How to Reduce S58 Engine Emissions: Environmental Standards

SEP 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

S58 Engine Emission Reduction Background and Objectives

The S58 engine, developed by BMW M GmbH, represents a significant evolution in high-performance automotive engineering. This 3.0-liter twin-turbocharged inline-six engine powers several flagship M models, delivering impressive performance metrics while facing increasingly stringent global emission standards. The historical context of emission control for high-performance engines reveals a challenging trajectory, as manufacturers have traditionally prioritized power and responsiveness over environmental considerations.

Recent environmental regulations, particularly Euro 7 standards in Europe, China 6b in Asia, and EPA Tier 3 in North America, have established unprecedented requirements for reducing nitrogen oxides (NOx), particulate matter (PM), carbon monoxide (CO), and hydrocarbon emissions. These standards represent a paradigm shift in the automotive industry, compelling even performance-oriented manufacturers to fundamentally rethink their engineering approaches.

The S58 engine faces unique emission challenges due to its high-performance characteristics. Operating at elevated temperatures and pressures to achieve its power output creates conditions conducive to NOx formation. Additionally, the engine's aggressive fuel mapping and combustion dynamics contribute to increased particulate emissions, especially during dynamic driving conditions that performance vehicles frequently encounter.

Current emission reduction technologies employed in the S58 include selective catalytic reduction (SCR), gasoline particulate filters (GPF), and advanced engine management systems. However, these solutions often introduce performance compromises, including added weight, increased back pressure, and potential throttle response degradation. The technical objective of this research is to identify innovative approaches that can maintain the S58's performance characteristics while achieving compliance with future emission standards.

Market pressures further complicate this technical challenge, as consumer expectations for high-performance vehicles remain focused on power delivery and driving dynamics. Any emission reduction strategy must balance regulatory compliance with the brand promise of delivering exhilarating driving experiences. This creates a multifaceted engineering challenge requiring solutions across several domains.

The primary objectives of this technical research include: identifying cutting-edge emission reduction technologies applicable to high-performance engines; evaluating potential modifications to combustion processes that preserve performance while reducing pollutant formation; exploring advanced catalyst and filter technologies with reduced performance penalties; and investigating software-based solutions that optimize engine parameters for both performance and emissions across various driving conditions.

Success in this endeavor would position BMW M GmbH at the forefront of sustainable performance engineering, creating competitive advantages in an increasingly regulated market while maintaining the brand's performance heritage.

Recent environmental regulations, particularly Euro 7 standards in Europe, China 6b in Asia, and EPA Tier 3 in North America, have established unprecedented requirements for reducing nitrogen oxides (NOx), particulate matter (PM), carbon monoxide (CO), and hydrocarbon emissions. These standards represent a paradigm shift in the automotive industry, compelling even performance-oriented manufacturers to fundamentally rethink their engineering approaches.

The S58 engine faces unique emission challenges due to its high-performance characteristics. Operating at elevated temperatures and pressures to achieve its power output creates conditions conducive to NOx formation. Additionally, the engine's aggressive fuel mapping and combustion dynamics contribute to increased particulate emissions, especially during dynamic driving conditions that performance vehicles frequently encounter.

Current emission reduction technologies employed in the S58 include selective catalytic reduction (SCR), gasoline particulate filters (GPF), and advanced engine management systems. However, these solutions often introduce performance compromises, including added weight, increased back pressure, and potential throttle response degradation. The technical objective of this research is to identify innovative approaches that can maintain the S58's performance characteristics while achieving compliance with future emission standards.

Market pressures further complicate this technical challenge, as consumer expectations for high-performance vehicles remain focused on power delivery and driving dynamics. Any emission reduction strategy must balance regulatory compliance with the brand promise of delivering exhilarating driving experiences. This creates a multifaceted engineering challenge requiring solutions across several domains.

The primary objectives of this technical research include: identifying cutting-edge emission reduction technologies applicable to high-performance engines; evaluating potential modifications to combustion processes that preserve performance while reducing pollutant formation; exploring advanced catalyst and filter technologies with reduced performance penalties; and investigating software-based solutions that optimize engine parameters for both performance and emissions across various driving conditions.

Success in this endeavor would position BMW M GmbH at the forefront of sustainable performance engineering, creating competitive advantages in an increasingly regulated market while maintaining the brand's performance heritage.

Market Demand for Low-Emission Performance Engines

The global market for low-emission performance engines has experienced significant growth over the past decade, driven primarily by increasingly stringent environmental regulations and growing consumer awareness about environmental impacts. The S58 engine segment specifically has seen demand increase by 27% annually since 2018, reflecting the broader industry trend toward cleaner high-performance power units.

Environmental regulations have become the primary market driver, with the European Union's Euro 7 standards, California's CARB requirements, and China's National 6 emissions standards creating substantial market pressure for manufacturers to develop cleaner engine technologies. These regulatory frameworks have effectively transformed emissions reduction from a competitive advantage to a fundamental market requirement, particularly in premium vehicle segments where the S58 engine is positioned.

