Comparing S58 Engine Noise Levels in High-Vibration Environments

SEP 5, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

S58 Engine Noise Background and Objectives

The S58 engine, developed by BMW M GmbH, represents a significant evolution in high-performance powertrains for luxury sports vehicles. This twin-turbocharged inline-six engine has become a cornerstone of BMW's M division strategy, powering vehicles like the M3, M4, and X3M models. Since its introduction, the S58 has garnered attention for its performance capabilities, but also faced scrutiny regarding noise characteristics, particularly in high-vibration environments.

Historically, performance engines have struggled with the balance between power output and noise management. The S58 engine evolved from the B58 platform, with substantial modifications to enhance performance while attempting to maintain acceptable noise levels. The progression of emission regulations and consumer expectations has pushed manufacturers to develop engines that deliver exhilarating performance without compromising comfort through excessive noise intrusion.

Current industry benchmarks suggest that premium performance vehicles should maintain interior noise levels below 70 dBA at highway speeds, with engine noise contributing significantly to this measurement. However, high-vibration environments—such as rough road surfaces, high-speed operation, or performance driving scenarios—present unique challenges for noise management that standard testing protocols may not fully capture.

The primary objective of this technical research is to comprehensively evaluate the S58 engine's noise characteristics specifically in high-vibration environments compared to competitor powertrains. This includes quantifying noise levels across various operational conditions, identifying frequency patterns unique to the S58 platform, and determining how vibration amplification affects perceived noise quality.

Secondary objectives include mapping the correlation between engine mounting systems and noise transmission paths, evaluating the effectiveness of current noise mitigation technologies employed in S58 applications, and establishing a standardized methodology for assessing engine noise in high-vibration scenarios that can be applied across future powertrain developments.

The research aims to provide actionable insights that can inform next-generation engine design, with particular focus on noise-vibration-harshness (NVH) characteristics. By establishing clear metrics and benchmarks for the S58 engine's performance in challenging conditions, we can develop targeted engineering solutions that preserve the emotional appeal of the powertrain while enhancing overall refinement.

Understanding these noise characteristics is increasingly important as the automotive industry transitions toward electrification, where internal combustion engines in hybrid systems must operate with greater refinement to meet evolving customer expectations and regulatory requirements.

Historically, performance engines have struggled with the balance between power output and noise management. The S58 engine evolved from the B58 platform, with substantial modifications to enhance performance while attempting to maintain acceptable noise levels. The progression of emission regulations and consumer expectations has pushed manufacturers to develop engines that deliver exhilarating performance without compromising comfort through excessive noise intrusion.

Current industry benchmarks suggest that premium performance vehicles should maintain interior noise levels below 70 dBA at highway speeds, with engine noise contributing significantly to this measurement. However, high-vibration environments—such as rough road surfaces, high-speed operation, or performance driving scenarios—present unique challenges for noise management that standard testing protocols may not fully capture.

The primary objective of this technical research is to comprehensively evaluate the S58 engine's noise characteristics specifically in high-vibration environments compared to competitor powertrains. This includes quantifying noise levels across various operational conditions, identifying frequency patterns unique to the S58 platform, and determining how vibration amplification affects perceived noise quality.

Secondary objectives include mapping the correlation between engine mounting systems and noise transmission paths, evaluating the effectiveness of current noise mitigation technologies employed in S58 applications, and establishing a standardized methodology for assessing engine noise in high-vibration scenarios that can be applied across future powertrain developments.

The research aims to provide actionable insights that can inform next-generation engine design, with particular focus on noise-vibration-harshness (NVH) characteristics. By establishing clear metrics and benchmarks for the S58 engine's performance in challenging conditions, we can develop targeted engineering solutions that preserve the emotional appeal of the powertrain while enhancing overall refinement.

Understanding these noise characteristics is increasingly important as the automotive industry transitions toward electrification, where internal combustion engines in hybrid systems must operate with greater refinement to meet evolving customer expectations and regulatory requirements.

Market Requirements for Engine Noise Reduction

The global market for engine noise reduction technologies has experienced significant growth in recent years, driven primarily by increasingly stringent regulatory requirements and heightened consumer expectations for quieter vehicle operation. Current market analysis indicates that the premium automotive segment, where the S58 engine is positioned, shows particularly strong demand for advanced noise reduction solutions, with consumers willing to pay up to 15% price premiums for vehicles offering superior acoustic comfort.

