How to Measure S58 Engine Vibration Impact on Durability

SEP 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

S58 Engine Vibration Analysis Background and Objectives

The S58 engine, developed as a high-performance inline-six powerplant for BMW M vehicles, represents a significant advancement in automotive engineering with its twin-turbo configuration and robust power output exceeding 500 horsepower. Since its introduction in 2019, this engine has become a cornerstone for BMW's performance lineup, powering vehicles such as the M3, M4, and X3M. Understanding vibration characteristics and their impact on durability is critical for ensuring the longevity and reliability of this premium powertrain.

Engine vibration analysis has evolved significantly over the past decades, transitioning from basic mechanical measurements to sophisticated digital analysis techniques. The historical progression of vibration analysis methodologies has seen advancements from simple accelerometers to complex multi-channel data acquisition systems capable of capturing high-resolution vibration signatures across multiple frequency domains. These technological developments have enabled engineers to identify subtle vibration patterns that may indicate potential durability issues before they manifest as mechanical failures.

The S58 engine presents unique vibration challenges due to its high-performance nature. Operating at elevated RPMs and producing substantial torque, this powerplant generates complex vibration patterns that differ significantly from standard production engines. These vibrations propagate through various engine components and mounting systems, potentially affecting long-term durability of both the engine itself and surrounding vehicle systems.

The primary objective of this technical research is to establish comprehensive methodologies for measuring, analyzing, and correlating S58 engine vibrations with durability outcomes. This includes developing testing protocols that can accurately capture vibration data under various operating conditions, from idle to full-load scenarios, and across the entire RPM range. Additionally, we aim to identify specific vibration signatures that may serve as early indicators of potential durability concerns.

Secondary objectives include creating a vibration profile database that can serve as a benchmark for quality control during production, establishing correlation models between specific vibration patterns and component wear rates, and developing predictive algorithms that can estimate remaining useful life based on vibration characteristics. These objectives align with the broader industry trend toward predictive maintenance and condition-based monitoring systems.

The technological trajectory in this field points toward integration of real-time vibration monitoring systems that can provide continuous feedback during vehicle operation. This evolution represents a shift from traditional interval-based testing to dynamic monitoring approaches that can detect anomalies as they develop, potentially preventing catastrophic failures and extending engine service life significantly.

Engine vibration analysis has evolved significantly over the past decades, transitioning from basic mechanical measurements to sophisticated digital analysis techniques. The historical progression of vibration analysis methodologies has seen advancements from simple accelerometers to complex multi-channel data acquisition systems capable of capturing high-resolution vibration signatures across multiple frequency domains. These technological developments have enabled engineers to identify subtle vibration patterns that may indicate potential durability issues before they manifest as mechanical failures.

The S58 engine presents unique vibration challenges due to its high-performance nature. Operating at elevated RPMs and producing substantial torque, this powerplant generates complex vibration patterns that differ significantly from standard production engines. These vibrations propagate through various engine components and mounting systems, potentially affecting long-term durability of both the engine itself and surrounding vehicle systems.

The primary objective of this technical research is to establish comprehensive methodologies for measuring, analyzing, and correlating S58 engine vibrations with durability outcomes. This includes developing testing protocols that can accurately capture vibration data under various operating conditions, from idle to full-load scenarios, and across the entire RPM range. Additionally, we aim to identify specific vibration signatures that may serve as early indicators of potential durability concerns.

Secondary objectives include creating a vibration profile database that can serve as a benchmark for quality control during production, establishing correlation models between specific vibration patterns and component wear rates, and developing predictive algorithms that can estimate remaining useful life based on vibration characteristics. These objectives align with the broader industry trend toward predictive maintenance and condition-based monitoring systems.

The technological trajectory in this field points toward integration of real-time vibration monitoring systems that can provide continuous feedback during vehicle operation. This evolution represents a shift from traditional interval-based testing to dynamic monitoring approaches that can detect anomalies as they develop, potentially preventing catastrophic failures and extending engine service life significantly.

Market Requirements for Engine Durability Assessment

The automotive industry has witnessed a significant shift in market requirements for engine durability assessment, particularly for high-performance engines like the S58. Original Equipment Manufacturers (OEMs) and consumers alike are demanding longer engine lifespans with minimal maintenance requirements, creating pressure for more sophisticated durability testing methodologies that accurately predict real-world performance.

