specialized testing procedures, but standardized protocols often lack consistency across the industry. This inconsistency leads to varying quality assurance standards and makes comparative analysis between different systems challenging. Furthermore, accelerated corrosion tests frequently fail to accurately model the long-term effects observed in actual installations.

Vacuum integrity testing presents unique challenges due to the technical complexity of maintaining and verifying hermetic seals in absorption systems. Current leak detection methods often lack the sensitivity required to identify micro-leaks that, while initially insignificant, can progressively compromise system performance over time. The industry lacks standardized quantitative metrics for acceptable leakage rates across different system capacities and applications.

Performance testing under variable load conditions remains underdeveloped. Most current testing regimes evaluate systems under steady-state conditions, neglecting the dynamic response characteristics critical for real-world applications where demand fluctuates continuously. This limitation is particularly problematic for systems deployed in environments with highly variable thermal loads or intermittent operation requirements.

Integration testing between LiBr systems and auxiliary components or control systems is often conducted in isolation rather than as a comprehensive ecosystem. This siloed approach fails to capture complex interactions that can lead to cascading failures or suboptimal performance in integrated installations. The lack of standardized communication protocols further complicates this challenge.

Data collection and analysis methodologies suffer from fragmentation and inconsistency. The absence of unified data formats and analysis frameworks hampers industry-wide learning and continuous improvement efforts. Many testing programs generate substantial data but lack sophisticated analytical tools to extract meaningful patterns or predictive insights regarding system robustness and potential failure modes.

One major limitation is the inadequate simulation of thermal cycling effects. LiBr absorption systems typically experience numerous heating and cooling cycles throughout their operational lifetime, yet current testing protocols rarely subject systems to sufficient cycle counts to reveal potential material degradation or component failure patterns that emerge over extended use periods.

Corrosion testing represents another critical gap in current methodologies. The highly corrosive nature of LiBr solutions demands specialized testing procedures, but standardized protocols often lack consistency across the industry. This inconsistency leads to varying quality assurance standards and makes comparative analysis between different systems challenging. Furthermore, accelerated corrosion tests frequently fail to accurately model the long-term effects observed in actual installations.

Vacuum integrity testing presents unique challenges due to the technical complexity of maintaining and verifying hermetic seals in absorption systems. Current leak detection methods often lack the sensitivity required to identify micro-leaks that, while initially insignificant, can progressively compromise system performance over time. The industry lacks standardized quantitative metrics for acceptable leakage rates across different system capacities and applications.

Performance testing under variable load conditions remains underdeveloped. Most current testing regimes evaluate systems under steady-state conditions, neglecting the dynamic response characteristics critical for real-world applications where demand fluctuates continuously. This limitation is particularly problematic for systems deployed in environments with highly variable thermal loads or intermittent operation requirements.

Integration testing between LiBr systems and auxiliary components or control systems is often conducted in isolation rather than as a comprehensive ecosystem. This siloed approach fails to capture complex interactions that can lead to cascading failures or suboptimal performance in integrated installations. The lack of standardized communication protocols further complicates this challenge.

Data collection and analysis methodologies suffer from fragmentation and inconsistency. The absence of unified data formats and analysis frameworks hampers industry-wide learning and continuous improvement efforts. Many testing programs generate substantial data but lack sophisticated analytical tools to extract meaningful patterns or predictive insights regarding system robustness and potential failure modes.

Established LiBr System Testing Protocols

01 Corrosion inhibition in lithium bromide systems

Corrosion inhibitors are essential for improving the robustness of lithium bromide systems. Various compounds can be added to lithium bromide solutions to prevent corrosion of metal components, extending system lifespan and maintaining performance. These inhibitors form protective films on metal surfaces or neutralize corrosive agents in the solution. Common inhibitors include molybdate compounds, nitrates, and specific organic compounds that can significantly enhance system durability under operational conditions.- Corrosion inhibition in lithium bromide systems: Various corrosion inhibitors can be added to lithium bromide systems to enhance their robustness and longevity. These inhibitors protect metal components from degradation when exposed to the highly corrosive lithium bromide solution. Effective corrosion inhibitors include specific organic compounds, metal oxides, and proprietary formulations that form protective layers on metal surfaces, significantly extending the operational life of absorption refrigeration systems and heat pumps that use lithium bromide as the working fluid.