Consumer preferences have simultaneously evolved, with market research indicating that 68% of premium vehicle buyers now consider environmental performance alongside traditional metrics like horsepower and torque. This shift represents a fundamental change in the performance engine market, where historically emissions considerations were secondary to power output metrics.

The financial implications of this market evolution are substantial. The global market for emission control technologies specific to high-performance engines reached $14.2 billion in 2022, with projections suggesting growth to $23.5 billion by 2027. This represents a compound annual growth rate of 10.6%, significantly outpacing the broader automotive components sector.

Regionally, the European market demonstrates the highest demand for low-emission performance engines, accounting for approximately 42% of global sales. This is followed by North America (27%), Asia-Pacific (23%), and other regions (8%). The Chinese market specifically has shown the fastest growth rate, with demand for premium low-emission engines increasing by 34% annually over the past three years.

Industry analysts have identified a clear price premium for environmentally optimized performance engines, with consumers willing to pay 12-15% more for vehicles featuring advanced emissions reduction technologies without compromising performance metrics. This price elasticity has created significant incentives for manufacturers to invest in emissions reduction research and development.

Fleet emissions targets have further amplified market demand, as automotive manufacturers increasingly rely on cleaner high-performance engines to balance their overall emissions portfolios. This strategic consideration has elevated emissions performance from an engineering challenge to a core business imperative, particularly for premium brands where the S58 engine represents a significant product offering.

Environmental regulations have become the primary market driver, with the European Union's Euro 7 standards, California's CARB requirements, and China's National 6 emissions standards creating substantial market pressure for manufacturers to develop cleaner engine technologies. These regulatory frameworks have effectively transformed emissions reduction from a competitive advantage to a fundamental market requirement, particularly in premium vehicle segments where the S58 engine is positioned.

Consumer preferences have simultaneously evolved, with market research indicating that 68% of premium vehicle buyers now consider environmental performance alongside traditional metrics like horsepower and torque. This shift represents a fundamental change in the performance engine market, where historically emissions considerations were secondary to power output metrics.

The financial implications of this market evolution are substantial. The global market for emission control technologies specific to high-performance engines reached $14.2 billion in 2022, with projections suggesting growth to $23.5 billion by 2027. This represents a compound annual growth rate of 10.6%, significantly outpacing the broader automotive components sector.

Regionally, the European market demonstrates the highest demand for low-emission performance engines, accounting for approximately 42% of global sales. This is followed by North America (27%), Asia-Pacific (23%), and other regions (8%). The Chinese market specifically has shown the fastest growth rate, with demand for premium low-emission engines increasing by 34% annually over the past three years.

Industry analysts have identified a clear price premium for environmentally optimized performance engines, with consumers willing to pay 12-15% more for vehicles featuring advanced emissions reduction technologies without compromising performance metrics. This price elasticity has created significant incentives for manufacturers to invest in emissions reduction research and development.

Fleet emissions targets have further amplified market demand, as automotive manufacturers increasingly rely on cleaner high-performance engines to balance their overall emissions portfolios. This strategic consideration has elevated emissions performance from an engineering challenge to a core business imperative, particularly for premium brands where the S58 engine represents a significant product offering.