Market research indicates that premium vehicle owners expect engines to maintain optimal performance for at least 150,000 miles without major repairs, representing a 25% increase in durability expectations compared to a decade ago. This shift has been particularly pronounced in the performance vehicle segment, where the S58 engine operates, as buyers increasingly use these vehicles as daily drivers rather than occasional recreational vehicles.

Regulatory bodies worldwide have also tightened requirements for engine emissions durability, with the European Union's Euro 7 standards and similar regulations in North America and Asia mandating that emissions control systems maintain effectiveness for extended periods. These regulations directly impact vibration testing requirements, as excessive vibration can accelerate wear on emissions components.

Insurance companies and fleet operators have emerged as significant stakeholders in durability assessment, using engine reliability data to determine premiums and total cost of ownership calculations. Their data shows that vibration-related failures account for approximately 18% of major engine warranty claims, highlighting the economic importance of accurate vibration impact assessment.

The aftermarket performance sector presents additional requirements, with tuning companies seeking detailed vibration data to ensure their modifications don't compromise long-term durability. This market segment has grown substantially, with performance tuning representing a multi-billion dollar industry that depends on reliable vibration impact data.

Manufacturing efficiency demands have also shaped durability assessment requirements, with production engineers requiring testing methodologies that can be integrated into existing quality control processes without significantly extending production time. The ideal vibration assessment solution must therefore balance thoroughness with practical implementation constraints.

Customer satisfaction metrics increasingly correlate perceived quality with noise, vibration, and harshness (NVH) characteristics, making vibration assessment a critical component of brand perception management. Premium manufacturers have responded by establishing more stringent internal standards for acceptable vibration levels throughout the engine's service life.

These market requirements collectively point toward the need for comprehensive, data-driven approaches to measuring the S58 engine's vibration impact on durability, with particular emphasis on real-world operating conditions rather than simplified laboratory testing alone.

Market research indicates that premium vehicle owners expect engines to maintain optimal performance for at least 150,000 miles without major repairs, representing a 25% increase in durability expectations compared to a decade ago. This shift has been particularly pronounced in the performance vehicle segment, where the S58 engine operates, as buyers increasingly use these vehicles as daily drivers rather than occasional recreational vehicles.

Regulatory bodies worldwide have also tightened requirements for engine emissions durability, with the European Union's Euro 7 standards and similar regulations in North America and Asia mandating that emissions control systems maintain effectiveness for extended periods. These regulations directly impact vibration testing requirements, as excessive vibration can accelerate wear on emissions components.

Insurance companies and fleet operators have emerged as significant stakeholders in durability assessment, using engine reliability data to determine premiums and total cost of ownership calculations. Their data shows that vibration-related failures account for approximately 18% of major engine warranty claims, highlighting the economic importance of accurate vibration impact assessment.

The aftermarket performance sector presents additional requirements, with tuning companies seeking detailed vibration data to ensure their modifications don't compromise long-term durability. This market segment has grown substantially, with performance tuning representing a multi-billion dollar industry that depends on reliable vibration impact data.

Manufacturing efficiency demands have also shaped durability assessment requirements, with production engineers requiring testing methodologies that can be integrated into existing quality control processes without significantly extending production time. The ideal vibration assessment solution must therefore balance thoroughness with practical implementation constraints.

Customer satisfaction metrics increasingly correlate perceived quality with noise, vibration, and harshness (NVH) characteristics, making vibration assessment a critical component of brand perception management. Premium manufacturers have responded by establishing more stringent internal standards for acceptable vibration levels throughout the engine's service life.

These market requirements collectively point toward the need for comprehensive, data-driven approaches to measuring the S58 engine's vibration impact on durability, with particular emphasis on real-world operating conditions rather than simplified laboratory testing alone.

Current Vibration Measurement Technologies and Challenges

The measurement of engine vibration is a critical aspect of automotive engineering, particularly for high-performance engines like the BMW S58. Current vibration measurement technologies employ several sophisticated approaches, each with distinct advantages and limitations when assessing durability impacts.

Accelerometers remain the most widely utilized sensors for vibration measurement, with piezoelectric accelerometers being the industry standard due to their robust performance across a wide frequency range. These sensors can be strategically mounted at critical points on the S58 engine to capture vibration signatures during operation. Modern systems typically employ tri-axial accelerometers to simultaneously measure vibration in multiple directions, providing comprehensive data about complex vibration patterns.

