Comparing Lithium Bromide with Cutting-Edge Absorption Technologies

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Absorption Refrigeration Technology Background and Objectives

Absorption refrigeration technology has evolved significantly since its inception in the 1850s when Ferdinand Carré first demonstrated the ammonia-water absorption system. This technology represents a sustainable alternative to conventional vapor compression refrigeration systems, particularly valuable in scenarios where electrical power is limited or expensive. The fundamental principle relies on a thermochemical process where a refrigerant is absorbed and released by an absorbent material, driven primarily by heat rather than mechanical energy.

Lithium Bromide (LiBr) absorption systems emerged in the mid-20th century as a significant advancement, offering improved efficiency and safety compared to ammonia-based predecessors. These systems typically utilize water as the refrigerant and LiBr solution as the absorbent, operating effectively in commercial air conditioning and industrial cooling applications. The technology has gained prominence due to its ability to utilize low-grade thermal energy from sources such as solar collectors, waste heat from industrial processes, or cogeneration systems.

The current technological landscape shows a clear trajectory toward enhancing energy efficiency, reducing environmental impact, and expanding application versatility. Modern research focuses on improving the coefficient of performance (COP), which historically ranges from 0.7 to 1.2 for single-effect systems. Advanced multi-effect configurations have demonstrated COPs approaching 1.8, representing significant efficiency improvements.

Global concerns regarding climate change and energy security have accelerated interest in absorption refrigeration technologies. The phase-out of hydrochlorofluorocarbons (HCFCs) and hydrofluorocarbons (HFCs) under international agreements has further highlighted the importance of alternative cooling technologies with minimal environmental footprint. Absorption systems, particularly those utilizing natural working pairs like LiBr-water, offer promising solutions with zero ozone depletion potential and negligible global warming impact.

The primary objective of this technical research is to comprehensively compare traditional LiBr absorption systems with emerging cutting-edge absorption technologies. This includes evaluating novel working pairs, advanced system configurations, and innovative component designs that promise enhanced performance characteristics. The assessment aims to identify technological breakthroughs that could overcome current limitations such as crystallization risks, corrosion issues, and size constraints that have historically restricted wider adoption of absorption systems.

Additionally, this research seeks to establish a clear technological roadmap for absorption refrigeration development, identifying critical research priorities and potential commercialization pathways. By analyzing performance metrics, economic viability, and environmental benefits across different absorption technologies, this study will provide valuable insights for strategic R&D investments and market positioning in the evolving sustainable cooling landscape.

Lithium Bromide (LiBr) absorption systems emerged in the mid-20th century as a significant advancement, offering improved efficiency and safety compared to ammonia-based predecessors. These systems typically utilize water as the refrigerant and LiBr solution as the absorbent, operating effectively in commercial air conditioning and industrial cooling applications. The technology has gained prominence due to its ability to utilize low-grade thermal energy from sources such as solar collectors, waste heat from industrial processes, or cogeneration systems.

The current technological landscape shows a clear trajectory toward enhancing energy efficiency, reducing environmental impact, and expanding application versatility. Modern research focuses on improving the coefficient of performance (COP), which historically ranges from 0.7 to 1.2 for single-effect systems. Advanced multi-effect configurations have demonstrated COPs approaching 1.8, representing significant efficiency improvements.

Global concerns regarding climate change and energy security have accelerated interest in absorption refrigeration technologies. The phase-out of hydrochlorofluorocarbons (HCFCs) and hydrofluorocarbons (HFCs) under international agreements has further highlighted the importance of alternative cooling technologies with minimal environmental footprint. Absorption systems, particularly those utilizing natural working pairs like LiBr-water, offer promising solutions with zero ozone depletion potential and negligible global warming impact.

The primary objective of this technical research is to comprehensively compare traditional LiBr absorption systems with emerging cutting-edge absorption technologies. This includes evaluating novel working pairs, advanced system configurations, and innovative component designs that promise enhanced performance characteristics. The assessment aims to identify technological breakthroughs that could overcome current limitations such as crystallization risks, corrosion issues, and size constraints that have historically restricted wider adoption of absorption systems.

Additionally, this research seeks to establish a clear technological roadmap for absorption refrigeration development, identifying critical research priorities and potential commercialization pathways. By analyzing performance metrics, economic viability, and environmental benefits across different absorption technologies, this study will provide valuable insights for strategic R&D investments and market positioning in the evolving sustainable cooling landscape.

