Enhancing Lithium Bromide Absorption Units for Better Efficiency

AUG 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LiBr Absorption Technology Background and Objectives

Lithium Bromide (LiBr) absorption technology represents a significant advancement in cooling and refrigeration systems, dating back to the early 20th century. The fundamental principle leverages the hygroscopic properties of LiBr solution to absorb water vapor, creating a refrigeration effect without conventional mechanical compression. This technology gained prominence in the 1950s and 1960s as an energy-efficient alternative to traditional vapor compression systems, particularly for large-scale industrial and commercial applications.

The evolution of LiBr absorption technology has been characterized by continuous improvements in system design, component efficiency, and operational parameters. Early systems faced challenges related to crystallization, corrosion, and limited coefficient of performance (COP). However, subsequent innovations in heat exchanger design, solution additives, and control systems have progressively enhanced system reliability and performance.

Current market trends indicate a renewed interest in absorption cooling technologies driven by increasing energy costs, environmental regulations, and the growing emphasis on sustainable energy solutions. LiBr absorption units offer significant advantages in scenarios where waste heat or low-grade thermal energy is available, making them particularly valuable in combined heat and power (CHP) systems, district cooling networks, and industrial processes with excess thermal energy.

The primary technical objective for enhancing LiBr absorption units centers on improving their efficiency metrics, particularly the COP, which typically ranges from 0.7 to 1.2 for single-effect systems. Achieving higher efficiency would significantly expand the technology's application scope and economic viability. This improvement pathway involves optimizing heat and mass transfer processes, reducing internal losses, and enhancing component performance.

Secondary objectives include addressing persistent operational challenges such as crystallization risk, corrosion management, and system size reduction. These factors currently limit wider adoption of LiBr absorption technology in certain applications, particularly in smaller-scale or residential settings where space constraints and maintenance considerations are critical factors.

From a sustainability perspective, enhancing LiBr absorption technology aligns with global decarbonization goals by enabling more efficient utilization of thermal energy sources, including renewable heat, industrial waste heat, and solar thermal energy. The technology offers a pathway to reduce electricity consumption for cooling purposes, potentially decreasing peak electrical demand and associated carbon emissions.

The technological trajectory suggests promising opportunities for hybrid systems that combine LiBr absorption with other cooling technologies, intelligent control systems leveraging IoT and AI for optimized operation, and novel materials that could overcome current limitations in heat transfer and solution properties.

The evolution of LiBr absorption technology has been characterized by continuous improvements in system design, component efficiency, and operational parameters. Early systems faced challenges related to crystallization, corrosion, and limited coefficient of performance (COP). However, subsequent innovations in heat exchanger design, solution additives, and control systems have progressively enhanced system reliability and performance.

Current market trends indicate a renewed interest in absorption cooling technologies driven by increasing energy costs, environmental regulations, and the growing emphasis on sustainable energy solutions. LiBr absorption units offer significant advantages in scenarios where waste heat or low-grade thermal energy is available, making them particularly valuable in combined heat and power (CHP) systems, district cooling networks, and industrial processes with excess thermal energy.

The primary technical objective for enhancing LiBr absorption units centers on improving their efficiency metrics, particularly the COP, which typically ranges from 0.7 to 1.2 for single-effect systems. Achieving higher efficiency would significantly expand the technology's application scope and economic viability. This improvement pathway involves optimizing heat and mass transfer processes, reducing internal losses, and enhancing component performance.

Secondary objectives include addressing persistent operational challenges such as crystallization risk, corrosion management, and system size reduction. These factors currently limit wider adoption of LiBr absorption technology in certain applications, particularly in smaller-scale or residential settings where space constraints and maintenance considerations are critical factors.

From a sustainability perspective, enhancing LiBr absorption technology aligns with global decarbonization goals by enabling more efficient utilization of thermal energy sources, including renewable heat, industrial waste heat, and solar thermal energy. The technology offers a pathway to reduce electricity consumption for cooling purposes, potentially decreasing peak electrical demand and associated carbon emissions.

The technological trajectory suggests promising opportunities for hybrid systems that combine LiBr absorption with other cooling technologies, intelligent control systems leveraging IoT and AI for optimized operation, and novel materials that could overcome current limitations in heat transfer and solution properties.

