Optimize S58 Engine for Fuel Injection Efficiency

SEP 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

S58 Engine Fuel Injection Background and Objectives

The S58 engine, developed by BMW M GmbH, represents a significant evolution in high-performance inline-six engine technology. Introduced in 2019, this 3.0-liter twin-turbocharged powerplant serves as the heart of BMW's latest M-series vehicles, including the M3, M4, and X3 M models. The S58 builds upon the foundation of its predecessor, the S55, while incorporating substantial technological advancements aimed at enhancing performance, efficiency, and emissions compliance.

Fuel injection technology has evolved dramatically in automotive engineering over the past decades, transitioning from mechanical systems to sophisticated electronic direct injection. The S58 engine employs a high-precision direct injection system operating at pressures up to 350 bar, significantly higher than conventional systems. This advancement allows for more precise fuel atomization and combustion control, directly impacting both performance and efficiency metrics.

Current industry trends show a clear trajectory toward increasingly stringent emissions regulations globally, particularly in European and North American markets. These regulatory pressures have accelerated the development of more efficient fuel delivery systems that can maintain performance while reducing particulate emissions and improving fuel economy. The S58 engine exists at this critical intersection of performance expectations and environmental compliance requirements.

The primary technical objective for optimizing the S58 engine's fuel injection efficiency encompasses several interconnected goals. First, enhancing the precision of fuel delivery timing and quantity to achieve more complete combustion across all operating conditions. Second, reducing parasitic power losses in the high-pressure fuel pump system to improve overall engine efficiency. Third, optimizing injection spray patterns to minimize cylinder wall wetting, which contributes to particulate formation and oil dilution.

Additionally, there are objectives related to cold-start emissions reduction, as this operational phase represents a disproportionate contribution to total emissions. The optimization must also address transient response characteristics during rapid load changes, which present unique challenges for maintaining optimal air-fuel ratios and combustion stability.

From a market perspective, the optimization goals must balance pure performance metrics valued by enthusiast customers with increasingly important efficiency considerations. BMW's positioning of M-series vehicles as both track-capable and daily-drivable machines necessitates a fuel injection system that can seamlessly transition between these sometimes contradictory use cases.

The technological evolution path for high-performance engine fuel injection systems points toward even higher injection pressures (potentially exceeding 500 bar), multiple injection events per combustion cycle, and more sophisticated integration with other engine subsystems including variable valve timing, turbocharger control, and exhaust aftertreatment technologies.

Fuel injection technology has evolved dramatically in automotive engineering over the past decades, transitioning from mechanical systems to sophisticated electronic direct injection. The S58 engine employs a high-precision direct injection system operating at pressures up to 350 bar, significantly higher than conventional systems. This advancement allows for more precise fuel atomization and combustion control, directly impacting both performance and efficiency metrics.

Current industry trends show a clear trajectory toward increasingly stringent emissions regulations globally, particularly in European and North American markets. These regulatory pressures have accelerated the development of more efficient fuel delivery systems that can maintain performance while reducing particulate emissions and improving fuel economy. The S58 engine exists at this critical intersection of performance expectations and environmental compliance requirements.

The primary technical objective for optimizing the S58 engine's fuel injection efficiency encompasses several interconnected goals. First, enhancing the precision of fuel delivery timing and quantity to achieve more complete combustion across all operating conditions. Second, reducing parasitic power losses in the high-pressure fuel pump system to improve overall engine efficiency. Third, optimizing injection spray patterns to minimize cylinder wall wetting, which contributes to particulate formation and oil dilution.

Additionally, there are objectives related to cold-start emissions reduction, as this operational phase represents a disproportionate contribution to total emissions. The optimization must also address transient response characteristics during rapid load changes, which present unique challenges for maintaining optimal air-fuel ratios and combustion stability.

From a market perspective, the optimization goals must balance pure performance metrics valued by enthusiast customers with increasingly important efficiency considerations. BMW's positioning of M-series vehicles as both track-capable and daily-drivable machines necessitates a fuel injection system that can seamlessly transition between these sometimes contradictory use cases.