Market Analysis of Absorption Cooling Systems

The global absorption cooling systems market has been experiencing steady growth, valued at approximately $1.2 billion in 2022 with projections to reach $1.8 billion by 2028, representing a compound annual growth rate (CAGR) of 6.7%. This growth is primarily driven by increasing demand for energy-efficient cooling solutions across various sectors including commercial buildings, industrial processes, and residential applications.

Asia-Pacific currently dominates the market share, accounting for nearly 45% of global installations, with China and India leading regional adoption due to rapid industrialization and increasing focus on sustainable technologies. North America and Europe follow with approximately 25% and 20% market share respectively, where stringent environmental regulations and energy efficiency standards are accelerating market penetration.

The commercial segment represents the largest application area, constituting about 60% of the total market, particularly in hotels, hospitals, and office buildings where the integration with existing heating systems provides significant operational cost benefits. Industrial applications account for roughly 30%, primarily in food processing, chemical manufacturing, and pharmaceutical production where process cooling is essential.

Lithium bromide-based absorption systems currently dominate with approximately 70% market share due to their established technology, higher coefficient of performance (COP), and suitability for medium to large-scale applications. However, ammonia-water systems hold about 25% of the market, particularly in industrial refrigeration and low-temperature applications where their ability to achieve sub-zero cooling provides a competitive advantage.

Market trends indicate growing interest in triple-effect absorption chillers, which offer COPs approaching 1.7 compared to traditional double-effect systems (COP 1.2-1.4). Additionally, hybrid systems combining absorption cooling with conventional vapor compression technologies are gaining traction, offering flexibility and improved energy management.

Key market drivers include rising energy costs, with electricity prices increasing at an average of 3-5% annually in developed markets, making the operational cost advantages of absorption systems more attractive. Environmental regulations targeting refrigerants with high global warming potential are also accelerating adoption, as absorption systems utilize environmentally benign working fluids.

Market barriers include high initial capital costs, with absorption systems typically requiring 1.5-2 times the investment of equivalent vapor compression systems. Limited awareness and technical expertise among building professionals and facility managers also hinders wider adoption, particularly in emerging markets.

Asia-Pacific currently dominates the market share, accounting for nearly 45% of global installations, with China and India leading regional adoption due to rapid industrialization and increasing focus on sustainable technologies. North America and Europe follow with approximately 25% and 20% market share respectively, where stringent environmental regulations and energy efficiency standards are accelerating market penetration.

The commercial segment represents the largest application area, constituting about 60% of the total market, particularly in hotels, hospitals, and office buildings where the integration with existing heating systems provides significant operational cost benefits. Industrial applications account for roughly 30%, primarily in food processing, chemical manufacturing, and pharmaceutical production where process cooling is essential.

Lithium bromide-based absorption systems currently dominate with approximately 70% market share due to their established technology, higher coefficient of performance (COP), and suitability for medium to large-scale applications. However, ammonia-water systems hold about 25% of the market, particularly in industrial refrigeration and low-temperature applications where their ability to achieve sub-zero cooling provides a competitive advantage.

Market trends indicate growing interest in triple-effect absorption chillers, which offer COPs approaching 1.7 compared to traditional double-effect systems (COP 1.2-1.4). Additionally, hybrid systems combining absorption cooling with conventional vapor compression technologies are gaining traction, offering flexibility and improved energy management.

Key market drivers include rising energy costs, with electricity prices increasing at an average of 3-5% annually in developed markets, making the operational cost advantages of absorption systems more attractive. Environmental regulations targeting refrigerants with high global warming potential are also accelerating adoption, as absorption systems utilize environmentally benign working fluids.

Market barriers include high initial capital costs, with absorption systems typically requiring 1.5-2 times the investment of equivalent vapor compression systems. Limited awareness and technical expertise among building professionals and facility managers also hinders wider adoption, particularly in emerging markets.

Current State and Challenges of LiBr Absorption Technology

Lithium Bromide (LiBr) absorption technology has been a cornerstone in industrial cooling and refrigeration systems for decades, particularly in applications requiring large-scale cooling capacities. Currently, LiBr absorption chillers dominate the commercial absorption cooling market, with installations ranging from 10 kW to several megawatts in capacity. The technology leverages the strong affinity between LiBr and water, with water serving as the refrigerant and LiBr solution as the absorbent.