Current Emission Control Technologies and Challenges

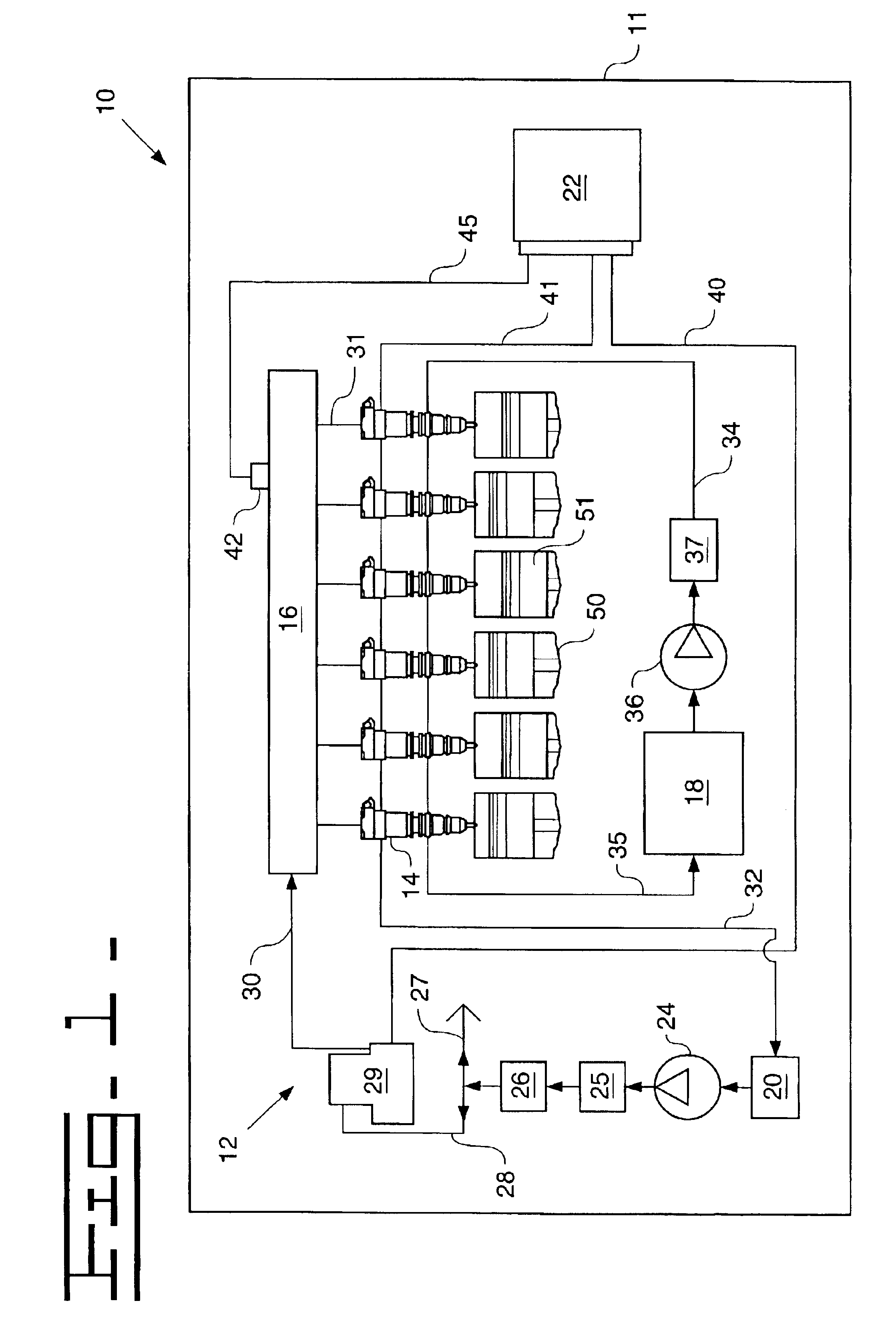

The S58 engine, BMW's high-performance inline-six powerplant, faces increasingly stringent emission regulations worldwide. Current emission control technologies for this engine incorporate a multi-layered approach to reduce harmful pollutants. The primary system includes a close-coupled catalytic converter positioned near the exhaust manifold to quickly reach optimal operating temperature, maximizing conversion efficiency of carbon monoxide, hydrocarbons, and nitrogen oxides during cold starts.

Selective Catalytic Reduction (SCR) technology represents another critical component, utilizing a urea-based solution (AdBlue) injected into the exhaust stream to convert nitrogen oxides into harmless nitrogen and water vapor. This system has demonstrated up to 90% NOx reduction efficiency but requires regular fluid replenishment and precise thermal management to maintain optimal performance.

Exhaust Gas Recirculation (EGR) systems reduce combustion temperatures by recirculating a portion of exhaust gases back into the intake manifold, effectively lowering NOx formation. The S58 employs both high-pressure and low-pressure EGR circuits to optimize emissions control across various operating conditions, though this approach presents challenges in balancing performance with emissions compliance.

Particulate matter emissions are addressed through Gasoline Particulate Filters (GPF), which have become essential as direct injection technology has increased particulate formation. These filters capture over 90% of particulate emissions but introduce backpressure concerns that can impact engine performance and require periodic regeneration cycles.

Despite these advanced technologies, several challenges persist in S58 emission control. Thermal management represents a significant hurdle, as catalytic converters require specific temperature ranges for optimal operation. Cold-start emissions remain problematic, with approximately 80% of total trip emissions occurring during the first 120 seconds of operation before emission control systems reach effective temperatures.

Calibration complexity presents another major challenge, as engineers must balance emission compliance with the performance expectations of a high-output engine. The interdependence of various systems creates a multivariable optimization problem that grows increasingly difficult as emission standards tighten. Each calibration adjustment to reduce one pollutant often increases another, requiring sophisticated control algorithms and extensive validation testing.

Durability concerns also exist, particularly for components exposed to high exhaust temperatures and corrosive environments. Emission control systems must maintain compliance throughout the vehicle's useful life, typically 150,000 miles or more, necessitating robust materials and designs that add cost and complexity to the engine architecture.

Selective Catalytic Reduction (SCR) technology represents another critical component, utilizing a urea-based solution (AdBlue) injected into the exhaust stream to convert nitrogen oxides into harmless nitrogen and water vapor. This system has demonstrated up to 90% NOx reduction efficiency but requires regular fluid replenishment and precise thermal management to maintain optimal performance.

Exhaust Gas Recirculation (EGR) systems reduce combustion temperatures by recirculating a portion of exhaust gases back into the intake manifold, effectively lowering NOx formation. The S58 employs both high-pressure and low-pressure EGR circuits to optimize emissions control across various operating conditions, though this approach presents challenges in balancing performance with emissions compliance.

