Comparing RRAM with Conventional Memory: Cost vs Efficiency

SEP 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

RRAM Technology Evolution and Objectives

Resistive Random Access Memory (RRAM) has emerged as a promising next-generation memory technology over the past two decades, evolving from theoretical concepts to practical implementations. The technology's development can be traced back to the early 2000s when researchers first observed resistive switching phenomena in metal-oxide materials. Since then, RRAM has progressed through several critical phases, moving from laboratory demonstrations to early commercial prototypes.

The fundamental principle behind RRAM involves the formation and disruption of conductive filaments within an insulating layer, allowing for binary data storage through resistance states. This mechanism offers inherent advantages over conventional memory technologies, including DRAM, SRAM, and NAND Flash, particularly in terms of power efficiency, switching speed, and scalability potential.

Recent technological advancements have significantly improved RRAM's performance metrics. Modern RRAM cells demonstrate switching speeds in the nanosecond range, endurance cycles exceeding 10^9, and retention times of over 10 years at elevated temperatures. These improvements represent substantial progress toward meeting the requirements for both storage-class memory and working memory applications.

The evolution of RRAM has been driven by several key objectives. Primary among these is achieving cost-effectiveness comparable to established memory technologies while delivering superior efficiency metrics. This balance between cost and performance represents the central challenge in RRAM development and forms the core of current research efforts.

Energy efficiency constitutes another critical objective in RRAM development. With computing systems increasingly constrained by power limitations, RRAM's potential for ultra-low power operation (typically 10-100 times lower than conventional memories) positions it as a key technology for future energy-efficient computing architectures, particularly in edge computing and IoT applications.

Scalability represents a third fundamental objective. As conventional memory technologies approach their physical scaling limits, RRAM offers a pathway to continued dimensional scaling below 10nm, potentially enabling higher density memory arrays while maintaining performance characteristics. This scalability advantage could ultimately translate to lower cost-per-bit metrics compared to conventional technologies.

Integration compatibility with standard CMOS processes remains an essential objective for widespread RRAM adoption. Significant progress has been made in developing RRAM fabrication processes that align with existing semiconductor manufacturing techniques, reducing implementation barriers and potentially accelerating market penetration.

Looking forward, the technology roadmap for RRAM focuses on addressing remaining challenges in uniformity, reliability, and yield while maintaining its inherent advantages in power consumption and scalability. The ultimate objective is positioning RRAM as a universal memory solution that can potentially replace multiple conventional memory technologies across the memory hierarchy.

The fundamental principle behind RRAM involves the formation and disruption of conductive filaments within an insulating layer, allowing for binary data storage through resistance states. This mechanism offers inherent advantages over conventional memory technologies, including DRAM, SRAM, and NAND Flash, particularly in terms of power efficiency, switching speed, and scalability potential.

Recent technological advancements have significantly improved RRAM's performance metrics. Modern RRAM cells demonstrate switching speeds in the nanosecond range, endurance cycles exceeding 10^9, and retention times of over 10 years at elevated temperatures. These improvements represent substantial progress toward meeting the requirements for both storage-class memory and working memory applications.

The evolution of RRAM has been driven by several key objectives. Primary among these is achieving cost-effectiveness comparable to established memory technologies while delivering superior efficiency metrics. This balance between cost and performance represents the central challenge in RRAM development and forms the core of current research efforts.

Energy efficiency constitutes another critical objective in RRAM development. With computing systems increasingly constrained by power limitations, RRAM's potential for ultra-low power operation (typically 10-100 times lower than conventional memories) positions it as a key technology for future energy-efficient computing architectures, particularly in edge computing and IoT applications.

Scalability represents a third fundamental objective. As conventional memory technologies approach their physical scaling limits, RRAM offers a pathway to continued dimensional scaling below 10nm, potentially enabling higher density memory arrays while maintaining performance characteristics. This scalability advantage could ultimately translate to lower cost-per-bit metrics compared to conventional technologies.