Market Analysis for Efficient Cooling Solutions

The global cooling solutions market is experiencing significant growth, driven by increasing urbanization, rising global temperatures, and growing demand for comfort cooling in both residential and commercial sectors. The market for efficient cooling technologies is projected to reach $300 billion by 2027, with absorption cooling systems representing a growing segment due to their potential for energy efficiency and environmental benefits.

Lithium Bromide (LiBr) absorption cooling systems hold a substantial market share within the industrial and commercial cooling sectors, particularly in regions with high cooling demands such as Asia-Pacific, Middle East, and North America. These systems are increasingly preferred in applications where waste heat recovery is possible, including manufacturing facilities, data centers, and large commercial buildings.

Market research indicates that energy efficiency has become the primary purchasing criterion for cooling systems, with over 70% of commercial buyers citing operational cost reduction as their main consideration. This trend strongly favors enhanced LiBr absorption units, which can potentially reduce energy consumption by 30-50% compared to conventional vapor compression systems when properly optimized.

The market for absorption cooling is segmented by application type, with industrial processes accounting for approximately 40% of demand, followed by commercial buildings (35%), and district cooling systems (25%). Within these segments, there is growing interest in systems that can operate effectively at lower generator temperatures, expanding the potential applications for waste heat recovery.

Regulatory factors are significantly influencing market dynamics, with environmental regulations phasing out traditional refrigerants in many regions. The Montreal Protocol and subsequent amendments have accelerated the transition toward alternative cooling technologies, benefiting absorption systems that use environmentally benign working fluids like water and lithium bromide.

Customer demand patterns reveal increasing interest in integrated energy systems that combine cooling with heating and power generation. This trend favors absorption technologies that can be effectively incorporated into trigeneration or combined cooling, heating, and power (CCHP) systems, offering superior overall energy utilization efficiency.

Market barriers include the higher initial capital costs of absorption systems compared to conventional alternatives, with LiBr systems typically commanding a 20-30% premium. However, lifecycle cost analyses demonstrate that enhanced efficiency units can achieve payback periods of 3-5 years in applications with high cooling loads and available waste heat sources.

Competitive analysis shows that the market is dominated by established HVAC manufacturers and specialized absorption chiller producers, with increasing competition from Asian manufacturers offering cost-competitive solutions. This competitive landscape is driving innovation in efficiency enhancements, with particular focus on heat exchanger design, working fluid formulations, and control system optimization.

Lithium Bromide (LiBr) absorption cooling systems hold a substantial market share within the industrial and commercial cooling sectors, particularly in regions with high cooling demands such as Asia-Pacific, Middle East, and North America. These systems are increasingly preferred in applications where waste heat recovery is possible, including manufacturing facilities, data centers, and large commercial buildings.

Market research indicates that energy efficiency has become the primary purchasing criterion for cooling systems, with over 70% of commercial buyers citing operational cost reduction as their main consideration. This trend strongly favors enhanced LiBr absorption units, which can potentially reduce energy consumption by 30-50% compared to conventional vapor compression systems when properly optimized.

The market for absorption cooling is segmented by application type, with industrial processes accounting for approximately 40% of demand, followed by commercial buildings (35%), and district cooling systems (25%). Within these segments, there is growing interest in systems that can operate effectively at lower generator temperatures, expanding the potential applications for waste heat recovery.

Regulatory factors are significantly influencing market dynamics, with environmental regulations phasing out traditional refrigerants in many regions. The Montreal Protocol and subsequent amendments have accelerated the transition toward alternative cooling technologies, benefiting absorption systems that use environmentally benign working fluids like water and lithium bromide.

Customer demand patterns reveal increasing interest in integrated energy systems that combine cooling with heating and power generation. This trend favors absorption technologies that can be effectively incorporated into trigeneration or combined cooling, heating, and power (CCHP) systems, offering superior overall energy utilization efficiency.

Market barriers include the higher initial capital costs of absorption systems compared to conventional alternatives, with LiBr systems typically commanding a 20-30% premium. However, lifecycle cost analyses demonstrate that enhanced efficiency units can achieve payback periods of 3-5 years in applications with high cooling loads and available waste heat sources.

Competitive analysis shows that the market is dominated by established HVAC manufacturers and specialized absorption chiller producers, with increasing competition from Asian manufacturers offering cost-competitive solutions. This competitive landscape is driving innovation in efficiency enhancements, with particular focus on heat exchanger design, working fluid formulations, and control system optimization.

