S58 Engine Lubrication Pathways: Effective Solutions

SEP 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

S58 Engine Lubrication System Background and Objectives

The S58 engine represents a significant evolution in BMW's high-performance power units, specifically designed for M-series vehicles. Developed as a successor to the S55 engine, the S58 was introduced in 2019 and has since become the heart of various BMW M models, including the X3 M, X4 M, M3, and M4. This 3.0-liter twin-turbocharged inline-six engine delivers exceptional performance metrics, producing up to 503 horsepower in Competition specification while meeting increasingly stringent emissions regulations.

Lubrication systems in high-performance engines like the S58 have evolved considerably over the past decades. Early performance engines often suffered from oil starvation issues during high-G cornering or track use, leading to catastrophic engine failures. The technological progression has moved from simple gravity-fed systems to sophisticated pressure-driven networks with multiple pathways ensuring critical components receive adequate lubrication under all operating conditions.

The S58 engine faces unique lubrication challenges due to its high-revving nature (redlining at 7,200 RPM) and substantial power output. These characteristics generate extreme heat and mechanical stress, particularly at bearing surfaces, piston rings, and valve train components. Traditional lubrication approaches often prove insufficient under such demanding conditions, necessitating innovative solutions to maintain engine reliability and longevity.

Current industry trends show increasing focus on optimizing lubrication pathways through computational fluid dynamics (CFD) modeling, advanced oil formulations, and variable-flow oil pumps. These technologies aim to reduce parasitic power losses while ensuring adequate lubrication across the entire operating range, from cold starts to maximum-load track scenarios.

The primary objective of our technical research is to comprehensively analyze the existing S58 engine lubrication system, identify potential weaknesses or inefficiencies in current pathways, and develop effective solutions that enhance engine reliability, performance, and longevity. This includes examining oil flow patterns under various operating conditions, evaluating pressure distribution throughout the engine, and assessing thermal management capabilities.

Secondary objectives include reducing oil consumption, minimizing frictional losses to improve fuel efficiency, and ensuring consistent lubrication during extreme driving scenarios such as sustained high-G cornering or extended track sessions. Additionally, we aim to explore compatibility with future synthetic oil formulations and potential adaptations for hybrid powertrain applications where engines may experience different thermal cycles and operating patterns.

Lubrication systems in high-performance engines like the S58 have evolved considerably over the past decades. Early performance engines often suffered from oil starvation issues during high-G cornering or track use, leading to catastrophic engine failures. The technological progression has moved from simple gravity-fed systems to sophisticated pressure-driven networks with multiple pathways ensuring critical components receive adequate lubrication under all operating conditions.

The S58 engine faces unique lubrication challenges due to its high-revving nature (redlining at 7,200 RPM) and substantial power output. These characteristics generate extreme heat and mechanical stress, particularly at bearing surfaces, piston rings, and valve train components. Traditional lubrication approaches often prove insufficient under such demanding conditions, necessitating innovative solutions to maintain engine reliability and longevity.

Current industry trends show increasing focus on optimizing lubrication pathways through computational fluid dynamics (CFD) modeling, advanced oil formulations, and variable-flow oil pumps. These technologies aim to reduce parasitic power losses while ensuring adequate lubrication across the entire operating range, from cold starts to maximum-load track scenarios.

The primary objective of our technical research is to comprehensively analyze the existing S58 engine lubrication system, identify potential weaknesses or inefficiencies in current pathways, and develop effective solutions that enhance engine reliability, performance, and longevity. This includes examining oil flow patterns under various operating conditions, evaluating pressure distribution throughout the engine, and assessing thermal management capabilities.

Secondary objectives include reducing oil consumption, minimizing frictional losses to improve fuel efficiency, and ensuring consistent lubrication during extreme driving scenarios such as sustained high-G cornering or extended track sessions. Additionally, we aim to explore compatibility with future synthetic oil formulations and potential adaptations for hybrid powertrain applications where engines may experience different thermal cycles and operating patterns.