Laser Doppler vibrometers represent a non-contact alternative that has gained prominence in recent years. These systems measure vibration velocity by detecting the Doppler shift in reflected laser light, allowing for measurements on hot surfaces or in locations where physical sensor mounting is impractical. For S58 engine applications, this technology enables precise measurement of small components without mass loading effects that might alter vibration characteristics.

Modal analysis systems combine multiple sensors with sophisticated software to characterize the structural dynamics of the engine. This approach identifies resonant frequencies, mode shapes, and damping characteristics, which are essential for understanding how vibration energy propagates through the engine structure and potentially impacts durability.

Despite these advanced technologies, significant challenges persist in accurately correlating measured vibration data with actual durability outcomes. Temperature variations during engine operation can significantly affect sensor performance and material properties, introducing measurement uncertainties. The complex operating environment of the S58 engine, with varying loads, speeds, and thermal conditions, makes it difficult to establish consistent measurement protocols.

Data interpretation presents another substantial challenge. The massive volumes of vibration data generated require advanced signal processing techniques to extract meaningful patterns. Distinguishing between normal operational vibrations and those that indicate potential durability issues demands sophisticated algorithms and extensive baseline data for comparison.

Long-term monitoring capabilities remain limited by sensor durability and data storage constraints. While short-term vibration profiles are relatively easy to capture, understanding how vibration patterns evolve over thousands of operating hours—critical for durability assessment—requires more robust monitoring solutions than currently available.

Integration challenges also exist between vibration measurement systems and other diagnostic tools. Creating a holistic view of engine health that incorporates vibration data alongside other parameters (temperature, pressure, emissions) requires complex data fusion approaches that are still evolving in automotive applications.

Accelerometers remain the most widely utilized sensors for vibration measurement, with piezoelectric accelerometers being the industry standard due to their robust performance across a wide frequency range. These sensors can be strategically mounted at critical points on the S58 engine to capture vibration signatures during operation. Modern systems typically employ tri-axial accelerometers to simultaneously measure vibration in multiple directions, providing comprehensive data about complex vibration patterns.

Laser Doppler vibrometers represent a non-contact alternative that has gained prominence in recent years. These systems measure vibration velocity by detecting the Doppler shift in reflected laser light, allowing for measurements on hot surfaces or in locations where physical sensor mounting is impractical. For S58 engine applications, this technology enables precise measurement of small components without mass loading effects that might alter vibration characteristics.

Modal analysis systems combine multiple sensors with sophisticated software to characterize the structural dynamics of the engine. This approach identifies resonant frequencies, mode shapes, and damping characteristics, which are essential for understanding how vibration energy propagates through the engine structure and potentially impacts durability.

Despite these advanced technologies, significant challenges persist in accurately correlating measured vibration data with actual durability outcomes. Temperature variations during engine operation can significantly affect sensor performance and material properties, introducing measurement uncertainties. The complex operating environment of the S58 engine, with varying loads, speeds, and thermal conditions, makes it difficult to establish consistent measurement protocols.

Data interpretation presents another substantial challenge. The massive volumes of vibration data generated require advanced signal processing techniques to extract meaningful patterns. Distinguishing between normal operational vibrations and those that indicate potential durability issues demands sophisticated algorithms and extensive baseline data for comparison.

Long-term monitoring capabilities remain limited by sensor durability and data storage constraints. While short-term vibration profiles are relatively easy to capture, understanding how vibration patterns evolve over thousands of operating hours—critical for durability assessment—requires more robust monitoring solutions than currently available.

Integration challenges also exist between vibration measurement systems and other diagnostic tools. Creating a holistic view of engine health that incorporates vibration data alongside other parameters (temperature, pressure, emissions) requires complex data fusion approaches that are still evolving in automotive applications.

