Comparing Lithium Bromide with Novel Absorption Materials

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Absorption Materials Evolution and Research Objectives

Absorption refrigeration technology has evolved significantly since its inception in the 1850s when Ferdinand Carré first demonstrated the ammonia-water absorption system. The 1930s marked a pivotal shift with the introduction of lithium bromide-water (LiBr-H2O) systems by Carrier Corporation, which quickly became the industry standard for commercial cooling applications due to their higher efficiency and lower operating pressures compared to ammonia-based systems.

For decades, lithium bromide has dominated the absorption refrigeration market, particularly in large-scale commercial and industrial applications. Its strong affinity for water vapor, relatively high thermal stability, and non-toxicity compared to ammonia made it the preferred working pair. However, LiBr systems face inherent limitations including crystallization risks at high concentrations, corrosion issues, and limited operating temperature ranges.

Recent environmental concerns and energy efficiency demands have accelerated research into alternative absorption materials. The past decade has witnessed significant advancements in novel working pairs and composite materials designed to overcome LiBr's limitations. These include ionic liquids, metal-organic frameworks (MOFs), composite salt matrices, and various nanostructured materials that demonstrate promising sorption characteristics.

The primary research objectives in this field focus on developing absorption materials that offer higher coefficient of performance (COP), broader operating temperature ranges, and reduced environmental impact. Specifically, researchers aim to identify materials that can function efficiently at lower generator temperatures (below 80°C), enabling the utilization of low-grade waste heat and renewable energy sources such as solar thermal collectors.

Another critical research goal involves addressing the crystallization and corrosion issues inherent to traditional LiBr systems. Novel materials must demonstrate stable performance across varying concentration levels and temperature conditions while maintaining long-term durability in practical applications. Additionally, there is significant interest in materials that can operate effectively in compact systems, potentially expanding absorption technology into residential and small commercial applications.

The evolution trajectory suggests a gradual shift from single-salt solutions to multi-component systems and engineered nanostructured materials. These advanced materials aim to combine the favorable thermodynamic properties of traditional working pairs with enhanced heat and mass transfer characteristics, stability improvements, and broader operating ranges. The ultimate objective is to develop next-generation absorption systems that can compete with conventional vapor compression technologies in terms of efficiency, cost, and versatility while offering superior environmental benefits.

For decades, lithium bromide has dominated the absorption refrigeration market, particularly in large-scale commercial and industrial applications. Its strong affinity for water vapor, relatively high thermal stability, and non-toxicity compared to ammonia made it the preferred working pair. However, LiBr systems face inherent limitations including crystallization risks at high concentrations, corrosion issues, and limited operating temperature ranges.

Recent environmental concerns and energy efficiency demands have accelerated research into alternative absorption materials. The past decade has witnessed significant advancements in novel working pairs and composite materials designed to overcome LiBr's limitations. These include ionic liquids, metal-organic frameworks (MOFs), composite salt matrices, and various nanostructured materials that demonstrate promising sorption characteristics.

The primary research objectives in this field focus on developing absorption materials that offer higher coefficient of performance (COP), broader operating temperature ranges, and reduced environmental impact. Specifically, researchers aim to identify materials that can function efficiently at lower generator temperatures (below 80°C), enabling the utilization of low-grade waste heat and renewable energy sources such as solar thermal collectors.

Another critical research goal involves addressing the crystallization and corrosion issues inherent to traditional LiBr systems. Novel materials must demonstrate stable performance across varying concentration levels and temperature conditions while maintaining long-term durability in practical applications. Additionally, there is significant interest in materials that can operate effectively in compact systems, potentially expanding absorption technology into residential and small commercial applications.

The evolution trajectory suggests a gradual shift from single-salt solutions to multi-component systems and engineered nanostructured materials. These advanced materials aim to combine the favorable thermodynamic properties of traditional working pairs with enhanced heat and mass transfer characteristics, stability improvements, and broader operating ranges. The ultimate objective is to develop next-generation absorption systems that can compete with conventional vapor compression technologies in terms of efficiency, cost, and versatility while offering superior environmental benefits.

Market Analysis for Advanced Absorption Refrigeration Systems

The global market for absorption refrigeration systems is experiencing significant growth, driven by increasing demand for energy-efficient cooling solutions across various sectors. Currently valued at approximately 9.7 billion USD, this market is projected to expand at a compound annual growth rate of 6.8% through 2028, reflecting the growing emphasis on sustainable technologies and reduced environmental impact in cooling applications.

