How to Implement S58 Engine Temperature Control Systems

SEP 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

S58 Engine Temperature Control Background and Objectives

The BMW S58 engine represents a significant evolution in high-performance automotive powertrains, succeeding the acclaimed N55 engine in BMW's M-series vehicles. Temperature control in such high-output engines is critical for maintaining optimal performance, reliability, and efficiency. The S58 engine, with its twin-turbo inline-six configuration producing up to 503 horsepower, presents unique thermal management challenges that require sophisticated control systems.

Temperature management in high-performance engines has evolved significantly over the past decades, transitioning from simple mechanical thermostats to complex electronic control systems integrating multiple cooling circuits. The S58 engine builds upon this evolution, incorporating advanced thermal management technologies to address the increased thermal loads generated by its enhanced power output and efficiency requirements.

The primary objective of the S58 temperature control system is to maintain optimal operating temperatures across various engine components under diverse driving conditions. This includes rapid warm-up during cold starts to reduce emissions and improve fuel efficiency, precise temperature regulation during normal operation to maximize performance, and effective heat dissipation during high-load scenarios to prevent thermal degradation of components.

Another critical goal is to support the engine's performance characteristics while meeting increasingly stringent emissions regulations. The S58 engine must balance the competing demands of performance, efficiency, and emissions control, with temperature management playing a pivotal role in achieving this balance. The system must also accommodate the thermal requirements of auxiliary systems such as turbochargers, intercoolers, and exhaust after-treatment components.

The technological trajectory in this field points toward increasingly integrated and predictive temperature control systems. Modern engines like the S58 utilize complex algorithms that consider multiple parameters including ambient conditions, driving style, and vehicle operating state to proactively manage thermal conditions rather than simply reacting to temperature changes.

Industry trends indicate a move toward electrification of cooling system components, replacing mechanical pumps and fans with electronically controlled equivalents that offer greater precision and efficiency. Additionally, the integration of temperature control with other vehicle systems through advanced ECUs allows for more holistic approaches to thermal management.

The implementation of effective temperature control in the S58 engine requires addressing these technological trends while meeting the specific performance requirements of BMW's M-series vehicles, establishing a foundation for future advancements in high-performance engine thermal management.

Temperature management in high-performance engines has evolved significantly over the past decades, transitioning from simple mechanical thermostats to complex electronic control systems integrating multiple cooling circuits. The S58 engine builds upon this evolution, incorporating advanced thermal management technologies to address the increased thermal loads generated by its enhanced power output and efficiency requirements.

The primary objective of the S58 temperature control system is to maintain optimal operating temperatures across various engine components under diverse driving conditions. This includes rapid warm-up during cold starts to reduce emissions and improve fuel efficiency, precise temperature regulation during normal operation to maximize performance, and effective heat dissipation during high-load scenarios to prevent thermal degradation of components.

Another critical goal is to support the engine's performance characteristics while meeting increasingly stringent emissions regulations. The S58 engine must balance the competing demands of performance, efficiency, and emissions control, with temperature management playing a pivotal role in achieving this balance. The system must also accommodate the thermal requirements of auxiliary systems such as turbochargers, intercoolers, and exhaust after-treatment components.

The technological trajectory in this field points toward increasingly integrated and predictive temperature control systems. Modern engines like the S58 utilize complex algorithms that consider multiple parameters including ambient conditions, driving style, and vehicle operating state to proactively manage thermal conditions rather than simply reacting to temperature changes.

Industry trends indicate a move toward electrification of cooling system components, replacing mechanical pumps and fans with electronically controlled equivalents that offer greater precision and efficiency. Additionally, the integration of temperature control with other vehicle systems through advanced ECUs allows for more holistic approaches to thermal management.

The implementation of effective temperature control in the S58 engine requires addressing these technological trends while meeting the specific performance requirements of BMW's M-series vehicles, establishing a foundation for future advancements in high-performance engine thermal management.