Established Methodologies for S58 Vibration Impact Assessment

01 Engine mounting systems for vibration reduction

Various mounting systems are designed to isolate and reduce engine vibrations in S58 engines. These systems typically include specialized rubber or hydraulic mounts positioned strategically around the engine to absorb vibrations before they transfer to the vehicle chassis. Advanced mounting systems may incorporate active or semi-active components that adjust damping characteristics based on engine operating conditions, effectively minimizing vibration across different RPM ranges.- Vibration damping systems for S58 engines: Various vibration damping systems are designed specifically for S58 engines to reduce operational vibrations. These systems typically include specialized mounts, dampers, and isolation components that absorb and dissipate vibrational energy. The damping mechanisms are engineered to target the specific frequency ranges produced by S58 engines, providing effective vibration reduction without compromising engine performance or durability.

- Engine mounting solutions for vibration control: Advanced mounting solutions are implemented to control and minimize vibrations in S58 engines. These mounting systems utilize elastomeric materials, hydraulic elements, or active control mechanisms to isolate engine vibrations from the vehicle chassis. The mounts are strategically positioned to counteract the primary vibration vectors generated during engine operation, resulting in smoother performance and reduced noise transmission to the vehicle cabin.

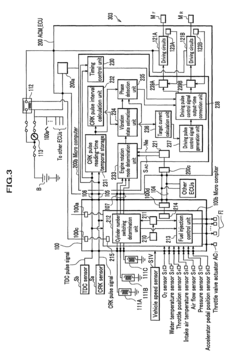

- Electronic vibration detection and control systems: Electronic systems are employed to detect and actively control vibrations in S58 engines. These systems utilize sensors to monitor vibration patterns and engine operating conditions in real-time. The collected data is processed by control units that adjust engine parameters or activate counterbalancing mechanisms to minimize vibrations. This approach allows for dynamic vibration management across various engine speeds and load conditions, optimizing both performance and comfort.

- Structural modifications to reduce engine vibration: Structural modifications are implemented in S58 engines to inherently reduce vibration generation. These modifications include redesigned engine blocks with reinforced mounting points, optimized crankshaft balancing, and improved internal component geometries. By addressing vibration at its source through structural engineering, these solutions provide fundamental improvements to engine smoothness without relying solely on external damping systems.

- Balance shaft technology for S58 engines: Balance shaft technology is utilized in S58 engines to counteract inherent vibrations caused by reciprocating and rotating components. These precision-engineered shafts rotate at specific speeds and phases to generate forces that offset primary and secondary vibrations. The implementation of balance shafts significantly reduces engine vibration across the operational RPM range, improving overall refinement and reducing wear on engine components and mounting systems.

02 Vibration dampening components and materials

Specific components and materials are employed to dampen vibrations in S58 engines. These include specialized dampeners, balance shafts, and vibration-absorbing materials integrated into engine components. Composite materials with vibration-dampening properties may be used in critical areas to reduce resonance. Additionally, specialized coatings or inserts can be applied to engine components to absorb vibration energy and convert it to minimal heat, reducing overall engine vibration.Expand Specific Solutions03 Electronic vibration control systems

Advanced electronic systems are implemented to monitor and control vibrations in S58 engines. These systems utilize sensors to detect vibration patterns and frequencies, then adjust engine parameters such as timing, fuel delivery, and throttle response to minimize vibration. Some systems incorporate predictive algorithms that anticipate vibration issues based on engine load and speed, making proactive adjustments to maintain smooth operation. Electronic control units may also coordinate with other vehicle systems to provide comprehensive vibration management.Expand Specific Solutions04 Structural design modifications for vibration reduction

Specific structural modifications to the S58 engine design help reduce inherent vibrations. These include optimized crankshaft balancing, reinforced engine blocks with strategic ribbing, and redesigned cylinder heads that minimize resonance. The internal geometry of components may be modified to distribute forces more evenly throughout the engine. Additionally, precision manufacturing techniques ensure tight tolerances that reduce mechanical play which can contribute to vibration.Expand Specific Solutions05 Diagnostic and testing methods for engine vibration

Specialized diagnostic and testing methods are developed to identify and address vibration issues in S58 engines. These include vibration analysis tools that can pinpoint the source and frequency of problematic vibrations, allowing for targeted solutions. Testing protocols may involve specialized equipment to measure vibration under various operating conditions. Maintenance procedures specifically designed to address vibration-related wear and component degradation help maintain optimal engine performance and longevity.Expand Specific Solutions

Leading Companies in Engine Vibration Analysis Equipment

The S58 engine vibration impact on durability assessment market is in a growth phase, with increasing demand driven by automotive and aerospace sectors' focus on reliability and longevity. The market size is expanding as manufacturers prioritize vibration analysis to extend engine life and reduce warranty costs. Technologically, the field shows varying maturity levels across players. Toyota, DENSO, and Mitsubishi Electric lead with advanced vibration measurement systems, while emerging competitors like Changan Automobile and Leapmotor are developing specialized solutions. Academic institutions including Harbin Institute of Technology and Beihang University contribute significant research, creating a competitive ecosystem balancing established corporations and innovative newcomers in this specialized engineering domain.