The global market for LiBr absorption systems has seen steady growth, particularly in regions with high electricity costs or abundant waste heat sources. Asia-Pacific, especially Japan and China, leads in both manufacturing and deployment of these systems, followed by Europe and North America. Recent market analyses indicate a compound annual growth rate of approximately 3.5-4.5% for LiBr absorption technology, driven primarily by increasing emphasis on energy efficiency and sustainable cooling solutions.

Despite its established presence, LiBr absorption technology faces several significant challenges. Crystallization risk remains a primary concern, occurring when the LiBr solution concentration exceeds solubility limits, leading to system blockages and performance degradation. This issue necessitates sophisticated control systems and limits the operating temperature range, particularly in applications requiring deep cooling.

Corrosion presents another persistent challenge, as LiBr solutions are highly corrosive to many conventional metals used in heat exchange equipment. This necessitates the use of expensive corrosion-resistant materials or inhibitors, increasing both initial and maintenance costs. The industry has developed various corrosion inhibitors, but a universally effective and environmentally friendly solution remains elusive.

Energy efficiency limitations also constrain wider adoption of LiBr systems. Current commercial single-effect LiBr chillers typically achieve a Coefficient of Performance (COP) of 0.7-0.8, while double-effect systems reach 1.2-1.4. These values, while improved over historical performance, still lag behind conventional vapor compression systems, which commonly achieve COPs of 3.0-5.0.

Size and weight constraints further challenge LiBr technology adoption in space-sensitive applications. The technology requires substantial heat exchange surface area, resulting in bulky equipment that limits installation flexibility, particularly in retrofit applications or buildings with space constraints.

Recent research has focused on addressing these challenges through advanced materials, improved system designs, and hybrid approaches. Developments in nanotechnology, particularly nanofluids and nanocoatings, show promise in enhancing heat transfer efficiency and reducing corrosion. Meanwhile, membrane-based absorption systems are emerging as potential solutions to size and crystallization issues, though commercial viability remains to be established.

The global market for LiBr absorption systems has seen steady growth, particularly in regions with high electricity costs or abundant waste heat sources. Asia-Pacific, especially Japan and China, leads in both manufacturing and deployment of these systems, followed by Europe and North America. Recent market analyses indicate a compound annual growth rate of approximately 3.5-4.5% for LiBr absorption technology, driven primarily by increasing emphasis on energy efficiency and sustainable cooling solutions.

Despite its established presence, LiBr absorption technology faces several significant challenges. Crystallization risk remains a primary concern, occurring when the LiBr solution concentration exceeds solubility limits, leading to system blockages and performance degradation. This issue necessitates sophisticated control systems and limits the operating temperature range, particularly in applications requiring deep cooling.

Corrosion presents another persistent challenge, as LiBr solutions are highly corrosive to many conventional metals used in heat exchange equipment. This necessitates the use of expensive corrosion-resistant materials or inhibitors, increasing both initial and maintenance costs. The industry has developed various corrosion inhibitors, but a universally effective and environmentally friendly solution remains elusive.

Energy efficiency limitations also constrain wider adoption of LiBr systems. Current commercial single-effect LiBr chillers typically achieve a Coefficient of Performance (COP) of 0.7-0.8, while double-effect systems reach 1.2-1.4. These values, while improved over historical performance, still lag behind conventional vapor compression systems, which commonly achieve COPs of 3.0-5.0.

Size and weight constraints further challenge LiBr technology adoption in space-sensitive applications. The technology requires substantial heat exchange surface area, resulting in bulky equipment that limits installation flexibility, particularly in retrofit applications or buildings with space constraints.

Recent research has focused on addressing these challenges through advanced materials, improved system designs, and hybrid approaches. Developments in nanotechnology, particularly nanofluids and nanocoatings, show promise in enhancing heat transfer efficiency and reducing corrosion. Meanwhile, membrane-based absorption systems are emerging as potential solutions to size and crystallization issues, though commercial viability remains to be established.

Comparative Analysis of LiBr vs. Alternative Working Pairs

01 Lithium bromide absorption refrigeration systems

Lithium bromide (LiBr) is widely used as an absorbent in absorption refrigeration systems due to its excellent absorption properties. These systems utilize LiBr solution to absorb refrigerant vapor (typically water), enabling efficient cooling processes. The technology includes various components such as generators, absorbers, condensers, and evaporators working together in a cycle. These systems are energy-efficient alternatives to conventional compression refrigeration, particularly valuable in applications where waste heat is available.- Lithium bromide absorption refrigeration systems: Lithium bromide (LiBr) is widely used as an absorbent in absorption refrigeration systems due to its excellent absorption properties. These systems utilize the ability of LiBr solution to absorb water vapor, creating a refrigeration effect. The technology includes various components such as generators, absorbers, condensers, and evaporators working together in a cycle. These systems are energy-efficient alternatives to conventional vapor compression refrigeration, especially when waste heat or solar energy is available as the driving force.