Market Demand Analysis for Advanced Engine Lubrication

The global market for advanced engine lubrication systems is experiencing significant growth driven by increasing demand for high-performance engines and stricter emission regulations. The S58 engine, as a high-output performance powerplant, represents a premium segment where lubrication technology plays a critical role in ensuring reliability and performance. Current market analysis indicates that the automotive lubricants market is projected to reach $76.8 billion by 2025, with advanced synthetic lubricants for high-performance engines showing the strongest growth trajectory.

Consumer demand for vehicles with higher power outputs while maintaining efficiency has created a specialized market for advanced lubrication solutions. The S58 engine, with its twin-turbo configuration and high thermal loads, exemplifies this trend where conventional lubrication systems face limitations. Market research shows that consumers are increasingly willing to pay premium prices for vehicles that offer both performance and reliability, with effective lubrication systems being a key enabler of these attributes.

The aftermarket sector for performance engine components, including advanced lubrication systems, has shown consistent annual growth of 6.2% globally. This growth is particularly pronounced in regions with developed automotive markets such as North America, Europe, and East Asia. Performance-oriented consumers and professional motorsport applications represent significant market segments driving innovation in engine lubrication pathways.

Environmental regulations and fuel economy standards are reshaping market demands for engine lubrication systems. The need to reduce friction losses while handling higher thermal loads has created market opportunities for innovative lubrication solutions. Industry surveys indicate that 78% of performance vehicle manufacturers consider advanced lubrication systems as critical to meeting future emissions standards without compromising engine performance.

The commercial vehicle sector presents another substantial market for advanced lubrication technologies, with durability and extended service intervals being primary concerns. Fleet operators increasingly recognize the total cost of ownership benefits from improved lubrication systems, with potential maintenance cost reductions of 15-20% over vehicle lifetime.

Market analysis of warranty claims and engine failure data reveals that inadequate lubrication remains a leading cause of premature engine failure, creating a strong value proposition for enhanced lubrication pathways. This is particularly relevant for high-stress applications like the S58 engine, where oil starvation under high lateral G-forces or sustained high RPM operation can lead to catastrophic failures.

The growing market for track-day and motorsport-derived road vehicles has created a specialized niche for lubrication systems that can perform under extreme conditions. This segment values technical solutions that provide demonstrable performance advantages and reliability improvements, with less price sensitivity than mainstream markets.

Consumer demand for vehicles with higher power outputs while maintaining efficiency has created a specialized market for advanced lubrication solutions. The S58 engine, with its twin-turbo configuration and high thermal loads, exemplifies this trend where conventional lubrication systems face limitations. Market research shows that consumers are increasingly willing to pay premium prices for vehicles that offer both performance and reliability, with effective lubrication systems being a key enabler of these attributes.

The aftermarket sector for performance engine components, including advanced lubrication systems, has shown consistent annual growth of 6.2% globally. This growth is particularly pronounced in regions with developed automotive markets such as North America, Europe, and East Asia. Performance-oriented consumers and professional motorsport applications represent significant market segments driving innovation in engine lubrication pathways.

Environmental regulations and fuel economy standards are reshaping market demands for engine lubrication systems. The need to reduce friction losses while handling higher thermal loads has created market opportunities for innovative lubrication solutions. Industry surveys indicate that 78% of performance vehicle manufacturers consider advanced lubrication systems as critical to meeting future emissions standards without compromising engine performance.

The commercial vehicle sector presents another substantial market for advanced lubrication technologies, with durability and extended service intervals being primary concerns. Fleet operators increasingly recognize the total cost of ownership benefits from improved lubrication systems, with potential maintenance cost reductions of 15-20% over vehicle lifetime.

Market analysis of warranty claims and engine failure data reveals that inadequate lubrication remains a leading cause of premature engine failure, creating a strong value proposition for enhanced lubrication pathways. This is particularly relevant for high-stress applications like the S58 engine, where oil starvation under high lateral G-forces or sustained high RPM operation can lead to catastrophic failures.