Toyota Motor Corp.

Technical Solution: Toyota has developed a comprehensive engine vibration measurement system for the S58 engine that combines multiple sensing technologies. Their approach utilizes accelerometers strategically placed at critical points on the engine block, cylinder heads, and mounting points to capture multi-directional vibration data. Toyota implements advanced signal processing algorithms to filter noise and isolate specific vibration frequencies related to durability concerns. Their system incorporates real-time monitoring capabilities during various operating conditions, including cold starts, idle, acceleration, and high-load scenarios. Toyota's durability assessment methodology includes correlation between vibration signatures and component fatigue through extensive bench testing and field validation. They have established specific vibration thresholds and profiles that indicate potential durability issues before physical damage occurs.

Strengths: Toyota's system benefits from integration with their extensive durability testing infrastructure and historical engine data, allowing for precise correlation between vibration patterns and actual component failures. Their approach enables early detection of potential issues during development phases. Weaknesses: The system requires significant calibration for each engine variant and may be less effective at detecting intermittent vibration issues that occur under specific environmental conditions.

DENSO Corp.

Technical Solution: DENSO has engineered a specialized vibration measurement system for engine durability assessment that focuses on high-precision data acquisition. Their technology employs piezoelectric sensors with high sampling rates (up to 50kHz) to capture micro-vibrations that might indicate early-stage durability concerns. DENSO's approach incorporates temperature compensation algorithms to account for thermal expansion effects on vibration characteristics across operating temperatures. Their system features wireless sensor networks that minimize the need for complex wiring harnesses, allowing for more measurement points without compromising engine packaging. DENSO has developed proprietary machine learning algorithms that can identify abnormal vibration patterns by comparing real-time data against baseline profiles established during engine development. Their durability impact assessment includes simulation models that predict component life based on measured vibration loads and material properties.

Strengths: DENSO's system offers exceptional sensitivity to early-stage vibration anomalies before they manifest as visible damage, providing valuable lead time for engineering interventions. Their wireless approach enables more comprehensive measurement coverage. Weaknesses: The system's high sensitivity can sometimes generate false positives, requiring additional verification steps. The sophisticated algorithms require significant computing resources for real-time analysis.

Critical Patents in Engine Vibration Measurement Technology

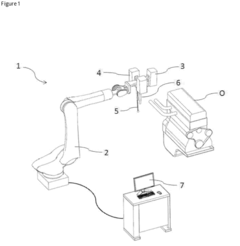

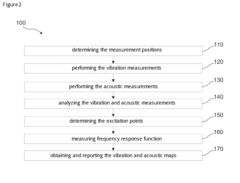

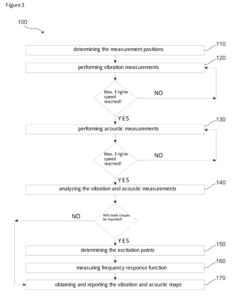

Vibration and noise mapping system and method

PatentActiveUS20190025159A1

Innovation

- A vibration and noise mapping system utilizing a mobile robotic arm with vibration and acoustic measurement units, contactless acoustic excitation, and geometric scanning to perform automatic, tri-directional measurements, generating maps with vectorial orientations and enabling quick identification of areas for improvement.