The technological evolution path for high-performance engine fuel injection systems points toward even higher injection pressures (potentially exceeding 500 bar), multiple injection events per combustion cycle, and more sophisticated integration with other engine subsystems including variable valve timing, turbocharger control, and exhaust aftertreatment technologies.

Market Demand Analysis for Efficient Fuel Injection Systems

The global market for efficient fuel injection systems has experienced substantial growth in recent years, driven primarily by stringent emission regulations and increasing consumer demand for fuel-efficient vehicles. The market value reached approximately 66 billion USD in 2022 and is projected to grow at a compound annual growth rate of 6.8% through 2030, reflecting the automotive industry's shift toward more sustainable technologies.

High-performance engines like the S58, used in premium vehicles, represent a significant segment within this market. These engines require advanced fuel injection systems that can deliver optimal performance while meeting increasingly strict environmental standards. Market research indicates that consumers of premium vehicles are willing to pay a premium of 8-12% for improved fuel efficiency without compromising performance characteristics.

Regional analysis reveals varying market dynamics. European markets show the highest demand for efficient fuel injection technologies due to stringent Euro 7 emission standards, followed by North America and Asia-Pacific regions. China, in particular, has emerged as a rapidly growing market, with a 15% year-over-year increase in demand for advanced fuel injection systems as the country implements China VI emission standards.

The commercial vehicle segment presents another substantial market opportunity. Fleet operators increasingly prioritize fuel efficiency as fuel costs represent 30-35% of their total operating expenses. Even a 3-5% improvement in fuel efficiency can translate to significant cost savings over a vehicle's operational lifetime, creating strong economic incentives for adoption.

Market surveys indicate that OEMs are increasingly focused on fuel injection optimization as a key differentiator. Approximately 78% of automotive manufacturers cite improved fuel injection efficiency as a top priority in their engine development programs, with particular emphasis on direct injection technologies and precise fuel delivery control systems.

The aftermarket for performance upgrades also represents a growing segment, with enthusiasts seeking fuel injection modifications that can enhance both power output and efficiency. This segment has grown by approximately 9% annually over the past five years, creating additional revenue streams for component manufacturers and specialized service providers.

Forecasting models suggest that the market for high-efficiency fuel injection systems specifically for premium performance engines like the S58 will continue to expand as manufacturers balance performance requirements with efficiency mandates. Industry analysts predict that technologies enabling 10-15% efficiency improvements while maintaining or enhancing performance characteristics will command significant market premiums and competitive advantage in the coming decade.

High-performance engines like the S58, used in premium vehicles, represent a significant segment within this market. These engines require advanced fuel injection systems that can deliver optimal performance while meeting increasingly strict environmental standards. Market research indicates that consumers of premium vehicles are willing to pay a premium of 8-12% for improved fuel efficiency without compromising performance characteristics.

Regional analysis reveals varying market dynamics. European markets show the highest demand for efficient fuel injection technologies due to stringent Euro 7 emission standards, followed by North America and Asia-Pacific regions. China, in particular, has emerged as a rapidly growing market, with a 15% year-over-year increase in demand for advanced fuel injection systems as the country implements China VI emission standards.

The commercial vehicle segment presents another substantial market opportunity. Fleet operators increasingly prioritize fuel efficiency as fuel costs represent 30-35% of their total operating expenses. Even a 3-5% improvement in fuel efficiency can translate to significant cost savings over a vehicle's operational lifetime, creating strong economic incentives for adoption.

Market surveys indicate that OEMs are increasingly focused on fuel injection optimization as a key differentiator. Approximately 78% of automotive manufacturers cite improved fuel injection efficiency as a top priority in their engine development programs, with particular emphasis on direct injection technologies and precise fuel delivery control systems.