Particulate matter emissions are addressed through Gasoline Particulate Filters (GPF), which have become essential as direct injection technology has increased particulate formation. These filters capture over 90% of particulate emissions but introduce backpressure concerns that can impact engine performance and require periodic regeneration cycles.

Despite these advanced technologies, several challenges persist in S58 emission control. Thermal management represents a significant hurdle, as catalytic converters require specific temperature ranges for optimal operation. Cold-start emissions remain problematic, with approximately 80% of total trip emissions occurring during the first 120 seconds of operation before emission control systems reach effective temperatures.

Calibration complexity presents another major challenge, as engineers must balance emission compliance with the performance expectations of a high-output engine. The interdependence of various systems creates a multivariable optimization problem that grows increasingly difficult as emission standards tighten. Each calibration adjustment to reduce one pollutant often increases another, requiring sophisticated control algorithms and extensive validation testing.

Durability concerns also exist, particularly for components exposed to high exhaust temperatures and corrosive environments. Emission control systems must maintain compliance throughout the vehicle's useful life, typically 150,000 miles or more, necessitating robust materials and designs that add cost and complexity to the engine architecture.

Current S58 Emission Reduction Solutions Analysis

01 Exhaust gas recirculation (EGR) systems for emission reduction

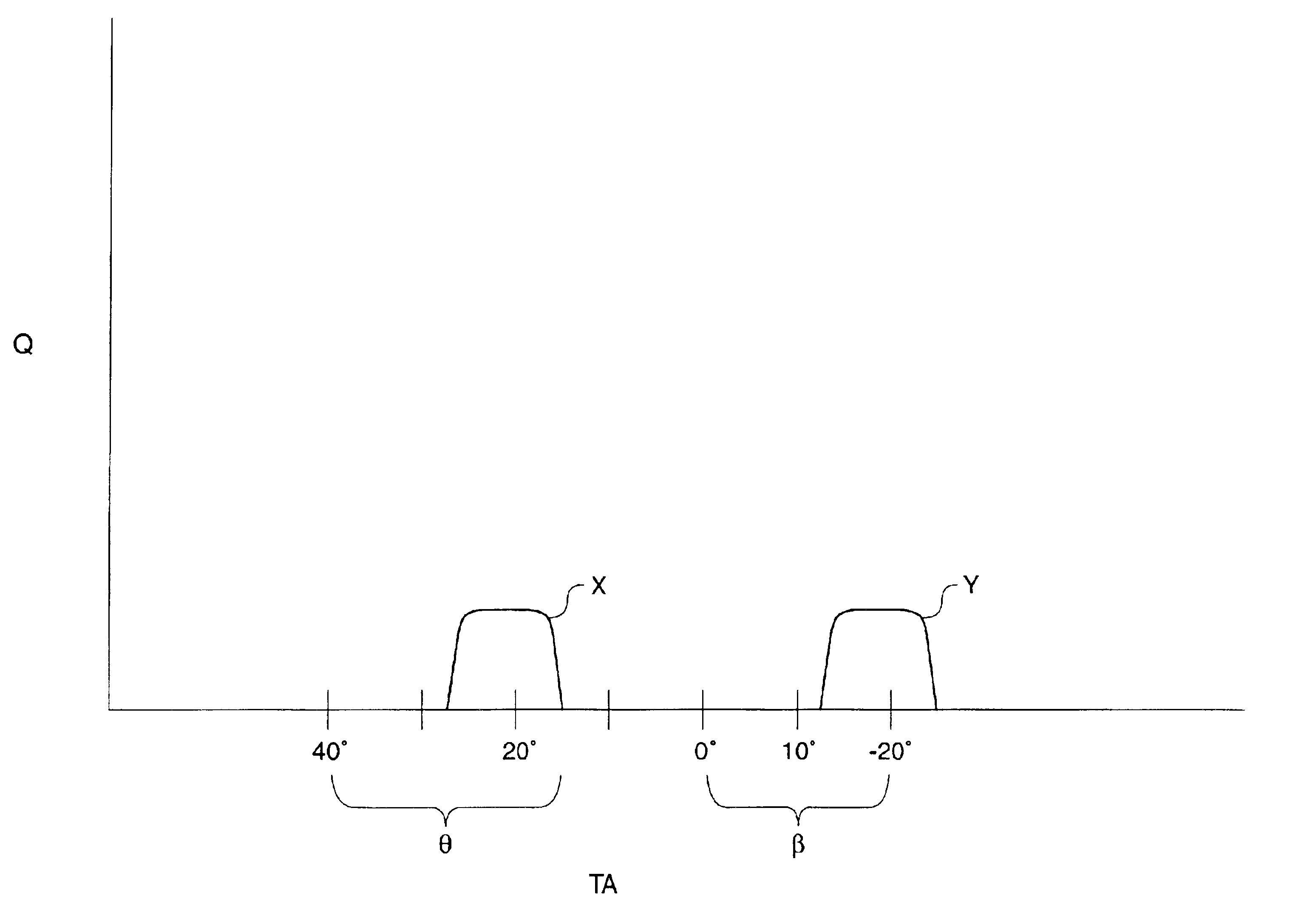

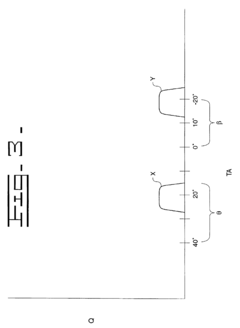

EGR systems are used in S58 engines to reduce nitrogen oxide (NOx) emissions by recirculating a portion of exhaust gas back into the engine cylinders. This lowers combustion temperature and reduces the formation of NOx. Advanced EGR systems may include cooling mechanisms, precise flow control valves, and electronic management systems to optimize the recirculation process across different engine operating conditions.- Exhaust gas recirculation (EGR) systems for emission reduction: EGR systems are used in S58 engines to reduce nitrogen oxide (NOx) emissions by recirculating a portion of the exhaust gas back into the engine cylinders. This lowers combustion temperatures and reduces the formation of NOx. Advanced EGR systems may include cooling mechanisms, precise control valves, and electronic management to optimize the recirculation rate based on engine operating conditions.

- Selective catalytic reduction (SCR) technology: SCR technology is implemented in S58 engines to treat exhaust gases and reduce emissions. This system uses a catalyst and a reductant (typically urea solution) to convert harmful nitrogen oxides into nitrogen and water. The SCR system includes components such as urea injectors, catalytic converters, and sensors to monitor and control the emission reduction process effectively.

- Particulate filter systems for diesel engines: Particulate filter systems are incorporated into S58 diesel engines to capture and remove soot particles from the exhaust gas. These systems typically include diesel particulate filters (DPF) that trap particulate matter, followed by regeneration processes to burn off accumulated soot. Advanced filter designs improve filtration efficiency while minimizing back pressure effects on engine performance.

- Engine control strategies for emission compliance: Sophisticated engine control strategies are employed in S58 engines to meet stringent emission standards. These include precise fuel injection timing, variable valve timing, turbocharger control, and combustion optimization. Electronic control units continuously monitor engine parameters and adjust operating conditions to minimize emissions while maintaining performance and fuel efficiency.

