Comparing RRAM with Universal Memory Technologies

SEP 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

RRAM Evolution and Development Objectives

Resistive Random Access Memory (RRAM) has evolved significantly since its conceptual introduction in the 1960s. The technology gained substantial research momentum in the early 2000s when researchers demonstrated reliable resistive switching behaviors in various metal oxide materials. This marked the beginning of intensive development efforts to position RRAM as a potential universal memory solution that could combine the speed of SRAM, density of DRAM, and non-volatility of flash memory.

The evolution of RRAM has been characterized by several key technological breakthroughs. Initially, simple metal-insulator-metal (MIM) structures demonstrated basic switching capabilities but suffered from poor endurance and reliability. By the mid-2000s, researchers had developed more sophisticated material stacks and doping techniques that significantly improved switching characteristics and reliability. The 2010s saw the emergence of multi-layer RRAM structures and advanced fabrication techniques that further enhanced performance metrics.

A critical milestone in RRAM development was the transition from laboratory demonstrations to commercial prototypes. Companies like Crossbar, Weebit Nano, and Adesto Technologies have made significant progress in scaling RRAM technology for commercial applications. These efforts have focused on addressing key challenges such as reducing operating voltages, improving retention times, and enhancing endurance cycles to meet industry requirements.

The primary development objectives for RRAM technology center around positioning it as a viable universal memory solution. This requires achieving performance metrics that can compete with established memory technologies across multiple dimensions. Specifically, RRAM aims to deliver write speeds below 10ns, retention times exceeding 10 years, endurance cycles greater than 10^12, and power consumption comparable to or better than existing memory technologies.

Another crucial objective is scaling RRAM to advanced technology nodes below 10nm while maintaining performance integrity. This presents significant materials engineering and fabrication challenges that researchers are actively addressing through novel material combinations and innovative device architectures. The industry is particularly focused on developing RRAM solutions that can be manufactured using standard CMOS processes to facilitate integration with existing semiconductor manufacturing infrastructure.

Beyond traditional memory applications, RRAM development objectives have expanded to include neuromorphic computing capabilities. The analog nature of resistive switching makes RRAM particularly suitable for implementing artificial neural networks in hardware. This has opened new development pathways focused on optimizing RRAM for in-memory computing and brain-inspired computing architectures, potentially revolutionizing how computational tasks are performed in next-generation systems.

The evolution of RRAM has been characterized by several key technological breakthroughs. Initially, simple metal-insulator-metal (MIM) structures demonstrated basic switching capabilities but suffered from poor endurance and reliability. By the mid-2000s, researchers had developed more sophisticated material stacks and doping techniques that significantly improved switching characteristics and reliability. The 2010s saw the emergence of multi-layer RRAM structures and advanced fabrication techniques that further enhanced performance metrics.

A critical milestone in RRAM development was the transition from laboratory demonstrations to commercial prototypes. Companies like Crossbar, Weebit Nano, and Adesto Technologies have made significant progress in scaling RRAM technology for commercial applications. These efforts have focused on addressing key challenges such as reducing operating voltages, improving retention times, and enhancing endurance cycles to meet industry requirements.

The primary development objectives for RRAM technology center around positioning it as a viable universal memory solution. This requires achieving performance metrics that can compete with established memory technologies across multiple dimensions. Specifically, RRAM aims to deliver write speeds below 10ns, retention times exceeding 10 years, endurance cycles greater than 10^12, and power consumption comparable to or better than existing memory technologies.

Another crucial objective is scaling RRAM to advanced technology nodes below 10nm while maintaining performance integrity. This presents significant materials engineering and fabrication challenges that researchers are actively addressing through novel material combinations and innovative device architectures. The industry is particularly focused on developing RRAM solutions that can be manufactured using standard CMOS processes to facilitate integration with existing semiconductor manufacturing infrastructure.

Beyond traditional memory applications, RRAM development objectives have expanded to include neuromorphic computing capabilities. The analog nature of resistive switching makes RRAM particularly suitable for implementing artificial neural networks in hardware. This has opened new development pathways focused on optimizing RRAM for in-memory computing and brain-inspired computing architectures, potentially revolutionizing how computational tasks are performed in next-generation systems.