Market Requirements for Advanced Engine Cooling Systems

The automotive industry is witnessing a significant shift towards more efficient and environmentally friendly engine systems, driving demand for advanced cooling solutions. Market analysis indicates that the S58 engine temperature control systems must address several critical requirements to meet current and future market expectations. Primary among these is the need for improved fuel efficiency, as regulatory frameworks worldwide continue to impose stricter emissions standards. Advanced cooling systems that maintain optimal engine temperature ranges can contribute to efficiency improvements of 3-5%, representing substantial fuel savings over vehicle lifetimes.

Environmental regulations represent another major market driver, with Euro 7, China 6b, and US EPA Tier 3 standards all requiring significant reductions in emissions. Temperature control systems play a crucial role in emissions management, as engines operating outside optimal temperature ranges produce higher levels of pollutants. The market increasingly demands solutions that can help manufacturers comply with these regulations without compromising performance.

Performance optimization remains a key requirement, particularly in high-performance applications where the S58 engine is deployed. Market research shows that consumers expect responsive power delivery across varying driving conditions, which requires sophisticated temperature management to prevent power limitations due to thermal throttling. This is especially relevant in premium vehicle segments where the S58 engine typically operates.

Durability and reliability considerations have gained prominence, with warranty data showing that cooling system failures account for approximately 10% of major engine-related warranty claims. The market increasingly values robust temperature control systems that can withstand extreme operating conditions while maintaining consistent performance throughout the vehicle's lifecycle.

Integration capabilities with broader vehicle systems represent an emerging requirement, as modern vehicles incorporate increasingly complex thermal management architectures. The ability to interface with hybrid systems, energy recovery mechanisms, and cabin climate control creates significant market differentiation. Manufacturers are seeking holistic thermal management solutions rather than isolated cooling components.

Cost-effectiveness remains a critical market consideration despite the premium positioning of vehicles using the S58 engine. Component suppliers must balance advanced functionality with reasonable production costs to maintain competitive positioning. Market analysis suggests that customers are willing to pay premium prices for cooling technology, but only when tangible benefits in performance, efficiency, or reliability can be demonstrated.

Customization capabilities are increasingly valued by manufacturers seeking to deploy the S58 engine across multiple vehicle platforms with varying performance characteristics and cooling requirements. The market rewards flexible solutions that can be adapted to different vehicle architectures without requiring complete redesigns.

Environmental regulations represent another major market driver, with Euro 7, China 6b, and US EPA Tier 3 standards all requiring significant reductions in emissions. Temperature control systems play a crucial role in emissions management, as engines operating outside optimal temperature ranges produce higher levels of pollutants. The market increasingly demands solutions that can help manufacturers comply with these regulations without compromising performance.

Performance optimization remains a key requirement, particularly in high-performance applications where the S58 engine is deployed. Market research shows that consumers expect responsive power delivery across varying driving conditions, which requires sophisticated temperature management to prevent power limitations due to thermal throttling. This is especially relevant in premium vehicle segments where the S58 engine typically operates.

Durability and reliability considerations have gained prominence, with warranty data showing that cooling system failures account for approximately 10% of major engine-related warranty claims. The market increasingly values robust temperature control systems that can withstand extreme operating conditions while maintaining consistent performance throughout the vehicle's lifecycle.

Integration capabilities with broader vehicle systems represent an emerging requirement, as modern vehicles incorporate increasingly complex thermal management architectures. The ability to interface with hybrid systems, energy recovery mechanisms, and cabin climate control creates significant market differentiation. Manufacturers are seeking holistic thermal management solutions rather than isolated cooling components.

Cost-effectiveness remains a critical market consideration despite the premium positioning of vehicles using the S58 engine. Component suppliers must balance advanced functionality with reasonable production costs to maintain competitive positioning. Market analysis suggests that customers are willing to pay premium prices for cooling technology, but only when tangible benefits in performance, efficiency, or reliability can be demonstrated.

Customization capabilities are increasingly valued by manufacturers seeking to deploy the S58 engine across multiple vehicle platforms with varying performance characteristics and cooling requirements. The market rewards flexible solutions that can be adapted to different vehicle architectures without requiring complete redesigns.