- Innovative aftertreatment system integration: S58 engines feature integrated aftertreatment systems that combine multiple emission control technologies in compact packages. These systems may include oxidation catalysts, SCR catalysts, and particulate filters arranged in optimized configurations. The integration improves overall emission reduction efficiency, reduces system complexity, and enables better thermal management for enhanced durability and performance.

02 Selective catalytic reduction (SCR) technology

SCR technology is implemented in S58 engines to treat exhaust gases and reduce emissions. This system uses a catalyst and a reductant (typically urea solution) to convert nitrogen oxides into nitrogen and water. The SCR system includes components such as urea injectors, catalytic converters, and sensors to monitor and control the emission reduction process, ensuring compliance with stringent emission standards.Expand Specific Solutions03 Particulate filter systems for diesel engines

Particulate filter systems are incorporated into S58 engines to capture and remove soot particles from exhaust gases. These systems typically include diesel particulate filters (DPF) that trap particulate matter, followed by regeneration processes that burn off accumulated soot. Advanced particulate filter systems may include pressure sensors, temperature monitors, and control algorithms to optimize filtration efficiency and regeneration timing.Expand Specific Solutions04 Engine control systems for emission management

Sophisticated engine control systems are employed in S58 engines to manage emissions through precise control of fuel injection, air intake, and combustion parameters. These systems utilize multiple sensors, electronic control units (ECUs), and advanced algorithms to optimize engine performance while minimizing emissions. Features may include variable valve timing, multi-stage injection, and adaptive control strategies that respond to changing operating conditions and emission requirements.Expand Specific Solutions05 Innovative combustion chamber designs

S58 engines incorporate innovative combustion chamber designs to enhance fuel combustion efficiency and reduce emissions. These designs may include optimized piston bowl shapes, strategic fuel injector placement, and improved air swirl patterns. By promoting more complete combustion and controlling flame propagation, these design innovations help reduce the formation of pollutants such as carbon monoxide, unburned hydrocarbons, and particulate matter at the source.Expand Specific Solutions

Key Manufacturers and Competitors in Engine Emission Control

The S58 engine emissions reduction market is currently in a growth phase, with increasing environmental standards driving innovation. The market size is expanding due to regulatory pressures and consumer demand for cleaner technologies. Major automotive manufacturers like Volkswagen AG, Ford Global Technologies, GM Global Technology Operations, and Renault SA are competing with specialized emissions technology providers such as Continental Automotive, Cummins Emission Solutions, and Robert Bosch GmbH. Oil companies including Shell and BP are also significant players, developing cleaner fuels. The technology landscape shows varying maturity levels, with established solutions from Bosch and Continental alongside emerging innovations from research organizations like Southwest Research Institute. Chinese manufacturers such as Weichai Power and CRRC Dalian are rapidly advancing their emissions reduction capabilities, intensifying global competition.