Market Analysis for Next-Generation Memory Solutions

The memory technology market is experiencing a significant transformation driven by the increasing demands of data-intensive applications across various sectors. The global next-generation memory market was valued at approximately $2.9 billion in 2021 and is projected to reach $13.7 billion by 2028, growing at a CAGR of 24.8% during this period. This growth is primarily fueled by the exponential increase in data generation and processing requirements in cloud computing, artificial intelligence, Internet of Things (IoT), and edge computing applications.

RRAM (Resistive Random Access Memory) has emerged as a promising contender in the universal memory landscape, competing with technologies such as MRAM (Magnetoresistive RAM), PCM (Phase Change Memory), and FeRAM (Ferroelectric RAM). The market for RRAM specifically is expected to grow from $310 million in 2022 to approximately $1.2 billion by 2027, representing a CAGR of 31.2%, outpacing the overall next-generation memory market growth.

Industry verticals showing the strongest demand for advanced memory solutions include automotive (particularly for autonomous vehicles), consumer electronics, enterprise storage, and industrial automation. The automotive sector alone is projected to increase its consumption of next-generation memory by 37% annually through 2026, driven by the integration of advanced driver-assistance systems and infotainment technologies.

Regional analysis indicates that Asia-Pacific currently dominates the market with a 42% share, followed by North America (31%) and Europe (21%). China and Taiwan are particularly significant manufacturing hubs, while research and development activities are concentrated in the United States, Japan, and South Korea.

Customer requirements are increasingly focused on memory solutions that combine high density, low power consumption, non-volatility, and high endurance. Market surveys indicate that 68% of enterprise customers prioritize power efficiency, while 72% emphasize reliability and data retention capabilities. RRAM addresses many of these requirements, offering superior power efficiency compared to DRAM and faster write speeds than NAND flash.

The pricing trends show that while next-generation memory technologies currently command a premium (RRAM costs approximately 2.3x more per gigabyte than DRAM), this gap is expected to narrow to 1.4x by 2026 as manufacturing processes mature and economies of scale are achieved. This price reduction will be crucial for broader market adoption, particularly in consumer electronics and mobile devices.

Market barriers include the entrenched position of conventional memory technologies, significant capital requirements for manufacturing infrastructure, and technical challenges related to scaling and reliability. Nevertheless, the compelling performance advantages of RRAM and other universal memory technologies are driving substantial investment in research and commercialization efforts.

RRAM (Resistive Random Access Memory) has emerged as a promising contender in the universal memory landscape, competing with technologies such as MRAM (Magnetoresistive RAM), PCM (Phase Change Memory), and FeRAM (Ferroelectric RAM). The market for RRAM specifically is expected to grow from $310 million in 2022 to approximately $1.2 billion by 2027, representing a CAGR of 31.2%, outpacing the overall next-generation memory market growth.

Industry verticals showing the strongest demand for advanced memory solutions include automotive (particularly for autonomous vehicles), consumer electronics, enterprise storage, and industrial automation. The automotive sector alone is projected to increase its consumption of next-generation memory by 37% annually through 2026, driven by the integration of advanced driver-assistance systems and infotainment technologies.

Regional analysis indicates that Asia-Pacific currently dominates the market with a 42% share, followed by North America (31%) and Europe (21%). China and Taiwan are particularly significant manufacturing hubs, while research and development activities are concentrated in the United States, Japan, and South Korea.

Customer requirements are increasingly focused on memory solutions that combine high density, low power consumption, non-volatility, and high endurance. Market surveys indicate that 68% of enterprise customers prioritize power efficiency, while 72% emphasize reliability and data retention capabilities. RRAM addresses many of these requirements, offering superior power efficiency compared to DRAM and faster write speeds than NAND flash.

The pricing trends show that while next-generation memory technologies currently command a premium (RRAM costs approximately 2.3x more per gigabyte than DRAM), this gap is expected to narrow to 1.4x by 2026 as manufacturing processes mature and economies of scale are achieved. This price reduction will be crucial for broader market adoption, particularly in consumer electronics and mobile devices.

Market barriers include the entrenched position of conventional memory technologies, significant capital requirements for manufacturing infrastructure, and technical challenges related to scaling and reliability. Nevertheless, the compelling performance advantages of RRAM and other universal memory technologies are driving substantial investment in research and commercialization efforts.