- Stability enhancement through additives: The robustness of lithium bromide systems can be improved through the addition of specific stabilizing compounds. These additives help maintain solution properties under varying operating conditions, prevent crystallization, and improve heat transfer efficiency. Common stabilizers include specific salts, polymers, and surfactants that modify the thermodynamic and physical properties of the lithium bromide solution, resulting in more reliable operation across a wider range of temperatures and concentrations.

- Advanced system design for operational reliability: Innovative mechanical and structural designs can significantly improve the robustness of lithium bromide absorption systems. These designs include specialized heat exchangers, solution distribution systems, and control mechanisms that enhance system stability during fluctuating operating conditions. Features such as improved solution circulation, optimized component geometry, and strategic placement of sensors contribute to more reliable operation and reduced maintenance requirements in lithium bromide-based cooling and heating applications.

- Monitoring and control systems for performance optimization: Advanced monitoring and control technologies play a crucial role in maintaining the robustness of lithium bromide systems. These technologies include real-time concentration monitoring, predictive maintenance algorithms, and automated adjustment mechanisms that respond to changing operating conditions. By continuously monitoring key parameters such as temperature, pressure, and solution concentration, these systems can prevent crystallization, optimize energy efficiency, and extend equipment life through early detection of potential issues.

- Purification and maintenance techniques: Regular purification and maintenance procedures are essential for ensuring the long-term robustness of lithium bromide systems. These techniques include filtration methods, solution reconditioning processes, and periodic system cleaning to remove contaminants and degradation products. Effective maintenance protocols can prevent issues such as crystallization, corrosion, and reduced heat transfer efficiency, thereby maintaining optimal system performance and extending the operational lifespan of lithium bromide absorption equipment.

02 Stabilization techniques for lithium bromide solutions

Stabilization methods are crucial for maintaining the robustness of lithium bromide systems over time. These techniques include precise pH control, addition of buffer solutions, and incorporation of stabilizing agents that prevent solution degradation. Stabilized lithium bromide solutions demonstrate improved thermal stability, reduced crystallization risk, and enhanced absorption efficiency. These improvements directly contribute to more reliable operation and extended maintenance intervals for absorption refrigeration and heat pump systems.Expand Specific Solutions03 Advanced monitoring and control systems

Implementing sophisticated monitoring and control systems significantly enhances lithium bromide system robustness. These systems utilize sensors to continuously track critical parameters such as concentration, temperature, pressure, and flow rates. Real-time data analysis allows for early detection of potential issues and automatic adjustments to maintain optimal operating conditions. Advanced control algorithms can predict and prevent crystallization, overheating, or other failure modes, thereby increasing system reliability and operational efficiency.Expand Specific Solutions04 Structural design improvements for system durability

Innovative structural designs enhance the robustness of lithium bromide systems. These improvements include optimized heat exchanger configurations, enhanced flow distribution mechanisms, and specialized component materials that resist corrosion and scaling. Structural modifications can also incorporate redundant systems, improved sealing technologies, and vibration dampening features. Such design enhancements result in more durable systems that can withstand thermal cycling, pressure fluctuations, and other operational stresses while maintaining consistent performance.Expand Specific Solutions05 Purification and maintenance protocols

Effective purification and maintenance protocols are essential for ensuring long-term robustness of lithium bromide systems. These include filtration techniques to remove particulates, degassing procedures to eliminate non-condensable gases, and periodic solution reconditioning to maintain optimal concentration. Regular maintenance schedules with specific procedures for component inspection, cleaning, and replacement help prevent system degradation. Implementation of these protocols significantly extends system lifespan and maintains consistent performance under varying operational conditions.Expand Specific Solutions

Leading Organizations in LiBr Testing Standards

The lithium bromide test case market is currently in a growth phase, with increasing demand for robust system testing solutions across various industries. The market size is expanding due to the rising adoption of lithium bromide in HVAC systems, refrigeration, and energy storage applications. Technologically, the field shows varying maturity levels, with established players like Boehringer Ingelheim Pharma, Robert Bosch GmbH, and STMicroelectronics leading with comprehensive testing frameworks, while newer entrants such as Ningde Amperex Technology and Anhui Annaijie New Energy Technology are rapidly advancing their capabilities. Companies like Huawei Technologies and BMW Brilliance Automotive are investing significantly in developing specialized test cases for automotive and electronics applications, indicating a competitive landscape that balances innovation from tech giants with specialized expertise from industry-focused firms.