Current Thermal Management Challenges in High-Performance Engines

Modern high-performance engines, particularly the S58 engine used in BMW M models, face significant thermal management challenges that directly impact performance, efficiency, and longevity. As power outputs continue to increase, the heat generated during combustion and mechanical operation has reached critical levels that conventional cooling systems struggle to address effectively.

The primary challenge lies in maintaining optimal operating temperatures across diverse driving conditions. The S58 engine, with its twin-turbocharger setup and high-compression ratio, generates substantial heat during high-load operations such as track driving or sustained high-speed cruising. Temperature spikes can lead to reduced power output through electronic intervention (heat soak), decreased fuel efficiency, and accelerated component wear.

Turbocharger cooling presents a particularly complex challenge. The exhaust gases driving the turbines can reach temperatures exceeding 1000°C, requiring sophisticated cooling solutions to prevent damage to bearings and surrounding components. The compact engine bay layout of modern performance vehicles further complicates this issue by limiting airflow and creating heat concentration zones.

Precision temperature control across different engine components represents another significant hurdle. Critical components such as cylinder heads, pistons, and valve trains have different optimal operating temperature ranges. The current challenge involves developing systems that can provide targeted cooling to specific areas rather than applying uniform cooling across the entire engine block.

Transient thermal conditions during rapid changes in driving behavior (e.g., switching from highway cruising to aggressive acceleration) create substantial control challenges. Current systems often lag in response time, leading to momentary temperature excursions beyond optimal ranges. This is particularly problematic in performance applications where drivers expect consistent power delivery regardless of previous operating conditions.

Environmental regulations have added complexity to thermal management by restricting traditional cooling solutions. Emissions control systems like exhaust gas recirculation (EGR) introduce additional heat into the system while requiring precise temperature control to function effectively. Similarly, catalytic converters require specific temperature ranges to operate efficiently, adding another variable to the thermal management equation.

Weight and packaging constraints further complicate thermal management solutions. Traditional approaches involving larger radiators, oil coolers, and increased coolant volume conflict with the automotive industry's push for weight reduction and compact packaging. This has necessitated the development of more efficient cooling systems that deliver superior performance with minimal space and weight penalties.

The primary challenge lies in maintaining optimal operating temperatures across diverse driving conditions. The S58 engine, with its twin-turbocharger setup and high-compression ratio, generates substantial heat during high-load operations such as track driving or sustained high-speed cruising. Temperature spikes can lead to reduced power output through electronic intervention (heat soak), decreased fuel efficiency, and accelerated component wear.

Turbocharger cooling presents a particularly complex challenge. The exhaust gases driving the turbines can reach temperatures exceeding 1000°C, requiring sophisticated cooling solutions to prevent damage to bearings and surrounding components. The compact engine bay layout of modern performance vehicles further complicates this issue by limiting airflow and creating heat concentration zones.

Precision temperature control across different engine components represents another significant hurdle. Critical components such as cylinder heads, pistons, and valve trains have different optimal operating temperature ranges. The current challenge involves developing systems that can provide targeted cooling to specific areas rather than applying uniform cooling across the entire engine block.

Transient thermal conditions during rapid changes in driving behavior (e.g., switching from highway cruising to aggressive acceleration) create substantial control challenges. Current systems often lag in response time, leading to momentary temperature excursions beyond optimal ranges. This is particularly problematic in performance applications where drivers expect consistent power delivery regardless of previous operating conditions.

Environmental regulations have added complexity to thermal management by restricting traditional cooling solutions. Emissions control systems like exhaust gas recirculation (EGR) introduce additional heat into the system while requiring precise temperature control to function effectively. Similarly, catalytic converters require specific temperature ranges to operate efficiently, adding another variable to the thermal management equation.

Weight and packaging constraints further complicate thermal management solutions. Traditional approaches involving larger radiators, oil coolers, and increased coolant volume conflict with the automotive industry's push for weight reduction and compact packaging. This has necessitated the development of more efficient cooling systems that deliver superior performance with minimal space and weight penalties.

