How to Safely Use Lithium Bromide in Industrial Processes

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lithium Bromide Safety Background and Objectives

Lithium bromide has been utilized in industrial processes for decades, with its applications evolving significantly since the 1930s. Initially employed primarily in absorption refrigeration systems, this hygroscopic salt has expanded its industrial footprint to include air conditioning systems, heat pumps, and various chemical synthesis processes. The technological trajectory shows increasing adoption across pharmaceutical manufacturing, organic synthesis, and battery technologies, highlighting its versatility as both a reagent and functional material.

The evolution of lithium bromide usage has been accompanied by growing awareness of its associated hazards. Historical incidents involving lithium bromide have underscored the importance of proper handling protocols, particularly regarding its corrosive properties and potential for generating hydrogen bromide gas when exposed to acids. These incidents have shaped current safety standards and handling practices, creating a foundation for continuous improvement in risk management strategies.

Current industrial applications of lithium bromide present specific safety challenges that must be addressed systematically. In absorption refrigeration systems, the concentrated solutions can cause severe skin burns and eye damage upon contact. In pharmaceutical applications, cross-contamination risks must be mitigated. The hygroscopic nature of the compound creates additional handling complexities across all applications, necessitating specialized containment and environmental controls.

The primary objective of this technical investigation is to establish comprehensive safety protocols for lithium bromide handling across diverse industrial settings. This includes developing standardized procedures for storage, handling, and disposal that minimize exposure risks while maintaining operational efficiency. Additionally, we aim to identify innovative engineering controls that can further reduce hazard potential without compromising the functional benefits of lithium bromide in industrial processes.

Secondary objectives include quantifying exposure thresholds based on the latest toxicological data, evaluating the effectiveness of current personal protective equipment specifications, and exploring potential substitute materials for high-risk applications. These objectives align with broader industry trends toward inherently safer design principles and sustainable chemistry practices.

The scope of this investigation encompasses the entire lifecycle of lithium bromide in industrial settings, from initial receipt and storage through operational use and ultimate disposal. Special attention will be given to transition points in material handling where exposure risks typically increase. By addressing these objectives comprehensively, we aim to establish a new safety benchmark for lithium bromide utilization that balances operational requirements with rigorous protection of worker health and environmental considerations.

The evolution of lithium bromide usage has been accompanied by growing awareness of its associated hazards. Historical incidents involving lithium bromide have underscored the importance of proper handling protocols, particularly regarding its corrosive properties and potential for generating hydrogen bromide gas when exposed to acids. These incidents have shaped current safety standards and handling practices, creating a foundation for continuous improvement in risk management strategies.

Current industrial applications of lithium bromide present specific safety challenges that must be addressed systematically. In absorption refrigeration systems, the concentrated solutions can cause severe skin burns and eye damage upon contact. In pharmaceutical applications, cross-contamination risks must be mitigated. The hygroscopic nature of the compound creates additional handling complexities across all applications, necessitating specialized containment and environmental controls.

The primary objective of this technical investigation is to establish comprehensive safety protocols for lithium bromide handling across diverse industrial settings. This includes developing standardized procedures for storage, handling, and disposal that minimize exposure risks while maintaining operational efficiency. Additionally, we aim to identify innovative engineering controls that can further reduce hazard potential without compromising the functional benefits of lithium bromide in industrial processes.

Secondary objectives include quantifying exposure thresholds based on the latest toxicological data, evaluating the effectiveness of current personal protective equipment specifications, and exploring potential substitute materials for high-risk applications. These objectives align with broader industry trends toward inherently safer design principles and sustainable chemistry practices.

The scope of this investigation encompasses the entire lifecycle of lithium bromide in industrial settings, from initial receipt and storage through operational use and ultimate disposal. Special attention will be given to transition points in material handling where exposure risks typically increase. By addressing these objectives comprehensively, we aim to establish a new safety benchmark for lithium bromide utilization that balances operational requirements with rigorous protection of worker health and environmental considerations.

