How to Control Lithium Bromide Solution Flow for System Balance

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LiBr Flow Control Technology Background and Objectives

Lithium Bromide (LiBr) flow control technology has evolved significantly over the past decades, primarily driven by the increasing demand for efficient absorption refrigeration and heat pump systems. The technology originated in the early 20th century but gained substantial momentum in the 1950s when absorption cooling systems became commercially viable alternatives to conventional vapor compression systems. The fundamental principle involves utilizing LiBr solution as an absorbent for water vapor, creating a refrigeration effect through phase change processes.

The evolution of LiBr flow control has progressed from manual adjustment mechanisms to sophisticated automated control systems. Early systems relied on simple mechanical flow regulators and float valves, which provided limited precision and responsiveness. By the 1980s, electronic control systems began to emerge, offering improved accuracy but still facing challenges in maintaining optimal solution concentration and preventing crystallization issues.

Recent technological advancements have introduced adaptive control algorithms, precision flow meters, and advanced sensors capable of real-time monitoring of solution properties. These developments have significantly enhanced system efficiency and reliability while reducing maintenance requirements. The integration of IoT capabilities and machine learning algorithms represents the cutting edge of current LiBr flow control technology, enabling predictive maintenance and self-optimizing operation.

The primary technical objective in LiBr flow control is to maintain precise system balance across varying operational conditions. This involves ensuring optimal solution concentration, preventing crystallization, minimizing corrosion, and maximizing heat transfer efficiency. Achieving these objectives requires precise control of solution flow rates between the generator, absorber, and heat exchangers to maintain appropriate temperature and concentration gradients throughout the system.

Secondary objectives include reducing energy consumption, minimizing pump power requirements, extending equipment lifespan, and ensuring stable operation during load fluctuations. Modern systems also aim to achieve rapid response to changing cooling or heating demands while maintaining efficiency across a wide operational range.

Future technological goals focus on developing more compact systems with reduced solution charge requirements, implementing advanced materials resistant to corrosion, and creating intelligent control systems capable of self-diagnosis and optimization. Research is increasingly directed toward hybrid systems that combine LiBr absorption technology with renewable energy sources, particularly solar thermal energy, to create sustainable cooling solutions with minimal environmental impact.

The advancement of LiBr flow control technology continues to be driven by global energy efficiency standards, environmental regulations limiting refrigerant use, and the growing market demand for sustainable HVAC solutions in both industrial and commercial applications.

The evolution of LiBr flow control has progressed from manual adjustment mechanisms to sophisticated automated control systems. Early systems relied on simple mechanical flow regulators and float valves, which provided limited precision and responsiveness. By the 1980s, electronic control systems began to emerge, offering improved accuracy but still facing challenges in maintaining optimal solution concentration and preventing crystallization issues.

Recent technological advancements have introduced adaptive control algorithms, precision flow meters, and advanced sensors capable of real-time monitoring of solution properties. These developments have significantly enhanced system efficiency and reliability while reducing maintenance requirements. The integration of IoT capabilities and machine learning algorithms represents the cutting edge of current LiBr flow control technology, enabling predictive maintenance and self-optimizing operation.

The primary technical objective in LiBr flow control is to maintain precise system balance across varying operational conditions. This involves ensuring optimal solution concentration, preventing crystallization, minimizing corrosion, and maximizing heat transfer efficiency. Achieving these objectives requires precise control of solution flow rates between the generator, absorber, and heat exchangers to maintain appropriate temperature and concentration gradients throughout the system.

Secondary objectives include reducing energy consumption, minimizing pump power requirements, extending equipment lifespan, and ensuring stable operation during load fluctuations. Modern systems also aim to achieve rapid response to changing cooling or heating demands while maintaining efficiency across a wide operational range.

Future technological goals focus on developing more compact systems with reduced solution charge requirements, implementing advanced materials resistant to corrosion, and creating intelligent control systems capable of self-diagnosis and optimization. Research is increasingly directed toward hybrid systems that combine LiBr absorption technology with renewable energy sources, particularly solar thermal energy, to create sustainable cooling solutions with minimal environmental impact.

The advancement of LiBr flow control technology continues to be driven by global energy efficiency standards, environmental regulations limiting refrigerant use, and the growing market demand for sustainable HVAC solutions in both industrial and commercial applications.