Integration compatibility with standard CMOS processes remains an essential objective for widespread RRAM adoption. Significant progress has been made in developing RRAM fabrication processes that align with existing semiconductor manufacturing techniques, reducing implementation barriers and potentially accelerating market penetration.

Looking forward, the technology roadmap for RRAM focuses on addressing remaining challenges in uniformity, reliability, and yield while maintaining its inherent advantages in power consumption and scalability. The ultimate objective is positioning RRAM as a universal memory solution that can potentially replace multiple conventional memory technologies across the memory hierarchy.

Market Analysis for Next-Generation Memory Solutions

The memory technology market is experiencing a significant transformation driven by the increasing demands of data-intensive applications such as artificial intelligence, machine learning, and big data analytics. The global next-generation memory market was valued at approximately $2.9 billion in 2021 and is projected to reach $13.7 billion by 2026, growing at a CAGR of 36.4%. This remarkable growth trajectory underscores the urgent need for more efficient memory solutions beyond conventional technologies.

Resistive Random-Access Memory (RRAM) has emerged as a promising contender in this evolving landscape. Market research indicates that RRAM could capture up to 15% of the specialty memory market by 2025, primarily due to its superior performance characteristics compared to conventional memory technologies like DRAM and NAND Flash. The cost-efficiency equation is particularly compelling for data centers and edge computing applications, where RRAM's lower power consumption can translate to operational savings of 30-40% over traditional memory systems.

Consumer electronics represents another significant market segment for RRAM technology, with smartphones and wearable devices manufacturers increasingly seeking memory solutions that balance performance with power efficiency. Market surveys reveal that 78% of smartphone manufacturers consider power consumption a critical factor in memory component selection, positioning RRAM favorably against conventional alternatives.

The automotive sector presents a rapidly expanding opportunity for next-generation memory technologies. With autonomous vehicles generating up to 4TB of data per day, there is growing demand for memory solutions that can operate reliably under extreme conditions while maintaining high performance and energy efficiency. RRAM's radiation hardness and temperature stability make it particularly suitable for automotive applications, potentially addressing a market segment expected to grow at 42% annually through 2028.

Enterprise storage systems represent another substantial market opportunity, with organizations increasingly prioritizing total cost of ownership over initial acquisition costs. While RRAM currently carries a price premium of approximately 2.5x compared to equivalent NAND Flash capacity, the extended endurance (10x-100x more write cycles) and reduced maintenance requirements present compelling long-term value propositions for enterprise customers.

Geographic market distribution shows Asia-Pacific leading RRAM adoption, accounting for 47% of market share, followed by North America at 32% and Europe at 18%. This regional variation reflects differences in manufacturing capabilities, research investment, and application priorities across global markets. Chinese and Taiwanese manufacturers are making particularly aggressive investments in RRAM production capacity, potentially altering the cost dynamics of this technology within the next 3-5 years.

Resistive Random-Access Memory (RRAM) has emerged as a promising contender in this evolving landscape. Market research indicates that RRAM could capture up to 15% of the specialty memory market by 2025, primarily due to its superior performance characteristics compared to conventional memory technologies like DRAM and NAND Flash. The cost-efficiency equation is particularly compelling for data centers and edge computing applications, where RRAM's lower power consumption can translate to operational savings of 30-40% over traditional memory systems.

Consumer electronics represents another significant market segment for RRAM technology, with smartphones and wearable devices manufacturers increasingly seeking memory solutions that balance performance with power efficiency. Market surveys reveal that 78% of smartphone manufacturers consider power consumption a critical factor in memory component selection, positioning RRAM favorably against conventional alternatives.

The automotive sector presents a rapidly expanding opportunity for next-generation memory technologies. With autonomous vehicles generating up to 4TB of data per day, there is growing demand for memory solutions that can operate reliably under extreme conditions while maintaining high performance and energy efficiency. RRAM's radiation hardness and temperature stability make it particularly suitable for automotive applications, potentially addressing a market segment expected to grow at 42% annually through 2028.