The aftermarket for performance upgrades also represents a growing segment, with enthusiasts seeking fuel injection modifications that can enhance both power output and efficiency. This segment has grown by approximately 9% annually over the past five years, creating additional revenue streams for component manufacturers and specialized service providers.

Forecasting models suggest that the market for high-efficiency fuel injection systems specifically for premium performance engines like the S58 will continue to expand as manufacturers balance performance requirements with efficiency mandates. Industry analysts predict that technologies enabling 10-15% efficiency improvements while maintaining or enhancing performance characteristics will command significant market premiums and competitive advantage in the coming decade.

Current Fuel Injection Technology Challenges

The S58 engine, BMW's latest high-performance inline-six powerplant, faces several critical challenges in optimizing fuel injection efficiency. Current direct injection systems operate at pressures up to 350 bar, but struggle with maintaining optimal spray patterns across the engine's wide operational range. This inconsistency leads to incomplete combustion, particularly during cold starts and low-load conditions, resulting in increased emissions and reduced thermal efficiency.

Fuel atomization quality remains problematic, especially at lower injection pressures. The current injector nozzle designs create droplets with inconsistent size distribution, affecting the homogeneity of the air-fuel mixture. This variability directly impacts combustion stability and contributes to increased particulate matter formation, challenging compliance with increasingly stringent emission standards like Euro 7 and China 6b.

Injector deposit formation represents another significant obstacle. The high-pressure, high-temperature environment of the S58 combustion chamber promotes carbon buildup on injector tips, gradually altering spray patterns and reducing volumetric efficiency. Current cleaning additives provide only temporary relief, necessitating more fundamental design solutions to maintain long-term injection performance.

The multi-injection strategy employed in the S58 engine faces timing precision limitations. While the current system can perform up to five injections per cycle, the electronic control unit struggles to maintain precise timing at higher engine speeds above 5,500 RPM. This timing variance reduces the effectiveness of pilot and post injections, compromising both performance and emissions control during high-load operation.

Fuel rail pressure fluctuations present additional challenges. The current high-pressure pump design experiences pressure drops during sudden throttle changes, affecting injection quantity accuracy. This pressure instability becomes particularly problematic during dynamic driving conditions, where rapid load changes are common, resulting in momentary air-fuel ratio deviations that impact drivability and transient emissions.

Integration challenges with the S58's variable valve timing system further complicate fuel injection optimization. The current injection timing parameters are not fully synchronized with the variable camshaft positions, creating occasional overlap conflicts that reduce volumetric efficiency. This misalignment becomes more pronounced at the extremes of the engine's operational envelope, limiting the full potential of both systems.

Finally, the current engine control software lacks adaptive learning capabilities sophisticated enough to compensate for injector wear over time. As injectors age, their flow characteristics change, but the system cannot sufficiently adjust parameters to maintain optimal performance, resulting in gradual efficiency degradation that affects both power delivery and fuel economy throughout the engine's service life.

Fuel atomization quality remains problematic, especially at lower injection pressures. The current injector nozzle designs create droplets with inconsistent size distribution, affecting the homogeneity of the air-fuel mixture. This variability directly impacts combustion stability and contributes to increased particulate matter formation, challenging compliance with increasingly stringent emission standards like Euro 7 and China 6b.

Injector deposit formation represents another significant obstacle. The high-pressure, high-temperature environment of the S58 combustion chamber promotes carbon buildup on injector tips, gradually altering spray patterns and reducing volumetric efficiency. Current cleaning additives provide only temporary relief, necessitating more fundamental design solutions to maintain long-term injection performance.

The multi-injection strategy employed in the S58 engine faces timing precision limitations. While the current system can perform up to five injections per cycle, the electronic control unit struggles to maintain precise timing at higher engine speeds above 5,500 RPM. This timing variance reduces the effectiveness of pilot and post injections, compromising both performance and emissions control during high-load operation.