Market Analysis for LiBr Absorption Systems

The global market for Lithium Bromide (LiBr) absorption systems has been experiencing steady growth, driven primarily by increasing demand for energy-efficient cooling solutions in commercial and industrial applications. The market size was valued at approximately $1.2 billion in 2022 and is projected to reach $1.8 billion by 2028, representing a compound annual growth rate of 6.7% during the forecast period.

Asia-Pacific currently dominates the market, accounting for over 40% of the global share, with China and Japan being the largest contributors. This regional dominance can be attributed to rapid industrialization, stringent energy efficiency regulations, and government initiatives promoting sustainable cooling technologies. North America and Europe follow, with growing adoption rates particularly in the commercial building sector.

The demand for LiBr absorption systems is segmented across various end-use industries. HVAC applications in commercial buildings represent the largest market segment at 45%, followed by industrial process cooling at 30%, and district cooling systems at 15%. The remaining 10% is distributed among specialized applications such as refrigeration in food processing and pharmaceutical manufacturing.

Key market drivers include rising energy costs, increasing environmental regulations limiting the use of conventional refrigerants, and growing awareness of sustainable cooling technologies. The ability of LiBr absorption systems to utilize waste heat or renewable energy sources makes them particularly attractive in regions with high electricity costs or unreliable grid infrastructure.

Market challenges primarily revolve around technical limitations, including crystallization issues related to LiBr solution flow control, higher initial capital costs compared to conventional cooling systems, and the need for specialized maintenance expertise. These factors have somewhat limited market penetration in smaller commercial applications and residential sectors.

Recent market trends indicate growing interest in modular and compact LiBr absorption systems that offer improved solution flow control mechanisms, reducing the risk of crystallization and improving overall system efficiency. Additionally, there is increasing demand for hybrid systems that combine absorption cooling with conventional electric cooling to optimize performance across varying load conditions.

The competitive landscape features established players like Carrier Corporation, Johnson Controls, and Thermax, alongside emerging companies focusing on technological innovations specifically addressing solution flow control challenges. Chinese manufacturers have been gaining market share by offering cost-competitive systems, though often with less sophisticated flow control mechanisms.

Asia-Pacific currently dominates the market, accounting for over 40% of the global share, with China and Japan being the largest contributors. This regional dominance can be attributed to rapid industrialization, stringent energy efficiency regulations, and government initiatives promoting sustainable cooling technologies. North America and Europe follow, with growing adoption rates particularly in the commercial building sector.

The demand for LiBr absorption systems is segmented across various end-use industries. HVAC applications in commercial buildings represent the largest market segment at 45%, followed by industrial process cooling at 30%, and district cooling systems at 15%. The remaining 10% is distributed among specialized applications such as refrigeration in food processing and pharmaceutical manufacturing.

Key market drivers include rising energy costs, increasing environmental regulations limiting the use of conventional refrigerants, and growing awareness of sustainable cooling technologies. The ability of LiBr absorption systems to utilize waste heat or renewable energy sources makes them particularly attractive in regions with high electricity costs or unreliable grid infrastructure.

Market challenges primarily revolve around technical limitations, including crystallization issues related to LiBr solution flow control, higher initial capital costs compared to conventional cooling systems, and the need for specialized maintenance expertise. These factors have somewhat limited market penetration in smaller commercial applications and residential sectors.

Recent market trends indicate growing interest in modular and compact LiBr absorption systems that offer improved solution flow control mechanisms, reducing the risk of crystallization and improving overall system efficiency. Additionally, there is increasing demand for hybrid systems that combine absorption cooling with conventional electric cooling to optimize performance across varying load conditions.

The competitive landscape features established players like Carrier Corporation, Johnson Controls, and Thermax, alongside emerging companies focusing on technological innovations specifically addressing solution flow control challenges. Chinese manufacturers have been gaining market share by offering cost-competitive systems, though often with less sophisticated flow control mechanisms.

Current Challenges in LiBr Solution Flow Control

Lithium bromide (LiBr) absorption refrigeration systems face significant challenges in solution flow control that impact overall system balance and efficiency. The primary difficulty lies in maintaining precise flow rates across varying operational conditions, as LiBr solution properties change dramatically with concentration and temperature fluctuations. Viscosity increases exponentially at higher concentrations, creating unpredictable flow behaviors that conventional control systems struggle to manage effectively.