Ningde Amperex Technology Ltd.

Technical Solution: Ningde Amperex Technology Ltd. (CATL) has developed a comprehensive lithium bromide test case framework for battery management systems that ensures robustness through multi-level validation protocols. Their approach includes accelerated aging tests that simulate years of operation in various environmental conditions, with temperature ranges from -40°C to 85°C. The system employs real-time monitoring with distributed sensors that track over 50 parameters simultaneously, allowing for early detection of potential issues. CATL's test methodology incorporates machine learning algorithms that analyze historical test data to predict potential failure modes and optimize test parameters accordingly. Their battery management systems undergo rigorous electromagnetic compatibility (EMC) testing to ensure performance stability under electromagnetic interference conditions commonly encountered in electric vehicles and energy storage applications.

Strengths: Industry-leading battery testing infrastructure with high precision measurement capabilities and extensive historical data for comparative analysis. Their testing protocols are widely adopted as industry benchmarks. Weaknesses: The comprehensive testing approach requires significant time and resources, potentially extending product development cycles compared to competitors with less rigorous testing standards.

Robert Bosch GmbH

Technical Solution: Robert Bosch GmbH has engineered a sophisticated lithium bromide test case system for automotive and industrial applications that focuses on functional safety and reliability. Their approach integrates hardware-in-the-loop (HIL) simulation environments that can reproduce complex operational scenarios while monitoring system responses. Bosch's test methodology includes fault injection testing where over 1,000 different fault scenarios are systematically introduced to validate system recovery mechanisms. Their test cases specifically address lithium bromide absorption refrigeration systems used in automotive climate control and industrial cooling applications, with particular attention to corrosion resistance and long-term stability. The company employs automated test execution platforms that can run continuous test cycles for up to 10,000 hours, simulating the entire lifecycle of components while monitoring for performance degradation or unexpected behaviors.

Strengths: Exceptional integration of safety standards (ISO 26262) into test methodologies and strong focus on functional safety validation. Their test systems benefit from Bosch's extensive automotive experience and cross-industry knowledge. Weaknesses: Their test frameworks tend to be optimized for automotive applications, sometimes requiring significant adaptation for other industries or novel applications of lithium bromide technology.

Critical Test Case Analysis and Design

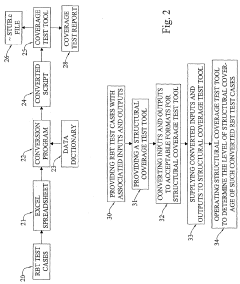

Providing support for structural converage testing

PatentWO2005020005A2

Innovation

- The method involves providing RBT test cases with associated inputs and outputs, converting them to a format acceptable for a structural coverage test tool, and operating the tool to determine structural coverage, thereby avoiding the need for simulation or modeling, using tools like IBM Rational Test RealTime for structural coverage analysis.

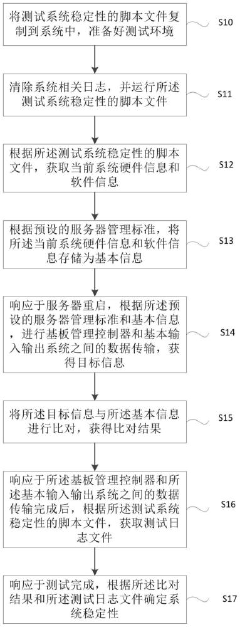

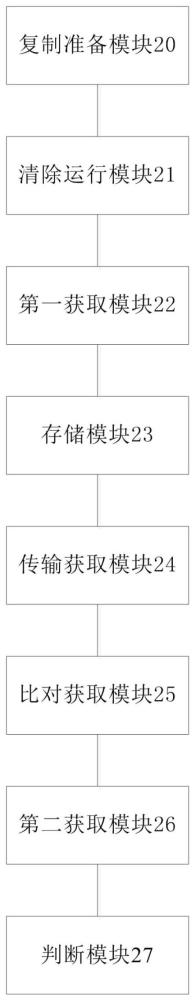

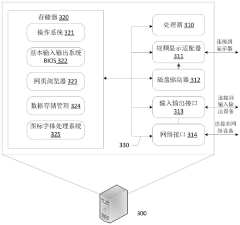

Method and device for testing system stability, equipment and storage medium

PatentPendingCN117251361A

Innovation

- Provide a method and device for testing system stability, obtain hardware and software information through script files, perform data transmission between the baseboard management controller and the basic input and output system, compare information before and after transmission, and obtain comparison results and log files , to determine system stability.