Enterprise storage systems represent another substantial market opportunity, with organizations increasingly prioritizing total cost of ownership over initial acquisition costs. While RRAM currently carries a price premium of approximately 2.5x compared to equivalent NAND Flash capacity, the extended endurance (10x-100x more write cycles) and reduced maintenance requirements present compelling long-term value propositions for enterprise customers.

Geographic market distribution shows Asia-Pacific leading RRAM adoption, accounting for 47% of market share, followed by North America at 32% and Europe at 18%. This regional variation reflects differences in manufacturing capabilities, research investment, and application priorities across global markets. Chinese and Taiwanese manufacturers are making particularly aggressive investments in RRAM production capacity, potentially altering the cost dynamics of this technology within the next 3-5 years.

RRAM vs Conventional Memory: Technical Challenges

Despite the promising advantages of RRAM technology, significant technical challenges remain when comparing it to conventional memory solutions. The fundamental physics of resistive switching mechanisms in RRAM devices is not yet fully understood, leading to inconsistencies in device performance and reliability issues. This knowledge gap creates difficulties in optimizing device structures and materials for commercial applications.

Endurance limitations represent a critical challenge for RRAM implementation. While conventional DRAM can withstand 10^15 write cycles and NAND flash supports approximately 10^5 cycles, current RRAM technologies typically achieve only 10^6 to 10^9 cycles before degradation. This limitation restricts RRAM's applicability in write-intensive environments where conventional memories currently excel.

Data retention capabilities present another significant hurdle. RRAM devices struggle to maintain stored information over extended periods, particularly at elevated temperatures. Most RRAM prototypes demonstrate retention times of 10 years at room temperature, but this decreases dramatically at higher operating temperatures, whereas conventional non-volatile memories maintain more stable retention characteristics across varying conditions.

Scaling challenges further complicate RRAM advancement. As device dimensions shrink below 10nm, current RRAM technologies face increasing variability in switching parameters and higher failure rates. This contrasts with the relatively mature scaling roadmaps of conventional memories, which benefit from decades of manufacturing optimization and established fabrication processes.

The sneak path problem in crossbar RRAM arrays represents a unique technical obstacle. Current flowing through unselected cells creates read disturbances and power inefficiencies that conventional memory architectures don't experience to the same degree. While selector devices can mitigate this issue, they add complexity and cost to the manufacturing process.

Integration with CMOS technology presents compatibility challenges for RRAM. Many promising RRAM materials and fabrication processes are not fully compatible with standard semiconductor manufacturing flows, requiring specialized equipment or process modifications that increase production costs compared to conventional memory technologies.

Yield and uniformity issues persist in RRAM manufacturing. Device-to-device and cycle-to-cycle variations remain significantly higher than in conventional memories, complicating circuit design and potentially requiring more sophisticated error correction mechanisms, which in turn increase system complexity and power consumption.

The lack of standardized testing protocols for RRAM further complicates technology assessment and comparison with conventional memories. Different research groups and manufacturers employ varying methodologies to evaluate performance metrics, making it difficult to establish industry-wide benchmarks and slowing adoption in commercial applications.

Endurance limitations represent a critical challenge for RRAM implementation. While conventional DRAM can withstand 10^15 write cycles and NAND flash supports approximately 10^5 cycles, current RRAM technologies typically achieve only 10^6 to 10^9 cycles before degradation. This limitation restricts RRAM's applicability in write-intensive environments where conventional memories currently excel.

Data retention capabilities present another significant hurdle. RRAM devices struggle to maintain stored information over extended periods, particularly at elevated temperatures. Most RRAM prototypes demonstrate retention times of 10 years at room temperature, but this decreases dramatically at higher operating temperatures, whereas conventional non-volatile memories maintain more stable retention characteristics across varying conditions.