Flow distribution imbalances between system components represent another critical challenge. When solution flow becomes uneven between the absorber and generator, it leads to concentration gradients that reduce thermal exchange efficiency and increase the risk of crystallization. This crystallization phenomenon, where LiBr precipitates out of solution at high concentrations, can block flow channels and cause catastrophic system failure, requiring extensive maintenance interventions.

Pump cavitation presents a persistent operational challenge in LiBr systems. The negative pressure environments combined with solution property variations create conditions where vapor bubbles form and collapse within pumping equipment, causing mechanical damage, flow instabilities, and reduced equipment lifespan. Current pumping technologies have not fully addressed these specialized requirements of LiBr solution handling.

Measurement and sensing limitations further complicate flow control efforts. Traditional flow meters suffer from accuracy degradation when exposed to the corrosive properties of LiBr solutions, while non-invasive measurement techniques often lack the precision required for optimal system control. This sensing gap creates a fundamental barrier to implementing advanced control algorithms that could otherwise compensate for system dynamics.

Control system response time represents another significant hurdle. The thermal inertia inherent in absorption systems creates substantial lag between control actions and system responses. Current PID control approaches struggle to accommodate these delays, resulting in hunting behaviors, oscillations, and suboptimal performance during transient operational states such as startup, shutdown, or load changes.

Energy efficiency concerns are paramount, as pumping power requirements for LiBr solutions can be substantial due to their high viscosity. Existing variable speed drive implementations have shown limited success in optimizing the energy-performance balance across the full operational envelope. The trade-off between pumping energy and thermal performance remains poorly optimized in most commercial systems.

Miniaturization efforts for compact absorption systems face particular challenges in solution flow control, as smaller channel dimensions amplify the effects of concentration gradients and crystallization risks. The scaling relationships between flow channel geometry and solution behavior are not fully characterized, limiting design optimization for next-generation compact absorption chillers.

Flow distribution imbalances between system components represent another critical challenge. When solution flow becomes uneven between the absorber and generator, it leads to concentration gradients that reduce thermal exchange efficiency and increase the risk of crystallization. This crystallization phenomenon, where LiBr precipitates out of solution at high concentrations, can block flow channels and cause catastrophic system failure, requiring extensive maintenance interventions.

Pump cavitation presents a persistent operational challenge in LiBr systems. The negative pressure environments combined with solution property variations create conditions where vapor bubbles form and collapse within pumping equipment, causing mechanical damage, flow instabilities, and reduced equipment lifespan. Current pumping technologies have not fully addressed these specialized requirements of LiBr solution handling.

Measurement and sensing limitations further complicate flow control efforts. Traditional flow meters suffer from accuracy degradation when exposed to the corrosive properties of LiBr solutions, while non-invasive measurement techniques often lack the precision required for optimal system control. This sensing gap creates a fundamental barrier to implementing advanced control algorithms that could otherwise compensate for system dynamics.

Control system response time represents another significant hurdle. The thermal inertia inherent in absorption systems creates substantial lag between control actions and system responses. Current PID control approaches struggle to accommodate these delays, resulting in hunting behaviors, oscillations, and suboptimal performance during transient operational states such as startup, shutdown, or load changes.

Energy efficiency concerns are paramount, as pumping power requirements for LiBr solutions can be substantial due to their high viscosity. Existing variable speed drive implementations have shown limited success in optimizing the energy-performance balance across the full operational envelope. The trade-off between pumping energy and thermal performance remains poorly optimized in most commercial systems.

Miniaturization efforts for compact absorption systems face particular challenges in solution flow control, as smaller channel dimensions amplify the effects of concentration gradients and crystallization risks. The scaling relationships between flow channel geometry and solution behavior are not fully characterized, limiting design optimization for next-generation compact absorption chillers.

Current LiBr Flow Control Solutions

01 Flow control mechanisms for lithium bromide absorption systems

Various flow control mechanisms are employed in lithium bromide absorption refrigeration systems to maintain optimal solution circulation. These mechanisms include specialized valves, flow meters, and control algorithms that regulate the flow rate of lithium bromide solution between the absorber and generator components. Proper flow control ensures system efficiency, prevents crystallization issues, and maintains stable cooling capacity under varying load conditions.- Flow control mechanisms for lithium bromide absorption systems: Various flow control mechanisms are employed in lithium bromide absorption refrigeration systems to maintain optimal solution circulation. These mechanisms include specialized valves, flow meters, and control algorithms that regulate the flow rate of lithium bromide solution between the absorber and generator components. Proper flow control ensures efficient heat exchange and maintains the concentration balance necessary for effective refrigeration cycles.