Current Limitations and Technical Challenges in LiBr Systems

Lithium Bromide (LiBr) absorption refrigeration systems, while offering significant advantages in terms of energy efficiency and environmental friendliness, face several critical limitations that hinder their widespread adoption and optimal performance. One of the primary challenges is crystallization, which occurs when the LiBr solution concentration exceeds its solubility limit. This phenomenon, particularly prevalent during low-temperature operations, can cause blockages in heat exchangers and solution lines, leading to system failure and increased maintenance costs.

Corrosion presents another significant challenge in LiBr systems. The highly corrosive nature of LiBr solutions, especially at elevated temperatures and concentrations, accelerates the degradation of system components, including heat exchangers, pumps, and piping. This not only reduces system lifespan but also compromises operational safety and increases maintenance requirements. Current corrosion inhibitors often introduce additional complexities or reduce system efficiency.

Heat and mass transfer inefficiencies constitute a major technical barrier. The absorption and desorption processes in LiBr systems are inherently limited by the rate of heat and mass transfer between the refrigerant vapor and the absorbent solution. Poor wetting of heat exchange surfaces, inadequate mixing, and suboptimal flow distribution contribute to reduced performance and higher energy consumption.

Vacuum maintenance poses another significant challenge. LiBr absorption systems operate under vacuum conditions, and any air leakage into the system can severely impair performance. The presence of non-condensable gases increases the pressure in the evaporator and absorber, raising the solution boiling point and reducing cooling capacity. Current vacuum maintenance technologies often require substantial energy input or frequent servicing.

Energy input requirements for solution pumping and regeneration represent another limitation. Despite their thermodynamic advantages, LiBr systems still require electrical energy for solution circulation and thermal energy for regeneration. The coefficient of performance (COP) typically ranges from 0.7 to 1.2, which, while competitive, leaves significant room for improvement compared to theoretical limits.

Scale formation on heat transfer surfaces, particularly in the presence of hard water or when using cooling towers, reduces heat transfer efficiency and increases pressure drops. Current scale prevention methods often involve chemical treatments that may have environmental implications or require frequent system maintenance.

Finally, system complexity and control challenges remain significant barriers. LiBr absorption systems require sophisticated control strategies to maintain optimal operation across varying load conditions and to prevent crystallization. The complexity of these systems increases installation and maintenance costs, while limiting their applicability in smaller-scale applications or in regions with limited technical expertise.

Corrosion presents another significant challenge in LiBr systems. The highly corrosive nature of LiBr solutions, especially at elevated temperatures and concentrations, accelerates the degradation of system components, including heat exchangers, pumps, and piping. This not only reduces system lifespan but also compromises operational safety and increases maintenance requirements. Current corrosion inhibitors often introduce additional complexities or reduce system efficiency.

Heat and mass transfer inefficiencies constitute a major technical barrier. The absorption and desorption processes in LiBr systems are inherently limited by the rate of heat and mass transfer between the refrigerant vapor and the absorbent solution. Poor wetting of heat exchange surfaces, inadequate mixing, and suboptimal flow distribution contribute to reduced performance and higher energy consumption.

Vacuum maintenance poses another significant challenge. LiBr absorption systems operate under vacuum conditions, and any air leakage into the system can severely impair performance. The presence of non-condensable gases increases the pressure in the evaporator and absorber, raising the solution boiling point and reducing cooling capacity. Current vacuum maintenance technologies often require substantial energy input or frequent servicing.

Energy input requirements for solution pumping and regeneration represent another limitation. Despite their thermodynamic advantages, LiBr systems still require electrical energy for solution circulation and thermal energy for regeneration. The coefficient of performance (COP) typically ranges from 0.7 to 1.2, which, while competitive, leaves significant room for improvement compared to theoretical limits.

Scale formation on heat transfer surfaces, particularly in the presence of hard water or when using cooling towers, reduces heat transfer efficiency and increases pressure drops. Current scale prevention methods often involve chemical treatments that may have environmental implications or require frequent system maintenance.

Finally, system complexity and control challenges remain significant barriers. LiBr absorption systems require sophisticated control strategies to maintain optimal operation across varying load conditions and to prevent crystallization. The complexity of these systems increases installation and maintenance costs, while limiting their applicability in smaller-scale applications or in regions with limited technical expertise.