Fuel rail pressure fluctuations present additional challenges. The current high-pressure pump design experiences pressure drops during sudden throttle changes, affecting injection quantity accuracy. This pressure instability becomes particularly problematic during dynamic driving conditions, where rapid load changes are common, resulting in momentary air-fuel ratio deviations that impact drivability and transient emissions.

Integration challenges with the S58's variable valve timing system further complicate fuel injection optimization. The current injection timing parameters are not fully synchronized with the variable camshaft positions, creating occasional overlap conflicts that reduce volumetric efficiency. This misalignment becomes more pronounced at the extremes of the engine's operational envelope, limiting the full potential of both systems.

Finally, the current engine control software lacks adaptive learning capabilities sophisticated enough to compensate for injector wear over time. As injectors age, their flow characteristics change, but the system cannot sufficiently adjust parameters to maintain optimal performance, resulting in gradual efficiency degradation that affects both power delivery and fuel economy throughout the engine's service life.

Current S58 Engine Fuel Injection Solutions

01 Direct Fuel Injection Systems for S58 Engine

Direct fuel injection systems improve the efficiency of S58 engines by precisely controlling the amount and timing of fuel delivery directly into the combustion chamber. These systems utilize high-pressure injectors that atomize the fuel more effectively, resulting in better fuel-air mixture formation and more complete combustion. The improved atomization and targeting of fuel spray patterns enhance combustion efficiency and reduce emissions while providing better power output and fuel economy.- Direct fuel injection systems for improved efficiency: Direct fuel injection systems can significantly improve the efficiency of S58 engines by precisely controlling the amount and timing of fuel delivery directly into the combustion chamber. These systems allow for better atomization of fuel, resulting in more complete combustion and reduced fuel consumption. Advanced direct injection technologies enable multiple injection events per cycle, optimizing the air-fuel mixture for different operating conditions and reducing emissions while enhancing power output.

- Electronic control systems for fuel injection: Electronic control units (ECUs) play a crucial role in optimizing fuel injection efficiency in S58 engines. These sophisticated systems continuously monitor various engine parameters such as temperature, load, speed, and oxygen levels to adjust fuel delivery in real-time. Advanced algorithms and mapping techniques enable precise control of injection timing, duration, and pressure, resulting in improved combustion efficiency across different operating conditions and reducing fuel consumption while maintaining optimal performance.

- High-pressure fuel injection technology: High-pressure fuel injection systems enhance the efficiency of S58 engines by delivering fuel at significantly elevated pressures, typically ranging from 1,500 to 2,500 bar. This high-pressure delivery results in superior fuel atomization, creating smaller droplets that mix more effectively with air. The improved atomization leads to more complete combustion, reduced emissions, better fuel economy, and enhanced power output. These systems typically incorporate precision-engineered injector nozzles with optimized spray patterns for different combustion chamber designs.

- Multiple injection strategies for combustion optimization: Multiple injection strategies involve delivering fuel in several discrete events during each combustion cycle rather than a single injection. This approach allows for pre-injection, main injection, and post-injection phases that can be precisely controlled to optimize combustion. Pre-injection reduces combustion noise and NOx formation, main injection delivers the bulk of the fuel for power generation, and post-injection helps in particulate matter reduction. By implementing sophisticated multiple injection strategies, S58 engines can achieve better fuel efficiency, reduced emissions, and improved performance across various operating conditions.

- Fuel injector design and materials for enhanced durability: Advanced fuel injector designs incorporate specialized materials and precision engineering to withstand the extreme conditions present in high-performance S58 engines. These injectors feature wear-resistant components, optimized nozzle geometries, and improved sealing technologies to maintain consistent spray patterns and flow rates throughout their operational life. Innovations in injector design include multi-hole nozzles with optimized spray angles, piezoelectric actuators for faster response times, and diamond-like carbon coatings to reduce friction and wear. These enhancements ensure long-term reliability and consistent fuel delivery, maintaining optimal engine efficiency over extended periods.