- Solution concentration balancing techniques: Maintaining the proper concentration of lithium bromide solution is critical for system efficiency. These techniques involve monitoring and adjusting the concentration through controlled dilution or concentration processes. Systems may incorporate density meters, conductivity sensors, or other measurement devices to continuously monitor solution concentration and trigger automatic adjustment mechanisms when deviations occur, ensuring optimal absorption refrigeration performance.

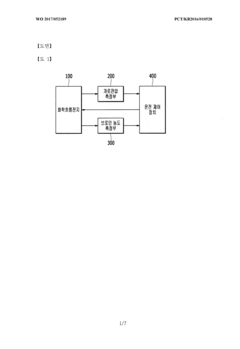

- Automated control systems for solution distribution: Advanced control systems utilize sensors, controllers, and actuators to automatically manage lithium bromide solution distribution throughout the absorption system. These systems employ PLC controllers, microprocessors, or dedicated control units that process real-time data from multiple sensors to make adjustments to flow rates, temperatures, and pressures. The automated approach ensures system stability and optimal performance under varying load conditions.

- Heat exchange optimization for solution balance: Heat exchange optimization involves specialized components and configurations designed to enhance thermal transfer efficiency while maintaining proper solution balance. These systems incorporate heat recovery exchangers, enhanced surface area designs, and strategic flow paths that maximize energy efficiency. By optimizing heat exchange between strong and weak lithium bromide solutions, these systems reduce energy consumption while maintaining stable operation.

- Crystallization prevention mechanisms: Specialized mechanisms are implemented to prevent lithium bromide crystallization, which can block flow paths and reduce system efficiency. These include temperature control systems, solution dilution mechanisms, and specialized flow patterns that maintain solution properties within safe operating parameters. Some systems incorporate purge units, filtration systems, or additive injection to further prevent crystallization and maintain consistent solution flow throughout the absorption cycle.

02 Solution concentration balancing techniques

Maintaining proper concentration balance of lithium bromide solution is critical for absorption refrigeration system performance. These techniques involve monitoring and adjusting solution concentration through density measurements, temperature sensors, and automated control systems. Balanced concentration prevents crystallization while maximizing heat absorption capacity, ensuring efficient heat exchange between system components and stable operation across varying thermal loads.Expand Specific Solutions03 Integrated monitoring and control systems

Advanced monitoring and control systems integrate multiple sensors and controllers to maintain optimal lithium bromide solution flow balance. These systems utilize temperature, pressure, flow rate, and concentration sensors connected to programmable logic controllers or microprocessors. Real-time data analysis enables automatic adjustments to pumps, valves, and heat exchangers, preventing system imbalances and ensuring efficient operation under changing environmental conditions.Expand Specific Solutions04 Anti-crystallization mechanisms

Specialized mechanisms prevent lithium bromide crystallization, which can block flow paths and damage system components. These include solution dilution systems, heat tracing elements, bypass circuits, and controlled mixing chambers. By maintaining solution temperature above crystallization points and implementing emergency dilution procedures when crystallization risk is detected, these mechanisms ensure continuous system operation and extend equipment lifespan.Expand Specific Solutions05 Energy-efficient solution circulation designs

Energy-efficient designs optimize lithium bromide solution circulation while minimizing power consumption. These include variable speed pumps, gravity-assisted flow paths, heat recovery exchangers, and optimized piping configurations. By reducing pumping requirements and utilizing natural pressure differentials, these designs maintain proper solution balance while significantly decreasing the energy input needed for system operation, improving overall coefficient of performance.Expand Specific Solutions

Key Industry Players in Absorption Refrigeration

The lithium bromide solution flow control market for system balance is in a growth phase, with increasing demand driven by HVAC, refrigeration, and emerging applications in energy storage. The market is expected to reach significant scale by 2025, fueled by energy efficiency regulations and sustainable cooling solutions. Technology maturity varies across players, with established companies like Carrier Corp. and Honeywell International Technologies leading innovation in absorption cooling systems. Emerging specialists such as SciAps and Waters Technology are advancing monitoring and control technologies. Academic institutions including Beijing University of Chemical Technology and Beihang University contribute fundamental research, while automotive manufacturers like Toyota, Nissan, and Renault explore applications in vehicle thermal management systems.