State-of-the-Art LiBr Absorption Enhancement Methods

01 Heat exchanger design for improved efficiency

Optimized heat exchanger designs can significantly improve the efficiency of lithium bromide absorption units. These designs include enhanced heat transfer surfaces, improved flow distribution, and specialized configurations that maximize thermal exchange between the refrigerant and absorbent solution. Such innovations reduce energy consumption and increase the coefficient of performance (COP) of the absorption refrigeration system.- Heat exchanger design improvements for LiBr absorption units: Various heat exchanger design improvements can enhance the efficiency of lithium bromide absorption units. These include optimized tube arrangements, enhanced heat transfer surfaces, and improved flow distribution mechanisms. Such design modifications can reduce thermal resistance, minimize pressure drops, and increase the overall heat transfer coefficient, leading to better system performance and higher coefficient of performance (COP) values.

- Solution circulation and spray system optimization: Optimizing the solution circulation and spray systems in lithium bromide absorption units can significantly improve efficiency. This includes enhanced solution distribution methods, improved spray nozzle designs, and optimized solution flow rates. Better solution distribution ensures more effective absorption/desorption processes, reduces crystallization risks, and improves heat and mass transfer rates throughout the system.

- Additives and solution enhancement for LiBr systems: Various additives can be incorporated into lithium bromide solutions to enhance system efficiency. These include corrosion inhibitors, crystallization inhibitors, surfactants, and heat transfer enhancers. These additives can improve solution stability, reduce crystallization risks, enhance heat and mass transfer properties, and protect system components from corrosion, thereby extending equipment life and maintaining optimal performance.

- Advanced control strategies and system integration: Implementing advanced control strategies and system integration techniques can optimize lithium bromide absorption unit efficiency. These include intelligent control algorithms, variable flow control, capacity modulation techniques, and integration with renewable energy sources. Such approaches enable dynamic response to changing conditions, optimize operating parameters in real-time, and ensure the system operates at peak efficiency across various load conditions.

- Multi-stage and hybrid absorption system configurations: Multi-stage and hybrid system configurations can significantly improve the efficiency of lithium bromide absorption units. These include double-effect, triple-effect designs, cascade systems, and hybrid absorption-compression systems. Such configurations enable better utilization of input energy, improved heat recovery, higher temperature lifts, and increased coefficient of performance compared to conventional single-effect systems.

02 Solution concentration control methods

Controlling the concentration of lithium bromide solution is crucial for maintaining optimal absorption efficiency. Various methods include precise metering systems, automated concentration monitoring, and solution regeneration techniques. These approaches prevent crystallization issues, reduce corrosion risks, and ensure consistent performance across varying operating conditions, ultimately enhancing the overall efficiency of the absorption unit.Expand Specific Solutions03 Vacuum system optimization

Maintaining proper vacuum conditions is essential for lithium bromide absorption units. Improved vacuum systems incorporate advanced sealing technologies, efficient non-condensable gas removal mechanisms, and pressure control devices. These enhancements minimize air infiltration, reduce system resistance, and create optimal pressure conditions for the absorption process, significantly improving the unit's efficiency and reliability.Expand Specific Solutions04 Additives and inhibitors for performance enhancement

Various additives and inhibitors can be incorporated into lithium bromide solutions to enhance absorption unit efficiency. These include corrosion inhibitors, crystallization preventers, heat transfer enhancers, and surface tension modifiers. Such chemical additions improve solution stability, extend equipment lifespan, reduce maintenance requirements, and increase the overall thermal efficiency of the absorption refrigeration cycle.Expand Specific Solutions05 Energy recovery and system integration

Advanced energy recovery techniques and system integration approaches can significantly boost lithium bromide absorption unit efficiency. These include waste heat utilization, multi-stage absorption configurations, hybrid systems combining absorption with other technologies, and intelligent control systems. Such innovations optimize energy flows, reduce primary energy consumption, and improve the overall coefficient of performance of absorption refrigeration units.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Absorption Cooling

The lithium bromide absorption technology market is currently in a growth phase, with increasing demand for energy-efficient cooling solutions driving expansion. The market is characterized by a mix of established HVAC manufacturers and specialized chemical companies competing to enhance efficiency. Key players include Shuangliang Eco-Energy Systems and Gree Electric Appliances from China, alongside global corporations like Carrier, DAIKIN, and DuPont. Academic institutions such as Dalian Maritime University and research organizations like KIST are contributing significant innovations. The technology is approaching maturity in conventional applications, but research continues in advanced materials and system optimization, with companies like LG Chem and Sumitomo Chemical developing improved absorption media. Market differentiation is increasingly focused on energy efficiency improvements and integration with renewable energy systems.