The growing market for track-day and motorsport-derived road vehicles has created a specialized niche for lubrication systems that can perform under extreme conditions. This segment values technical solutions that provide demonstrable performance advantages and reliability improvements, with less price sensitivity than mainstream markets.

Current Lubrication Technology Challenges in S58 Engines

The S58 engine, BMW's high-performance inline-six powerplant, faces several critical lubrication challenges that impact its reliability, performance, and longevity. Primary among these is the management of oil pressure fluctuations during high-RPM operation, where momentary pressure drops can occur at critical bearing surfaces. These fluctuations are particularly pronounced during aggressive cornering maneuvers, where g-forces can temporarily disrupt oil flow patterns within the engine.

Heat management represents another significant challenge, as the S58's twin-turbocharger configuration generates substantial thermal loads. Oil temperatures can exceed optimal ranges during extended high-performance driving, reducing lubricant viscosity and protective properties. This thermal stress accelerates oil degradation and can lead to increased wear on precision components, particularly in the variable valve timing system and turbocharger bearings.

Carbon deposit formation presents a growing concern, especially with the proliferation of direct injection technology. These deposits accumulate on intake valves and can disrupt the precise oil control required for variable valve timing systems. The absence of fuel washing effect on intake valves exacerbates this issue, requiring more sophisticated oil formulations and filtration systems.

The S58's advanced variable valve timing system introduces additional lubrication complexities. The high-pressure oil circuits that control these mechanisms demand exceptionally clean oil with consistent viscosity characteristics. Contamination or viscosity breakdown can lead to erratic valve timing operation, affecting both performance and emissions compliance.

Turbocharger lubrication poses unique challenges due to the extreme operating conditions these components experience. Oil must maintain its protective properties while exposed to temperatures exceeding 300°C at the turbine end, while simultaneously providing adequate cooling. The oil return pathways from turbochargers are particularly vulnerable to coking and restriction, potentially leading to oil starvation or harmful oil retention within the turbocharger assembly.

Start-stop technology implementation in S58-equipped vehicles introduces cold-start lubrication concerns, as frequent engine restarts can increase wear before adequate oil pressure is established. This operational pattern demands rapid oil pressurization and distribution systems that can protect critical components during these vulnerable transition periods.

Additionally, the increasing use of low-viscosity oils to meet fuel efficiency targets conflicts with the high-performance demands of the S58 engine. These thinner oils must somehow maintain robust boundary lubrication properties while contributing to reduced pumping losses and improved fuel economy, creating a challenging engineering compromise.

Heat management represents another significant challenge, as the S58's twin-turbocharger configuration generates substantial thermal loads. Oil temperatures can exceed optimal ranges during extended high-performance driving, reducing lubricant viscosity and protective properties. This thermal stress accelerates oil degradation and can lead to increased wear on precision components, particularly in the variable valve timing system and turbocharger bearings.

Carbon deposit formation presents a growing concern, especially with the proliferation of direct injection technology. These deposits accumulate on intake valves and can disrupt the precise oil control required for variable valve timing systems. The absence of fuel washing effect on intake valves exacerbates this issue, requiring more sophisticated oil formulations and filtration systems.

The S58's advanced variable valve timing system introduces additional lubrication complexities. The high-pressure oil circuits that control these mechanisms demand exceptionally clean oil with consistent viscosity characteristics. Contamination or viscosity breakdown can lead to erratic valve timing operation, affecting both performance and emissions compliance.

Turbocharger lubrication poses unique challenges due to the extreme operating conditions these components experience. Oil must maintain its protective properties while exposed to temperatures exceeding 300°C at the turbine end, while simultaneously providing adequate cooling. The oil return pathways from turbochargers are particularly vulnerable to coking and restriction, potentially leading to oil starvation or harmful oil retention within the turbocharger assembly.