Carrier Corp.

Technical Solution: Carrier Corporation has developed an advanced absorption chiller system that precisely controls lithium bromide solution flow for optimal system balance. Their technology utilizes variable speed pumps coupled with microprocessor-based control algorithms to continuously adjust solution circulation rates based on cooling load demands and ambient conditions. The system incorporates multiple flow sensors strategically positioned throughout the absorption cycle to monitor concentration levels and flow rates in real-time[1]. Carrier's proprietary control logic employs predictive modeling to anticipate system imbalances before they occur, allowing for proactive flow adjustments rather than reactive corrections. Their solution also features automated crystallization prevention through temperature and concentration monitoring, with automatic dilution cycles when approaching crystallization thresholds[3]. The system maintains optimal heat transfer efficiency by ensuring proper wetting of heat exchanger surfaces while preventing excess solution carryover that could reduce system performance.

Strengths: Superior energy efficiency through precise flow matching to actual load conditions; advanced crystallization prevention capabilities; seamless integration with building management systems for remote monitoring and control. Weaknesses: Higher initial capital cost compared to conventional systems; requires more sophisticated maintenance expertise; system complexity may present challenges in troubleshooting for technicians without specialized training.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has engineered a comprehensive lithium bromide flow control solution for absorption refrigeration systems that combines hardware and software innovations. Their approach utilizes precision electromagnetic flow meters specifically calibrated for the corrosive properties of lithium bromide solutions, providing accuracy within ±0.5% across varying concentration levels[2]. The system employs a cascade control architecture where primary controllers maintain optimal absorption/desorption rates while secondary controllers precisely regulate solution flow rates. Honeywell's patented adaptive control algorithm continuously analyzes system performance metrics including cooling capacity, COP (Coefficient of Performance), and crystallization risk factors to dynamically adjust flow parameters[4]. Their solution incorporates ultrasonic level sensors in the absorber and generator vessels to maintain optimal solution inventory distribution throughout the system. Additionally, Honeywell has developed specialized corrosion-resistant valve trim materials specifically designed to withstand the highly corrosive nature of lithium bromide solutions while maintaining precise flow control characteristics over extended operational periods.

Strengths: Industry-leading control accuracy through multi-parameter monitoring and adaptive algorithms; robust components specifically engineered for lithium bromide environments; extensive data analytics capabilities for performance optimization and predictive maintenance. Weaknesses: Premium pricing positions the technology primarily for high-end commercial and industrial applications; proprietary communication protocols may limit integration with third-party systems; requires periodic recalibration to maintain specified accuracy levels.

Core Technical Innovations in Flow Balancing

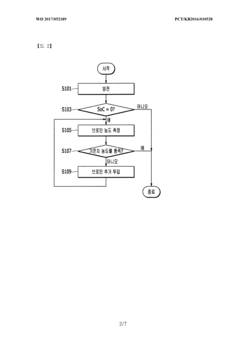

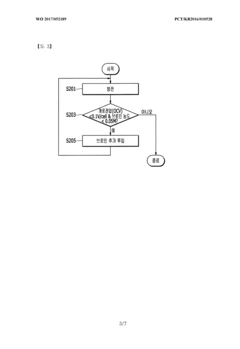

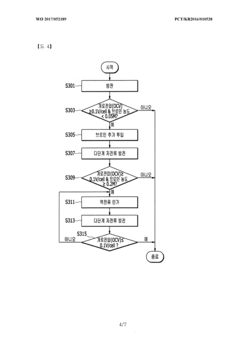

Method for controlling operation of chemical flow battery

PatentWO2017052189A1

Innovation

- A method involving the measurement and adjustment of bromine (Br2) concentration in the electrolyte, including its introduction to maintain levels between 0.05M and 0.2M, and the application of multi-stage low current discharge and reverse current to remove unreacted substances and increase the electrode reaction area.