Shuangliang Eco-Energy Systems Co., Ltd.

Technical Solution: Shuangliang has developed advanced lithium bromide absorption refrigeration units with multi-stage absorption technology that significantly enhances thermal efficiency. Their system incorporates a patented high-efficiency heat exchanger design with specialized surface treatments to minimize crystallization issues common in LiBr systems. The company has implemented a sophisticated solution circulation system with variable flow control that adapts to changing cooling demands and ambient conditions. Their units feature advanced vacuum maintenance technology with automatic purging systems that remove non-condensable gases, maintaining optimal operating pressure and improving heat transfer efficiency. Shuangliang's systems also incorporate intelligent control algorithms that optimize the relationship between solution concentration, temperature, and flow rate to maximize coefficient of performance (COP) values reaching up to 1.4 for single-effect and 2.1 for double-effect systems.

Strengths: Industry-leading heat exchanger design with specialized anti-crystallization technology; comprehensive system integration expertise; advanced control systems that optimize performance across varying conditions. Weaknesses: Higher initial capital costs compared to conventional cooling systems; requires specialized maintenance expertise; performance can still degrade in extremely high ambient temperature environments.

DuPont de Nemours, Inc.

Technical Solution: DuPont has developed advanced material solutions specifically engineered to enhance lithium bromide absorption systems. Their approach focuses on specialized corrosion inhibitors and surface treatments that significantly extend equipment lifespan while maintaining optimal heat transfer characteristics. DuPont has created proprietary polymer-based heat exchanger coatings that resist degradation from lithium bromide solutions while enhancing surface wetting properties, improving absorption efficiency. Their materials science expertise has led to the development of specialized gaskets, seals, and component materials that maintain integrity under the challenging conditions of LiBr systems, including vacuum operation and exposure to potentially corrosive solutions. DuPont has engineered advanced membrane technologies that enable more efficient solution purification and concentration processes, reducing energy requirements for solution regeneration. Additionally, they have developed specialized additives that modify solution properties, reducing crystallization risks while enhancing heat and mass transfer characteristics.

Strengths: Unparalleled materials science expertise applicable to multiple system components; solutions can be implemented across different manufacturers' equipment; innovations address fundamental chemical and material challenges in LiBr systems. Weaknesses: Primarily a materials and components supplier rather than complete system provider; implementation requires collaboration with system manufacturers; some solutions may require significant system redesign for optimal integration.

Key Patents and Innovations in Absorption Efficiency

Operating medium for an absorption refrigeration device

PatentInactiveEP2510069A1

Innovation

- A working medium comprising 5-30% water and 65-95% lithium bromide with an ionic liquid, in a weight ratio of 0.5:1 to 5:1, which reduces friction and prevents crystallization, allowing for a single-phase solution and reduced mechanical energy consumption.

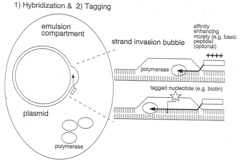

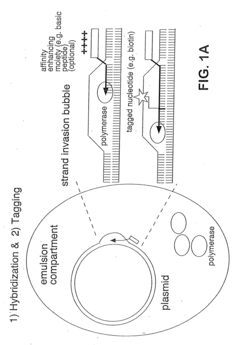

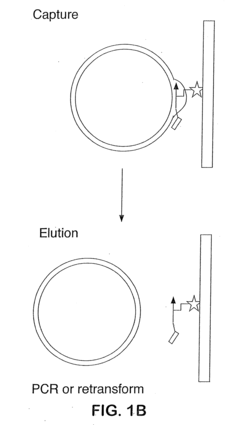

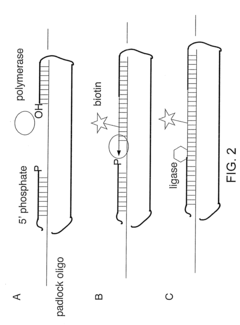

Compartmentalized self tagging

PatentInactiveUS20100184071A1

Innovation

- The development of Compartmentalized Self-Tagging (CST) method, which allows for the selection of nucleic acid processing enzymes by compartmentalizing plasmids with oligonucleotides specific to a region on the plasmid, enabling activity-dependent tagging and capture without requiring complete replication of the enzyme encoding gene, thus accommodating enzymes with low catalytic turnover and processivity.