Lithium bromide-based absorption systems have traditionally dominated the commercial and industrial segments, accounting for roughly 65% of the total absorption refrigeration market. These systems are particularly prevalent in large-scale applications such as district cooling, industrial process cooling, and commercial building air conditioning. The Asia-Pacific region, especially China and Japan, represents the largest market for these traditional systems, followed by North America and Europe.

However, market dynamics are shifting as novel absorption materials emerge as viable alternatives. Water-ammonia systems currently hold about 20% of the market share, primarily in small to medium-scale applications and regions where lower temperature refrigeration is required. The remaining 15% is distributed among newer technologies utilizing alternative working pairs such as lithium chloride-water, calcium chloride-ammonia, and various ionic liquids.

Demand drivers for advanced absorption refrigeration systems include stringent environmental regulations limiting the use of conventional refrigerants, rising energy costs, and increasing integration with renewable energy sources. The commercial building sector represents the largest end-user segment (38%), followed by industrial processes (27%), healthcare facilities (15%), and data centers (12%), with other applications comprising the remaining 8%.

Geographically, emerging markets in Southeast Asia, India, and the Middle East are showing the fastest growth rates, with projected market expansion exceeding 9% annually. These regions are increasingly adopting absorption cooling technologies due to their compatibility with solar thermal systems and waste heat recovery applications, which are particularly advantageous in areas with high solar irradiation and industrial activity.

Price sensitivity varies significantly across market segments, with initial capital costs remaining a primary barrier to wider adoption. Systems utilizing novel absorption materials typically command a 15-30% premium over traditional lithium bromide systems, though this gap is narrowing as manufacturing scales increase and technology matures. The total cost of ownership analysis increasingly favors advanced systems when factoring in energy savings, maintenance requirements, and operational lifespan.

Market forecasts indicate that novel absorption materials could capture up to 35% of the total market by 2030, primarily displacing traditional lithium bromide systems in applications where their specific advantages—such as lower corrosivity, wider operating temperature ranges, or higher efficiency—provide compelling value propositions.

Lithium bromide-based absorption systems have traditionally dominated the commercial and industrial segments, accounting for roughly 65% of the total absorption refrigeration market. These systems are particularly prevalent in large-scale applications such as district cooling, industrial process cooling, and commercial building air conditioning. The Asia-Pacific region, especially China and Japan, represents the largest market for these traditional systems, followed by North America and Europe.

However, market dynamics are shifting as novel absorption materials emerge as viable alternatives. Water-ammonia systems currently hold about 20% of the market share, primarily in small to medium-scale applications and regions where lower temperature refrigeration is required. The remaining 15% is distributed among newer technologies utilizing alternative working pairs such as lithium chloride-water, calcium chloride-ammonia, and various ionic liquids.

Demand drivers for advanced absorption refrigeration systems include stringent environmental regulations limiting the use of conventional refrigerants, rising energy costs, and increasing integration with renewable energy sources. The commercial building sector represents the largest end-user segment (38%), followed by industrial processes (27%), healthcare facilities (15%), and data centers (12%), with other applications comprising the remaining 8%.

Geographically, emerging markets in Southeast Asia, India, and the Middle East are showing the fastest growth rates, with projected market expansion exceeding 9% annually. These regions are increasingly adopting absorption cooling technologies due to their compatibility with solar thermal systems and waste heat recovery applications, which are particularly advantageous in areas with high solar irradiation and industrial activity.

Price sensitivity varies significantly across market segments, with initial capital costs remaining a primary barrier to wider adoption. Systems utilizing novel absorption materials typically command a 15-30% premium over traditional lithium bromide systems, though this gap is narrowing as manufacturing scales increase and technology matures. The total cost of ownership analysis increasingly favors advanced systems when factoring in energy savings, maintenance requirements, and operational lifespan.

Market forecasts indicate that novel absorption materials could capture up to 35% of the total market by 2030, primarily displacing traditional lithium bromide systems in applications where their specific advantages—such as lower corrosivity, wider operating temperature ranges, or higher efficiency—provide compelling value propositions.