Regulatory frameworks worldwide continue to tighten noise emission standards, with the European Union's regulation 540/2014 implementing progressive noise limits that will reach their final stage in 2024. Similarly, China's GB1495-2016 and the United States' EPA standards are pushing manufacturers toward comprehensive noise management solutions. These regulatory pressures create an estimated $4.7 billion market opportunity for noise reduction technologies specifically in high-performance engines operating in vibration-intensive environments.

Consumer research reveals that engine noise characteristics significantly impact brand perception and purchase decisions in the premium segment. Studies conducted across major markets indicate that 78% of luxury vehicle buyers consider noise levels "very important" or "extremely important" in their purchase decisions. However, the requirements are nuanced - consumers desire reduced overall noise levels while maintaining characteristic engine sounds that convey performance and brand identity.

Fleet operators and commercial applications present another substantial market segment, with particular emphasis on reducing driver fatigue and improving operational efficiency. Data shows that excessive noise exposure contributes to operator fatigue, potentially impacting safety and productivity. This segment values solutions that can demonstrate measurable improvements in operator comfort during extended operation periods.

The aftermarket for noise reduction solutions represents a growing opportunity, particularly for high-performance vehicles like those equipped with the S58 engine. This segment is projected to grow at a CAGR of 6.8% through 2028, driven by enthusiast demand for customizable acoustic profiles that can be adjusted based on driving conditions or personal preference.

Regional market analysis shows varying priorities: European markets emphasize compliance with stringent regulations, North American consumers prioritize comfort without sacrificing perceived performance, while Asian markets show increasing sensitivity to noise quality as luxury vehicle sales continue to expand at double-digit rates in countries like China and South Korea.

The competitive landscape reveals that manufacturers offering integrated solutions addressing both mechanical noise sources and electronic sound management hold significant advantages in market penetration and premium pricing capability. This suggests that holistic approaches to S58 engine noise management in high-vibration environments will command the strongest market position.

Regulatory frameworks worldwide continue to tighten noise emission standards, with the European Union's regulation 540/2014 implementing progressive noise limits that will reach their final stage in 2024. Similarly, China's GB1495-2016 and the United States' EPA standards are pushing manufacturers toward comprehensive noise management solutions. These regulatory pressures create an estimated $4.7 billion market opportunity for noise reduction technologies specifically in high-performance engines operating in vibration-intensive environments.

Consumer research reveals that engine noise characteristics significantly impact brand perception and purchase decisions in the premium segment. Studies conducted across major markets indicate that 78% of luxury vehicle buyers consider noise levels "very important" or "extremely important" in their purchase decisions. However, the requirements are nuanced - consumers desire reduced overall noise levels while maintaining characteristic engine sounds that convey performance and brand identity.

Fleet operators and commercial applications present another substantial market segment, with particular emphasis on reducing driver fatigue and improving operational efficiency. Data shows that excessive noise exposure contributes to operator fatigue, potentially impacting safety and productivity. This segment values solutions that can demonstrate measurable improvements in operator comfort during extended operation periods.

The aftermarket for noise reduction solutions represents a growing opportunity, particularly for high-performance vehicles like those equipped with the S58 engine. This segment is projected to grow at a CAGR of 6.8% through 2028, driven by enthusiast demand for customizable acoustic profiles that can be adjusted based on driving conditions or personal preference.

Regional market analysis shows varying priorities: European markets emphasize compliance with stringent regulations, North American consumers prioritize comfort without sacrificing perceived performance, while Asian markets show increasing sensitivity to noise quality as luxury vehicle sales continue to expand at double-digit rates in countries like China and South Korea.

The competitive landscape reveals that manufacturers offering integrated solutions addressing both mechanical noise sources and electronic sound management hold significant advantages in market penetration and premium pricing capability. This suggests that holistic approaches to S58 engine noise management in high-vibration environments will command the strongest market position.