02 Electronic Control Units for Fuel Injection Optimization

Advanced electronic control units (ECUs) play a crucial role in optimizing fuel injection efficiency in S58 engines. These systems continuously monitor engine parameters such as temperature, load, speed, and oxygen levels to adjust injection timing and duration in real-time. By implementing sophisticated algorithms and mapping, ECUs can adapt fuel delivery strategies to various driving conditions, ensuring optimal air-fuel ratios across the entire operating range of the engine, resulting in improved efficiency and performance.Expand Specific Solutions03 Multiple Injection Strategies for Enhanced Combustion

Multiple injection strategies involve delivering fuel in several smaller injections rather than a single injection event during each combustion cycle. This approach allows for pre-injection, main injection, and post-injection phases that can be precisely controlled to optimize the combustion process. By implementing multiple injection strategies, S58 engines achieve more gradual and complete fuel burning, reduced noise, lower emissions, better cold-start performance, and improved overall fuel efficiency across various operating conditions.Expand Specific Solutions04 Fuel Injector Design and Materials

Advanced fuel injector designs and materials significantly impact the efficiency of S58 engine fuel systems. Modern injectors feature precision-engineered nozzles with optimized spray patterns and flow characteristics. The use of wear-resistant materials and coatings extends injector lifespan while maintaining consistent performance. Innovations in injector design include improved solenoid or piezoelectric actuators that allow for faster response times and more precise control of fuel delivery, contributing to better atomization and mixing of fuel with air.Expand Specific Solutions05 Fuel Pressure Regulation and Delivery Systems

High-performance fuel pressure regulation and delivery systems are essential for maintaining optimal fuel injection efficiency in S58 engines. These systems include high-pressure fuel pumps, pressure regulators, and fuel rails designed to deliver consistent fuel pressure across all operating conditions. Advanced pressure control mechanisms can dynamically adjust fuel pressure based on engine demands, ensuring proper atomization at both low and high engine speeds. Improved fuel delivery systems also incorporate features to minimize pressure pulsations and ensure uniform distribution to all cylinders.Expand Specific Solutions

Key Industry Players in Engine Optimization

The fuel injection efficiency optimization for S58 engines is currently in a mature development phase, with a global market size estimated to exceed $5 billion annually. Leading automotive manufacturers and suppliers are competing intensely in this space, with Robert Bosch GmbH maintaining technological leadership through advanced electronic control systems. Toyota, Ford, and Nissan have made significant advancements in direct injection technologies, while Mercedes-Benz and GM focus on integration with hybrid powertrains. Chinese players like Weichai Power and SAIC are rapidly closing the technology gap. The competitive landscape is characterized by increasing collaboration between OEMs and tier-1 suppliers, with companies like Denso and Bosch providing cutting-edge solutions that balance performance optimization with increasingly stringent emissions requirements.

Robert Bosch GmbH

Technical Solution: Bosch has developed advanced direct injection systems specifically optimized for high-performance engines like the S58. Their solution incorporates piezoelectric injectors operating at pressures up to 350 bar, enabling multiple injection events per cycle with precision timing down to microseconds[1]. The system features adaptive spray patterns that automatically adjust based on engine load, temperature, and driving conditions. Bosch's proprietary control algorithms continuously optimize the air-fuel mixture by processing data from multiple sensors including oxygen, temperature, and knock sensors[3]. Their system includes integrated exhaust gas recirculation management that works in concert with the injection timing to reduce emissions while maintaining performance. Recent innovations include machine learning algorithms that learn driver patterns to predictively adjust injection parameters for optimal efficiency[5].

Strengths: Industry-leading precision in fuel delivery timing and quantity control; comprehensive integration with other engine management systems; proven reliability in high-performance applications. Weaknesses: Higher system cost compared to conventional injection systems; requires sophisticated calibration processes; greater complexity potentially impacts long-term maintenance.

Toyota Motor Corp.