Environmental Impact Considerations

The environmental impact of lithium bromide (LiBr) systems requires thorough assessment to ensure sustainable implementation. LiBr absorption refrigeration systems, while energy-efficient alternatives to conventional cooling technologies, present several environmental concerns that must be addressed through comprehensive test protocols. The primary environmental consideration involves potential leakage of lithium bromide solution, which can contaminate soil and water systems. Testing must verify containment integrity under various operational conditions, including thermal cycling, pressure fluctuations, and mechanical stress that simulate real-world scenarios.

Corrosion testing represents another critical environmental dimension, as LiBr's corrosive properties can lead to system deterioration and subsequent environmental release. Test cases should evaluate material compatibility and long-term corrosion resistance, particularly at connection points and seals where failure risks are heightened. Additionally, energy consumption metrics must be incorporated into robustness testing, as environmental benefits of LiBr systems largely depend on their operational efficiency compared to conventional refrigeration technologies.

Water usage constitutes a significant environmental factor in LiBr absorption systems. Test protocols should measure water consumption rates under various operating conditions and evaluate water conservation strategies. This includes assessing the effectiveness of water recovery systems and quantifying evaporative losses that impact the system's overall environmental footprint. Furthermore, testing should verify that water discharge from these systems meets environmental quality standards, particularly regarding temperature and chemical composition.

End-of-life considerations represent an often overlooked environmental aspect of LiBr systems. Test cases should evaluate component recyclability and the feasibility of lithium bromide recovery for reuse. Protocols must assess the environmental impact of disposal methods and identify potential hazardous waste concerns. This lifecycle approach ensures that environmental impacts are considered beyond operational parameters to include manufacturing and decommissioning phases.

Climate impact testing should measure direct and indirect greenhouse gas emissions associated with LiBr systems. While these systems typically use environmentally benign working fluids compared to conventional refrigerants with high global warming potential, their overall climate impact depends on energy source and operational efficiency. Test cases should quantify emissions under various energy supply scenarios and compare results with alternative technologies to provide comprehensive environmental performance data.

Regulatory compliance testing constitutes the final environmental consideration, ensuring systems meet increasingly stringent environmental standards across different jurisdictions. Test protocols should verify compliance with chemical handling regulations, emissions standards, and energy efficiency requirements. This forward-looking approach helps anticipate regulatory changes and ensures system designs remain environmentally viable throughout their operational lifespan.

Corrosion testing represents another critical environmental dimension, as LiBr's corrosive properties can lead to system deterioration and subsequent environmental release. Test cases should evaluate material compatibility and long-term corrosion resistance, particularly at connection points and seals where failure risks are heightened. Additionally, energy consumption metrics must be incorporated into robustness testing, as environmental benefits of LiBr systems largely depend on their operational efficiency compared to conventional refrigeration technologies.

Water usage constitutes a significant environmental factor in LiBr absorption systems. Test protocols should measure water consumption rates under various operating conditions and evaluate water conservation strategies. This includes assessing the effectiveness of water recovery systems and quantifying evaporative losses that impact the system's overall environmental footprint. Furthermore, testing should verify that water discharge from these systems meets environmental quality standards, particularly regarding temperature and chemical composition.

End-of-life considerations represent an often overlooked environmental aspect of LiBr systems. Test cases should evaluate component recyclability and the feasibility of lithium bromide recovery for reuse. Protocols must assess the environmental impact of disposal methods and identify potential hazardous waste concerns. This lifecycle approach ensures that environmental impacts are considered beyond operational parameters to include manufacturing and decommissioning phases.

Climate impact testing should measure direct and indirect greenhouse gas emissions associated with LiBr systems. While these systems typically use environmentally benign working fluids compared to conventional refrigerants with high global warming potential, their overall climate impact depends on energy source and operational efficiency. Test cases should quantify emissions under various energy supply scenarios and compare results with alternative technologies to provide comprehensive environmental performance data.

Regulatory compliance testing constitutes the final environmental consideration, ensuring systems meet increasingly stringent environmental standards across different jurisdictions. Test protocols should verify compliance with chemical handling regulations, emissions standards, and energy efficiency requirements. This forward-looking approach helps anticipate regulatory changes and ensures system designs remain environmentally viable throughout their operational lifespan.