Industrial Market Demand Analysis for Lithium Bromide

The global market for lithium bromide has been experiencing steady growth, primarily driven by its extensive applications in absorption refrigeration systems, air conditioning units, and various industrial processes. The compound's hygroscopic properties make it an excellent desiccant and absorbent, creating substantial demand across multiple sectors. Current market valuations indicate that the global lithium bromide market is projected to grow at a CAGR of 4.5% through 2028, with the industrial applications segment showing particularly strong momentum.

In the HVAC industry, lithium bromide remains the preferred absorbent for large-scale absorption chillers due to its superior thermodynamic properties. This sector represents approximately 65% of total lithium bromide consumption globally. The increasing focus on energy-efficient cooling systems in commercial buildings, hospitals, and industrial facilities is further accelerating demand in this segment. Additionally, stringent environmental regulations limiting the use of conventional refrigerants with high global warming potential are pushing industries toward absorption cooling technologies that utilize lithium bromide solutions.

The pharmaceutical and chemical processing industries constitute another significant market for lithium bromide, where it serves as a catalyst and reagent in various synthesis processes. These sectors value lithium bromide for its stability and effectiveness in controlled reaction environments. Market research indicates that pharmaceutical applications of lithium bromide are growing at above-average rates compared to other industrial uses.

Regional analysis reveals that Asia Pacific dominates the lithium bromide market, accounting for over 40% of global consumption. This dominance is attributed to rapid industrialization, expanding manufacturing bases, and increasing adoption of absorption cooling technologies in countries like China, Japan, and South Korea. North America and Europe follow as significant markets, with particular growth observed in sustainable building technologies that incorporate lithium bromide-based cooling systems.

Supply chain considerations are becoming increasingly important in the lithium bromide market. The compound's production is directly tied to lithium availability, which has faced volatility in recent years due to the surge in demand for lithium-ion batteries. This interconnection has led to price fluctuations that impact industrial users of lithium bromide, prompting some manufacturers to seek long-term supply agreements or explore alternative technologies.

Customer demand patterns indicate a growing preference for higher purity grades of lithium bromide, particularly in applications requiring precise concentration control and minimal contaminants. This trend is driving manufacturers to invest in advanced purification technologies and quality control measures, creating a premium segment within the market that commands higher margins.

In the HVAC industry, lithium bromide remains the preferred absorbent for large-scale absorption chillers due to its superior thermodynamic properties. This sector represents approximately 65% of total lithium bromide consumption globally. The increasing focus on energy-efficient cooling systems in commercial buildings, hospitals, and industrial facilities is further accelerating demand in this segment. Additionally, stringent environmental regulations limiting the use of conventional refrigerants with high global warming potential are pushing industries toward absorption cooling technologies that utilize lithium bromide solutions.

The pharmaceutical and chemical processing industries constitute another significant market for lithium bromide, where it serves as a catalyst and reagent in various synthesis processes. These sectors value lithium bromide for its stability and effectiveness in controlled reaction environments. Market research indicates that pharmaceutical applications of lithium bromide are growing at above-average rates compared to other industrial uses.

Regional analysis reveals that Asia Pacific dominates the lithium bromide market, accounting for over 40% of global consumption. This dominance is attributed to rapid industrialization, expanding manufacturing bases, and increasing adoption of absorption cooling technologies in countries like China, Japan, and South Korea. North America and Europe follow as significant markets, with particular growth observed in sustainable building technologies that incorporate lithium bromide-based cooling systems.

Supply chain considerations are becoming increasingly important in the lithium bromide market. The compound's production is directly tied to lithium availability, which has faced volatility in recent years due to the surge in demand for lithium-ion batteries. This interconnection has led to price fluctuations that impact industrial users of lithium bromide, prompting some manufacturers to seek long-term supply agreements or explore alternative technologies.

Customer demand patterns indicate a growing preference for higher purity grades of lithium bromide, particularly in applications requiring precise concentration control and minimal contaminants. This trend is driving manufacturers to invest in advanced purification technologies and quality control measures, creating a premium segment within the market that commands higher margins.