Current Limitations and Technical Barriers of Absorption Materials

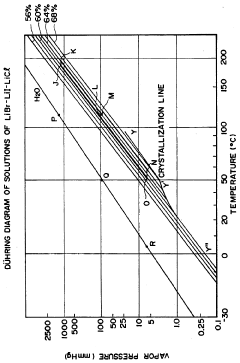

Despite its widespread use in absorption refrigeration systems, lithium bromide (LiBr) presents several significant limitations that hinder optimal performance. The hygroscopic nature of LiBr solutions causes crystallization issues when concentration exceeds 65%, leading to system blockages and efficiency losses. This crystallization risk restricts the operational temperature range, particularly in high-temperature environments, limiting application versatility.

Corrosion represents another major challenge, as LiBr solutions are highly corrosive to many common metals used in refrigeration systems. This necessitates expensive corrosion inhibitors and specialized materials, increasing both initial investment and maintenance costs. The corrosion issue also shortens system lifespan and raises safety concerns in industrial applications.

Energy efficiency limitations are evident in LiBr-based systems, which typically achieve a coefficient of performance (COP) between 0.7-1.2, significantly lower than mechanical vapor compression systems. This efficiency gap becomes particularly problematic in applications requiring precise temperature control or rapid cooling responses.

Environmental considerations also pose barriers, as LiBr production involves energy-intensive processes and potential environmental contamination during disposal. While not as harmful as traditional refrigerants like CFCs, the environmental footprint remains a concern for sustainability-focused industries.

Novel absorption materials face their own set of challenges. Metal-organic frameworks (MOFs), despite promising adsorption properties, struggle with long-term stability issues under repeated thermal cycling. Their complex synthesis processes and high production costs currently limit commercial viability, restricting widespread adoption.

Ionic liquids show potential as alternative absorbents but face challenges related to viscosity management and thermal stability at higher temperatures. Their relatively recent development means comprehensive long-term performance data remains limited, creating uncertainty for potential industrial adopters.

Composite materials combining multiple absorbents often face compatibility issues between components, leading to degradation over time. The optimization of these multi-component systems requires extensive research to balance enhanced performance with practical implementation considerations.

Technical barriers to commercialization persist across novel materials, including scalability challenges, integration with existing infrastructure, and economic viability compared to established LiBr systems. The absence of standardized testing protocols for new absorption materials further complicates comparative analysis and industry acceptance.

Addressing these limitations requires interdisciplinary research focusing on material stability, system integration, and cost-effective manufacturing processes to bridge the gap between promising laboratory results and commercially viable absorption refrigeration technologies.

Corrosion represents another major challenge, as LiBr solutions are highly corrosive to many common metals used in refrigeration systems. This necessitates expensive corrosion inhibitors and specialized materials, increasing both initial investment and maintenance costs. The corrosion issue also shortens system lifespan and raises safety concerns in industrial applications.

Energy efficiency limitations are evident in LiBr-based systems, which typically achieve a coefficient of performance (COP) between 0.7-1.2, significantly lower than mechanical vapor compression systems. This efficiency gap becomes particularly problematic in applications requiring precise temperature control or rapid cooling responses.

Environmental considerations also pose barriers, as LiBr production involves energy-intensive processes and potential environmental contamination during disposal. While not as harmful as traditional refrigerants like CFCs, the environmental footprint remains a concern for sustainability-focused industries.

Novel absorption materials face their own set of challenges. Metal-organic frameworks (MOFs), despite promising adsorption properties, struggle with long-term stability issues under repeated thermal cycling. Their complex synthesis processes and high production costs currently limit commercial viability, restricting widespread adoption.

Ionic liquids show potential as alternative absorbents but face challenges related to viscosity management and thermal stability at higher temperatures. Their relatively recent development means comprehensive long-term performance data remains limited, creating uncertainty for potential industrial adopters.

Composite materials combining multiple absorbents often face compatibility issues between components, leading to degradation over time. The optimization of these multi-component systems requires extensive research to balance enhanced performance with practical implementation considerations.

Technical barriers to commercialization persist across novel materials, including scalability challenges, integration with existing infrastructure, and economic viability compared to established LiBr systems. The absence of standardized testing protocols for new absorption materials further complicates comparative analysis and industry acceptance.

Addressing these limitations requires interdisciplinary research focusing on material stability, system integration, and cost-effective manufacturing processes to bridge the gap between promising laboratory results and commercially viable absorption refrigeration technologies.