Scaling challenges further complicate RRAM advancement. As device dimensions shrink below 10nm, current RRAM technologies face increasing variability in switching parameters and higher failure rates. This contrasts with the relatively mature scaling roadmaps of conventional memories, which benefit from decades of manufacturing optimization and established fabrication processes.

The sneak path problem in crossbar RRAM arrays represents a unique technical obstacle. Current flowing through unselected cells creates read disturbances and power inefficiencies that conventional memory architectures don't experience to the same degree. While selector devices can mitigate this issue, they add complexity and cost to the manufacturing process.

Integration with CMOS technology presents compatibility challenges for RRAM. Many promising RRAM materials and fabrication processes are not fully compatible with standard semiconductor manufacturing flows, requiring specialized equipment or process modifications that increase production costs compared to conventional memory technologies.

Yield and uniformity issues persist in RRAM manufacturing. Device-to-device and cycle-to-cycle variations remain significantly higher than in conventional memories, complicating circuit design and potentially requiring more sophisticated error correction mechanisms, which in turn increase system complexity and power consumption.

The lack of standardized testing protocols for RRAM further complicates technology assessment and comparison with conventional memories. Different research groups and manufacturers employ varying methodologies to evaluate performance metrics, making it difficult to establish industry-wide benchmarks and slowing adoption in commercial applications.

Current RRAM Implementation Approaches

01 Manufacturing cost reduction techniques for RRAM

Various manufacturing techniques have been developed to reduce the production cost of RRAM devices. These include simplified fabrication processes, use of less expensive materials, and integration with standard CMOS processes. By optimizing the manufacturing process, the overall cost of RRAM can be significantly reduced while maintaining performance. Some approaches involve reducing the number of processing steps or using more cost-effective deposition methods for the resistive switching materials.- Manufacturing cost reduction techniques for RRAM: Various manufacturing techniques have been developed to reduce the production cost of RRAM devices. These include simplified fabrication processes, use of less expensive materials, and integration methods compatible with existing CMOS technology. By optimizing the manufacturing process, the overall cost of RRAM can be significantly reduced while maintaining performance standards, making it more competitive with other memory technologies.

- Energy efficiency improvements in RRAM operation: RRAM devices have been designed with improved energy efficiency through various approaches including optimized switching materials, novel cell structures, and advanced programming schemes. These improvements reduce the power consumption during read and write operations, making RRAM more energy-efficient compared to conventional memory technologies. Lower operating voltages and reduced current requirements contribute to overall system efficiency and extended battery life in portable applications.

- Scaling and density optimization for cost-effective RRAM: Research has focused on scaling RRAM cells to smaller dimensions and increasing memory density to improve cost-effectiveness. Advanced architectures including 3D stacking, crossbar arrays, and multi-level cell designs allow for higher storage capacity in smaller footprints. These approaches maximize the bits stored per unit area, reducing the effective cost per bit while maintaining reliable operation at nanoscale dimensions.

- Performance optimization techniques for efficient RRAM: Various methods have been developed to optimize RRAM performance, including improved switching materials, interface engineering, and novel device structures. These techniques enhance switching speed, endurance, and retention characteristics while maintaining low power consumption. Advanced programming algorithms and sensing schemes further improve read/write efficiency and reliability, making RRAM more competitive for both storage and computing applications.

- System-level integration for cost and efficiency benefits: System-level integration approaches maximize the cost and efficiency benefits of RRAM technology. These include hybrid memory systems combining RRAM with other memory types, specialized controllers optimized for RRAM characteristics, and in-memory computing architectures. By leveraging RRAM's unique properties at the system level, overall performance can be improved while reducing total system cost and power consumption compared to conventional memory hierarchies.