RRAM vs Universal Memory: Current Status and Barriers

RRAM (Resistive Random Access Memory) technology has emerged as a promising candidate in the non-volatile memory landscape, offering advantages in scalability, power consumption, and switching speed. However, when compared to the ideal concept of Universal Memory, RRAM still faces significant barriers that prevent its widespread adoption as a true "memory-storage" convergence solution.

Currently, RRAM devices demonstrate impressive characteristics including sub-nanosecond switching speeds, endurance cycles of 10^12, and retention times exceeding 10 years at 85°C. These metrics position RRAM favorably against traditional storage technologies like NAND flash. However, RRAM still falls short of the Universal Memory requirements that demand simultaneous excellence in speed, endurance, retention, power efficiency, and cost-effectiveness.

The primary technical barriers for RRAM include variability issues at the device level, particularly in resistance states and switching voltages. This variability stems from the stochastic nature of filament formation and rupture processes, creating challenges for reliable multi-level cell operation. Statistical variations become more pronounced as devices scale down, affecting yield and reliability in high-density arrays.

Another significant challenge is the trade-off between retention and switching speed. RRAM devices designed for long retention typically require higher operating voltages and exhibit slower switching characteristics. Conversely, devices optimized for speed often compromise on retention capabilities, creating a fundamental barrier to achieving Universal Memory specifications.

Endurance limitations also persist in RRAM technology. While certain RRAM variants demonstrate impressive endurance, they often sacrifice other critical parameters. The physical mechanisms behind endurance degradation, including electrode material migration and oxygen vacancy redistribution, remain challenging to control in practical device architectures.

From a manufacturing perspective, RRAM faces integration challenges with CMOS technology. Issues such as thermal budget constraints, material compatibility, and process complexity increase production costs and hinder mass adoption. The selector device requirements for large crossbar arrays add another layer of complexity to the integration process.

Energy efficiency presents another barrier, particularly for write operations that require significant current for filament formation or rupture. This energy requirement limits RRAM's applicability in ultra-low-power applications and creates thermal management challenges in high-density arrays.

While RRAM has made remarkable progress, the gap between current capabilities and Universal Memory requirements remains substantial. The technology must overcome these fundamental barriers through innovative materials engineering, novel device architectures, and advanced manufacturing techniques before it can truly fulfill the Universal Memory promise.

Currently, RRAM devices demonstrate impressive characteristics including sub-nanosecond switching speeds, endurance cycles of 10^12, and retention times exceeding 10 years at 85°C. These metrics position RRAM favorably against traditional storage technologies like NAND flash. However, RRAM still falls short of the Universal Memory requirements that demand simultaneous excellence in speed, endurance, retention, power efficiency, and cost-effectiveness.

The primary technical barriers for RRAM include variability issues at the device level, particularly in resistance states and switching voltages. This variability stems from the stochastic nature of filament formation and rupture processes, creating challenges for reliable multi-level cell operation. Statistical variations become more pronounced as devices scale down, affecting yield and reliability in high-density arrays.

Another significant challenge is the trade-off between retention and switching speed. RRAM devices designed for long retention typically require higher operating voltages and exhibit slower switching characteristics. Conversely, devices optimized for speed often compromise on retention capabilities, creating a fundamental barrier to achieving Universal Memory specifications.

Endurance limitations also persist in RRAM technology. While certain RRAM variants demonstrate impressive endurance, they often sacrifice other critical parameters. The physical mechanisms behind endurance degradation, including electrode material migration and oxygen vacancy redistribution, remain challenging to control in practical device architectures.

From a manufacturing perspective, RRAM faces integration challenges with CMOS technology. Issues such as thermal budget constraints, material compatibility, and process complexity increase production costs and hinder mass adoption. The selector device requirements for large crossbar arrays add another layer of complexity to the integration process.

Energy efficiency presents another barrier, particularly for write operations that require significant current for filament formation or rupture. This energy requirement limits RRAM's applicability in ultra-low-power applications and creates thermal management challenges in high-density arrays.

While RRAM has made remarkable progress, the gap between current capabilities and Universal Memory requirements remains substantial. The technology must overcome these fundamental barriers through innovative materials engineering, novel device architectures, and advanced manufacturing techniques before it can truly fulfill the Universal Memory promise.