- Enhanced heat and mass transfer in LiBr absorption systems: Various technological improvements focus on enhancing the heat and mass transfer efficiency in lithium bromide absorption systems. These include advanced heat exchanger designs, improved solution distribution methods, and enhanced surface treatments to promote absorption. Some innovations incorporate special additives to the LiBr solution to reduce crystallization risks and improve thermal conductivity. Other approaches involve optimized flow patterns and component geometries to maximize the contact area between the absorbent solution and refrigerant vapor.

- Corrosion inhibition in LiBr absorption systems: Lithium bromide solutions are highly corrosive to many metals commonly used in absorption systems. Various technologies address this challenge through corrosion inhibitors, material selection, and protective coatings. Some approaches involve adding specific compounds to the LiBr solution that form protective layers on metal surfaces. Other innovations focus on developing corrosion-resistant materials or applying protective coatings to critical components. These technologies significantly extend the service life of absorption equipment and improve system reliability.

- Solar-powered LiBr absorption cooling systems: Solar energy can be effectively utilized to drive lithium bromide absorption cooling systems, offering environmentally friendly cooling solutions. These technologies integrate solar thermal collectors with LiBr absorption chillers to provide cooling using renewable energy. Various designs optimize the system configuration to match the intermittent nature of solar energy with cooling demands. Some innovations include thermal storage components to extend operation beyond sunshine hours, while others focus on improving system efficiency at variable heat source temperatures.

- Compact and modular LiBr absorption units: Innovations in compact and modular lithium bromide absorption units make this technology more accessible for various applications. These designs focus on reducing the physical footprint while maintaining or improving performance. Some approaches involve novel component arrangements to minimize space requirements, while others develop integrated packages that simplify installation and maintenance. Modular designs allow for capacity expansion and easier integration with existing systems. These compact units are particularly suitable for distributed cooling applications and building integration.

02 Corrosion inhibition in LiBr absorption systems

Corrosion is a significant challenge in lithium bromide absorption systems due to the corrosive nature of LiBr solutions. Various corrosion inhibitors and techniques have been developed to protect system components, particularly those made of metal. These include adding specific chemical compounds to the LiBr solution, surface treatments for metal components, and the use of corrosion-resistant materials. Effective corrosion inhibition extends the service life of absorption systems and maintains their operational efficiency.Expand Specific Solutions03 Enhanced heat and mass transfer in LiBr absorption processes

Improving heat and mass transfer efficiency is crucial for optimizing lithium bromide absorption technologies. Innovations include advanced heat exchanger designs, enhanced surface structures for absorbers and generators, and improved flow distribution systems. These enhancements increase the contact area between the LiBr solution and refrigerant vapor, accelerate the absorption process, and improve overall system performance. Various techniques such as spray distribution, falling film, and bubble absorption methods are employed to maximize the efficiency of heat and mass transfer.Expand Specific Solutions04 Multi-effect and multi-stage LiBr absorption systems

Multi-effect and multi-stage configurations significantly improve the efficiency of lithium bromide absorption systems. These designs reuse thermal energy within the system by cascading the absorption and generation processes across multiple stages or effects. This approach increases the coefficient of performance (COP) and reduces energy consumption. Advanced control strategies and optimized flow arrangements are implemented to manage the complex interactions between different stages and maintain stable operation under varying conditions.Expand Specific Solutions05 Integration of LiBr absorption systems with renewable energy sources

Lithium bromide absorption technologies are increasingly being integrated with renewable energy sources such as solar thermal, geothermal, and waste heat recovery systems. These integrated systems leverage low-grade thermal energy to drive the absorption cycle, reducing dependence on conventional energy sources. Special design considerations include thermal storage systems to manage intermittent renewable energy availability, optimized operating parameters for varying heat source temperatures, and hybrid configurations that combine multiple energy sources for enhanced reliability and efficiency.Expand Specific Solutions