Comparative Analysis of LiBr and Novel Absorption Working Pairs

01 Lithium bromide as absorption material

Lithium bromide is widely used as an absorption material in absorption refrigeration systems due to its excellent absorption efficiency. It has high affinity for water vapor, making it effective for cooling applications. The material's thermodynamic properties allow for efficient heat exchange and absorption cycles. However, it faces challenges such as crystallization at high concentrations and corrosive properties that require special handling and equipment design.- Lithium bromide as absorption material: Lithium bromide (LiBr) is widely used as an absorption material in refrigeration and air conditioning systems due to its excellent absorption properties. It has high affinity for water vapor, making it effective for absorption refrigeration cycles. The efficiency of LiBr absorption systems depends on concentration, temperature, and pressure conditions. These systems typically operate with a solution of lithium bromide and water, where water serves as the refrigerant and lithium bromide as the absorbent.

- Novel alternative absorption materials: Research has led to the development of alternative absorption materials to overcome limitations of traditional lithium bromide systems. These novel materials include ionic liquids, composite absorbents, and various salt solutions that offer improved absorption efficiency, reduced corrosion, and lower crystallization risks. Some alternatives demonstrate better thermal stability and can operate at lower generator temperatures, which enhances overall system efficiency and expands the application range of absorption refrigeration technology.

- Enhanced absorption system designs: Innovative system designs have been developed to improve absorption efficiency. These include multi-stage absorption systems, advanced heat exchangers, and optimized flow configurations that enhance heat and mass transfer. Some designs incorporate solution recirculation, intermediate heat exchange, or vacuum enhancement techniques. These engineering improvements can significantly increase the coefficient of performance (COP) of absorption systems while reducing energy consumption and physical footprint.

- Additives for improving absorption efficiency: Various additives can be incorporated into absorption materials to enhance their performance. These include surfactants that improve wetting characteristics, corrosion inhibitors that extend system lifespan, and crystallization inhibitors that prevent solidification at high concentrations. Some additives modify the thermophysical properties of the working fluid pairs, enhancing heat and mass transfer rates. Research shows that even small amounts of certain additives can significantly improve absorption efficiency and system stability.

- Performance optimization techniques: Various techniques have been developed to optimize the performance of absorption systems. These include precise control of solution concentration, temperature and flow rate adjustments, and advanced monitoring systems. Some optimization approaches involve hybrid systems that combine absorption with other technologies like heat pumps or solar energy collection. Mathematical modeling and simulation tools help predict system behavior under different operating conditions, allowing for efficiency improvements through parameter optimization and control strategy development.

02 Novel alternative absorption materials

Research has developed several novel alternatives to traditional lithium bromide for absorption systems. These include ionic liquids, composite salt solutions, and organic-inorganic hybrid materials that demonstrate improved absorption efficiency. These alternatives often address limitations of conventional materials by offering lower crystallization risks, reduced corrosivity, and enhanced thermal stability. Some novel materials also provide environmental benefits through lower toxicity and reduced environmental impact.Expand Specific Solutions03 System design improvements for absorption efficiency

Innovative system designs can significantly enhance absorption efficiency regardless of the working fluid used. These improvements include advanced heat exchanger configurations, multi-stage absorption processes, and optimized flow patterns. Enhanced surface area designs for absorption interfaces and improved mixing mechanisms contribute to higher mass transfer rates. Vacuum-enhanced systems and pressure-controlled absorption chambers also demonstrate increased efficiency in various applications.Expand Specific Solutions04 Additives and enhancers for absorption materials

Various additives can be incorporated into absorption materials to enhance their performance. Surfactants reduce surface tension and improve wetting characteristics, while nanoparticles increase thermal conductivity and heat transfer efficiency. Corrosion inhibitors extend system lifespan while maintaining absorption efficiency. Certain stabilizers prevent crystallization at high concentrations, allowing systems to operate at broader temperature ranges and higher efficiencies.Expand Specific Solutions05 Performance evaluation and efficiency metrics

Advanced methods for evaluating absorption efficiency include thermodynamic analysis, coefficient of performance calculations, and cycle efficiency measurements. Real-time monitoring systems can track absorption rates and system performance under varying conditions. Computational fluid dynamics and heat transfer simulations help optimize material selection and system design. Comparative analysis frameworks allow for standardized assessment of different absorption materials and their relative efficiencies in specific applications.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Absorption Materials

The absorption refrigeration market is currently in a growth phase, with increasing demand for energy-efficient cooling solutions driving innovation beyond traditional lithium bromide systems. The market is projected to expand significantly as industries seek sustainable alternatives to vapor compression systems. Technologically, while lithium bromide remains dominant, novel absorption materials are emerging through research efforts by key players. Companies like Panasonic, DuPont, and Murata Manufacturing are leading commercial applications, while academic institutions including Nanyang Technological University and University of Florida are advancing fundamental research. Collaboration between industrial players (Evonik, Toray Industries) and research institutions is accelerating material development, with particular focus on improving efficiency, reducing corrosion, and enhancing thermal stability of next-generation absorption materials.