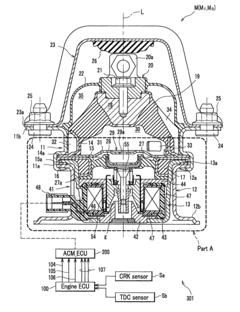

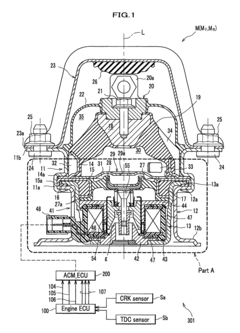

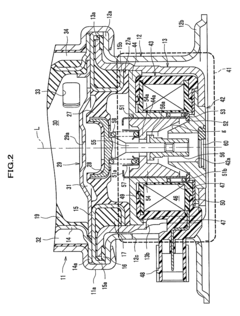

Active anti-vibration supporting device and anti-vibration control method for same

PatentInactiveUS8775019B2

Innovation

- An active anti-vibration supporting device with a control unit that estimates engine vibration state, calculates a target current waveform, and adjusts phase delays by dividing the calculated phase delay by a predetermined time based on engine rotation speed to ensure appropriate timing for actuator driving, thereby maintaining continuous current supply and effective vibration control.

Simulation and Digital Twin Applications for Vibration Analysis

Simulation and digital twin technologies have revolutionized the approach to vibration analysis in engine development, particularly for the S58 engine durability assessment. These advanced computational methods enable engineers to create virtual replicas of physical engines and their operating environments, allowing for comprehensive vibration impact studies without extensive physical testing.

Digital twins of the S58 engine incorporate detailed component geometries, material properties, and boundary conditions to accurately represent the physical system. These virtual models can simulate various operating conditions, from idle to maximum power output, capturing the complex vibration patterns that emerge across different RPM ranges and load conditions.

Finite Element Analysis (FEA) serves as a cornerstone technique within these simulation environments, enabling precise calculation of stress distributions and deformation patterns resulting from engine vibrations. Engineers can identify critical components susceptible to fatigue failure by analyzing resonance frequencies and vibration modes through modal analysis simulations.

Time-domain and frequency-domain analyses provide complementary perspectives on vibration characteristics. Time-domain simulations track vibration amplitude variations over operational cycles, while frequency-domain analysis identifies dominant frequencies that may align with natural frequencies of engine components, potentially leading to resonance conditions.

Multi-physics simulation capabilities integrate thermal effects with vibration analysis, accounting for how temperature gradients affect material properties and clearances, which subsequently influence vibration transmission paths and amplitudes. This holistic approach captures the complex interplay between thermal expansion, mechanical loads, and resulting vibration patterns.

Machine learning algorithms increasingly complement traditional simulation approaches by processing vast simulation datasets to identify patterns and correlations between operating parameters and vibration signatures. These algorithms can predict potential durability issues based on simulated vibration data, enabling preemptive design modifications.

Real-time monitoring systems can be developed and validated using digital twin technology, where sensor placement optimization is performed virtually before physical implementation. This ensures optimal detection of critical vibration patterns during actual engine operation, creating a feedback loop between simulation and real-world performance.

The integration of simulation results with accelerated life testing methodologies allows engineers to extrapolate short-term vibration data to predict long-term durability outcomes. This hybrid approach combines the efficiency of computational analysis with targeted physical validation, significantly reducing development time while enhancing reliability predictions for the S58 engine.

Digital twins of the S58 engine incorporate detailed component geometries, material properties, and boundary conditions to accurately represent the physical system. These virtual models can simulate various operating conditions, from idle to maximum power output, capturing the complex vibration patterns that emerge across different RPM ranges and load conditions.

Finite Element Analysis (FEA) serves as a cornerstone technique within these simulation environments, enabling precise calculation of stress distributions and deformation patterns resulting from engine vibrations. Engineers can identify critical components susceptible to fatigue failure by analyzing resonance frequencies and vibration modes through modal analysis simulations.

Time-domain and frequency-domain analyses provide complementary perspectives on vibration characteristics. Time-domain simulations track vibration amplitude variations over operational cycles, while frequency-domain analysis identifies dominant frequencies that may align with natural frequencies of engine components, potentially leading to resonance conditions.

Multi-physics simulation capabilities integrate thermal effects with vibration analysis, accounting for how temperature gradients affect material properties and clearances, which subsequently influence vibration transmission paths and amplitudes. This holistic approach captures the complex interplay between thermal expansion, mechanical loads, and resulting vibration patterns.

Machine learning algorithms increasingly complement traditional simulation approaches by processing vast simulation datasets to identify patterns and correlations between operating parameters and vibration signatures. These algorithms can predict potential durability issues based on simulated vibration data, enabling preemptive design modifications.