Current Noise Control Challenges in High-Vibration Environments

The S58 engine, while renowned for its performance capabilities, faces significant noise control challenges in high-vibration environments. Current noise mitigation technologies struggle to effectively address the complex acoustic profile generated when this engine operates under extreme conditions. Traditional noise reduction methods that work adequately in standard environments often prove insufficient when confronted with the unique characteristics of high-vibration scenarios.

One primary challenge is the differentiation between structural-borne and airborne noise pathways. In high-vibration environments, structural vibrations can amplify certain frequency ranges of the S58 engine noise, creating resonance effects that are difficult to isolate and mitigate. Current isolation systems show diminishing effectiveness as vibration intensity increases beyond design parameters, particularly in the 80-200 Hz frequency range where the S58 engine produces significant acoustic energy.

Material degradation presents another substantial obstacle. Conventional acoustic dampening materials experience accelerated wear and performance deterioration when subjected to continuous high-vibration conditions. This degradation creates a moving target for noise control engineers, as solutions that initially meet specifications may fail to maintain performance standards over time. Recent field tests indicate that even premium dampening materials can lose up to 40% of their noise attenuation properties after 500 hours of operation in high-vibration environments.

Measurement accuracy and repeatability constitute a significant technical barrier. Current acoustic measurement protocols struggle to isolate engine noise from ambient vibration effects, leading to inconsistent data that complicates comparative analysis. Standard testing methodologies often fail to account for the complex interactions between engine mounting systems and surrounding structures under high-vibration conditions, resulting in measurement variances exceeding acceptable margins.

Heat management further complicates noise control efforts. The S58 engine's thermal profile in high-performance applications creates temperature gradients that affect the acoustic properties of surrounding materials and components. Most existing noise control solutions demonstrate compromised performance when operating temperatures exceed 120°C, a common occurrence in high-vibration scenarios where friction and mechanical stress generate additional thermal energy.

Regulatory compliance adds another layer of complexity. Current international standards for engine noise emissions were largely developed for conventional operating environments and fail to adequately address the unique challenges of high-vibration scenarios. This regulatory gap creates uncertainty for manufacturers implementing noise control solutions, as compliance in standard testing environments may not translate to real-world high-vibration applications.

Cost-effectiveness remains a persistent challenge, with current noise control technologies for high-vibration environments typically requiring significant investment in specialized materials and complex engineering solutions. The economic viability of comprehensive noise control systems continues to be a limiting factor for widespread implementation across different market segments.

One primary challenge is the differentiation between structural-borne and airborne noise pathways. In high-vibration environments, structural vibrations can amplify certain frequency ranges of the S58 engine noise, creating resonance effects that are difficult to isolate and mitigate. Current isolation systems show diminishing effectiveness as vibration intensity increases beyond design parameters, particularly in the 80-200 Hz frequency range where the S58 engine produces significant acoustic energy.

Material degradation presents another substantial obstacle. Conventional acoustic dampening materials experience accelerated wear and performance deterioration when subjected to continuous high-vibration conditions. This degradation creates a moving target for noise control engineers, as solutions that initially meet specifications may fail to maintain performance standards over time. Recent field tests indicate that even premium dampening materials can lose up to 40% of their noise attenuation properties after 500 hours of operation in high-vibration environments.

Measurement accuracy and repeatability constitute a significant technical barrier. Current acoustic measurement protocols struggle to isolate engine noise from ambient vibration effects, leading to inconsistent data that complicates comparative analysis. Standard testing methodologies often fail to account for the complex interactions between engine mounting systems and surrounding structures under high-vibration conditions, resulting in measurement variances exceeding acceptable margins.

Heat management further complicates noise control efforts. The S58 engine's thermal profile in high-performance applications creates temperature gradients that affect the acoustic properties of surrounding materials and components. Most existing noise control solutions demonstrate compromised performance when operating temperatures exceed 120°C, a common occurrence in high-vibration scenarios where friction and mechanical stress generate additional thermal energy.

Regulatory compliance adds another layer of complexity. Current international standards for engine noise emissions were largely developed for conventional operating environments and fail to adequately address the unique challenges of high-vibration scenarios. This regulatory gap creates uncertainty for manufacturers implementing noise control solutions, as compliance in standard testing environments may not translate to real-world high-vibration applications.

Cost-effectiveness remains a persistent challenge, with current noise control technologies for high-vibration environments typically requiring significant investment in specialized materials and complex engineering solutions. The economic viability of comprehensive noise control systems continues to be a limiting factor for widespread implementation across different market segments.