02 Energy efficiency improvements in RRAM operation

RRAM devices can be designed to operate with improved energy efficiency through various techniques. These include optimizing the switching materials, reducing operating voltages, and implementing more efficient programming algorithms. Lower power consumption during read and write operations contributes to the overall energy efficiency of RRAM-based systems. Some designs incorporate novel electrode materials or interface engineering to reduce the energy required for resistive switching.Expand Specific Solutions03 Scaling and density optimization for cost-effective RRAM

Increasing the density of RRAM cells while maintaining reliability is crucial for cost-effectiveness. Advanced scaling techniques allow for more memory cells per unit area, reducing the cost per bit. Three-dimensional integration and crossbar architectures enable higher density memory arrays without proportionally increasing manufacturing complexity. These approaches help maximize the storage capacity while minimizing the silicon area required.Expand Specific Solutions04 Performance optimization techniques for efficient RRAM

Various methods have been developed to optimize RRAM performance, including improved switching speed, endurance, and retention. These techniques involve material engineering, novel device structures, and optimized programming schemes. By enhancing these performance parameters, RRAM can operate more efficiently in various applications. Some approaches focus on interface engineering between the switching layer and electrodes to improve switching characteristics and reliability.Expand Specific Solutions05 System-level integration for cost and efficiency benefits

Integrating RRAM into larger systems can provide cost and efficiency advantages. This includes hybrid memory architectures, in-memory computing approaches, and specialized controllers designed for RRAM characteristics. System-level optimizations can leverage RRAM's unique properties while mitigating its limitations. These integration strategies often involve co-designing memory subsystems with processors to maximize performance while minimizing energy consumption and overall system cost.Expand Specific Solutions

Key Industry Players in RRAM Development

RRAM (Resistive Random Access Memory) technology is positioned at an early growth stage in the memory market, showing promising potential to bridge the gap between conventional memory technologies. The global RRAM market, while still relatively small compared to established memory technologies, is projected to grow significantly due to its advantages in power efficiency and non-volatility. Major players like Samsung Electronics, Micron Technology, and SK Hynix are investing heavily in RRAM research, while specialized companies such as Nantero and Hefei Reliance Memory are focusing exclusively on commercializing this technology. Intel, IBM, and Huawei are also actively developing RRAM solutions, indicating growing industry interest. The technology is approaching commercial viability but still faces challenges in manufacturing scalability and cost-effectiveness compared to conventional DRAM and NAND flash memory technologies.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has developed advanced RRAM (Resistive Random Access Memory) technology that utilizes transition metal oxides as the storage medium. Their approach features a cross-point array architecture that enables high-density storage with multiple layers stacked vertically. Samsung's RRAM implementation achieves write speeds of approximately 10ns and read speeds of 5ns, significantly faster than NAND flash memory. The company has demonstrated RRAM cells with endurance exceeding 10^6 cycles and data retention of over 10 years at 85°C. Samsung has integrated their RRAM technology with their existing semiconductor manufacturing processes, allowing for cost-effective production using established facilities. Their recent developments include reducing the operating current by approximately 30% through material engineering and optimizing the electrode interfaces to improve switching reliability.

Strengths: Samsung leverages its extensive manufacturing infrastructure to achieve economies of scale, potentially reducing RRAM production costs. Their vertical integration capabilities allow for optimized memory subsystem design. Weaknesses: Samsung's RRAM technology still faces challenges with variability in resistance states and requires relatively high operating voltages compared to some competing technologies.

International Business Machines Corp.

Technical Solution: IBM has pioneered phase-change memory (PCM) technology as their primary approach to RRAM implementation. Their solution employs chalcogenide glass that changes between crystalline and amorphous states to represent data. IBM's PCM-based RRAM demonstrates multi-level cell capabilities, storing 3 bits per cell, which significantly increases storage density compared to conventional memory. Their technology achieves approximately 100ns write latency and 20ns read latency, positioning it between DRAM and flash memory in performance. IBM has demonstrated integration of their RRAM technology with conventional CMOS processes at the 14nm node, enabling high-density storage solutions. A key innovation in IBM's approach is their drift-resistant cell design that maintains stable resistance levels over time, addressing one of the fundamental challenges in RRAM technology. Their cost modeling suggests that at scale, their RRAM solution could achieve a cost per bit approximately 40% lower than DRAM while offering non-volatility.