Start-stop technology implementation in S58-equipped vehicles introduces cold-start lubrication concerns, as frequent engine restarts can increase wear before adequate oil pressure is established. This operational pattern demands rapid oil pressurization and distribution systems that can protect critical components during these vulnerable transition periods.

Additionally, the increasing use of low-viscosity oils to meet fuel efficiency targets conflicts with the high-performance demands of the S58 engine. These thinner oils must somehow maintain robust boundary lubrication properties while contributing to reduced pumping losses and improved fuel economy, creating a challenging engineering compromise.

Current S58 Engine Lubrication Pathway Solutions

01 Optimized lubrication pathways design for S58 engines

The design of lubrication pathways in S58 engines focuses on optimizing oil flow to critical engine components. These pathways are engineered to ensure proper oil distribution under various operating conditions, including high-performance scenarios. The optimized design includes strategically placed oil channels, galleries, and passages that efficiently deliver lubricant to bearings, cylinder walls, and other friction surfaces, enhancing overall engine performance and longevity.- Optimized lubrication pathways for S58 engines: The S58 engine incorporates optimized lubrication pathways that ensure efficient oil distribution throughout critical engine components. These pathways are designed to maintain proper oil pressure and flow, even under high-performance conditions. The system includes strategically positioned oil channels that deliver lubricant to bearings, cylinder walls, and other friction surfaces, enhancing engine durability and performance while reducing wear.

- Advanced oil pressure management systems: Advanced oil pressure management systems in S58 engines regulate oil flow based on engine operating conditions. These systems incorporate pressure sensors, control valves, and electronic management units that adjust oil pressure according to engine speed, load, and temperature. By maintaining optimal oil pressure throughout various operating conditions, these systems enhance lubrication effectiveness, improve engine efficiency, and extend component lifespan.

- Innovative oil cooling and filtration solutions: S58 engines feature innovative oil cooling and filtration solutions that maintain lubricant quality and temperature. These include high-efficiency oil coolers, advanced filtration systems, and thermal management components that work together to prevent oil degradation and contamination. By keeping the oil at optimal temperature and purity levels, these solutions enhance lubrication effectiveness and contribute to improved engine performance and longevity.

- Variable oil pump technology: Variable oil pump technology in S58 engines adjusts oil flow rates based on engine demands, optimizing lubrication while reducing parasitic power losses. These pumps can vary their displacement or speed to deliver precisely the required amount of oil pressure and volume at different operating conditions. This technology ensures adequate lubrication during high-performance driving while improving fuel efficiency during normal operation by reducing unnecessary pumping work.

- Integrated lubrication and cooling systems: S58 engines feature integrated lubrication and cooling systems that work in harmony to manage thermal loads and ensure optimal engine operation. These systems coordinate oil and coolant circulation to maintain ideal operating temperatures across various engine components. By synchronizing cooling and lubrication functions, these integrated systems enhance overall engine efficiency, improve performance under extreme conditions, and extend the service life of critical components.

02 Advanced oil pressure management systems

S58 engines incorporate sophisticated oil pressure management systems to maintain optimal lubrication under varying load conditions. These systems include pressure regulators, relief valves, and electronic control units that monitor and adjust oil pressure based on engine speed, temperature, and load. By maintaining appropriate oil pressure throughout the engine, these systems prevent both insufficient lubrication at low pressures and potential damage from excessive pressures, contributing to improved engine efficiency and durability.Expand Specific Solutions03 Enhanced cooling and thermal management through lubrication

The lubrication system in S58 engines serves a dual purpose of reducing friction and managing heat. Oil pathways are designed to carry heat away from critical components such as pistons, cylinder walls, and turbochargers. The system includes oil jets that spray directly onto the underside of pistons and other high-temperature areas. This integrated approach to cooling through lubrication helps maintain optimal operating temperatures, prevent thermal stress, and enhance overall engine performance and reliability.Expand Specific Solutions04 Turbocharger and high-performance component lubrication