Current Safety Challenges in Lithium Bromide Handling

Lithium bromide handling in industrial settings presents significant safety challenges that require comprehensive management strategies. The corrosive nature of lithium bromide solutions poses serious risks to workers, with potential for severe chemical burns upon skin contact and respiratory damage if vapors are inhaled. These health hazards necessitate rigorous personal protective equipment protocols, including chemical-resistant gloves, face shields, and appropriate respiratory protection in areas with potential vapor exposure.

Material compatibility issues represent another critical challenge, as lithium bromide solutions are highly corrosive to many common metals. This corrosivity accelerates at elevated temperatures typical in absorption refrigeration systems, leading to equipment degradation, potential leaks, and system failures. Industries must carefully select corrosion-resistant materials such as titanium, specific stainless steel grades, or specialized coatings for components in contact with lithium bromide.

Environmental concerns also feature prominently among current challenges. Improper disposal of lithium bromide solutions can cause significant ecological damage, particularly to aquatic ecosystems where bromide compounds may persist and potentially form harmful byproducts. Regulatory compliance across different jurisdictions adds complexity to waste management protocols, requiring specialized disposal procedures that vary by location and concentration.

Storage stability presents ongoing difficulties, as lithium bromide is hygroscopic and can degrade when exposed to air and moisture. This property necessitates sealed storage systems and regular quality monitoring to prevent solution degradation that could compromise industrial processes. Temperature control during storage is equally important to prevent crystallization at lower temperatures or accelerated corrosion at higher temperatures.

Emergency response preparedness remains challenging due to lithium bromide's unique properties. Spill management requires specialized neutralization agents and containment strategies that differ from those used for other industrial chemicals. Many facilities lack adequate training and equipment for lithium bromide-specific incidents, creating vulnerability to escalating emergency situations.

Cross-contamination risks exist when lithium bromide interacts with incompatible chemicals, potentially generating hazardous byproducts including hydrogen bromide gas. This necessitates careful segregation in storage and handling areas, along with comprehensive chemical inventory management systems to prevent accidental mixing.

The concentration monitoring challenge is particularly acute in absorption refrigeration systems, where maintaining precise lithium bromide solution concentrations is critical for both safety and efficiency. Current monitoring technologies often lack real-time capabilities, creating potential for dangerous concentration fluctuations to go undetected until problems arise.

Material compatibility issues represent another critical challenge, as lithium bromide solutions are highly corrosive to many common metals. This corrosivity accelerates at elevated temperatures typical in absorption refrigeration systems, leading to equipment degradation, potential leaks, and system failures. Industries must carefully select corrosion-resistant materials such as titanium, specific stainless steel grades, or specialized coatings for components in contact with lithium bromide.

Environmental concerns also feature prominently among current challenges. Improper disposal of lithium bromide solutions can cause significant ecological damage, particularly to aquatic ecosystems where bromide compounds may persist and potentially form harmful byproducts. Regulatory compliance across different jurisdictions adds complexity to waste management protocols, requiring specialized disposal procedures that vary by location and concentration.

Storage stability presents ongoing difficulties, as lithium bromide is hygroscopic and can degrade when exposed to air and moisture. This property necessitates sealed storage systems and regular quality monitoring to prevent solution degradation that could compromise industrial processes. Temperature control during storage is equally important to prevent crystallization at lower temperatures or accelerated corrosion at higher temperatures.

Emergency response preparedness remains challenging due to lithium bromide's unique properties. Spill management requires specialized neutralization agents and containment strategies that differ from those used for other industrial chemicals. Many facilities lack adequate training and equipment for lithium bromide-specific incidents, creating vulnerability to escalating emergency situations.

Cross-contamination risks exist when lithium bromide interacts with incompatible chemicals, potentially generating hazardous byproducts including hydrogen bromide gas. This necessitates careful segregation in storage and handling areas, along with comprehensive chemical inventory management systems to prevent accidental mixing.

The concentration monitoring challenge is particularly acute in absorption refrigeration systems, where maintaining precise lithium bromide solution concentrations is critical for both safety and efficiency. Current monitoring technologies often lack real-time capabilities, creating potential for dangerous concentration fluctuations to go undetected until problems arise.