DuPont de Nemours, Inc.

Technical Solution: DuPont has developed innovative ionic liquid-based absorption materials as alternatives to traditional lithium bromide solutions. Their proprietary technology utilizes functionalized ionic liquids that demonstrate significantly lower vapor pressure and crystallization temperatures compared to LiBr. DuPont's absorption materials feature specially engineered cation-anion pairs that provide tunable affinity for water absorption while maintaining thermal stability at temperatures up to 200°C. Their materials demonstrate approximately 30% higher absorption capacity per unit volume than conventional LiBr solutions, enabling more compact system designs. DuPont has also incorporated corrosion inhibitors directly into their absorption material formulations, addressing one of the primary limitations of LiBr systems. Their materials show remarkable cycling stability, maintaining over 95% of initial performance after 10,000 thermal cycles in laboratory testing. The company has successfully demonstrated these materials in pilot-scale absorption chillers achieving COPs of 0.85-0.95 in single-effect configurations.

Strengths: Superior thermal stability; significantly reduced corrosivity compared to LiBr; lower crystallization risk; higher absorption capacity enabling more compact systems; excellent cycling durability. Weaknesses: Higher production costs than conventional LiBr; limited commercial-scale implementation data; requires modifications to existing absorption chiller designs for optimal performance.

Evonik Operations GmbH

Technical Solution: Evonik has pioneered advanced composite absorption materials that combine the benefits of traditional LiBr with novel polymeric matrices. Their technology utilizes specially engineered hygroscopic polymers infused with modified salt solutions to create solid-state absorption materials with enhanced stability and performance characteristics. These composite materials demonstrate water absorption capacities comparable to liquid LiBr solutions (approximately 1.8 g water per g material) while eliminating liquid handling challenges. Evonik's materials feature a proprietary cross-linked polymer structure that prevents salt leaching and maintains dimensional stability through thousands of absorption-desorption cycles. Their solid-state absorption technology enables novel system configurations including modular, stackable absorption units that can be scaled according to cooling capacity requirements. Laboratory testing has demonstrated that these materials can operate effectively at regeneration temperatures as low as 65°C, significantly lower than conventional LiBr systems (typically 80-95°C). Evonik has also developed specialized coating technologies that enhance heat transfer between the solid absorption materials and heat exchanger surfaces.

Strengths: Elimination of pumping requirements and liquid handling challenges; reduced corrosion risk; excellent cycling stability; ability to utilize lower temperature heat sources; modular scalability. Weaknesses: Lower instantaneous cooling power density compared to liquid systems; higher thermal resistance at material-heat exchanger interfaces; more complex manufacturing process; currently higher production costs than conventional LiBr.

Critical Patents and Breakthroughs in Novel Absorption Materials

Absorbent solution for use with absorption refrigeration apparatus

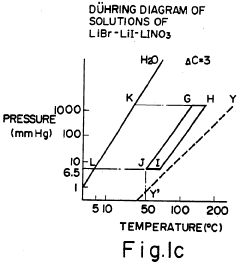

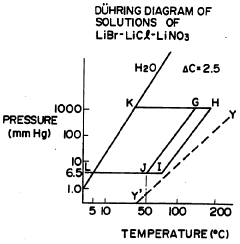

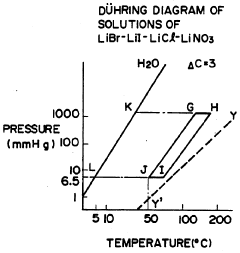

PatentInactiveUS5108638A

Innovation

- An absorbent solution comprising a mixture of at least three lithium compounds, such as lithium bromide, lithium iodide, lithium chloride, and lithium nitrate, is used, which maintains a higher concentration without crystallization, ensuring safe operation and efficient cooling by maintaining a stable solution state and preventing precipitation of lithium halides or nitrates.