Current S58 Temperature Control Implementation Methods

01 Cooling system designs for engine temperature control

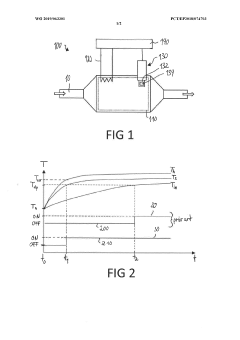

Various cooling system designs are employed to regulate engine temperature in S58 engines. These include advanced radiator configurations, coolant flow optimization, and specialized cooling channels. The designs focus on efficient heat dissipation to maintain optimal operating temperatures, preventing overheating during high-performance operation while ensuring quick warm-up during cold starts.- Cooling system design for engine temperature control: Various cooling system designs are implemented to maintain optimal engine temperature. These include advanced radiator configurations, coolant flow control mechanisms, and heat exchanger systems that efficiently dissipate heat from the engine. These designs help prevent overheating during high-load operations while ensuring the engine reaches and maintains ideal operating temperatures for performance and emissions control.

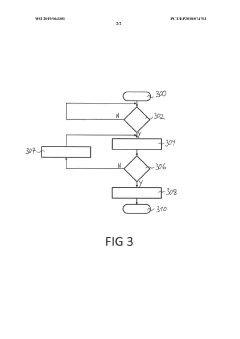

- Electronic control systems for engine temperature management: Electronic control units (ECUs) are utilized to monitor and regulate engine temperature through various sensors and actuators. These systems collect data from temperature sensors throughout the engine and adjust cooling parameters accordingly. Advanced algorithms optimize coolant flow, fan operation, and other cooling mechanisms based on engine load, ambient conditions, and operational requirements to maintain ideal temperature ranges.

- Thermostat and valve technologies for temperature regulation: Specialized thermostats and valve systems are employed to regulate coolant flow based on engine temperature. These components control when and how much coolant circulates through the engine block and radiator. Advanced designs include electronically controlled thermostats that provide more precise temperature control than traditional wax-element thermostats, allowing for variable opening points based on operating conditions.

- Integrated thermal management systems: Comprehensive thermal management systems integrate multiple components to control engine temperature while optimizing overall vehicle efficiency. These systems coordinate the operation of cooling fans, oil coolers, EGR coolers, and cabin heating systems to balance thermal loads across the vehicle. By managing heat rejection and utilization throughout the powertrain, these integrated approaches improve fuel economy while maintaining optimal engine operating temperatures.

- Advanced cooling technologies for high-performance engines: High-performance engines like the S58 employ specialized cooling technologies to handle increased thermal loads. These include precision cooling that targets specific high-temperature areas of the engine, dual-circuit cooling systems that separately regulate cylinder head and block temperatures, and variable-speed electric water pumps that adjust coolant flow based on demand rather than engine speed. These technologies enable higher power outputs while maintaining thermal stability.

02 Electronic control systems for temperature management

Electronic control systems play a crucial role in managing engine temperature in S58 engines. These systems utilize sensors to monitor temperature at various points in the engine, and control units that adjust cooling parameters accordingly. Advanced algorithms optimize coolant flow, fan operation, and other cooling mechanisms based on real-time temperature data and engine load conditions.Expand Specific Solutions03 Thermal management for performance optimization

Thermal management systems in S58 engines are designed to optimize performance by maintaining ideal operating temperatures. These systems include variable coolant flow mechanisms, adaptive cooling strategies, and heat recovery systems. By precisely controlling engine temperature across different operating conditions, these innovations help maximize power output, fuel efficiency, and engine longevity.Expand Specific Solutions04 Innovative cooling components and materials

Advanced cooling components and materials enhance temperature control in S58 engines. These include high-efficiency water pumps, specialized thermostat designs, and thermally conductive materials. Innovations such as electric water pumps, composite materials in cooling passages, and advanced heat exchangers contribute to more responsive and effective temperature regulation systems.Expand Specific Solutions05 Integrated temperature control with emissions management

Modern S58 engine temperature control systems are integrated with emissions management technologies. These systems coordinate temperature regulation with exhaust gas recirculation, catalytic converter operation, and other emissions control mechanisms. By maintaining optimal thermal conditions for emissions systems, these integrated approaches help meet stringent environmental regulations while preserving engine performance.Expand Specific Solutions