Existing Safety Management Solutions for Lithium Bromide

01 Safety measures in lithium bromide absorption refrigeration systems

Lithium bromide absorption refrigeration systems require specific safety measures to prevent hazards. These include leak detection systems, proper ventilation, corrosion-resistant materials, and emergency shutdown mechanisms. The systems should be designed with safety valves and pressure relief devices to prevent dangerous pressure buildup. Regular maintenance and inspection protocols are essential to ensure safe operation and prevent potential exposure to lithium bromide solution.- Safety measures in lithium bromide handling and storage: Proper handling and storage procedures are essential for lithium bromide safety. This includes using appropriate containment systems, implementing leak detection mechanisms, and following specific storage protocols to prevent exposure. Safety measures also involve proper labeling, segregation from incompatible materials, and maintaining controlled environmental conditions to ensure stability of the compound.

- Protective equipment and exposure prevention: Personal protective equipment is crucial when working with lithium bromide to prevent skin contact, inhalation, and eye exposure. This includes specialized gloves, respiratory protection, safety goggles, and protective clothing. Engineering controls such as ventilation systems, fume hoods, and enclosed handling systems are also important to minimize exposure risks in industrial and laboratory settings.

- Emergency response and first aid procedures: Established emergency protocols for lithium bromide exposure include specific first aid measures for different types of contact. This covers procedures for eye contamination, skin exposure, inhalation, and accidental ingestion. Emergency response systems include decontamination procedures, spill management techniques, and medical intervention guidelines to minimize health impacts from accidental exposure.

- Safety in lithium bromide absorption refrigeration systems: Lithium bromide is commonly used in absorption refrigeration systems, requiring specific safety considerations. These include corrosion prevention measures, pressure monitoring systems, leak detection mechanisms, and proper maintenance protocols. Safety features in these systems focus on preventing release of lithium bromide solution, controlling crystallization, and ensuring system integrity to prevent equipment failure and potential exposure risks.

- Environmental and disposal safety considerations: Safe disposal and environmental protection measures for lithium bromide include neutralization techniques, waste treatment procedures, and containment strategies to prevent environmental contamination. This involves proper waste classification, specialized disposal containers, and compliance with environmental regulations. Recycling and recovery methods are also implemented to reduce environmental impact while ensuring safe handling throughout the disposal process.

02 Handling and storage safety protocols for lithium bromide

Proper handling and storage of lithium bromide is crucial for safety. This includes using appropriate personal protective equipment such as gloves, eye protection, and respiratory protection when handling the substance. Storage should be in sealed, corrosion-resistant containers in cool, dry, well-ventilated areas away from incompatible materials. Safety data sheets should be readily available, and personnel should be trained in emergency procedures for spills or exposure incidents.Expand Specific Solutions03 Environmental and health impact mitigation

Measures to mitigate the environmental and health impacts of lithium bromide include closed-loop systems to prevent release, wastewater treatment processes to remove lithium bromide before discharge, and air filtration systems to capture any vapors. Health monitoring programs for workers regularly exposed to lithium bromide are recommended. Emergency response plans should address potential environmental contamination scenarios and include procedures for containment and cleanup of spills.Expand Specific Solutions04 Safety enhancements through system design

Safety can be enhanced through improved system design features such as automatic concentration control to prevent crystallization, double-walled heat exchangers to contain potential leaks, and advanced monitoring systems that detect abnormal operating conditions. Innovative designs incorporate fail-safe mechanisms that automatically shut down systems when safety parameters are exceeded. Some designs also include dilution systems that can quickly reduce the concentration of lithium bromide solution in case of emergency.Expand Specific Solutions05 Alternative safer formulations and substitutes

Research has led to the development of safer lithium bromide formulations with additives that reduce corrosivity and toxicity. These include corrosion inhibitors, stabilizers, and pH adjusters that improve the safety profile while maintaining performance. Additionally, alternative working fluids and absorption pairs are being investigated as potential substitutes for lithium bromide in absorption refrigeration systems, aiming to provide similar efficiency with reduced safety concerns.Expand Specific Solutions