Method and device for neutralizing, by controlled gas injection, the formation of liquid slugs at the foot of a riser connected to a multiphase fluid transport pipe

PatentInactiveUS7103521B2

Innovation

- A method and device for controlled gas injection at the base of an inclined pipe riser, proportional to the mass flow rate variations of both gas and liquid phases, to prevent liquid slug formation and accumulation, using a computer-controlled system to modulate gas injection based on real-time flow rate measurements.

Energy Efficiency Considerations

Energy efficiency represents a critical dimension in the control of lithium bromide solution flow for absorption refrigeration systems. The energy consumption profile of these systems is directly influenced by the flow rate and distribution of the lithium bromide solution. Optimizing this flow can lead to significant energy savings, particularly in large-scale industrial and commercial cooling applications where absorption chillers are commonly deployed.

The primary energy input in lithium bromide absorption systems comes from the heat source that drives the generator. When solution flow is properly balanced, the system requires less thermal energy to achieve the same cooling effect. Research indicates that well-controlled solution flow can improve the coefficient of performance (COP) by 15-20% compared to systems with suboptimal flow management. This improvement translates directly to reduced energy consumption and lower operational costs.

Heat exchange efficiency between the solution and refrigerant (typically water) is heavily dependent on flow characteristics. Turbulent flow regimes generally enhance heat transfer but require more pumping energy. Conversely, laminar flow reduces pumping requirements but may compromise heat transfer efficiency. The optimal balance point varies based on system size, cooling load, and ambient conditions, necessitating adaptive control strategies that can respond to changing operational parameters.

Solution crystallization risk, a major concern in lithium bromide systems, also has energy implications. When crystallization occurs, system efficiency drops dramatically, and additional energy is required to restore normal operation. Proper flow control prevents concentration hotspots that might trigger crystallization, thereby maintaining consistent energy efficiency throughout the operational cycle.

Pumping energy represents another significant consideration. While higher flow rates may improve heat transfer in certain components, they also increase parasitic energy consumption by circulation pumps. Advanced variable-speed pumping systems can optimize this trade-off by adjusting flow rates according to actual cooling demands, potentially reducing pumping energy by up to 30% compared to fixed-speed alternatives.

Heat recovery opportunities within the system are enhanced by strategic flow control. By directing solution flows through heat exchangers in specific sequences and at appropriate rates, waste heat from one part of the cycle can be effectively utilized in another, further improving overall system efficiency. This internal heat recovery can reduce external energy requirements by 10-25% depending on system configuration and operational conditions.

The primary energy input in lithium bromide absorption systems comes from the heat source that drives the generator. When solution flow is properly balanced, the system requires less thermal energy to achieve the same cooling effect. Research indicates that well-controlled solution flow can improve the coefficient of performance (COP) by 15-20% compared to systems with suboptimal flow management. This improvement translates directly to reduced energy consumption and lower operational costs.

Heat exchange efficiency between the solution and refrigerant (typically water) is heavily dependent on flow characteristics. Turbulent flow regimes generally enhance heat transfer but require more pumping energy. Conversely, laminar flow reduces pumping requirements but may compromise heat transfer efficiency. The optimal balance point varies based on system size, cooling load, and ambient conditions, necessitating adaptive control strategies that can respond to changing operational parameters.

Solution crystallization risk, a major concern in lithium bromide systems, also has energy implications. When crystallization occurs, system efficiency drops dramatically, and additional energy is required to restore normal operation. Proper flow control prevents concentration hotspots that might trigger crystallization, thereby maintaining consistent energy efficiency throughout the operational cycle.

Pumping energy represents another significant consideration. While higher flow rates may improve heat transfer in certain components, they also increase parasitic energy consumption by circulation pumps. Advanced variable-speed pumping systems can optimize this trade-off by adjusting flow rates according to actual cooling demands, potentially reducing pumping energy by up to 30% compared to fixed-speed alternatives.

Heat recovery opportunities within the system are enhanced by strategic flow control. By directing solution flows through heat exchangers in specific sequences and at appropriate rates, waste heat from one part of the cycle can be effectively utilized in another, further improving overall system efficiency. This internal heat recovery can reduce external energy requirements by 10-25% depending on system configuration and operational conditions.

Corrosion Management Strategies

Corrosion management represents a critical aspect of lithium bromide (LiBr) absorption systems, as the highly concentrated salt solution can be extremely corrosive to system components. Effective flow control strategies must incorporate comprehensive corrosion prevention measures to ensure long-term system reliability and performance. The primary corrosion mechanisms in LiBr systems include galvanic corrosion, pitting corrosion, and stress corrosion cracking, all of which are exacerbated by improper flow control.