Technical Architectures of RRAM and Universal Memory

01 RRAM device structure optimization

Optimizing the structure of RRAM devices can significantly enhance memory performance. This includes designing multi-layer resistive switching layers, incorporating novel electrode materials, and implementing specialized cell architectures. These structural improvements can lead to better switching characteristics, reduced variability, and enhanced endurance. Specific approaches include using metal oxide-based switching materials, implementing crossbar arrays, and developing 3D stacking configurations to increase memory density while maintaining performance.- Materials and structures for improved RRAM performance: Various materials and structural designs can enhance RRAM performance. These include using specific metal oxides as switching layers, incorporating novel electrode materials, and implementing multi-layer structures. The selection of materials and their arrangement significantly impacts key performance metrics such as switching speed, endurance, and retention time. Advanced material engineering approaches can reduce variability and improve reliability in RRAM devices.

- Programming and operation techniques for RRAM: Specialized programming methods and operation techniques can optimize RRAM performance. These include pulse-width modulation, voltage amplitude control, and multi-level cell programming strategies. Advanced read/write schemes help mitigate issues like read disturbance and write variability. Implementing proper programming algorithms can extend device lifetime, improve data retention, and enable more reliable multi-bit storage capabilities.

- Integration and scaling of RRAM technology: Integration of RRAM with conventional CMOS technology and scaling considerations are crucial for commercial viability. This includes 3D integration approaches, crossbar array architectures, and selector device implementation to address sneak path issues. Advanced fabrication techniques enable higher density memory arrays while maintaining performance. Scaling solutions address challenges related to power consumption, thermal management, and signal integrity in high-density arrays.

- Performance enhancement through circuit design: Circuit-level innovations can significantly improve RRAM performance metrics. These include sense amplifier designs for faster and more reliable reading, peripheral circuits for precise current control, and error correction schemes. Advanced addressing and decoding circuits enable higher bandwidth and lower latency. Power management circuits optimize energy efficiency while maintaining performance requirements for various applications.

- Novel RRAM architectures for specific applications: Specialized RRAM architectures are being developed for specific applications like neuromorphic computing, in-memory computing, and edge AI. These designs optimize particular performance aspects such as analog computing capability, synaptic weight precision, or ultra-low power operation. Application-specific optimizations include implementing variable resistance states for neural networks, designing for radiation hardness in space applications, or focusing on retention time for long-term storage needs.

02 Switching mechanism and material engineering

The performance of RRAM devices heavily depends on the switching mechanism and materials used. By engineering the resistive switching materials and understanding the underlying physical mechanisms, memory performance can be significantly improved. This includes controlling oxygen vacancy migration, optimizing filament formation and rupture processes, and selecting appropriate dielectric materials. Advanced material combinations and doping strategies can enhance retention time, reduce operating voltages, and improve the overall reliability of RRAM devices.Expand Specific Solutions03 Programming and operation techniques

Novel programming algorithms and operation techniques can substantially improve RRAM performance metrics. These include implementing pulse-width modulation schemes, voltage amplitude control, and multi-level cell programming approaches. Advanced read/write operations, such as verify-based programming and adaptive pulse schemes, can enhance data retention, reduce error rates, and extend device lifetime. These techniques address issues like resistance drift and variability without requiring physical modifications to the memory structure.Expand Specific Solutions04 Integration with peripheral circuits

Effective integration of RRAM cells with peripheral circuits is crucial for overall memory performance. This includes designing specialized sense amplifiers, write drivers, and addressing circuits that accommodate the unique characteristics of resistive switching. Advanced selector devices can minimize sneak path currents in crossbar arrays, while dedicated error correction circuits can improve reliability. Optimized peripheral circuits can reduce power consumption, increase operating speed, and enhance the scalability of RRAM-based memory systems.Expand Specific Solutions05 System-level architecture and applications

System-level architectural innovations can leverage RRAM's unique characteristics to enhance overall memory performance. This includes developing hybrid memory systems that combine RRAM with conventional memories, implementing in-memory computing architectures, and designing specialized controllers for RRAM operation. These approaches can reduce the memory wall bottleneck, enable new computing paradigms like neuromorphic computing, and optimize RRAM for specific applications such as edge AI, IoT devices, and data-intensive computing where power efficiency and performance are critical.Expand Specific Solutions