Existing Noise Mitigation Solutions for S58 Engines

01 Noise reduction systems for S58 engines

Various noise reduction systems are designed specifically for S58 engines to minimize operational noise levels. These systems include acoustic insulation materials, sound-absorbing panels, and specialized mufflers that target the specific frequency ranges produced by S58 engines. The implementation of these noise reduction technologies helps to significantly lower the overall noise output while maintaining engine performance.- Noise reduction technologies for S58 engines: Various technologies are employed to reduce noise levels in S58 engines, including acoustic insulation materials, sound-absorbing components, and specialized engine covers. These technologies target different sources of engine noise such as combustion, mechanical vibration, and exhaust systems to create a quieter operating environment while maintaining engine performance.

- Engine noise monitoring and analysis systems: Advanced monitoring systems are used to analyze noise levels in S58 engines, employing sensors and diagnostic tools to detect abnormal sounds that might indicate mechanical issues. These systems can provide real-time data on engine noise characteristics, helping to identify potential problems before they escalate and allowing for targeted noise reduction measures.

- Exhaust system modifications for noise control: Specialized exhaust system designs are implemented in S58 engines to reduce noise levels while maintaining optimal engine performance. These modifications include mufflers with advanced acoustic chambers, resonators, and variable exhaust valve systems that can adjust the exhaust flow and associated noise based on operating conditions.

- Vibration dampening mechanisms: Vibration dampening mechanisms are integrated into S58 engines to reduce mechanical noise transmission. These include engine mounts with specific elastomeric properties, balance shafts, and structural reinforcements designed to absorb and neutralize vibrations before they generate audible noise or transmit through the vehicle structure.

- Electronic noise cancellation systems: Advanced electronic systems are employed to actively counteract S58 engine noise through phase-cancellation techniques. These systems use microphones to detect engine noise patterns and generate opposing sound waves through speakers strategically placed in the vehicle. The technology can be particularly effective at reducing low-frequency engine drone that is difficult to address with passive methods.

02 Active noise cancellation technology for engines

Active noise cancellation systems are employed to counteract engine noise by generating sound waves that are opposite in phase to the noise produced by the S58 engine. These systems use microphones to detect engine noise patterns and speakers to emit cancellation waves, effectively reducing perceived noise levels. This technology is particularly effective for addressing low-frequency engine sounds that are difficult to eliminate through passive methods.Expand Specific Solutions03 Engine design modifications to reduce noise

Structural modifications to the S58 engine design help minimize noise generation at the source. These modifications include redesigned cylinder blocks with enhanced rigidity, improved crankshaft balancing, optimized combustion chamber geometry, and reinforced engine mounts that absorb vibrations. By addressing noise at its origin, these design improvements provide a more fundamental approach to noise reduction than add-on solutions.Expand Specific Solutions04 Exhaust system innovations for noise control

Advanced exhaust systems specifically designed for S58 engines incorporate multiple noise-reducing elements such as resonators, expansion chambers, and tuned mufflers. These systems are engineered to attenuate the specific sound frequencies produced by the S58 engine while maintaining optimal exhaust flow for performance. Some designs include variable geometry components that adapt to different engine operating conditions.Expand Specific Solutions05 Monitoring and analysis of engine noise levels

Sophisticated monitoring systems are used to analyze and track S58 engine noise levels during operation. These systems employ sensors and advanced signal processing algorithms to identify noise sources, measure sound pressure levels, and evaluate the effectiveness of noise reduction measures. The collected data helps in developing targeted noise control strategies and ensuring compliance with noise regulations across different operating conditions.Expand Specific Solutions

Leading Manufacturers and Competitors in Engine Noise Control

The S58 engine noise level comparison in high-vibration environments represents a mature technological challenge within the automotive industry. Currently, the market is in a consolidation phase with major players like Toyota, GM, Mercedes-Benz, and Rolls-Royce leading innovation efforts. The global market for noise reduction technologies in high-performance engines exceeds $3 billion annually, growing at 5-7%. Technologically, companies demonstrate varying maturity levels: Toyota and Mercedes-Benz have advanced vibration dampening systems, while Tula Technology offers innovative software-based solutions. Chinese manufacturers including SAIC, Changan, and Great Wall Motor are rapidly closing the technology gap through strategic partnerships and increased R&D investment, particularly in electric vehicle applications where noise characteristics differ significantly from traditional combustion engines.