Key Industry Players and Safety Solution Providers

The lithium bromide industrial safety landscape is evolving rapidly, with the market currently in a growth phase driven by increasing applications in absorption refrigeration and energy storage systems. The global market size is expanding at approximately 5-7% annually, though technical maturity varies across applications. Leading players include Albemarle Corp. and Ganfeng Lithium Group, who dominate commercial production with established safety protocols, while DuPont and Chemetall GmbH focus on specialized applications. Academic institutions like South China University of Technology and Drexel University are advancing safety innovations through research partnerships with industry. The competitive landscape shows a clear division between established chemical conglomerates with comprehensive safety systems and newer specialized manufacturers seeking to differentiate through technological innovation and enhanced safety profiles.

Albemarle Corp.

Technical Solution: Albemarle Corporation has developed comprehensive safety protocols for lithium bromide handling in industrial applications, particularly focusing on absorption refrigeration systems. Their approach includes proprietary corrosion inhibitor packages that significantly extend equipment lifespan by forming protective films on metal surfaces exposed to lithium bromide solutions. The company has engineered specialized closed-loop handling systems that minimize worker exposure during transfer operations, incorporating automated monitoring of solution concentration, temperature, and pH to prevent crystallization and associated hazards. Albemarle's technology includes advanced filtration systems that continuously remove contaminants from lithium bromide solutions, maintaining optimal performance while reducing corrosion risks. Their safety management system integrates real-time monitoring with predictive maintenance algorithms to identify potential issues before they become critical safety concerns[1].

Strengths: Industry-leading corrosion inhibitor technology provides superior equipment protection; integrated monitoring systems offer comprehensive safety oversight; extensive experience in large-scale industrial applications. Weaknesses: Higher implementation costs compared to basic systems; requires specialized training for maintenance personnel; some proprietary components create vendor dependency.

Chemetall GmbH

Technical Solution: Chemetall GmbH has pioneered an integrated safety approach for lithium bromide applications in industrial absorption chillers and heat pumps. Their technology centers on specially formulated lithium bromide solutions with advanced stabilizing additives that significantly reduce corrosivity while maintaining thermal efficiency. The company's process safety system incorporates multi-stage purification techniques to remove critical impurities that could otherwise accelerate corrosion or crystallization. Chemetall has developed specialized sealed handling equipment that creates closed transfer systems, virtually eliminating worker exposure during maintenance operations. Their approach includes proprietary vapor suppression technology that reduces lithium bromide aerosol formation during high-temperature operations, addressing a key inhalation hazard. The company provides comprehensive material compatibility guidelines that specify appropriate construction materials for different concentration ranges and operating temperatures, preventing costly equipment failures and associated safety incidents[2].

Strengths: Advanced solution formulations with superior stability characteristics; comprehensive material compatibility data reduces implementation risks; vapor suppression technology addresses a critical exposure pathway. Weaknesses: Premium pricing structure limits accessibility for smaller operations; requires specialized equipment for optimal performance; some formulations have narrower operating temperature ranges than competitors.

Critical Safety Technologies and Best Practices

Method for preparing lithium bromide

PatentWO2024038429A1

Innovation

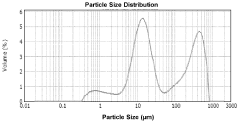

- Contacting high-purity lithium carbonate with gaseous hydrogen bromide at elevated temperatures, typically above 200°C, to directly produce anhydrous lithium bromide, with the reaction conditions optimized by adjusting temperature and particle size distribution of lithium carbonate to achieve high yields and purity exceeding 97%.

Processes for oxidation of bromides to produce bromine and catalysts useful therein

PatentInactiveUS20080085235A1

Innovation

- The use of an aqueous solution comprising a bromide source, an oxidant, and a catalyst comprising a Group 1 cation and a transition metal oxide, with a pKa of less than -1.74, to enhance bromine production, including the employment of sodium molybdate as a catalyst and hydrogen chloride to improve oxidation efficiency.