Leading Companies and Research Institutions in Memory Tech

The RRAM (Resistive Random Access Memory) technology market is currently in a growth phase, with increasing competition among key players in the universal memory landscape. The market is projected to expand significantly as RRAM offers advantages in power consumption, scalability, and non-volatility over traditional memory technologies. Companies like CrossBar, Avalanche Technology, and Hefei Reliance Memory are leading RRAM commercialization efforts, while established semiconductor manufacturers including Samsung, TSMC, and IBM are investing in research and development. Academic institutions such as Tsinghua University and Nanjing University of Posts & Telecommunications are contributing fundamental research. The technology is approaching maturity for specific applications, though challenges in manufacturing consistency and endurance remain before RRAM can fully realize its potential as a universal memory solution competing with established technologies from Macronix, Winbond, and other memory manufacturers.

International Business Machines Corp.

Technical Solution: IBM has developed a distinctive approach to RRAM technology through their phase-change memory (PCM) and magnetoresistive RAM (MRAM) research, positioning these as potential universal memory solutions alongside traditional RRAM. Their PCM technology utilizes chalcogenide materials that switch between amorphous and crystalline states, offering multi-level cell capabilities with 3-4 bits per cell. IBM's RRAM research focuses on metal-oxide systems with particular emphasis on tantalum oxide-based devices that demonstrate exceptional endurance (>10^12 cycles) and retention (>10 years at 85°C). A key innovation in IBM's approach is their "projected PCM" architecture that reduces the contact area between the heating element and phase-change material, significantly reducing programming current requirements. IBM has also pioneered the integration of RRAM technologies with their neuromorphic computing platforms, demonstrating analog weight storage for neural network applications with precision equivalent to 8-bit digital systems but at much higher energy efficiency.

Strengths: Industry-leading endurance characteristics approaching 10^12 cycles; strong integration with neuromorphic computing platforms; reduced programming current requirements through architectural innovations. Weaknesses: Higher manufacturing complexity compared to conventional memory technologies; still working to optimize density-performance tradeoffs for mainstream computing applications.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has developed an advanced RRAM technology that they position as a potential universal memory solution, combining elements of their expertise in DRAM and NAND flash production. Their RRAM implementation utilizes a metal-oxide switching layer (primarily HfO2-based) with proprietary electrode materials that optimize switching characteristics. Samsung's approach focuses on vertical 3D integration (similar to their V-NAND architecture) to achieve high density while maintaining performance. Their RRAM technology demonstrates read latencies of approximately 10ns, write speeds of 50ns, and endurance ratings approaching 10^9 cycles. Samsung has integrated their RRAM technology with their neuromorphic computing initiatives, leveraging the analog nature of resistance changes for in-memory computing applications. The company has also explored hybrid memory systems that combine RRAM with conventional memories to optimize system-level performance.

Strengths: Leverages Samsung's extensive manufacturing infrastructure and expertise in memory production; vertical 3D integration enables high density while maintaining performance; strong integration with neuromorphic computing initiatives. Weaknesses: Still faces challenges in scaling production to competitive cost points compared to established memory technologies; retention characteristics at smaller nodes require further optimization.

Key Patents and Breakthroughs in Resistive Memory

Novel process technique for embedded memory

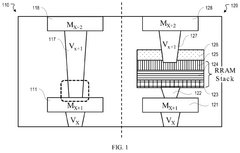

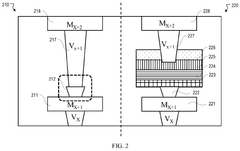

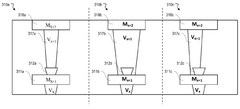

PatentWO2025059830A1

Innovation

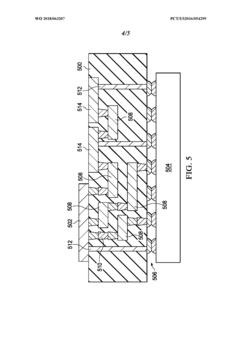

- A novel process technique that integrates embedded memory using a single integrated circuit with a memory region and a non-memory region, where the conductive structures are formed using a single photolithography process with a single photomask, reducing the need for additional photomasks.