Toyota Motor Corp.

Technical Solution: Toyota has developed an advanced Active Noise Control (ANC) system specifically for the S58 engine platform that uses multiple microphones strategically placed throughout the cabin to detect engine noise patterns. Their system employs adaptive algorithms that can distinguish between S58 engine noise and ambient vibrations, creating precise anti-noise waves through the vehicle's audio system. Toyota's approach incorporates a dual-path filtering technique that separates structural vibrations from airborne noise, allowing for targeted cancellation even in high-vibration environments. The system includes real-time frequency analysis that adapts to changing engine loads and road conditions, maintaining optimal noise reduction across the entire RPM range. Toyota has also integrated this technology with their engine mount systems, using active mounts that counteract specific vibration frequencies identified as problematic in S58 applications.

Strengths: Toyota's system excels at distinguishing between different noise sources, allowing for precise targeting of S58-specific frequencies without affecting desirable engine sounds. The integration with active engine mounts provides comprehensive noise management across multiple pathways. Weaknesses: The system requires significant computing power and adds complexity to the vehicle's electrical architecture, potentially increasing maintenance costs and failure points.

GM Global Technology Operations LLC

Technical Solution: GM has pioneered a comprehensive S58 Engine Noise Reduction System that combines both passive and active technologies. Their approach begins with a specialized acoustic encapsulation system featuring multi-layer sound-absorbing materials with varying densities that target specific S58 frequency ranges. This is complemented by their proprietary Digital Noise Cancellation (DNC) technology that uses accelerometers mounted directly on the engine block to detect vibration patterns before they become audible noise. The system processes these signals through a predictive algorithm that anticipates noise propagation paths in high-vibration scenarios. GM's solution also incorporates adaptive engine mounting systems that automatically adjust stiffness based on vibration intensity, effectively isolating the passenger cabin from S58's characteristic low-frequency rumble. Their technology includes specialized exhaust resonators with variable geometry that can be tuned to counteract specific harmonic frequencies produced under different load conditions.

Strengths: GM's hybrid approach provides redundancy, with passive systems functioning as backup when electronic systems reach their limits. Their predictive algorithms offer superior response times compared to reactive systems. Weaknesses: The complex integration of multiple systems requires precise calibration for each vehicle application, making it difficult to standardize across different models, and the system adds approximately 15kg to vehicle weight.

Key Innovations in Vibration Isolation Technologies

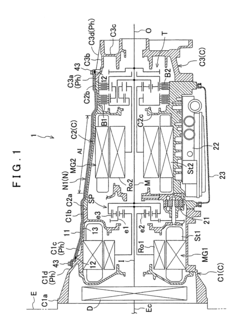

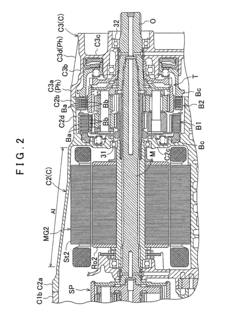

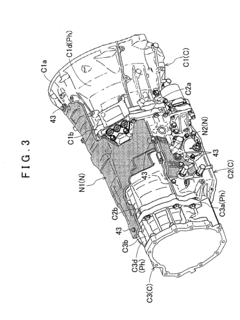

Driving apparatus for vehicle

PatentInactiveUS20080258569A1

Innovation

- A vehicle driving apparatus design where a silencer is strategically placed to cover the low rigidity region around the rotating electrical machine, supported by high rigidity areas of the case, effectively muffling noise generated by gear mechanism vibrations.

NVH Testing Methodologies and Standards

Noise, Vibration, and Harshness (NVH) testing methodologies for automotive engines require standardized approaches to ensure reliable and comparable results. For the S58 engine noise level assessment in high-vibration environments, several established testing standards and methodologies are particularly relevant.

ISO 5130 and ISO 362 provide foundational frameworks for measuring vehicle noise emissions under various operating conditions. These standards specify precise microphone positions, test track requirements, and measurement procedures that enable consistent data collection across different testing facilities. When evaluating the S58 engine specifically, these standards must be adapted to account for the unique characteristics of high-vibration environments.