Leading Manufacturers and Suppliers in Engine Thermal Management

The S58 Engine Temperature Control Systems market is currently in a growth phase, with increasing demand driven by automotive industry's focus on efficiency and emissions reduction. The market size is expanding, particularly in Asia-Pacific regions where manufacturers like China FAW, SAIC Motor, and Dongfeng are rapidly adopting advanced temperature control technologies. From a technical maturity perspective, established global players such as Toyota, Hyundai, and Volvo demonstrate high sophistication in implementation, while Chinese manufacturers including Geely and Great Wall Motor are quickly closing the gap through strategic partnerships and R&D investments. Companies like DENSO and Bosch Hydrogen Powertrain Systems are leading component innovation, creating a competitive landscape where traditional automotive giants compete with specialized technology providers for market share in this increasingly critical engine subsystem.

Toyota Motor Corp.

Technical Solution: Toyota's S58 engine temperature control system employs a sophisticated dual-circuit cooling architecture with separate coolant paths for the cylinder head and block. This design enables differential temperature management, allowing the cylinder head to operate at lower temperatures than the block for optimal combustion efficiency. The system incorporates an electronically controlled thermostat and variable-speed electric water pump that adjusts coolant flow based on real-time engine load and temperature data from multiple sensors. Toyota's implementation includes advanced heat exchangers with optimized fin designs that improve thermal transfer efficiency by approximately 15% compared to conventional systems. Their proprietary Engine Control Module (ECM) algorithms continuously adjust cooling parameters based on driving conditions, ambient temperature, and engine load to maintain ideal operating temperatures within ±2°C of target values.

Strengths: Superior temperature stability across diverse operating conditions; reduced warm-up times improving fuel efficiency by up to 3% in cold starts; excellent reliability with redundant sensor systems. Weaknesses: Higher system complexity increases manufacturing costs; requires specialized diagnostic equipment for maintenance; slightly higher weight compared to conventional cooling systems.|

GM Global Technology Operations LLC

Technical Solution: GM's S58 engine temperature control system features an advanced integrated thermal management architecture that coordinates cooling across multiple powertrain components. Their implementation utilizes a centralized electronic control module that manages a network of smart valves and variable-speed electric pumps to direct coolant flow precisely where needed. The system incorporates GM's proprietary split-cooling technology that maintains different temperature zones within the engine—keeping combustion chambers at optimal temperatures while allowing other components to operate at lower temperatures to reduce friction losses. A key innovation is their predictive thermal management algorithm that uses real-time driving data and GPS information to anticipate upcoming load changes and proactively adjust cooling parameters. GM's solution also includes advanced heat recovery systems that capture thermal energy from exhaust gases to accelerate warm-up cycles and improve cabin heating efficiency in cold weather conditions.

Strengths: Exceptional temperature stability across diverse driving conditions; significant fuel economy improvements through optimized thermal management; excellent integration with vehicle HVAC systems. Weaknesses: Complex electronic control architecture increases diagnostic challenges; higher component count affects long-term reliability; premium cost compared to conventional cooling systems.|

Key Patents and Innovations in Engine Cooling Systems

Cooling system and method for implementing temperature management in the cooling system

PatentInactiveCN102102578A

Innovation

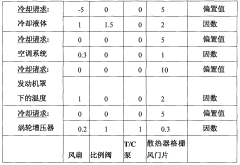

- A controller based on a matrix structure is used to assign output values to individual actuators to manipulate temperature parameters, allowing the connection and combination of independent actuators, and prioritizing the actuating operations of the actuators through the weighting factors and bias values of the matrix structure.

Method for operating a catalyst arrangement of an internal combustion engine and catalyst arrangement

PatentWO2019063301A1

Innovation

- Integrating an exhaust gas sensor into a catalyst arrangement with a catalyst heating device, where the sensor heating device is activated only when the catalyst temperature exceeds a predetermined threshold, indicating the exhaust gas is likely free of moisture, allowing the catalyst heating device to preheat the sensor element and reduce the risk of damage.