Energy Efficiency and Environmental Impact Assessment

Lithium Bromide (LiBr) absorption units represent a significant technology in the cooling and heating industry, with their efficiency directly impacting energy consumption patterns and environmental outcomes. Current LiBr absorption systems typically operate at Coefficient of Performance (COP) values between 0.7-1.2, significantly lower than conventional vapor compression systems. This efficiency gap presents both challenges and opportunities for technological advancement.

Energy consumption analysis reveals that enhanced LiBr absorption units can reduce primary energy usage by 30-45% compared to conventional cooling systems when powered by waste heat or renewable thermal sources. This reduction translates to approximately 0.15-0.25 kWh of electricity saved per ton-hour of cooling provided, representing substantial energy savings in large-scale applications such as district cooling or industrial processes.

The environmental benefits of improved LiBr absorption technology extend beyond energy savings. These systems utilize environmentally benign working fluids (water as refrigerant and lithium bromide as absorbent) with zero Ozone Depletion Potential (ODP) and zero Global Warming Potential (GWP), contrasting sharply with traditional refrigerants. Life cycle assessment studies indicate that optimized LiBr absorption systems can reduce greenhouse gas emissions by 40-60% compared to conventional electric chillers, depending on the regional electricity generation mix.

Water consumption represents another critical environmental consideration. Enhanced LiBr units with improved heat rejection systems can reduce cooling tower water consumption by 15-25%, addressing water scarcity concerns in many regions. Additionally, advanced corrosion inhibitors have reduced the environmental impact of system maintenance by extending equipment lifespan and reducing chemical discharge during servicing operations.

The embodied energy in manufacturing improved LiBr absorption units presents a trade-off that must be considered. Higher efficiency units often require more sophisticated heat exchangers and control systems, increasing initial manufacturing energy investment. However, life cycle analysis demonstrates that this additional embodied energy is typically recovered within 2-3 years of operation through improved operational efficiency.

Noise pollution reduction represents an often-overlooked environmental benefit of LiBr absorption technology. With fewer moving parts than conventional compression systems, enhanced absorption units can reduce operational noise by 10-15 dB, contributing to healthier urban environments and workplace conditions where these systems are deployed.

Future developments in LiBr absorption technology, including multi-effect configurations and hybrid systems, promise to further improve the energy-environmental balance, potentially achieving COPs above 1.8 while maintaining the inherent environmental advantages of the absorption cycle.

Energy consumption analysis reveals that enhanced LiBr absorption units can reduce primary energy usage by 30-45% compared to conventional cooling systems when powered by waste heat or renewable thermal sources. This reduction translates to approximately 0.15-0.25 kWh of electricity saved per ton-hour of cooling provided, representing substantial energy savings in large-scale applications such as district cooling or industrial processes.

The environmental benefits of improved LiBr absorption technology extend beyond energy savings. These systems utilize environmentally benign working fluids (water as refrigerant and lithium bromide as absorbent) with zero Ozone Depletion Potential (ODP) and zero Global Warming Potential (GWP), contrasting sharply with traditional refrigerants. Life cycle assessment studies indicate that optimized LiBr absorption systems can reduce greenhouse gas emissions by 40-60% compared to conventional electric chillers, depending on the regional electricity generation mix.

Water consumption represents another critical environmental consideration. Enhanced LiBr units with improved heat rejection systems can reduce cooling tower water consumption by 15-25%, addressing water scarcity concerns in many regions. Additionally, advanced corrosion inhibitors have reduced the environmental impact of system maintenance by extending equipment lifespan and reducing chemical discharge during servicing operations.

The embodied energy in manufacturing improved LiBr absorption units presents a trade-off that must be considered. Higher efficiency units often require more sophisticated heat exchangers and control systems, increasing initial manufacturing energy investment. However, life cycle analysis demonstrates that this additional embodied energy is typically recovered within 2-3 years of operation through improved operational efficiency.