Key Industry Players in Absorption Cooling Market

The absorption technology market is currently in a growth phase, with lithium bromide absorption systems remaining dominant despite emerging alternatives. The market is projected to expand significantly due to increasing demand for energy-efficient cooling solutions and waste heat recovery applications. While traditional LiBr technology has reached commercial maturity, companies like Shuangliang Eco-Energy Systems, Carrier Corp., and DuPont are driving innovation in advanced absorption technologies. Academic institutions including Cornell University, Xi'an Jiaotong University, and Nanyang Technological University are collaborating with industry players to develop next-generation systems with improved efficiency and reduced environmental impact. The competitive landscape shows a balance between established manufacturers optimizing conventional LiBr systems and research organizations exploring novel working pairs and hybrid configurations.

Shuangliang Eco-Energy Systems Co., Ltd.

Technical Solution: Shuangliang has developed advanced lithium bromide absorption refrigeration systems that utilize waste heat recovery technology. Their double-effect LiBr absorption chillers achieve a coefficient of performance (COP) of up to 1.45, significantly higher than traditional single-effect systems (0.7-0.8). The company has implemented proprietary crystallization prevention mechanisms that allow their systems to operate at higher concentrations of LiBr solution without the risk of crystallization that typically plagues these systems. Their technology incorporates vacuum-sealed heat exchangers with specialized corrosion-resistant materials to extend system lifespan and reduce maintenance requirements. Shuangliang has also pioneered hybrid absorption systems that combine LiBr absorption with vapor compression cycles, allowing for more flexible operation across varying thermal conditions and load profiles.

Strengths: High thermal efficiency compared to conventional systems; advanced crystallization prevention; robust corrosion resistance; flexible operation across varying loads. Weaknesses: Still requires significant heat source temperatures (>80°C); higher initial capital cost compared to conventional cooling systems; larger physical footprint than mechanical alternatives.

DuPont de Nemours, Inc.

Technical Solution: DuPont has developed innovative absorption refrigeration technology that moves beyond traditional lithium bromide systems by incorporating advanced ionic liquids and composite working pairs. Their proprietary working fluids combine the benefits of conventional LiBr solutions with specially formulated additives that significantly reduce crystallization risks while improving thermal stability. DuPont's absorption systems utilize nano-enhanced heat transfer surfaces that increase heat exchange efficiency by up to 30% compared to conventional designs. The company has pioneered membrane-assisted absorption processes that enhance mass transfer between absorbent and refrigerant, allowing for more compact equipment designs and faster response to changing load conditions. Their systems incorporate advanced corrosion inhibitors specifically designed for high-temperature operation, enabling higher efficiency multi-effect configurations while maintaining system integrity over extended operational lifespans.

Strengths: Superior working fluid properties with reduced crystallization risk; enhanced heat and mass transfer; compact design; excellent thermal stability at high temperatures. Weaknesses: Proprietary working fluids increase operational costs; more complex system design requires specialized maintenance; higher initial investment compared to conventional LiBr systems; limited field performance data compared to established technologies.

Technical Deep Dive: Advanced Absorption System Patents

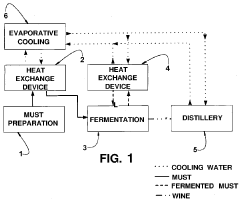

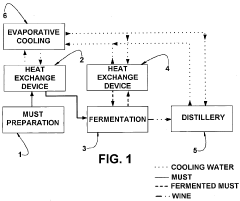

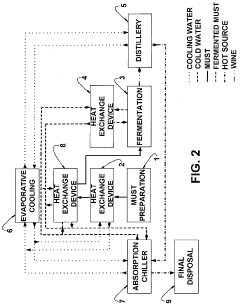

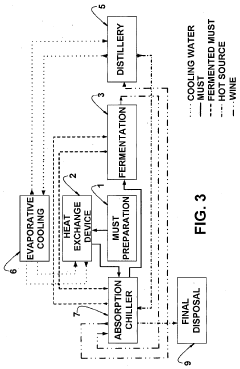

Process for producing ethanol from the fermentation of sugar sources in a fermentation medium with high ethanol content

PatentInactiveIN4268DELNP2013A

Innovation

- A process involving the preparation of a must with high sugar content (18-35% TRS) cooled to 8-30°C, fed with Saccharomyces cerevisiae yeast, and fermented at controlled temperatures between 28-30°C, using a lithium bromide-based absorption chiller for efficient cooling, reducing heat exchange and vinasse production.