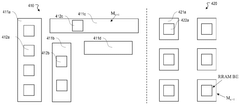

Resistive random access memory cell

PatentWO2018063207A1

Innovation

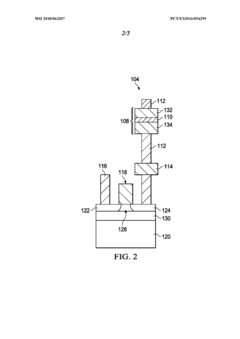

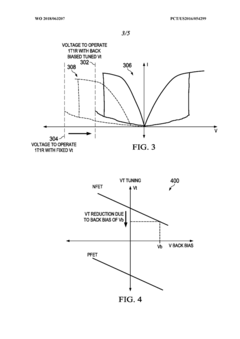

- The use of extremely thin silicon on insulator (ETSOI) or fully depleted silicon on insulator (FDSOI) substrates with back biasing to dynamically tune the threshold voltage, reducing junction leakage and parasitic capacitance, and addressing source follower issues by configuring transistors with semiconductor layers between source and drain junctions.

Performance Benchmarking and Standardization

Standardized performance benchmarking for RRAM and other universal memory technologies remains a significant challenge in the semiconductor industry. Current evaluation methodologies vary widely across research institutions and manufacturers, making direct comparisons difficult and potentially misleading. The industry urgently needs comprehensive standardization frameworks that address the unique characteristics of emerging non-volatile memory technologies.

When benchmarking RRAM against other universal memory candidates such as MRAM, PCM, and FeRAM, several key performance metrics must be systematically evaluated. These include write/read latency, endurance cycles, retention time, power consumption, and scalability potential. RRAM typically demonstrates excellent scalability below 10nm nodes and low power operation, but often faces challenges in endurance compared to MRAM and switching speed compared to SRAM.

The International Roadmap for Devices and Systems (IRDS) has proposed standardized testing protocols for emerging memory technologies, though adoption remains inconsistent. These protocols recommend specific temperature ranges (from -40°C to 125°C), endurance testing methodologies (logarithmic cycle counting with intermittent verification), and retention acceleration models that enable meaningful cross-technology comparisons.

Application-specific benchmarking has emerged as a critical approach, recognizing that universal memory technologies may excel in different deployment scenarios. For instance, RRAM demonstrates particular advantages in neuromorphic computing applications due to its analog switching capabilities, while MRAM may outperform in cache replacement scenarios requiring high endurance. Standardized application-specific test suites that simulate real-world workloads provide more relevant performance insights than isolated parameter measurements.

Industry consortia including JEDEC and IEEE have developed working groups focused on standardizing performance metrics for emerging memories. The JEDEC JC42.4 Committee has published testing methodologies specifically addressing non-volatile memory reliability assessment, while IEEE's International Roadmap for Devices and Systems (IRDS) provides projection targets that serve as de facto benchmarks for technology developers.

Cross-platform testing environments represent another crucial development in benchmarking. These environments enable fair comparison by implementing identical testing conditions across different memory technologies. The Emerging Memory Benchmark Suite (EMBS), developed through collaboration between industry and academia, provides open-source tools for consistent performance evaluation across multiple universal memory candidates, facilitating more transparent technology assessment and accelerating standardization efforts.

When benchmarking RRAM against other universal memory candidates such as MRAM, PCM, and FeRAM, several key performance metrics must be systematically evaluated. These include write/read latency, endurance cycles, retention time, power consumption, and scalability potential. RRAM typically demonstrates excellent scalability below 10nm nodes and low power operation, but often faces challenges in endurance compared to MRAM and switching speed compared to SRAM.

The International Roadmap for Devices and Systems (IRDS) has proposed standardized testing protocols for emerging memory technologies, though adoption remains inconsistent. These protocols recommend specific temperature ranges (from -40°C to 125°C), endurance testing methodologies (logarithmic cycle counting with intermittent verification), and retention acceleration models that enable meaningful cross-technology comparisons.

Application-specific benchmarking has emerged as a critical approach, recognizing that universal memory technologies may excel in different deployment scenarios. For instance, RRAM demonstrates particular advantages in neuromorphic computing applications due to its analog switching capabilities, while MRAM may outperform in cache replacement scenarios requiring high endurance. Standardized application-specific test suites that simulate real-world workloads provide more relevant performance insights than isolated parameter measurements.

Industry consortia including JEDEC and IEEE have developed working groups focused on standardizing performance metrics for emerging memories. The JEDEC JC42.4 Committee has published testing methodologies specifically addressing non-volatile memory reliability assessment, while IEEE's International Roadmap for Devices and Systems (IRDS) provides projection targets that serve as de facto benchmarks for technology developers.