Noise pollution reduction represents an often-overlooked environmental benefit of LiBr absorption technology. With fewer moving parts than conventional compression systems, enhanced absorption units can reduce operational noise by 10-15 dB, contributing to healthier urban environments and workplace conditions where these systems are deployed.

Future developments in LiBr absorption technology, including multi-effect configurations and hybrid systems, promise to further improve the energy-environmental balance, potentially achieving COPs above 1.8 while maintaining the inherent environmental advantages of the absorption cycle.

Integration Potential with Renewable Energy Sources

The integration of Lithium Bromide (LiBr) absorption units with renewable energy sources represents a significant opportunity to enhance system efficiency while reducing environmental impact. Solar thermal energy offers a particularly promising synergy with LiBr absorption cooling systems. By utilizing solar collectors to provide the heat input required for the generator component of absorption chillers, these systems can operate with minimal conventional energy consumption during periods of solar availability. This integration can achieve primary energy savings of 40-60% compared to conventional cooling systems when properly designed and implemented.

Wind energy integration presents another viable pathway, especially in hybrid systems where excess wind power during off-peak demand periods can be converted to thermal energy for storage and subsequent use in LiBr absorption units. This approach addresses the intermittency challenges of wind power while enhancing the overall energy utilization efficiency of the combined system.

Geothermal energy sources provide stable, continuous heat input that aligns perfectly with the operational requirements of LiBr absorption systems. Low to medium temperature geothermal resources (80-150°C) can directly drive absorption chillers, creating highly efficient and reliable cooling solutions with minimal environmental impact. Case studies from Iceland and New Zealand demonstrate coefficient of performance (COP) improvements of 15-25% when LiBr units are coupled with geothermal sources compared to conventional heating methods.

Biomass-powered systems offer another renewable integration option, particularly valuable in rural or agricultural settings where biomass resources are abundant. The waste heat from biomass combustion or gasification processes can be effectively utilized to drive LiBr absorption cycles, creating a closed-loop energy system with significantly reduced carbon footprint.

Smart grid integration represents an emerging frontier, where LiBr absorption systems can participate in demand response programs, utilizing renewable energy when available and shifting to minimal operation during peak grid demand. Advanced control algorithms can optimize this integration, predicting renewable energy availability and adjusting system parameters accordingly to maximize efficiency and minimize costs.

The economic viability of these integrated systems continues to improve as renewable energy costs decline and carbon pricing mechanisms expand globally. Payback periods for integrated LiBr-renewable systems have decreased from 8-10 years a decade ago to 4-6 years today in many markets, making them increasingly attractive for commercial and industrial applications seeking both operational cost savings and sustainability benefits.

Wind energy integration presents another viable pathway, especially in hybrid systems where excess wind power during off-peak demand periods can be converted to thermal energy for storage and subsequent use in LiBr absorption units. This approach addresses the intermittency challenges of wind power while enhancing the overall energy utilization efficiency of the combined system.

Geothermal energy sources provide stable, continuous heat input that aligns perfectly with the operational requirements of LiBr absorption systems. Low to medium temperature geothermal resources (80-150°C) can directly drive absorption chillers, creating highly efficient and reliable cooling solutions with minimal environmental impact. Case studies from Iceland and New Zealand demonstrate coefficient of performance (COP) improvements of 15-25% when LiBr units are coupled with geothermal sources compared to conventional heating methods.

Biomass-powered systems offer another renewable integration option, particularly valuable in rural or agricultural settings where biomass resources are abundant. The waste heat from biomass combustion or gasification processes can be effectively utilized to drive LiBr absorption cycles, creating a closed-loop energy system with significantly reduced carbon footprint.

Smart grid integration represents an emerging frontier, where LiBr absorption systems can participate in demand response programs, utilizing renewable energy when available and shifting to minimal operation during peak grid demand. Advanced control algorithms can optimize this integration, predicting renewable energy availability and adjusting system parameters accordingly to maximize efficiency and minimize costs.

The economic viability of these integrated systems continues to improve as renewable energy costs decline and carbon pricing mechanisms expand globally. Payback periods for integrated LiBr-renewable systems have decreased from 8-10 years a decade ago to 4-6 years today in many markets, making them increasingly attractive for commercial and industrial applications seeking both operational cost savings and sustainability benefits.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!