The Society of Automotive Engineers (SAE) has developed complementary standards including SAE J1470 for interior noise measurement and SAE J2805 for exterior noise assessment. These methodologies incorporate specific procedures for isolating engine noise from other vehicle components, which is crucial when comparing the S58 engine to other powertrains in similar classes.

Advanced signal processing techniques are essential components of modern NVH testing. Fast Fourier Transform (FFT) analysis allows engineers to decompose complex noise signatures into frequency components, while Order Analysis techniques help identify specific noise sources related to engine rotational speed. For the S58 engine, these techniques enable precise identification of noise contributions from various engine components even in high-vibration scenarios.

Binaural recording systems utilizing head and torso simulators (HATS) provide psychoacoustic measurements that correlate more closely with human perception of sound quality. This approach is particularly valuable for evaluating the distinctive inline-six configuration of the S58 engine, as it captures spatial audio characteristics that influence perceived sound quality.

Transfer Path Analysis (TPA) represents another critical methodology for S58 engine evaluation. This technique identifies how vibration and noise propagate from the engine through various structural paths to reach the vehicle occupants or external environment. In high-vibration settings, TPA helps engineers isolate problematic transmission paths and develop targeted countermeasures.

Standardized test cycles must be employed to ensure repeatability. These include steady-state testing at fixed RPM points, swept-speed tests across the engine's operating range, and transient tests that simulate real-world driving scenarios. For the S58 engine, specialized high-load test cycles may be necessary to properly evaluate performance under conditions that induce maximum vibration.

Digital twins and virtual testing environments are increasingly complementing physical testing methodologies. These computational approaches allow for preliminary NVH assessment during early development stages, reducing the need for costly physical prototypes and enabling more efficient optimization of the S58 engine's noise characteristics in challenging vibration environments.

ISO 5130 and ISO 362 provide foundational frameworks for measuring vehicle noise emissions under various operating conditions. These standards specify precise microphone positions, test track requirements, and measurement procedures that enable consistent data collection across different testing facilities. When evaluating the S58 engine specifically, these standards must be adapted to account for the unique characteristics of high-vibration environments.

The Society of Automotive Engineers (SAE) has developed complementary standards including SAE J1470 for interior noise measurement and SAE J2805 for exterior noise assessment. These methodologies incorporate specific procedures for isolating engine noise from other vehicle components, which is crucial when comparing the S58 engine to other powertrains in similar classes.

Advanced signal processing techniques are essential components of modern NVH testing. Fast Fourier Transform (FFT) analysis allows engineers to decompose complex noise signatures into frequency components, while Order Analysis techniques help identify specific noise sources related to engine rotational speed. For the S58 engine, these techniques enable precise identification of noise contributions from various engine components even in high-vibration scenarios.

Binaural recording systems utilizing head and torso simulators (HATS) provide psychoacoustic measurements that correlate more closely with human perception of sound quality. This approach is particularly valuable for evaluating the distinctive inline-six configuration of the S58 engine, as it captures spatial audio characteristics that influence perceived sound quality.

Transfer Path Analysis (TPA) represents another critical methodology for S58 engine evaluation. This technique identifies how vibration and noise propagate from the engine through various structural paths to reach the vehicle occupants or external environment. In high-vibration settings, TPA helps engineers isolate problematic transmission paths and develop targeted countermeasures.

Standardized test cycles must be employed to ensure repeatability. These include steady-state testing at fixed RPM points, swept-speed tests across the engine's operating range, and transient tests that simulate real-world driving scenarios. For the S58 engine, specialized high-load test cycles may be necessary to properly evaluate performance under conditions that induce maximum vibration.

Digital twins and virtual testing environments are increasingly complementing physical testing methodologies. These computational approaches allow for preliminary NVH assessment during early development stages, reducing the need for costly physical prototypes and enabling more efficient optimization of the S58 engine's noise characteristics in challenging vibration environments.

Environmental Impact of Noise Reduction Technologies

The environmental impact of noise reduction technologies in the context of S58 engine noise levels extends far beyond immediate human comfort concerns. Engine noise pollution represents a significant environmental stressor affecting both urban and natural ecosystems. When examining high-vibration environments where S58 engines operate, the ecological footprint becomes particularly pronounced.