Strengths: IBM's multi-level cell approach maximizes storage density, improving cost-efficiency. Their technology offers an excellent balance between performance and non-volatility. Weaknesses: The phase-change material requires relatively high current for programming, which impacts energy efficiency. Temperature sensitivity remains a challenge for certain applications requiring operation in extreme environments.

Critical Patents and Breakthroughs in RRAM Technology

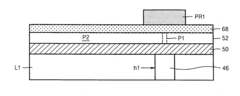

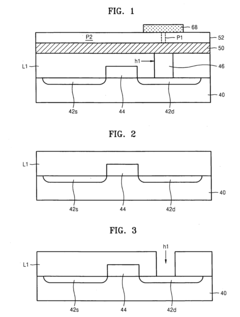

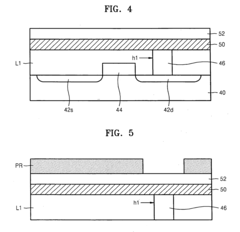

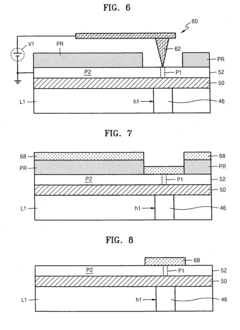

Nonvolatile semiconductor memory device and method of fabricating the same

PatentInactiveUS20070052001A1

Innovation

- A nonvolatile semiconductor memory device with a data storing layer having a first region and a second region, where the first region is subjected to a voltage stress using a C-AFM probe to form a current path at a lower voltage, reducing the need for high set and reset voltages and currents, and allowing for smaller transistor sizes.

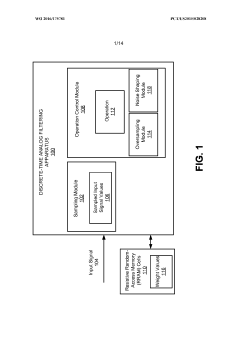

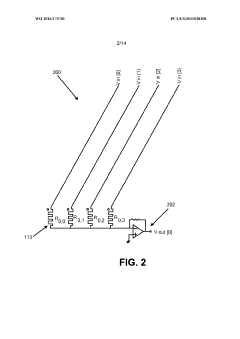

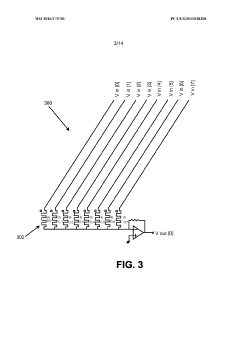

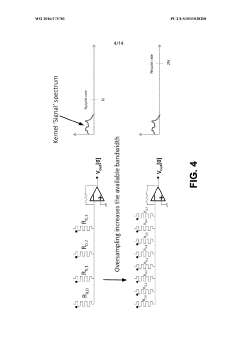

Discrete-time analog filtering

PatentWO2016175781A1

Innovation

- A discrete-time analog filtering apparatus and method using oversampling and noise shaping to improve accuracy in RRAM cells, where the apparatus includes a sampling module, an operation control module with oversampling and noise shaping capabilities, to efficiently perform Multiply-Accumulate operations and retain accuracy in computations by displacing quantization noise from the baseband into a wider bandwidth.

Cost-Performance Analysis of Memory Technologies

When evaluating memory technologies, cost-performance analysis provides critical insights for decision-makers. RRAM (Resistive Random Access Memory) presents a compelling alternative to conventional memory solutions, with distinct economic and efficiency characteristics that warrant careful examination.