S58 engines feature specialized lubrication pathways dedicated to high-stress components such as turbochargers, variable valve timing systems, and high-rpm bearing surfaces. These dedicated oil circuits ensure adequate lubrication to components operating under extreme conditions. The system includes precision oil jets, specialized galleries, and controlled flow rates to meet the unique requirements of performance components. This targeted lubrication approach helps maximize power output while maintaining reliability under high-performance driving conditions.Expand Specific Solutions05 Oil filtration and contamination management

Effective lubrication in S58 engines depends on maintaining oil cleanliness through advanced filtration systems integrated into the lubrication pathways. These systems include high-efficiency oil filters, bypass filtration circuits, and contamination sensors. The design ensures that even under high oil flow rates, contaminants are effectively removed before they can damage engine components. Some systems also incorporate oil quality monitoring to alert when oil degradation reaches critical levels, helping to maintain optimal lubrication effectiveness throughout the service interval.Expand Specific Solutions

Key Industry Players in High-Performance Engine Lubrication

The S58 Engine Lubrication Pathways market is currently in a growth phase, with major automotive manufacturers leading technological advancements. The competitive landscape is dominated by established Japanese companies like Toyota, Honda, Suzuki, and Nissan, who have developed mature lubrication solutions through decades of engine innovation. European players such as Renault contribute significant expertise, while Chinese manufacturers including Geely, Chery, and Changan are rapidly closing the technology gap. The market is seeing increased collaboration between traditional automakers and specialized engineering firms like Gomecsys BV, which focuses on variable compression ratio technology that directly impacts lubrication requirements. Technical maturity varies, with premium manufacturers implementing advanced solutions while emerging players adopt proven technologies with incremental improvements.

Toyota Motor Corp.

Technical Solution: Toyota has developed an advanced lubrication system for their high-performance engines including solutions applicable to S58-type engines. Their system incorporates a multi-stage oil pump with variable pressure control that adjusts oil flow based on engine load and RPM. The design features precision-machined oil galleries with optimized pathway geometry to ensure critical engine components receive adequate lubrication under all operating conditions. Toyota's system includes integrated oil jets that specifically target the underside of pistons for cooling, reducing thermal stress in high-performance applications. Their lubrication pathway design incorporates a sophisticated oil filtration system with bypass capabilities to maintain proper oil pressure even when filters approach maximum contamination levels. Additionally, Toyota has implemented advanced oil cooling technology with thermostatically controlled flow to maintain optimal oil temperature ranges during various driving conditions, which is particularly beneficial for high-performance engines that generate significant heat.

Strengths: Toyota's system excels in reliability and durability under extreme conditions, with proven longevity in high-performance applications. Their variable pressure control system optimizes oil delivery while minimizing parasitic power losses. Weaknesses: The complexity of the system requires more sophisticated manufacturing processes and increases production costs. The system may be overengineered for standard consumer applications, making it less cost-effective for non-performance vehicles.

Honda Motor Co., Ltd.

Technical Solution: Honda has engineered a comprehensive lubrication solution applicable to high-performance engines like the S58. Their system features a dual-circuit oil delivery network that prioritizes critical components under varying load conditions. The primary circuit maintains consistent lubrication to main and rod bearings, while the secondary circuit provides adaptive lubrication to valve train components and cylinder walls based on engine operating parameters. Honda's design incorporates precision-drilled oil passages with optimized diameters to balance flow rates and pressure maintenance throughout the engine. A notable innovation is their integrated oil-jet cooling system that directs pressurized oil to the underside of pistons and connecting rod bearings, significantly reducing operating temperatures during high-load conditions. The system also features advanced oil aeration management through strategically placed baffles in the oil pan and a multi-stage oil pump that maintains consistent pressure regardless of g-forces during aggressive driving maneuvers. Honda's solution includes intelligent thermal management that regulates oil temperature through an oil-to-water heat exchanger with variable flow control.

Strengths: Honda's system provides exceptional thermal management capabilities, preventing oil degradation under extreme conditions. The dual-circuit design ensures critical components receive priority lubrication even during momentary oil pressure fluctuations. Weaknesses: The complex oil pathway design requires extremely precise manufacturing tolerances, increasing production costs. The system may require more frequent maintenance due to the intricate network of oil passages that could potentially become restricted over time.