Cross-platform testing environments represent another crucial development in benchmarking. These environments enable fair comparison by implementing identical testing conditions across different memory technologies. The Emerging Memory Benchmark Suite (EMBS), developed through collaboration between industry and academia, provides open-source tools for consistent performance evaluation across multiple universal memory candidates, facilitating more transparent technology assessment and accelerating standardization efforts.

Energy Efficiency and Sustainability Considerations

Energy efficiency has emerged as a critical factor in the evaluation of memory technologies, particularly as data centers and mobile devices face increasing power constraints. RRAM (Resistive Random Access Memory) demonstrates significant advantages in this domain, consuming approximately 10-100 times less power during write operations compared to conventional flash memory. This reduced energy consumption stems from RRAM's fundamental operating principle, which requires only localized atomic rearrangements rather than the high-energy electron injection processes used in flash memory.

When compared with other universal memory contenders, RRAM maintains competitive positioning. While STT-MRAM (Spin-Transfer Torque Magnetoresistive RAM) offers excellent endurance and speed, it typically requires higher write currents than RRAM, resulting in greater power consumption during write operations. PCM (Phase Change Memory), another prominent technology, demands substantial energy to induce phase transitions, placing it at a disadvantage compared to RRAM in energy-constrained applications.

The standby power characteristics of RRAM further enhance its sustainability profile. With negligible leakage current in its high-resistance state, RRAM devices can maintain stored information with minimal energy expenditure during idle periods. This property makes RRAM particularly suitable for Internet of Things (IoT) applications where devices may operate on limited power sources for extended durations.

Manufacturing sustainability represents another dimension where RRAM offers advantages. The fabrication of RRAM cells generally involves fewer processing steps and lower thermal budgets compared to conventional memory technologies. Additionally, RRAM's material requirements are potentially less environmentally problematic than those of some competing technologies, which may rely on rare earth elements or materials with significant environmental extraction impacts.

Scaling considerations also favor RRAM from an energy perspective. As device dimensions decrease, RRAM's energy efficiency tends to improve proportionally, whereas some competing technologies face fundamental physical limitations that compromise efficiency at smaller nodes. This scaling advantage suggests that RRAM's energy benefits may become even more pronounced as manufacturing processes advance to smaller geometries.

Looking toward future developments, research into novel materials for RRAM devices promises to further enhance energy efficiency. Two-dimensional materials and advanced metal oxides are being investigated to reduce operating voltages while maintaining reliability, potentially extending RRAM's energy advantage over alternative universal memory technologies.

When compared with other universal memory contenders, RRAM maintains competitive positioning. While STT-MRAM (Spin-Transfer Torque Magnetoresistive RAM) offers excellent endurance and speed, it typically requires higher write currents than RRAM, resulting in greater power consumption during write operations. PCM (Phase Change Memory), another prominent technology, demands substantial energy to induce phase transitions, placing it at a disadvantage compared to RRAM in energy-constrained applications.

The standby power characteristics of RRAM further enhance its sustainability profile. With negligible leakage current in its high-resistance state, RRAM devices can maintain stored information with minimal energy expenditure during idle periods. This property makes RRAM particularly suitable for Internet of Things (IoT) applications where devices may operate on limited power sources for extended durations.

Manufacturing sustainability represents another dimension where RRAM offers advantages. The fabrication of RRAM cells generally involves fewer processing steps and lower thermal budgets compared to conventional memory technologies. Additionally, RRAM's material requirements are potentially less environmentally problematic than those of some competing technologies, which may rely on rare earth elements or materials with significant environmental extraction impacts.

Scaling considerations also favor RRAM from an energy perspective. As device dimensions decrease, RRAM's energy efficiency tends to improve proportionally, whereas some competing technologies face fundamental physical limitations that compromise efficiency at smaller nodes. This scaling advantage suggests that RRAM's energy benefits may become even more pronounced as manufacturing processes advance to smaller geometries.

Looking toward future developments, research into novel materials for RRAM devices promises to further enhance energy efficiency. Two-dimensional materials and advanced metal oxides are being investigated to reduce operating voltages while maintaining reliability, potentially extending RRAM's energy advantage over alternative universal memory technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!