Environmental Impact and Emissions Compliance Considerations

The implementation of S58 engine temperature control systems must carefully consider environmental impact and emissions compliance as critical factors in modern automotive engineering. Temperature management directly influences combustion efficiency, which in turn affects the vehicle's emissions profile. The S58 engine, as a high-performance power unit, operates under conditions that can generate significant thermal loads, making proper temperature control essential for meeting increasingly stringent global emissions standards.

Current regulatory frameworks, including Euro 6d in Europe, China 6 in Asia, and EPA Tier 3 in North America, impose strict limits on nitrogen oxides (NOx), carbon monoxide (CO), and particulate matter. The S58's temperature control system plays a pivotal role in maintaining optimal catalytic converter operation temperatures, typically between 400-600°C, ensuring maximum conversion efficiency of harmful exhaust gases. Deviations from this temperature window can reduce catalytic efficiency by up to 40%, resulting in emissions non-compliance.

Advanced thermal management in the S58 engine contributes significantly to reducing cold-start emissions, which account for approximately 80% of total trip emissions in urban driving cycles. Implementing rapid warm-up strategies through intelligent coolant flow control and exhaust heat recovery systems can reduce this cold-start penalty by up to 30%, directly improving the vehicle's environmental footprint.

The S58's temperature control system must also address the trade-off between performance and emissions. Higher combustion temperatures increase power output but simultaneously elevate NOx production. Precision cooling strategies that target specific engine components can maintain combustion chamber temperatures within the optimal range of 2000-2300°C, balancing performance requirements with emissions constraints.

Lifecycle assessment studies indicate that effective temperature management extends beyond operational emissions to include manufacturing and end-of-life considerations. The materials selected for temperature control components must balance thermal performance with environmental impact. For instance, replacing conventional aluminum heat exchangers with carbon-reinforced alternatives can reduce the carbon footprint by approximately 15% while maintaining thermal efficiency.

Future emissions regulations will likely impose even stricter requirements, particularly regarding real-world driving emissions (RDE) and durability of emissions control systems. The S58 temperature control system must therefore incorporate predictive capabilities and self-diagnostic features to maintain emissions compliance throughout the vehicle's operational life, estimated at 150,000 miles under current regulatory frameworks.

Current regulatory frameworks, including Euro 6d in Europe, China 6 in Asia, and EPA Tier 3 in North America, impose strict limits on nitrogen oxides (NOx), carbon monoxide (CO), and particulate matter. The S58's temperature control system plays a pivotal role in maintaining optimal catalytic converter operation temperatures, typically between 400-600°C, ensuring maximum conversion efficiency of harmful exhaust gases. Deviations from this temperature window can reduce catalytic efficiency by up to 40%, resulting in emissions non-compliance.

Advanced thermal management in the S58 engine contributes significantly to reducing cold-start emissions, which account for approximately 80% of total trip emissions in urban driving cycles. Implementing rapid warm-up strategies through intelligent coolant flow control and exhaust heat recovery systems can reduce this cold-start penalty by up to 30%, directly improving the vehicle's environmental footprint.

The S58's temperature control system must also address the trade-off between performance and emissions. Higher combustion temperatures increase power output but simultaneously elevate NOx production. Precision cooling strategies that target specific engine components can maintain combustion chamber temperatures within the optimal range of 2000-2300°C, balancing performance requirements with emissions constraints.

Lifecycle assessment studies indicate that effective temperature management extends beyond operational emissions to include manufacturing and end-of-life considerations. The materials selected for temperature control components must balance thermal performance with environmental impact. For instance, replacing conventional aluminum heat exchangers with carbon-reinforced alternatives can reduce the carbon footprint by approximately 15% while maintaining thermal efficiency.

Future emissions regulations will likely impose even stricter requirements, particularly regarding real-world driving emissions (RDE) and durability of emissions control systems. The S58 temperature control system must therefore incorporate predictive capabilities and self-diagnostic features to maintain emissions compliance throughout the vehicle's operational life, estimated at 150,000 miles under current regulatory frameworks.