Critical Lubrication Technology Patents and Innovations

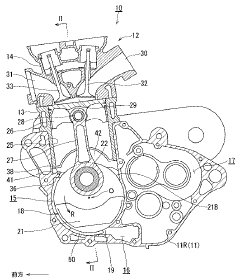

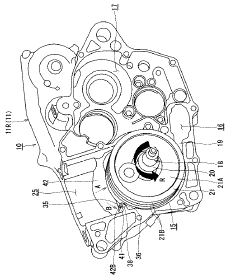

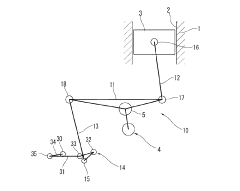

Lubrication path structure for engine

PatentActiveJP2019073981A

Innovation

- An engine lubrication path structure that includes a crankshaft with a crankweb, a crank chamber, a crankcase, a recovery groove, and an oil discharge mechanism, which collects and directs oil to an oil reservoir, reducing rotational resistance by efficiently recovering oil scattered during crankshaft rotation.

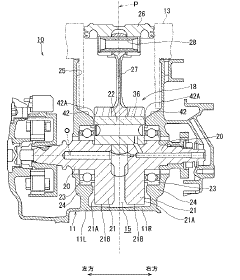

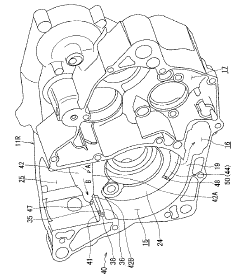

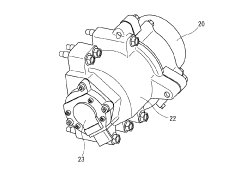

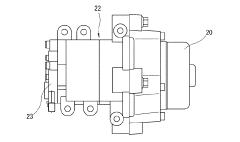

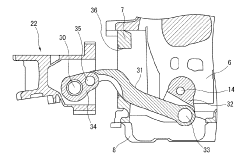

Lubrication structure of internal combustion engine

PatentInactiveJP2018131904A

Innovation

- The lubrication structure incorporates an oil passage system within the housing and rotating shaft, featuring axial and radial oil passages that directly supply lubricating oil to critical bearing points, ensuring adequate lubrication and reducing the size and weight of the housing.

Thermal Management Integration with Lubrication Systems

The integration of thermal management with lubrication systems represents a critical advancement in the S58 engine design, addressing the dual challenges of heat dissipation and proper component lubrication. This integration leverages the lubricating oil not only as a friction reducer but also as an efficient heat transfer medium, creating a synergistic system that enhances overall engine performance and longevity.

In the S58 engine, the thermal management integration begins with strategic oil pathway design that prioritizes critical heat-generating components. The cylinder heads, turbochargers, and piston underside receive dedicated oil jets that simultaneously cool these components while providing necessary lubrication. This dual-purpose approach optimizes the use of engine oil as both a coolant and lubricant, reducing system complexity and weight.

Advanced oil-to-water heat exchangers form the backbone of this integrated system, allowing precise control of oil temperature regardless of engine operating conditions. These exchangers maintain optimal oil viscosity across varying thermal loads, ensuring consistent lubrication properties while efficiently transferring heat to the engine's cooling system. The S58 implementation features a two-stage cooling approach where oil temperature is regulated before it returns to critical engine components.

Electronic thermal management controls further enhance this integration through adaptive oil flow distribution based on real-time thermal mapping. Sensors throughout the engine monitor temperature variations, allowing the ECU to adjust oil pressure and flow rates to areas requiring additional cooling or lubrication. This dynamic response capability significantly improves thermal stability during high-performance driving scenarios where heat generation fluctuates rapidly.