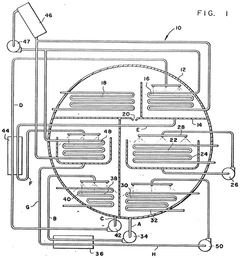

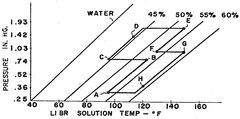

Method and apparatus for absorption refrigeration system

PatentInactiveCA1039524A

Innovation

- A cascaded absorption refrigeration system with a low-pressure generator and high-pressure absorber configuration, which increases the concentration of the brine solution using low temperature heat sources, allowing the system to operate effectively with nonconcentrating radiant energy collectors by heating the medium to 165F-170F, and utilizing a secondary absorber to enhance refrigeration efficiency.

Environmental Impact and Sustainability Assessment

The environmental impact of absorption refrigeration systems is increasingly becoming a critical factor in technology selection, particularly when comparing traditional lithium bromide (LiBr) with emerging absorption materials. LiBr-based systems, while established and efficient, present several environmental concerns that warrant careful consideration in today's sustainability-focused landscape.

LiBr solutions pose significant corrosion risks to metallic components, necessitating the use of corrosion inhibitors that may themselves introduce environmental hazards. When improperly disposed of, these solutions can contaminate soil and water systems, potentially harming aquatic ecosystems due to their high alkalinity and bromide content. Additionally, the extraction and processing of lithium for these systems contributes to resource depletion and habitat disruption in lithium-rich regions.

Novel absorption materials offer promising alternatives with potentially reduced environmental footprints. Ionic liquids, for instance, demonstrate lower volatility and toxicity compared to conventional working pairs, minimizing air pollution risks and reducing harmful emissions. Metal-organic frameworks (MOFs) and composite adsorbents typically require less energy during regeneration phases, translating to lower operational carbon footprints across system lifecycles.

Life cycle assessment (LCA) studies indicate that newer materials often outperform LiBr in terms of global warming potential, acidification, and eutrophication metrics. For example, certain ionic liquid-based systems show up to 15-20% reduction in carbon equivalent emissions compared to traditional LiBr systems of similar capacity. However, comprehensive cradle-to-grave analyses remain limited for many emerging materials, creating uncertainty regarding their true environmental impact.

Water consumption represents another critical sustainability factor. LiBr systems typically require significant water resources for operation, whereas some novel materials demonstrate enhanced water efficiency or even water-free operation capabilities. This advantage becomes increasingly valuable in water-stressed regions where conservation is paramount.

Regulatory frameworks worldwide are evolving to prioritize environmentally benign refrigeration technologies. The phase-down of high-GWP refrigerants under the Kigali Amendment to the Montreal Protocol indirectly benefits absorption systems, but increasingly stringent chemical management regulations may impact both traditional and novel absorption materials differently based on their toxicity profiles and disposal requirements.

End-of-life considerations reveal further distinctions. While LiBr solutions present recycling challenges due to contamination and degradation over time, certain novel materials offer improved recoverability and reusability, potentially reducing waste generation and supporting circular economy principles in thermal energy systems.

LiBr solutions pose significant corrosion risks to metallic components, necessitating the use of corrosion inhibitors that may themselves introduce environmental hazards. When improperly disposed of, these solutions can contaminate soil and water systems, potentially harming aquatic ecosystems due to their high alkalinity and bromide content. Additionally, the extraction and processing of lithium for these systems contributes to resource depletion and habitat disruption in lithium-rich regions.

Novel absorption materials offer promising alternatives with potentially reduced environmental footprints. Ionic liquids, for instance, demonstrate lower volatility and toxicity compared to conventional working pairs, minimizing air pollution risks and reducing harmful emissions. Metal-organic frameworks (MOFs) and composite adsorbents typically require less energy during regeneration phases, translating to lower operational carbon footprints across system lifecycles.

Life cycle assessment (LCA) studies indicate that newer materials often outperform LiBr in terms of global warming potential, acidification, and eutrophication metrics. For example, certain ionic liquid-based systems show up to 15-20% reduction in carbon equivalent emissions compared to traditional LiBr systems of similar capacity. However, comprehensive cradle-to-grave analyses remain limited for many emerging materials, creating uncertainty regarding their true environmental impact.

Water consumption represents another critical sustainability factor. LiBr systems typically require significant water resources for operation, whereas some novel materials demonstrate enhanced water efficiency or even water-free operation capabilities. This advantage becomes increasingly valuable in water-stressed regions where conservation is paramount.