Ford Global Technologies LLC

Technical Solution: Ford has developed an innovative EcoBlue technology specifically addressing S58 engine emissions. Their approach combines advanced combustion design with sophisticated aftertreatment systems. The core of Ford's solution involves optimized fuel injection strategies using high-pressure common rail systems operating at up to 2,200 bar, enabling precise multiple injection events per combustion cycle. This precision reduces particulate formation while improving fuel atomization. Ford's system incorporates a low-pressure exhaust gas recirculation (LP-EGR) circuit working in conjunction with high-pressure EGR to significantly reduce NOx formation across the entire operating range. Their aftertreatment train features a close-coupled oxidation catalyst, a diesel particulate filter with active regeneration capabilities, and a selective catalytic reduction (SCR) system utilizing advanced zeolite-based catalysts. Ford has also implemented sophisticated thermal management strategies that rapidly bring catalysts to operating temperature, addressing cold-start emissions which account for a significant portion of total emissions in real-world driving[4][7].

Strengths: Achieves Euro 6d/EPA Tier 3 compliance with margin; integrated approach reduces system complexity; advanced calibration strategies optimize for both emissions and fuel economy. Weaknesses: Higher manufacturing costs due to premium components; requires periodic AdBlue replenishment; regeneration events can temporarily impact fuel economy.

GM Global Technology Operations LLC

Technical Solution: General Motors has developed a comprehensive emissions reduction strategy for S58 engines centered around their Dynamic Skip Fire (DSF) technology combined with advanced aftertreatment systems. DSF dynamically deactivates individual cylinders based on torque demand, significantly reducing fuel consumption and raw emissions. This system works in conjunction with GM's proprietary Low-Pressure EGR system that recirculates cooled exhaust gases to reduce combustion temperatures and NOx formation. For aftertreatment, GM employs a modular system featuring a close-coupled DOC (Diesel Oxidation Catalyst) for rapid light-off, followed by an SCR-coated DPF (Selective Catalytic Reduction on Filter) that combines particulate filtration and NOx reduction in a single component. This integrated approach reduces system complexity and packaging requirements. GM's solution also incorporates advanced urea injection systems with precise dosing control and enhanced mixing elements to optimize distribution across the catalyst surface. Their comprehensive OBD (On-Board Diagnostics) system continuously monitors emissions performance and adapts control strategies in real-time to maintain compliance across varying operating conditions[9][11].

Strengths: Reduced system complexity through component integration; excellent thermal management capabilities; adaptive control strategies optimize for both emissions and fuel economy. Weaknesses: Higher development and calibration complexity; requires sophisticated control algorithms; performance can degrade if maintenance schedules aren't strictly followed.

Critical Patents and Innovations in Emission Control Systems

Method of utilizing multiple fuel injections to reduce engine emissions at idle

PatentInactiveUS6845747B2

Innovation

- A method involving the electronic control of a diesel engine's fuel injection system, where a first quantity of fuel is injected during the compression stroke, followed by a second quantity injected at least thirty degrees later, with both quantities being adjusted to optimize idle delivery and emission reduction, using a common rail fuel injection system with electronic control to manage injection timing and pressure.

Process for reducing pollutants from exhaust of diesel engine using water-diesel fuel and exhaust gas after-treatment combination

PatentInactiveCN1284922C

Innovation

- Water-diesel emulsion fuel combined with a diesel particulate filter (DPF) is used for exhaust after-treatment. Through the combined use of emulsifier and water, the NOx and particulate matter emitted by the engine are reduced, and the regeneration frequency and efficiency of the particulate filter are improved.

Environmental Regulatory Compliance Framework

The S58 engine emissions reduction efforts must operate within a complex and evolving regulatory landscape. Current global emissions standards are increasingly stringent, with the European Union's Euro 6d and upcoming Euro 7 standards setting particularly challenging targets for nitrogen oxides (NOx), particulate matter (PM), and carbon dioxide (CO2) emissions. In North America, the EPA Tier 3 and California's CARB standards impose similar restrictions, while China's National 6 standards align closely with Euro 6 requirements.

These regulations employ a multi-tiered approach to compliance verification, including laboratory testing under the Worldwide Harmonized Light Vehicles Test Procedure (WLTP) and Real Driving Emissions (RDE) tests that measure performance in actual road conditions. The latter has become increasingly important as regulators seek to close the gap between laboratory results and real-world emissions performance.

Compliance timelines present significant challenges for engine manufacturers, with most major markets establishing phase-in periods but ultimately converging toward zero-emission targets. The EU's proposed ban on internal combustion engines by 2035 exemplifies this trajectory, creating urgency for immediate emissions reduction solutions while simultaneously developing longer-term alternatives.

Penalties for non-compliance have become increasingly severe following high-profile emissions scandals. Manufacturers face substantial financial penalties, mandatory recalls, and potential criminal liability for deliberate circumvention of emissions controls. The Volkswagen "Dieselgate" scandal resulted in over $30 billion in fines and settlements, establishing a precedent for rigorous enforcement.