Regulatory Compliance Framework for Chemical Safety

The regulatory landscape for lithium bromide usage in industrial processes is complex and multifaceted, requiring comprehensive understanding and strict adherence. At the international level, organizations such as the United Nations Environment Programme (UNEP) and the International Labour Organization (ILO) have established guidelines for hazardous chemical management that directly impact lithium bromide handling protocols. These frameworks emphasize risk assessment, proper documentation, and emergency response planning.

In the United States, lithium bromide falls under the regulatory purview of multiple agencies. The Occupational Safety and Health Administration (OSHA) mandates specific workplace safety requirements through its Hazard Communication Standard (29 CFR 1910.1200) and Laboratory Standard (29 CFR 1910.1450). The Environmental Protection Agency (EPA) regulates lithium bromide under the Toxic Substances Control Act (TSCA) and Resource Conservation and Recovery Act (RCRA), particularly concerning waste disposal and environmental release.

European regulations present additional compliance requirements through the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) and Classification, Labelling and Packaging (CLP) frameworks. These regulations necessitate thorough documentation of chemical properties, exposure scenarios, and risk management measures for lithium bromide throughout its lifecycle in industrial applications.

Industry-specific standards further complement these regulatory frameworks. The American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) provides detailed guidelines for lithium bromide usage in absorption refrigeration systems. Similarly, the American Society for Testing and Materials (ASTM) offers standardized testing protocols for evaluating lithium bromide solutions' properties and performance characteristics.

Compliance documentation requirements represent a significant aspect of the regulatory framework. Companies must maintain comprehensive Safety Data Sheets (SDS), chemical inventories, exposure monitoring records, and training documentation. Regular audits and inspections by regulatory authorities necessitate systematic record-keeping practices and transparent reporting mechanisms.

Emerging regulatory trends indicate increasing stringency in chemical safety requirements. Recent developments include lower exposure thresholds, enhanced worker protection measures, and more comprehensive environmental impact assessments. Companies utilizing lithium bromide must establish proactive compliance strategies that anticipate these evolving regulatory demands rather than merely reacting to current requirements.

Implementing a robust compliance management system represents best practice for navigating this complex regulatory landscape. Such systems typically incorporate regular compliance audits, designated safety officers, comprehensive training programs, and established communication channels with regulatory authorities. This systematic approach enables organizations to maintain compliance while optimizing operational efficiency in lithium bromide applications.

In the United States, lithium bromide falls under the regulatory purview of multiple agencies. The Occupational Safety and Health Administration (OSHA) mandates specific workplace safety requirements through its Hazard Communication Standard (29 CFR 1910.1200) and Laboratory Standard (29 CFR 1910.1450). The Environmental Protection Agency (EPA) regulates lithium bromide under the Toxic Substances Control Act (TSCA) and Resource Conservation and Recovery Act (RCRA), particularly concerning waste disposal and environmental release.

European regulations present additional compliance requirements through the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) and Classification, Labelling and Packaging (CLP) frameworks. These regulations necessitate thorough documentation of chemical properties, exposure scenarios, and risk management measures for lithium bromide throughout its lifecycle in industrial applications.

Industry-specific standards further complement these regulatory frameworks. The American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) provides detailed guidelines for lithium bromide usage in absorption refrigeration systems. Similarly, the American Society for Testing and Materials (ASTM) offers standardized testing protocols for evaluating lithium bromide solutions' properties and performance characteristics.

Compliance documentation requirements represent a significant aspect of the regulatory framework. Companies must maintain comprehensive Safety Data Sheets (SDS), chemical inventories, exposure monitoring records, and training documentation. Regular audits and inspections by regulatory authorities necessitate systematic record-keeping practices and transparent reporting mechanisms.

Emerging regulatory trends indicate increasing stringency in chemical safety requirements. Recent developments include lower exposure thresholds, enhanced worker protection measures, and more comprehensive environmental impact assessments. Companies utilizing lithium bromide must establish proactive compliance strategies that anticipate these evolving regulatory demands rather than merely reacting to current requirements.