Real-time monitoring systems can be developed and validated using digital twin technology, where sensor placement optimization is performed virtually before physical implementation. This ensures optimal detection of critical vibration patterns during actual engine operation, creating a feedback loop between simulation and real-world performance.

The integration of simulation results with accelerated life testing methodologies allows engineers to extrapolate short-term vibration data to predict long-term durability outcomes. This hybrid approach combines the efficiency of computational analysis with targeted physical validation, significantly reducing development time while enhancing reliability predictions for the S58 engine.

Material Science Advancements for Vibration Resistance

Recent advancements in material science have revolutionized approaches to vibration resistance, particularly relevant for measuring and mitigating S58 engine vibration impacts on durability. Traditional materials used in engine components have been enhanced through innovative composite structures that combine lightweight properties with superior vibration dampening capabilities. These next-generation composites incorporate nano-reinforced polymers and ceramic matrices that can withstand high-frequency vibrations while maintaining structural integrity under extreme thermal conditions.

Metamaterials represent a significant breakthrough, engineered with precise microstructural arrangements that can redirect, absorb, or cancel specific vibration frequencies. When applied to critical S58 engine components, these materials can selectively target harmful resonant frequencies that most significantly impact durability. The development of phononic crystals—materials with periodic structures designed to control mechanical wave propagation—has enabled unprecedented precision in vibration management.

Self-healing materials constitute another frontier in vibration resistance technology. These advanced materials contain microcapsules or vascular networks filled with healing agents that automatically repair microcracks caused by vibration-induced fatigue before they propagate into catastrophic failures. This capability significantly extends component lifespan in high-vibration environments like those experienced in S58 engines.

Surface treatment technologies have also evolved substantially, with new coating formulations that provide both corrosion protection and vibration dampening. Multi-functional coatings incorporating viscoelastic polymers and ceramic particles can be precisely tuned to absorb energy across specific frequency ranges most detrimental to engine durability. These coatings can be applied through advanced deposition techniques that ensure uniform coverage even on complex geometries.

Computational material science has accelerated development through predictive modeling of material behavior under various vibration conditions. Machine learning algorithms now enable the design of materials with optimized microstructures specifically tailored to the vibration profile of S58 engines. These digital twins of materials can predict performance degradation over time, allowing for preventive maintenance before critical failures occur.

Biomimetic approaches have yielded promising results by emulating natural structures known for exceptional vibration resistance. Materials inspired by woodpecker skulls and mantis shrimp appendages demonstrate remarkable shock absorption capabilities that can be translated to engine component design. These bio-inspired materials often feature hierarchical structures that dissipate energy across multiple scales simultaneously.

Metamaterials represent a significant breakthrough, engineered with precise microstructural arrangements that can redirect, absorb, or cancel specific vibration frequencies. When applied to critical S58 engine components, these materials can selectively target harmful resonant frequencies that most significantly impact durability. The development of phononic crystals—materials with periodic structures designed to control mechanical wave propagation—has enabled unprecedented precision in vibration management.

Self-healing materials constitute another frontier in vibration resistance technology. These advanced materials contain microcapsules or vascular networks filled with healing agents that automatically repair microcracks caused by vibration-induced fatigue before they propagate into catastrophic failures. This capability significantly extends component lifespan in high-vibration environments like those experienced in S58 engines.

Surface treatment technologies have also evolved substantially, with new coating formulations that provide both corrosion protection and vibration dampening. Multi-functional coatings incorporating viscoelastic polymers and ceramic particles can be precisely tuned to absorb energy across specific frequency ranges most detrimental to engine durability. These coatings can be applied through advanced deposition techniques that ensure uniform coverage even on complex geometries.

Computational material science has accelerated development through predictive modeling of material behavior under various vibration conditions. Machine learning algorithms now enable the design of materials with optimized microstructures specifically tailored to the vibration profile of S58 engines. These digital twins of materials can predict performance degradation over time, allowing for preventive maintenance before critical failures occur.

Biomimetic approaches have yielded promising results by emulating natural structures known for exceptional vibration resistance. Materials inspired by woodpecker skulls and mantis shrimp appendages demonstrate remarkable shock absorption capabilities that can be translated to engine component design. These bio-inspired materials often feature hierarchical structures that dissipate energy across multiple scales simultaneously.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!