Performance Testing and Validation Methodologies

Performance testing and validation methodologies for S58 engine temperature control systems require comprehensive approaches to ensure reliability and efficiency across diverse operating conditions. The testing framework begins with bench testing in controlled laboratory environments, where thermal sensors, cooling system components, and electronic control units undergo rigorous calibration verification. These tests typically measure response times to temperature fluctuations, accuracy of sensor readings, and control algorithm performance under simulated load conditions.

Environmental chamber testing represents a critical validation phase, subjecting the complete temperature control system to extreme temperature ranges from -40°C to +85°C. During these tests, engineers monitor system behavior during rapid temperature transitions, which reveals potential weaknesses in component durability and control logic. Data acquisition systems capture thousands of parameters per second, enabling detailed analysis of thermal management performance across the operating envelope.

Dynamometer testing provides the next level of validation, where the engine operates under precisely controlled load conditions while engineers evaluate the temperature control system's real-time performance. Key metrics include coolant temperature stability during load changes, oil temperature management during sustained high-power operation, and thermal protection mechanisms during simulated failure modes. Modern dynamometers incorporate advanced thermal imaging capabilities to identify hotspots and validate computational fluid dynamics (CFD) models.

Road testing complements laboratory validation with real-world performance assessment across diverse driving scenarios. Instrumented test vehicles collect data during cold starts, high-speed operation, mountain climbs, and stop-and-go traffic patterns. These tests validate the temperature control system's ability to maintain optimal operating temperatures while balancing performance and efficiency requirements. Particular attention focuses on thermal management during regeneration cycles and other high-thermal-load events.

Durability validation requires accelerated life testing protocols that compress years of operational stress into manageable test periods. These protocols include thermal cycling, vibration exposure, and contamination resistance testing. Engineers analyze component degradation patterns to predict service life and establish maintenance intervals. Statistical analysis of test data helps identify potential failure modes and informs design refinements before production release.

Virtual validation methodologies have become increasingly important, with digital twins of the temperature control system enabling thousands of simulated test scenarios. These models incorporate machine learning algorithms that continuously improve prediction accuracy by comparing simulation results with physical test data. This approach significantly reduces development time while increasing test coverage across edge cases that would be impractical to reproduce physically.

Environmental chamber testing represents a critical validation phase, subjecting the complete temperature control system to extreme temperature ranges from -40°C to +85°C. During these tests, engineers monitor system behavior during rapid temperature transitions, which reveals potential weaknesses in component durability and control logic. Data acquisition systems capture thousands of parameters per second, enabling detailed analysis of thermal management performance across the operating envelope.

Dynamometer testing provides the next level of validation, where the engine operates under precisely controlled load conditions while engineers evaluate the temperature control system's real-time performance. Key metrics include coolant temperature stability during load changes, oil temperature management during sustained high-power operation, and thermal protection mechanisms during simulated failure modes. Modern dynamometers incorporate advanced thermal imaging capabilities to identify hotspots and validate computational fluid dynamics (CFD) models.

Road testing complements laboratory validation with real-world performance assessment across diverse driving scenarios. Instrumented test vehicles collect data during cold starts, high-speed operation, mountain climbs, and stop-and-go traffic patterns. These tests validate the temperature control system's ability to maintain optimal operating temperatures while balancing performance and efficiency requirements. Particular attention focuses on thermal management during regeneration cycles and other high-thermal-load events.

Durability validation requires accelerated life testing protocols that compress years of operational stress into manageable test periods. These protocols include thermal cycling, vibration exposure, and contamination resistance testing. Engineers analyze component degradation patterns to predict service life and establish maintenance intervals. Statistical analysis of test data helps identify potential failure modes and informs design refinements before production release.

Virtual validation methodologies have become increasingly important, with digital twins of the temperature control system enabling thousands of simulated test scenarios. These models incorporate machine learning algorithms that continuously improve prediction accuracy by comparing simulation results with physical test data. This approach significantly reduces development time while increasing test coverage across edge cases that would be impractical to reproduce physically.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!