Material selection serves as the first line of defense against corrosion in LiBr systems. Stainless steel grades 316 and 316L have demonstrated superior resistance to LiBr corrosion compared to carbon steel or copper alloys. For critical components exposed to high concentrations or elevated temperatures, titanium or specialized corrosion-resistant alloys may be necessary despite their higher cost. Flow control components such as valves and pumps require particular attention to material compatibility.

Inhibitor addition represents another essential strategy for corrosion management. Lithium molybdate, lithium nitrate, and lithium chromate have proven effective in reducing corrosion rates in LiBr systems. Modern flow control systems often incorporate automated inhibitor dosing stations that adjust inhibitor concentrations based on solution flow rates and concentration measurements, ensuring optimal protection across varying operating conditions.

pH control plays a crucial role in minimizing corrosion potential. Maintaining the LiBr solution at a slightly alkaline pH (typically 8.0-9.0) significantly reduces corrosion rates. Advanced flow control systems incorporate inline pH monitoring and adjustment capabilities, automatically introducing alkalizing agents when necessary to maintain optimal pH levels throughout the system.

Oxygen removal represents another critical aspect of corrosion management. Dissolved oxygen accelerates corrosion processes in LiBr systems. Vacuum deaeration, nitrogen purging, or oxygen scavengers can be integrated into flow control strategies to minimize oxygen content. Properly designed flow patterns that prevent air entrainment at solution interfaces further reduce oxygen introduction.

Regular monitoring and preventive maintenance form the foundation of effective corrosion management. Modern flow control systems incorporate corrosion monitoring technologies such as electrical resistance probes, linear polarization resistance measurements, or coupon testing. These monitoring systems can be integrated with flow control algorithms to adjust operating parameters when corrosion rates exceed acceptable thresholds.

Temperature management through precise flow control also impacts corrosion rates. Maintaining solution temperatures below critical thresholds (typically 180°C) through appropriate flow distribution helps prevent accelerated corrosion. Strategic placement of temperature sensors throughout the system enables dynamic flow adjustments to avoid localized hot spots that could accelerate corrosion processes.

Material selection serves as the first line of defense against corrosion in LiBr systems. Stainless steel grades 316 and 316L have demonstrated superior resistance to LiBr corrosion compared to carbon steel or copper alloys. For critical components exposed to high concentrations or elevated temperatures, titanium or specialized corrosion-resistant alloys may be necessary despite their higher cost. Flow control components such as valves and pumps require particular attention to material compatibility.

Inhibitor addition represents another essential strategy for corrosion management. Lithium molybdate, lithium nitrate, and lithium chromate have proven effective in reducing corrosion rates in LiBr systems. Modern flow control systems often incorporate automated inhibitor dosing stations that adjust inhibitor concentrations based on solution flow rates and concentration measurements, ensuring optimal protection across varying operating conditions.

pH control plays a crucial role in minimizing corrosion potential. Maintaining the LiBr solution at a slightly alkaline pH (typically 8.0-9.0) significantly reduces corrosion rates. Advanced flow control systems incorporate inline pH monitoring and adjustment capabilities, automatically introducing alkalizing agents when necessary to maintain optimal pH levels throughout the system.

Oxygen removal represents another critical aspect of corrosion management. Dissolved oxygen accelerates corrosion processes in LiBr systems. Vacuum deaeration, nitrogen purging, or oxygen scavengers can be integrated into flow control strategies to minimize oxygen content. Properly designed flow patterns that prevent air entrainment at solution interfaces further reduce oxygen introduction.

Regular monitoring and preventive maintenance form the foundation of effective corrosion management. Modern flow control systems incorporate corrosion monitoring technologies such as electrical resistance probes, linear polarization resistance measurements, or coupon testing. These monitoring systems can be integrated with flow control algorithms to adjust operating parameters when corrosion rates exceed acceptable thresholds.

Temperature management through precise flow control also impacts corrosion rates. Maintaining solution temperatures below critical thresholds (typically 180°C) through appropriate flow distribution helps prevent accelerated corrosion. Strategic placement of temperature sensors throughout the system enables dynamic flow adjustments to avoid localized hot spots that could accelerate corrosion processes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!