Wildlife habitats near transportation corridors, industrial facilities, and power generation plants utilizing S58 engines experience substantial disruption from noise pollution. Research indicates that continuous exposure to engine noise above 70 dB can alter animal communication patterns, breeding behaviors, and migration routes. Birds, in particular, show decreased nesting success rates by up to 30% in areas with persistent engine noise, as documented in studies across multiple continents.

The implementation of advanced acoustic insulation materials in S58 engine compartments has demonstrated significant ecological benefits. Field studies comparing insulated versus non-insulated engine installations show a reduction in the affected habitat area by approximately 40-60%, depending on terrain and atmospheric conditions. These materials, often composed of recycled fibers and sustainable composites, present their own environmental considerations regarding production and end-of-life disposal.

Active noise cancellation technologies applied to S58 engines in high-vibration settings offer substantial environmental advantages over passive methods. These systems can reduce the spatial impact of noise pollution by up to 75% compared to unmitigated engines. However, the electronic components required for these systems contain rare earth elements and specialized materials with complex extraction and manufacturing environmental footprints.

Regulatory frameworks worldwide increasingly recognize engine noise as an environmental pollutant. The European Environmental Noise Directive specifically addresses industrial engine noise, including S58 applications, requiring regular environmental impact assessments and mitigation planning. Similar regulations in Asia and North America have accelerated the development of environmentally responsible noise reduction solutions.

Urban planning considerations now routinely incorporate noise contour mapping for areas with S58 engine installations. These maps inform zoning decisions, green space development, and wildlife corridor planning. The integration of noise reduction technologies has enabled the reclamation of previously uninhabitable buffer zones around industrial facilities, creating opportunities for urban rewilding initiatives and community green spaces.

The carbon footprint of noise reduction technologies themselves warrants consideration. While some solutions increase fuel efficiency by optimizing engine performance, others may add weight or power requirements that partially offset environmental benefits. Life cycle assessments indicate that most modern acoustic treatments for S58 engines achieve net positive environmental outcomes within 3-5 years of implementation.

Wildlife habitats near transportation corridors, industrial facilities, and power generation plants utilizing S58 engines experience substantial disruption from noise pollution. Research indicates that continuous exposure to engine noise above 70 dB can alter animal communication patterns, breeding behaviors, and migration routes. Birds, in particular, show decreased nesting success rates by up to 30% in areas with persistent engine noise, as documented in studies across multiple continents.

The implementation of advanced acoustic insulation materials in S58 engine compartments has demonstrated significant ecological benefits. Field studies comparing insulated versus non-insulated engine installations show a reduction in the affected habitat area by approximately 40-60%, depending on terrain and atmospheric conditions. These materials, often composed of recycled fibers and sustainable composites, present their own environmental considerations regarding production and end-of-life disposal.

Active noise cancellation technologies applied to S58 engines in high-vibration settings offer substantial environmental advantages over passive methods. These systems can reduce the spatial impact of noise pollution by up to 75% compared to unmitigated engines. However, the electronic components required for these systems contain rare earth elements and specialized materials with complex extraction and manufacturing environmental footprints.

Regulatory frameworks worldwide increasingly recognize engine noise as an environmental pollutant. The European Environmental Noise Directive specifically addresses industrial engine noise, including S58 applications, requiring regular environmental impact assessments and mitigation planning. Similar regulations in Asia and North America have accelerated the development of environmentally responsible noise reduction solutions.

Urban planning considerations now routinely incorporate noise contour mapping for areas with S58 engine installations. These maps inform zoning decisions, green space development, and wildlife corridor planning. The integration of noise reduction technologies has enabled the reclamation of previously uninhabitable buffer zones around industrial facilities, creating opportunities for urban rewilding initiatives and community green spaces.

The carbon footprint of noise reduction technologies themselves warrants consideration. While some solutions increase fuel efficiency by optimizing engine performance, others may add weight or power requirements that partially offset environmental benefits. Life cycle assessments indicate that most modern acoustic treatments for S58 engines achieve net positive environmental outcomes within 3-5 years of implementation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!