Technical Solution: Toyota has engineered a D-4S (Direct injection 4-Stroke gasoline engine Superior version) dual injection system that could be adapted for the S58 engine platform. This technology combines both direct and port fuel injection methods, allowing the engine management system to select the optimal injection method based on operating conditions[2]. At low speeds and loads, port injection is favored for better fuel atomization and reduced carbon buildup, while at higher loads, direct injection takes over for improved cooling effect and performance. Toyota's system incorporates advanced spray-guided combustion chambers with optimized piston crown designs that enhance fuel-air mixing[4]. Their proprietary wide-range air-fuel ratio sensors provide feedback for ultra-precise mixture control across all operating conditions. The system also features variable swirl control valves that adjust intake air movement to optimize combustion efficiency depending on engine speed and load demands[7].

Strengths: Exceptional flexibility across different operating conditions; reduced carbon buildup compared to pure direct injection systems; proven technology with millions of units in the field. Weaknesses: Added complexity and cost from dual injection systems; requires more sophisticated control strategies; slightly higher maintenance requirements for dual system components.

Critical Patents and Innovations in Fuel Injection

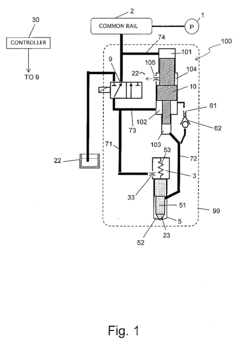

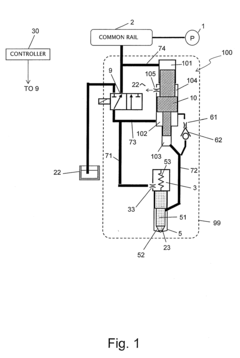

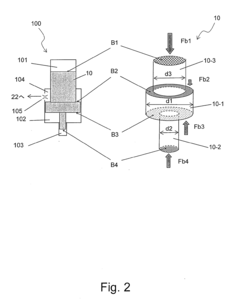

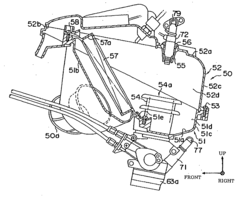

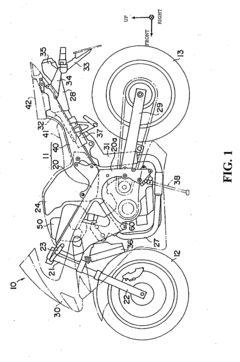

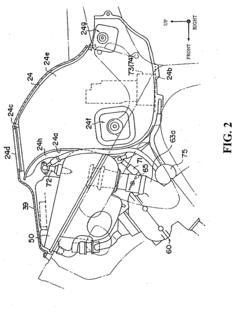

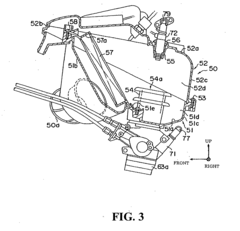

Fuel injection device

PatentInactiveEP1780401A1

Innovation

- A fuel injection device design where the fuel pressure is supplied to the fuel storage and injection control chamber during the valve-closing stroke, with the pressure to the storage being lower than to the control chamber, enhancing the needle's travel speed and allowing for improved injection termination, and incorporating a pressure booster unit to adjust fuel injection rates based on engine load.

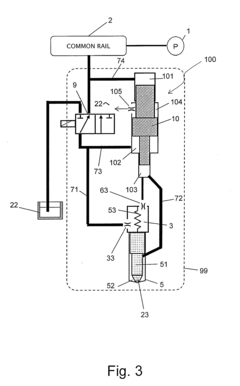

Fuel injection system for engine

PatentInactiveUS20070144491A1

Innovation

- A fuel injection system with upstream and downstream valves, where the upstream valve has a higher injection pressure and its share is adjusted based on engine load, allowing for optimized fuel distribution and increased output by ensuring the fuel reaches the combustion chamber in a timely manner, enhancing volumetric and combustion efficiency.