Method and micro device for the extraction of traces of chemical substances with different polarities

PatentWO2011071406A1

Innovation

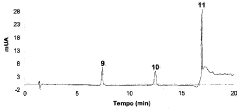

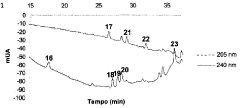

- A novel microdevice coated with adsorbent materials like activated carbons, zeolites, and silicas, which contacts the sample under agitation, allowing for adsorptive extraction and subsequent liquid desorption using organic solvents, enabling the analysis of polar compounds using chromatographic and capillary electrophoresis techniques.

Environmental Impact and Sustainability Assessment

The environmental impact of absorption cooling technologies represents a critical dimension in evaluating their overall viability and future potential. Lithium bromide (LiBr) absorption systems, while offering significant energy efficiency advantages over conventional vapor compression cooling, present several environmental considerations that warrant careful assessment.

Traditional LiBr absorption systems utilize water as the refrigerant, which has zero ozone depletion potential (ODP) and global warming potential (GWP), making them environmentally superior to systems using synthetic refrigerants. However, the production and disposal of lithium bromide solution raise concerns regarding resource extraction impacts, particularly lithium mining, which can lead to soil degradation, water pollution, and ecosystem disruption in mining regions.

Water consumption represents another significant environmental factor, as LiBr systems typically require substantial cooling water for heat rejection. In regions facing water scarcity, this dependency creates sustainability challenges that newer absorption technologies are attempting to address through air-cooled designs and closed-loop water systems that minimize consumption.

Emerging absorption technologies are increasingly incorporating life cycle assessment (LCA) methodologies to quantify their environmental footprint. Recent studies indicate that advanced LiBr systems with enhanced coefficient of performance (COP) can reduce primary energy consumption by 30-45% compared to conventional cooling systems when powered by waste heat or renewable thermal energy, substantially decreasing associated carbon emissions.

The sustainability profile of next-generation absorption technologies shows marked improvement through several innovations. These include the development of non-corrosive working pairs that reduce maintenance requirements and extend system lifespan, thereby decreasing material throughput and waste generation. Additionally, the integration of nanofluids and advanced heat exchangers has improved heat transfer efficiency, reducing the overall resource intensity of these systems.

From a circular economy perspective, newer absorption technologies demonstrate enhanced potential for component recovery and material recycling at end-of-life. Research indicates that up to 85% of materials in advanced absorption systems can be recovered or recycled, compared to approximately 60% in conventional LiBr systems, representing a significant sustainability advantage.

Policy frameworks increasingly recognize these environmental benefits, with several countries implementing incentive programs specifically targeting low-GWP cooling technologies. These regulatory developments are accelerating the transition toward more sustainable absorption cooling solutions, particularly in industrial applications where waste heat recovery potential is substantial.

Traditional LiBr absorption systems utilize water as the refrigerant, which has zero ozone depletion potential (ODP) and global warming potential (GWP), making them environmentally superior to systems using synthetic refrigerants. However, the production and disposal of lithium bromide solution raise concerns regarding resource extraction impacts, particularly lithium mining, which can lead to soil degradation, water pollution, and ecosystem disruption in mining regions.

Water consumption represents another significant environmental factor, as LiBr systems typically require substantial cooling water for heat rejection. In regions facing water scarcity, this dependency creates sustainability challenges that newer absorption technologies are attempting to address through air-cooled designs and closed-loop water systems that minimize consumption.

Emerging absorption technologies are increasingly incorporating life cycle assessment (LCA) methodologies to quantify their environmental footprint. Recent studies indicate that advanced LiBr systems with enhanced coefficient of performance (COP) can reduce primary energy consumption by 30-45% compared to conventional cooling systems when powered by waste heat or renewable thermal energy, substantially decreasing associated carbon emissions.

The sustainability profile of next-generation absorption technologies shows marked improvement through several innovations. These include the development of non-corrosive working pairs that reduce maintenance requirements and extend system lifespan, thereby decreasing material throughput and waste generation. Additionally, the integration of nanofluids and advanced heat exchangers has improved heat transfer efficiency, reducing the overall resource intensity of these systems.

From a circular economy perspective, newer absorption technologies demonstrate enhanced potential for component recovery and material recycling at end-of-life. Research indicates that up to 85% of materials in advanced absorption systems can be recovered or recycled, compared to approximately 60% in conventional LiBr systems, representing a significant sustainability advantage.