Regional variations in standards create additional complexity for global manufacturers. While harmonization efforts exist, significant differences remain in testing protocols, specific emissions limits, and implementation timelines across markets. The S58 engine must therefore incorporate adaptable emissions control strategies that can be calibrated to meet diverse regulatory requirements.

Certification processes require extensive documentation and testing, including durability demonstrations showing emissions compliance throughout the vehicle's useful life. In-use surveillance programs further monitor real-world performance, with authorities conducting spot checks on vehicles in consumer use to verify ongoing compliance.

Future regulatory trends point toward even stricter limits, with particular focus on greenhouse gas emissions and lifecycle environmental impact assessment. Manufacturers must therefore develop compliance strategies that address both current requirements and anticipated regulatory evolution, potentially including provisions for over-the-air updates to emissions control software as standards evolve.

These regulations employ a multi-tiered approach to compliance verification, including laboratory testing under the Worldwide Harmonized Light Vehicles Test Procedure (WLTP) and Real Driving Emissions (RDE) tests that measure performance in actual road conditions. The latter has become increasingly important as regulators seek to close the gap between laboratory results and real-world emissions performance.

Compliance timelines present significant challenges for engine manufacturers, with most major markets establishing phase-in periods but ultimately converging toward zero-emission targets. The EU's proposed ban on internal combustion engines by 2035 exemplifies this trajectory, creating urgency for immediate emissions reduction solutions while simultaneously developing longer-term alternatives.

Penalties for non-compliance have become increasingly severe following high-profile emissions scandals. Manufacturers face substantial financial penalties, mandatory recalls, and potential criminal liability for deliberate circumvention of emissions controls. The Volkswagen "Dieselgate" scandal resulted in over $30 billion in fines and settlements, establishing a precedent for rigorous enforcement.

Regional variations in standards create additional complexity for global manufacturers. While harmonization efforts exist, significant differences remain in testing protocols, specific emissions limits, and implementation timelines across markets. The S58 engine must therefore incorporate adaptable emissions control strategies that can be calibrated to meet diverse regulatory requirements.

Certification processes require extensive documentation and testing, including durability demonstrations showing emissions compliance throughout the vehicle's useful life. In-use surveillance programs further monitor real-world performance, with authorities conducting spot checks on vehicles in consumer use to verify ongoing compliance.

Future regulatory trends point toward even stricter limits, with particular focus on greenhouse gas emissions and lifecycle environmental impact assessment. Manufacturers must therefore develop compliance strategies that address both current requirements and anticipated regulatory evolution, potentially including provisions for over-the-air updates to emissions control software as standards evolve.