Emissions Regulations Impact on Fuel Injection Design

The evolution of emissions regulations has fundamentally transformed fuel injection design for modern engines, including the S58 engine. Since the introduction of Euro 1 standards in 1992, each subsequent regulatory framework has progressively tightened permissible emission levels, with Euro 6d and upcoming Euro 7 standards imposing particularly stringent requirements on nitrogen oxides (NOx), particulate matter, and carbon dioxide emissions.

These regulations have directly influenced the S58 engine's fuel injection architecture, necessitating precise control over fuel delivery timing, quantity, and spray pattern. The transition from port fuel injection to direct injection systems was largely driven by these regulatory pressures, enabling more complete combustion and reduced emissions. For the S58 specifically, compliance with Euro 6d standards required sophisticated high-pressure common rail systems operating at pressures exceeding 2,500 bar.

Regulatory frameworks have also accelerated the adoption of multiple injection events per combustion cycle in the S58 engine. Pre-injection, main injection, and post-injection strategies have become essential for managing the combustion process to minimize pollutant formation while maintaining performance. This approach allows for better control of combustion temperatures, reducing NOx formation while optimizing particulate matter oxidation.

Real Driving Emissions (RDE) testing, introduced with Euro 6d-TEMP standards, has further complicated fuel injection design by requiring consistent performance across varied driving conditions rather than just in laboratory settings. This has pushed S58 engine development toward adaptive injection strategies that can optimize for different operating conditions while maintaining regulatory compliance.

The California Air Resources Board (CARB) and other regional regulatory bodies have introduced additional requirements that influence global engine design. These variations necessitate flexible fuel injection systems capable of meeting multiple regulatory standards without significant hardware modifications, adding complexity to the S58 engine's injection system design.

Looking forward, upcoming regulations will likely demand even greater precision in fuel delivery. Zero-impact emission zones in urban centers may require the S58 engine to incorporate hybrid technologies with specialized injection strategies for transitional operation modes. The regulatory landscape thus continues to be a primary driver of innovation in fuel injection technology, pushing manufacturers toward increasingly sophisticated solutions for emission control while maintaining performance expectations.

These regulations have directly influenced the S58 engine's fuel injection architecture, necessitating precise control over fuel delivery timing, quantity, and spray pattern. The transition from port fuel injection to direct injection systems was largely driven by these regulatory pressures, enabling more complete combustion and reduced emissions. For the S58 specifically, compliance with Euro 6d standards required sophisticated high-pressure common rail systems operating at pressures exceeding 2,500 bar.

Regulatory frameworks have also accelerated the adoption of multiple injection events per combustion cycle in the S58 engine. Pre-injection, main injection, and post-injection strategies have become essential for managing the combustion process to minimize pollutant formation while maintaining performance. This approach allows for better control of combustion temperatures, reducing NOx formation while optimizing particulate matter oxidation.

Real Driving Emissions (RDE) testing, introduced with Euro 6d-TEMP standards, has further complicated fuel injection design by requiring consistent performance across varied driving conditions rather than just in laboratory settings. This has pushed S58 engine development toward adaptive injection strategies that can optimize for different operating conditions while maintaining regulatory compliance.

The California Air Resources Board (CARB) and other regional regulatory bodies have introduced additional requirements that influence global engine design. These variations necessitate flexible fuel injection systems capable of meeting multiple regulatory standards without significant hardware modifications, adding complexity to the S58 engine's injection system design.

Looking forward, upcoming regulations will likely demand even greater precision in fuel delivery. Zero-impact emission zones in urban centers may require the S58 engine to incorporate hybrid technologies with specialized injection strategies for transitional operation modes. The regulatory landscape thus continues to be a primary driver of innovation in fuel injection technology, pushing manufacturers toward increasingly sophisticated solutions for emission control while maintaining performance expectations.