Policy frameworks increasingly recognize these environmental benefits, with several countries implementing incentive programs specifically targeting low-GWP cooling technologies. These regulatory developments are accelerating the transition toward more sustainable absorption cooling solutions, particularly in industrial applications where waste heat recovery potential is substantial.

Energy Efficiency and Performance Benchmarking

Energy efficiency metrics for lithium bromide (LiBr) absorption systems reveal a coefficient of performance (COP) typically ranging from 0.7 to 1.2 for single-effect systems, while advanced double-effect configurations can achieve COPs of 1.2 to 1.5. When benchmarked against emerging absorption technologies, LiBr systems demonstrate competitive performance in specific operational contexts, particularly in applications requiring moderate temperature lifts and stable cooling loads.

Comparative analysis with ammonia-water absorption systems shows that while LiBr systems generally offer higher COPs under standard conditions, they face limitations in low-temperature applications where ammonia-water systems excel, achieving operational temperatures as low as -60°C compared to LiBr's practical limit of approximately 5°C. This performance differential becomes particularly significant in industrial refrigeration and process cooling applications.

Recent advancements in ionic liquid-based absorption technologies present a notable challenge to traditional LiBr systems. These novel working pairs demonstrate promising COPs ranging from 0.8 to 1.3 in experimental settings, with the additional advantage of eliminating crystallization risks that plague LiBr systems at high concentrations. However, their commercial viability remains constrained by higher material costs and limited field validation data.

From an energy consumption perspective, LiBr absorption systems typically require 1.2-1.8 kWh of thermal energy per kWh of cooling produced, compared to 0.9-1.5 kWh for the most advanced triple-effect systems currently under development. When factoring in parasitic electrical consumption for pumps and controls, LiBr systems consume approximately 0.05-0.08 kWh of electricity per kWh of cooling, positioning them favorably against conventional vapor compression systems in scenarios where waste heat is readily available.

Performance stability under varying ambient conditions represents another critical benchmarking parameter. Standard LiBr systems experience approximately 15-25% reduction in COP when ambient temperatures increase from 25°C to 35°C, while newer membrane-assisted absorption technologies demonstrate more robust performance with only 10-15% efficiency degradation under similar conditions.

Life-cycle energy analysis indicates that despite lower operational efficiency compared to vapor compression systems, LiBr absorption technologies can achieve 30-45% primary energy savings when powered by waste heat sources above 85°C. This advantage diminishes significantly when driven by dedicated heat sources, highlighting the importance of integration with existing thermal processes to maximize energy efficiency benefits.

Comparative analysis with ammonia-water absorption systems shows that while LiBr systems generally offer higher COPs under standard conditions, they face limitations in low-temperature applications where ammonia-water systems excel, achieving operational temperatures as low as -60°C compared to LiBr's practical limit of approximately 5°C. This performance differential becomes particularly significant in industrial refrigeration and process cooling applications.

Recent advancements in ionic liquid-based absorption technologies present a notable challenge to traditional LiBr systems. These novel working pairs demonstrate promising COPs ranging from 0.8 to 1.3 in experimental settings, with the additional advantage of eliminating crystallization risks that plague LiBr systems at high concentrations. However, their commercial viability remains constrained by higher material costs and limited field validation data.

From an energy consumption perspective, LiBr absorption systems typically require 1.2-1.8 kWh of thermal energy per kWh of cooling produced, compared to 0.9-1.5 kWh for the most advanced triple-effect systems currently under development. When factoring in parasitic electrical consumption for pumps and controls, LiBr systems consume approximately 0.05-0.08 kWh of electricity per kWh of cooling, positioning them favorably against conventional vapor compression systems in scenarios where waste heat is readily available.

Performance stability under varying ambient conditions represents another critical benchmarking parameter. Standard LiBr systems experience approximately 15-25% reduction in COP when ambient temperatures increase from 25°C to 35°C, while newer membrane-assisted absorption technologies demonstrate more robust performance with only 10-15% efficiency degradation under similar conditions.

Life-cycle energy analysis indicates that despite lower operational efficiency compared to vapor compression systems, LiBr absorption technologies can achieve 30-45% primary energy savings when powered by waste heat sources above 85°C. This advantage diminishes significantly when driven by dedicated heat sources, highlighting the importance of integration with existing thermal processes to maximize energy efficiency benefits.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!