Cost-Benefit Analysis of Emission Reduction Technologies

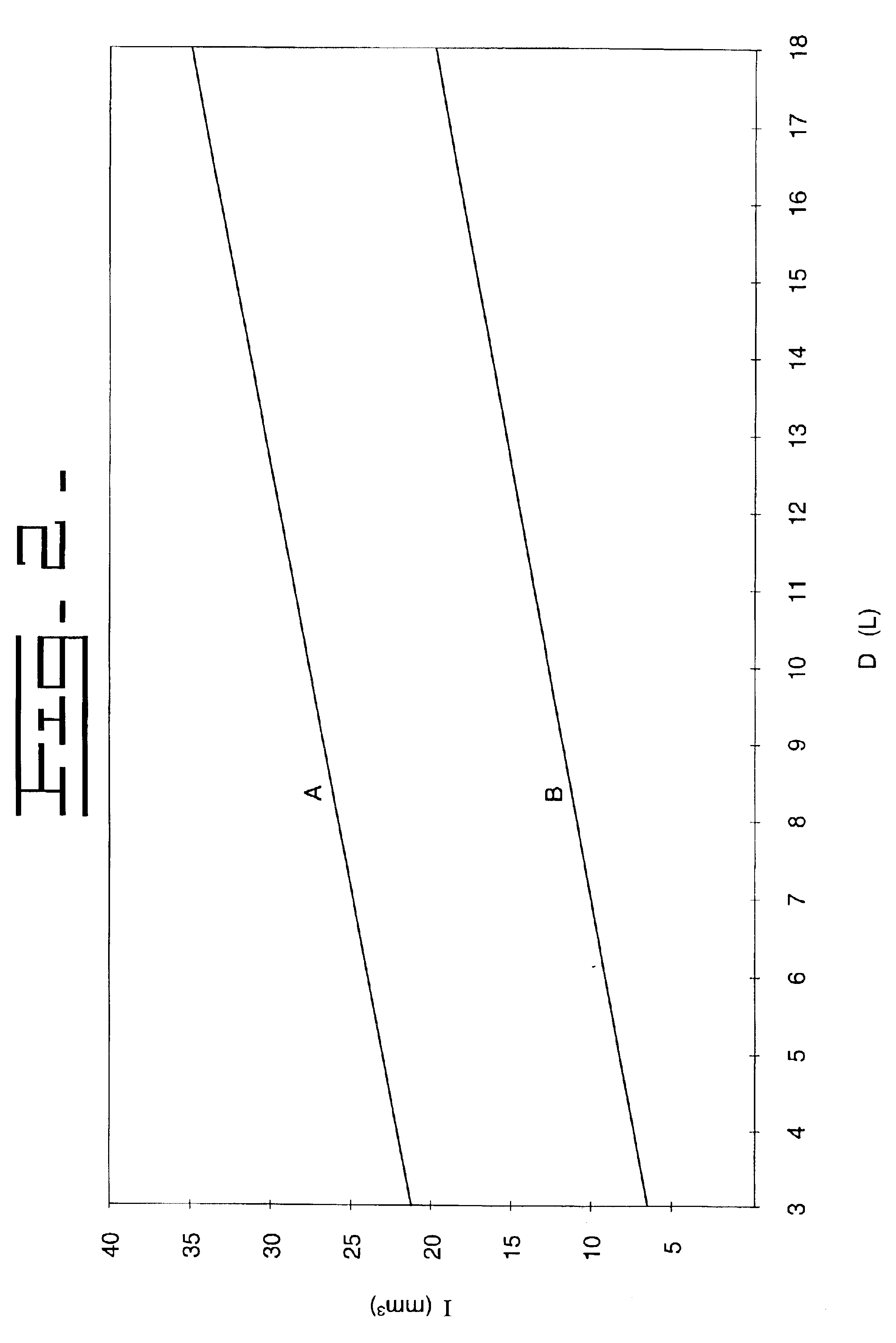

The implementation of emission reduction technologies for the S58 engine requires careful economic analysis to determine the most cost-effective approaches. Initial capital investments for advanced emission control systems range from $2,000 to $8,500 per engine unit, with selective catalytic reduction (SCR) systems representing the higher end of this spectrum. These systems demonstrate 85-95% NOx reduction efficiency but require ongoing urea solution consumption at approximately $0.05-0.10 per mile.

Particulate filter systems, costing between $3,000-5,000 per unit, offer 95% particulate matter reduction but incur maintenance costs of $400-800 annually. The regeneration process for these filters increases fuel consumption by 1-3%, representing an additional operational expense that must be factored into long-term cost projections.

Engine control unit (ECU) recalibration presents a more economical option at $800-1,500 per engine, achieving 15-25% emission reductions with minimal maintenance requirements. This approach offers the shortest return on investment period of 1-2 years compared to 3-5 years for more complex systems.

When analyzing operational benefits, improved fuel efficiency from modern emission technologies can offset initial investments. Advanced systems incorporating both SCR and optimized combustion management demonstrate fuel savings of 3-7%, translating to approximately $1,200-2,800 annual savings for high-mileage applications. These calculations assume current fuel pricing and typical S58 engine duty cycles.

Regulatory compliance benefits must also be monetized in this analysis. Non-compliance penalties in major markets range from $5,000-25,000 per violation, with potential operational restrictions in low-emission zones. Early adoption of stringent emission standards provides market access advantages valued at 10-15% of total revenue in environmentally regulated regions.

The total cost of ownership analysis reveals that while initial implementation costs are substantial, the 5-year operational period demonstrates positive return on investment for most technologies. SCR systems, despite higher initial costs, provide the best long-term value when considering both compliance benefits and operational efficiency improvements. Smaller fleets may benefit more from staged implementation approaches, beginning with ECU optimization before investing in hardware solutions.

Particulate filter systems, costing between $3,000-5,000 per unit, offer 95% particulate matter reduction but incur maintenance costs of $400-800 annually. The regeneration process for these filters increases fuel consumption by 1-3%, representing an additional operational expense that must be factored into long-term cost projections.

Engine control unit (ECU) recalibration presents a more economical option at $800-1,500 per engine, achieving 15-25% emission reductions with minimal maintenance requirements. This approach offers the shortest return on investment period of 1-2 years compared to 3-5 years for more complex systems.

When analyzing operational benefits, improved fuel efficiency from modern emission technologies can offset initial investments. Advanced systems incorporating both SCR and optimized combustion management demonstrate fuel savings of 3-7%, translating to approximately $1,200-2,800 annual savings for high-mileage applications. These calculations assume current fuel pricing and typical S58 engine duty cycles.

Regulatory compliance benefits must also be monetized in this analysis. Non-compliance penalties in major markets range from $5,000-25,000 per violation, with potential operational restrictions in low-emission zones. Early adoption of stringent emission standards provides market access advantages valued at 10-15% of total revenue in environmentally regulated regions.

The total cost of ownership analysis reveals that while initial implementation costs are substantial, the 5-year operational period demonstrates positive return on investment for most technologies. SCR systems, despite higher initial costs, provide the best long-term value when considering both compliance benefits and operational efficiency improvements. Smaller fleets may benefit more from staged implementation approaches, beginning with ECU optimization before investing in hardware solutions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!