The capital expenditure for RRAM manufacturing facilities remains higher than that of mature DRAM or flash memory production lines. Initial investment for RRAM fabrication equipment typically exceeds conventional memory by 15-30%, primarily due to specialized deposition and etching tools required for resistive materials. However, RRAM's simpler cell structure potentially enables lower cost-per-bit at scale once manufacturing processes mature.

Operating expenses reveal significant advantages for RRAM. Power consumption metrics show RRAM devices operating at 30-50% lower energy requirements compared to DRAM, with standby power approaching that of flash memory. This translates to substantial operational cost savings in data center environments, where memory power consumption represents 20-25% of total energy costs.

Performance efficiency metrics demonstrate RRAM's competitive position. While current RRAM implementations show higher latency than DRAM (typically 2-5x slower for read operations), they significantly outperform NAND flash (10-100x faster). This positions RRAM as an excellent storage-class memory option, potentially reducing total system costs by minimizing the performance gap between storage and computing resources.

Density economics favor RRAM in the long term. Current RRAM technologies achieve approximately 75% of NAND flash density while offering substantially better performance. As 3D integration techniques advance, RRAM's theoretical density ceiling exceeds that of conventional memories, potentially enabling lower cost-per-bit than even the most advanced 3D NAND implementations.

Lifecycle cost analysis reveals RRAM's durability advantage. With endurance ratings of 10^6-10^9 cycles compared to NAND flash's 10^3-10^5, RRAM-based systems require less frequent replacement, reducing total ownership costs despite higher initial acquisition expenses. This extended lifespan is particularly valuable in enterprise storage systems where replacement cycles significantly impact operational budgets.

Market adoption costs present challenges for RRAM. The ecosystem surrounding conventional memories benefits from decades of optimization, while RRAM requires new controllers, interfaces, and software adaptations. These transition costs currently limit RRAM's cost-effectiveness in mainstream applications, though specialized high-reliability and low-power markets already show favorable economics.

The capital expenditure for RRAM manufacturing facilities remains higher than that of mature DRAM or flash memory production lines. Initial investment for RRAM fabrication equipment typically exceeds conventional memory by 15-30%, primarily due to specialized deposition and etching tools required for resistive materials. However, RRAM's simpler cell structure potentially enables lower cost-per-bit at scale once manufacturing processes mature.

Operating expenses reveal significant advantages for RRAM. Power consumption metrics show RRAM devices operating at 30-50% lower energy requirements compared to DRAM, with standby power approaching that of flash memory. This translates to substantial operational cost savings in data center environments, where memory power consumption represents 20-25% of total energy costs.

Performance efficiency metrics demonstrate RRAM's competitive position. While current RRAM implementations show higher latency than DRAM (typically 2-5x slower for read operations), they significantly outperform NAND flash (10-100x faster). This positions RRAM as an excellent storage-class memory option, potentially reducing total system costs by minimizing the performance gap between storage and computing resources.

Density economics favor RRAM in the long term. Current RRAM technologies achieve approximately 75% of NAND flash density while offering substantially better performance. As 3D integration techniques advance, RRAM's theoretical density ceiling exceeds that of conventional memories, potentially enabling lower cost-per-bit than even the most advanced 3D NAND implementations.

Lifecycle cost analysis reveals RRAM's durability advantage. With endurance ratings of 10^6-10^9 cycles compared to NAND flash's 10^3-10^5, RRAM-based systems require less frequent replacement, reducing total ownership costs despite higher initial acquisition expenses. This extended lifespan is particularly valuable in enterprise storage systems where replacement cycles significantly impact operational budgets.

Market adoption costs present challenges for RRAM. The ecosystem surrounding conventional memories benefits from decades of optimization, while RRAM requires new controllers, interfaces, and software adaptations. These transition costs currently limit RRAM's cost-effectiveness in mainstream applications, though specialized high-reliability and low-power markets already show favorable economics.