Safety Compliance and Certification Requirements

Lithium bromide absorption systems must adhere to stringent safety compliance and certification requirements due to the potential hazards associated with the chemical. The primary regulatory frameworks governing these systems include ASHRAE Standard 15, which addresses refrigeration safety, and ASME Boiler and Pressure Vessel Code Section VIII, which covers pressure vessel design requirements essential for containing lithium bromide solutions under various operating conditions.

International standards such as ISO 5149 provide comprehensive guidelines for refrigeration systems and heat pumps, with specific provisions for absorption systems using lithium bromide. These standards establish minimum safety requirements for system design, construction, installation, and operation. Additionally, UL 471 and UL 1995 in the United States set forth safety standards for commercial refrigeration equipment and heating and cooling equipment respectively, which apply to lithium bromide absorption systems used in commercial and industrial settings.

The European Union's Pressure Equipment Directive (PED) 2014/68/EU imposes essential safety requirements for pressure equipment, including lithium bromide absorption systems operating above 0.5 bar. Compliance with this directive requires manufacturers to implement appropriate conformity assessment procedures and affix CE marking to their products before placing them on the EU market.

Testing protocols for lithium bromide systems must include corrosion resistance verification, as the solution can be highly corrosive to certain metals. ASTM G31 provides standard practices for laboratory immersion corrosion testing, while NACE TM0169 offers additional guidance for laboratory corrosion testing of metals. These tests are crucial for ensuring long-term system integrity and preventing leaks that could pose safety hazards.

Environmental regulations also impact lithium bromide systems, with requirements for proper handling, storage, and disposal of the solution. The U.S. Environmental Protection Agency (EPA) regulates these aspects under the Resource Conservation and Recovery Act (RCRA), while similar regulations exist in other jurisdictions worldwide.

Certification processes typically involve third-party verification by organizations such as TÜV, UL, or SGS. These entities conduct comprehensive assessments of system design, manufacturing processes, and quality control procedures. Manufacturers must maintain detailed documentation of compliance with all applicable standards and regulations, including test reports, risk assessments, and technical files that demonstrate conformity with safety requirements.

Regular inspection and maintenance requirements are often specified in certification standards, necessitating the development of robust maintenance protocols and documentation systems. These requirements ensure continued safe operation throughout the system's lifecycle and form an essential component of overall compliance strategy.

International standards such as ISO 5149 provide comprehensive guidelines for refrigeration systems and heat pumps, with specific provisions for absorption systems using lithium bromide. These standards establish minimum safety requirements for system design, construction, installation, and operation. Additionally, UL 471 and UL 1995 in the United States set forth safety standards for commercial refrigeration equipment and heating and cooling equipment respectively, which apply to lithium bromide absorption systems used in commercial and industrial settings.

The European Union's Pressure Equipment Directive (PED) 2014/68/EU imposes essential safety requirements for pressure equipment, including lithium bromide absorption systems operating above 0.5 bar. Compliance with this directive requires manufacturers to implement appropriate conformity assessment procedures and affix CE marking to their products before placing them on the EU market.

Testing protocols for lithium bromide systems must include corrosion resistance verification, as the solution can be highly corrosive to certain metals. ASTM G31 provides standard practices for laboratory immersion corrosion testing, while NACE TM0169 offers additional guidance for laboratory corrosion testing of metals. These tests are crucial for ensuring long-term system integrity and preventing leaks that could pose safety hazards.

Environmental regulations also impact lithium bromide systems, with requirements for proper handling, storage, and disposal of the solution. The U.S. Environmental Protection Agency (EPA) regulates these aspects under the Resource Conservation and Recovery Act (RCRA), while similar regulations exist in other jurisdictions worldwide.

Certification processes typically involve third-party verification by organizations such as TÜV, UL, or SGS. These entities conduct comprehensive assessments of system design, manufacturing processes, and quality control procedures. Manufacturers must maintain detailed documentation of compliance with all applicable standards and regulations, including test reports, risk assessments, and technical files that demonstrate conformity with safety requirements.

Regular inspection and maintenance requirements are often specified in certification standards, necessitating the development of robust maintenance protocols and documentation systems. These requirements ensure continued safe operation throughout the system's lifecycle and form an essential component of overall compliance strategy.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!