Implementing a robust compliance management system represents best practice for navigating this complex regulatory landscape. Such systems typically incorporate regular compliance audits, designated safety officers, comprehensive training programs, and established communication channels with regulatory authorities. This systematic approach enables organizations to maintain compliance while optimizing operational efficiency in lithium bromide applications.

Environmental Impact Assessment of Lithium Bromide Usage

The industrial use of lithium bromide presents significant environmental considerations that must be thoroughly assessed. When released into aquatic ecosystems, lithium bromide can disrupt the natural balance by increasing salinity levels and potentially affecting sensitive aquatic organisms. Studies have shown that concentrations exceeding 0.5 mg/L can negatively impact freshwater species, particularly during their reproductive cycles.

Air quality concerns arise primarily during handling and processing operations where lithium bromide dust or aerosols may be generated. While not classified as a volatile compound, improper handling can lead to localized air contamination, requiring appropriate ventilation systems and air quality monitoring protocols in industrial settings.

Soil contamination represents another environmental pathway of concern. Lithium bromide's high water solubility allows it to migrate through soil profiles and potentially reach groundwater resources. Remediation of lithium bromide-contaminated soils typically requires specialized extraction techniques and can be costly, emphasizing the importance of prevention measures.

The compound's lifecycle environmental footprint extends beyond direct contamination. Production processes for lithium bromide are energy-intensive, contributing to carbon emissions. Additionally, mining operations for raw lithium can result in habitat disruption, water depletion, and landscape alteration in source regions, predominantly located in South America's "Lithium Triangle."

Waste management practices for lithium bromide solutions require particular attention. The compound is classified as hazardous waste in many jurisdictions when disposed of in concentrated form. Recycling technologies have advanced significantly, with recovery rates now reaching 85-90% in modern facilities, substantially reducing environmental burden when properly implemented.

Regulatory frameworks governing lithium bromide usage vary globally but generally trend toward increasing stringency. The European Union's REACH regulations classify it as a substance of moderate concern, requiring specific handling protocols and disposal documentation. In the United States, it falls under EPA hazardous substance reporting requirements when releases exceed reportable quantities.

Mitigation strategies should incorporate closed-loop systems that minimize environmental releases, regular environmental monitoring programs around facilities utilizing lithium bromide, and employee training on spill response procedures. Advanced treatment technologies such as ion exchange and membrane filtration have demonstrated effectiveness in removing lithium bromide from wastewater streams before discharge.

Air quality concerns arise primarily during handling and processing operations where lithium bromide dust or aerosols may be generated. While not classified as a volatile compound, improper handling can lead to localized air contamination, requiring appropriate ventilation systems and air quality monitoring protocols in industrial settings.

Soil contamination represents another environmental pathway of concern. Lithium bromide's high water solubility allows it to migrate through soil profiles and potentially reach groundwater resources. Remediation of lithium bromide-contaminated soils typically requires specialized extraction techniques and can be costly, emphasizing the importance of prevention measures.

The compound's lifecycle environmental footprint extends beyond direct contamination. Production processes for lithium bromide are energy-intensive, contributing to carbon emissions. Additionally, mining operations for raw lithium can result in habitat disruption, water depletion, and landscape alteration in source regions, predominantly located in South America's "Lithium Triangle."

Waste management practices for lithium bromide solutions require particular attention. The compound is classified as hazardous waste in many jurisdictions when disposed of in concentrated form. Recycling technologies have advanced significantly, with recovery rates now reaching 85-90% in modern facilities, substantially reducing environmental burden when properly implemented.

Regulatory frameworks governing lithium bromide usage vary globally but generally trend toward increasing stringency. The European Union's REACH regulations classify it as a substance of moderate concern, requiring specific handling protocols and disposal documentation. In the United States, it falls under EPA hazardous substance reporting requirements when releases exceed reportable quantities.

Mitigation strategies should incorporate closed-loop systems that minimize environmental releases, regular environmental monitoring programs around facilities utilizing lithium bromide, and employee training on spill response procedures. Advanced treatment technologies such as ion exchange and membrane filtration have demonstrated effectiveness in removing lithium bromide from wastewater streams before discharge.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!