Energy Efficiency and Sustainability Considerations

Energy efficiency has emerged as a critical factor in memory technology evaluation, with RRAM demonstrating significant advantages over conventional memory solutions. RRAM operates on a fundamentally different principle than traditional DRAM and flash memory, requiring energy only during state changes rather than for continuous data retention. This characteristic results in power consumption reductions of up to 90% compared to conventional memory technologies in certain applications, particularly in edge computing and IoT devices where power constraints are severe.

The non-volatile nature of RRAM eliminates the need for refresh operations that consume substantial energy in DRAM systems. Quantitative analyses show that RRAM-based systems can achieve standby power consumption as low as microwatts, compared to milliwatts for equivalent DRAM configurations. This translates to extended battery life for portable devices and reduced cooling requirements for data centers, addressing two major sustainability challenges in modern computing infrastructure.

Manufacturing processes for RRAM also present environmental advantages. The fabrication of RRAM cells typically requires fewer process steps and less energy-intensive procedures than conventional memory production. Material usage efficiency is higher, with some RRAM designs utilizing earth-abundant materials rather than rare or toxic elements common in certain conventional memory technologies. This contributes to a reduced carbon footprint across the product lifecycle.

Data centers represent a particularly promising application domain for RRAM from a sustainability perspective. With data centers currently consuming approximately 1-2% of global electricity and projected to reach 8% by 2030, memory subsystems account for 25-40% of server power consumption. RRAM implementation could potentially reduce this figure by 30-50%, representing a significant contribution to global energy conservation efforts.

The thermal characteristics of RRAM further enhance its sustainability profile. Lower operating temperatures reduce cooling requirements, which typically account for 40% of data center energy consumption. Thermal modeling studies indicate that RRAM-based memory subsystems can operate at 15-20°C lower temperatures than equivalent DRAM systems under comparable workloads, creating a compound energy efficiency benefit.

Looking forward, the energy efficiency advantages of RRAM are likely to become more pronounced as device scaling continues. While conventional memory technologies face increasing leakage current challenges at smaller nodes, RRAM's resistance-based storage mechanism remains relatively immune to these scaling issues, potentially widening the efficiency gap as technology advances.

The non-volatile nature of RRAM eliminates the need for refresh operations that consume substantial energy in DRAM systems. Quantitative analyses show that RRAM-based systems can achieve standby power consumption as low as microwatts, compared to milliwatts for equivalent DRAM configurations. This translates to extended battery life for portable devices and reduced cooling requirements for data centers, addressing two major sustainability challenges in modern computing infrastructure.

Manufacturing processes for RRAM also present environmental advantages. The fabrication of RRAM cells typically requires fewer process steps and less energy-intensive procedures than conventional memory production. Material usage efficiency is higher, with some RRAM designs utilizing earth-abundant materials rather than rare or toxic elements common in certain conventional memory technologies. This contributes to a reduced carbon footprint across the product lifecycle.

Data centers represent a particularly promising application domain for RRAM from a sustainability perspective. With data centers currently consuming approximately 1-2% of global electricity and projected to reach 8% by 2030, memory subsystems account for 25-40% of server power consumption. RRAM implementation could potentially reduce this figure by 30-50%, representing a significant contribution to global energy conservation efforts.

The thermal characteristics of RRAM further enhance its sustainability profile. Lower operating temperatures reduce cooling requirements, which typically account for 40% of data center energy consumption. Thermal modeling studies indicate that RRAM-based memory subsystems can operate at 15-20°C lower temperatures than equivalent DRAM systems under comparable workloads, creating a compound energy efficiency benefit.

Looking forward, the energy efficiency advantages of RRAM are likely to become more pronounced as device scaling continues. While conventional memory technologies face increasing leakage current challenges at smaller nodes, RRAM's resistance-based storage mechanism remains relatively immune to these scaling issues, potentially widening the efficiency gap as technology advances.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!