Thermal Management Strategies for Optimized Injection

Thermal management plays a critical role in optimizing fuel injection efficiency for the S58 engine. The engine's performance is significantly influenced by the temperature of both the fuel and the injection system components. Maintaining optimal thermal conditions ensures proper fuel atomization, combustion efficiency, and emissions control.

The S58 engine, with its high-performance characteristics, generates substantial heat during operation. Without proper thermal management, this heat can lead to fuel vaporization before injection, resulting in vapor lock and reduced volumetric efficiency. Conversely, fuel that is too cold may not atomize properly, leading to incomplete combustion and increased emissions.

Advanced cooling systems specifically designed for the injection components represent a key thermal management strategy. These systems utilize precision-controlled coolant circulation around injectors and fuel rails to maintain consistent temperatures regardless of engine load or ambient conditions. Some implementations incorporate dedicated cooling circuits separate from the main engine cooling system, allowing for more precise temperature control of injection components.

Electronic thermal management modules (ETMs) have emerged as a sophisticated solution for the S58 engine. These systems use multiple temperature sensors and electronically controlled valves to regulate coolant flow based on real-time operating conditions. The ETM can prioritize cooling to different engine subsystems, including the injection system, based on thermal load and performance requirements.

Fuel pre-conditioning represents another important thermal management approach. This strategy involves controlling the temperature of fuel before it reaches the injection system. Advanced fuel delivery systems incorporate heat exchangers that can either cool or warm the fuel depending on operating conditions, ensuring it reaches the injectors at the optimal temperature for efficient atomization and combustion.

Thermal barrier coatings on injection components offer passive thermal management benefits. These specialized ceramic or metallic coatings reduce heat transfer between hot engine components and the fuel system, helping maintain fuel at appropriate temperatures before injection. Additionally, these coatings can protect sensitive electronic components in modern direct injection systems from thermal stress.

Integrated thermal management strategies also leverage waste heat recovery systems. By capturing and redirecting heat that would otherwise be lost, these systems can help bring the engine and its subsystems to optimal operating temperatures more quickly during cold starts, when injection efficiency is typically at its lowest. This approach significantly reduces emissions and fuel consumption during the critical warm-up phase.

The S58 engine, with its high-performance characteristics, generates substantial heat during operation. Without proper thermal management, this heat can lead to fuel vaporization before injection, resulting in vapor lock and reduced volumetric efficiency. Conversely, fuel that is too cold may not atomize properly, leading to incomplete combustion and increased emissions.

Advanced cooling systems specifically designed for the injection components represent a key thermal management strategy. These systems utilize precision-controlled coolant circulation around injectors and fuel rails to maintain consistent temperatures regardless of engine load or ambient conditions. Some implementations incorporate dedicated cooling circuits separate from the main engine cooling system, allowing for more precise temperature control of injection components.

Electronic thermal management modules (ETMs) have emerged as a sophisticated solution for the S58 engine. These systems use multiple temperature sensors and electronically controlled valves to regulate coolant flow based on real-time operating conditions. The ETM can prioritize cooling to different engine subsystems, including the injection system, based on thermal load and performance requirements.

Fuel pre-conditioning represents another important thermal management approach. This strategy involves controlling the temperature of fuel before it reaches the injection system. Advanced fuel delivery systems incorporate heat exchangers that can either cool or warm the fuel depending on operating conditions, ensuring it reaches the injectors at the optimal temperature for efficient atomization and combustion.

Thermal barrier coatings on injection components offer passive thermal management benefits. These specialized ceramic or metallic coatings reduce heat transfer between hot engine components and the fuel system, helping maintain fuel at appropriate temperatures before injection. Additionally, these coatings can protect sensitive electronic components in modern direct injection systems from thermal stress.

Integrated thermal management strategies also leverage waste heat recovery systems. By capturing and redirecting heat that would otherwise be lost, these systems can help bring the engine and its subsystems to optimal operating temperatures more quickly during cold starts, when injection efficiency is typically at its lowest. This approach significantly reduces emissions and fuel consumption during the critical warm-up phase.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!