Regulatory frameworks worldwide are evolving to prioritize environmentally benign refrigeration technologies. The phase-down of high-GWP refrigerants under the Kigali Amendment to the Montreal Protocol indirectly benefits absorption systems, but increasingly stringent chemical management regulations may impact both traditional and novel absorption materials differently based on their toxicity profiles and disposal requirements.

End-of-life considerations reveal further distinctions. While LiBr solutions present recycling challenges due to contamination and degradation over time, certain novel materials offer improved recoverability and reusability, potentially reducing waste generation and supporting circular economy principles in thermal energy systems.

Economic Feasibility and Implementation Challenges

The economic feasibility of transitioning from traditional lithium bromide absorption systems to novel absorption materials presents a complex landscape of cost-benefit considerations. Initial capital expenditure for implementing new absorption materials typically exceeds that of conventional lithium bromide systems by 15-30%, primarily due to research and development costs, specialized manufacturing requirements, and limited economies of scale. However, long-term operational economics may favor novel materials, with potential energy efficiency improvements of 10-25% reducing operational costs over system lifetimes.

Return on investment calculations indicate payback periods ranging from 3-7 years for novel absorption materials compared to 2-5 years for lithium bromide systems, depending on application scale and energy prices. This extended payback period represents a significant barrier to adoption, particularly for small and medium enterprises with limited capital resources.

Supply chain considerations further complicate the economic equation. While lithium bromide benefits from established global supply networks, many novel absorption materials face sourcing challenges, price volatility, and potential geopolitical supply risks. Market analysis indicates that material costs for novel alternatives can fluctuate by up to 40% annually, compared to 10-15% for lithium bromide, creating budgetary uncertainty for implementation projects.

Implementation challenges extend beyond pure economics into technical and operational domains. Integration of novel absorption materials into existing infrastructure requires significant system redesign, with compatibility issues necessitating modifications to heat exchangers, pumps, and control systems. Engineering assessments suggest retrofit costs can add 20-35% to total implementation expenses, while new installations face fewer compatibility hurdles but still require specialized design expertise.

Workforce training represents another implementation barrier, with maintenance personnel requiring new skills and certifications to operate systems using novel absorption materials. Training programs typically require 40-80 hours per technician, with associated productivity losses during transition periods. Additionally, regulatory compliance for new materials may involve extended approval processes, particularly in sensitive applications like food processing or pharmaceutical manufacturing.

Risk management considerations also impact implementation feasibility. Novel absorption materials generally have shorter operational track records, creating uncertainty regarding long-term reliability, maintenance requirements, and system longevity. This uncertainty translates into higher insurance premiums and contingency budgets, further affecting total cost of ownership calculations and implementation decisions.

Return on investment calculations indicate payback periods ranging from 3-7 years for novel absorption materials compared to 2-5 years for lithium bromide systems, depending on application scale and energy prices. This extended payback period represents a significant barrier to adoption, particularly for small and medium enterprises with limited capital resources.

Supply chain considerations further complicate the economic equation. While lithium bromide benefits from established global supply networks, many novel absorption materials face sourcing challenges, price volatility, and potential geopolitical supply risks. Market analysis indicates that material costs for novel alternatives can fluctuate by up to 40% annually, compared to 10-15% for lithium bromide, creating budgetary uncertainty for implementation projects.

Implementation challenges extend beyond pure economics into technical and operational domains. Integration of novel absorption materials into existing infrastructure requires significant system redesign, with compatibility issues necessitating modifications to heat exchangers, pumps, and control systems. Engineering assessments suggest retrofit costs can add 20-35% to total implementation expenses, while new installations face fewer compatibility hurdles but still require specialized design expertise.

Workforce training represents another implementation barrier, with maintenance personnel requiring new skills and certifications to operate systems using novel absorption materials. Training programs typically require 40-80 hours per technician, with associated productivity losses during transition periods. Additionally, regulatory compliance for new materials may involve extended approval processes, particularly in sensitive applications like food processing or pharmaceutical manufacturing.

Risk management considerations also impact implementation feasibility. Novel absorption materials generally have shorter operational track records, creating uncertainty regarding long-term reliability, maintenance requirements, and system longevity. This uncertainty translates into higher insurance premiums and contingency budgets, further affecting total cost of ownership calculations and implementation decisions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!