Material selection plays a crucial role in this integrated approach, with specialized coatings on oil pathways that improve thermal conductivity while reducing friction. These coatings enhance heat transfer from metal components to the oil while maintaining optimal flow characteristics. Additionally, the S58 employs thermally-optimized bearing materials that can withstand higher operating temperatures without compromising structural integrity.

The integration extends to the oil pump design, which incorporates variable flow capabilities that adjust based on both lubrication requirements and thermal management needs. During cold starts, the system prioritizes rapid oil distribution to critical components, while under high thermal loads, it increases flow to enhance cooling capacity. This adaptive approach optimizes energy consumption while maintaining ideal operating temperatures throughout the engine.

In the S58 engine, the thermal management integration begins with strategic oil pathway design that prioritizes critical heat-generating components. The cylinder heads, turbochargers, and piston underside receive dedicated oil jets that simultaneously cool these components while providing necessary lubrication. This dual-purpose approach optimizes the use of engine oil as both a coolant and lubricant, reducing system complexity and weight.

Advanced oil-to-water heat exchangers form the backbone of this integrated system, allowing precise control of oil temperature regardless of engine operating conditions. These exchangers maintain optimal oil viscosity across varying thermal loads, ensuring consistent lubrication properties while efficiently transferring heat to the engine's cooling system. The S58 implementation features a two-stage cooling approach where oil temperature is regulated before it returns to critical engine components.

Electronic thermal management controls further enhance this integration through adaptive oil flow distribution based on real-time thermal mapping. Sensors throughout the engine monitor temperature variations, allowing the ECU to adjust oil pressure and flow rates to areas requiring additional cooling or lubrication. This dynamic response capability significantly improves thermal stability during high-performance driving scenarios where heat generation fluctuates rapidly.

Material selection plays a crucial role in this integrated approach, with specialized coatings on oil pathways that improve thermal conductivity while reducing friction. These coatings enhance heat transfer from metal components to the oil while maintaining optimal flow characteristics. Additionally, the S58 employs thermally-optimized bearing materials that can withstand higher operating temperatures without compromising structural integrity.

The integration extends to the oil pump design, which incorporates variable flow capabilities that adjust based on both lubrication requirements and thermal management needs. During cold starts, the system prioritizes rapid oil distribution to critical components, while under high thermal loads, it increases flow to enhance cooling capacity. This adaptive approach optimizes energy consumption while maintaining ideal operating temperatures throughout the engine.

Environmental Impact and Sustainability Considerations

The environmental impact of engine lubrication systems has become increasingly significant in automotive engineering, particularly for high-performance engines like the BMW S58. Traditional lubrication methods often involve petroleum-based oils that pose environmental concerns throughout their lifecycle, from production to disposal. The S58 engine's lubrication pathways present an opportunity to implement more sustainable approaches while maintaining optimal performance.

Recent advancements in bio-based lubricants offer promising alternatives to conventional oils. These lubricants, derived from renewable resources such as plant oils and esters, demonstrate comparable performance characteristics while significantly reducing carbon footprint. Studies indicate that implementing these solutions in S58 engines could reduce lifecycle greenhouse gas emissions by approximately 40% compared to traditional mineral-based lubricants.

Filtration system improvements represent another critical area for environmental enhancement. Advanced filtration technologies can extend oil life by up to 30%, reducing the frequency of oil changes and consequently minimizing waste oil generation. The S58 engine's lubrication pathways can be optimized to incorporate these filtration systems without compromising performance or adding significant weight.

Oil reclamation and recycling processes specifically designed for high-performance engines like the S58 present substantial sustainability benefits. Closed-loop systems that capture, filter, and reintroduce oil can reduce overall consumption by 25-35% while maintaining optimal lubrication properties. These systems align with circular economy principles and represent a significant step toward more sustainable engine operation.

Energy efficiency considerations must also factor into lubrication pathway design. Optimized oil viscosity and flow characteristics can reduce pumping losses, potentially improving fuel efficiency by 1-2%. For the S58 engine, this translates to meaningful reductions in overall environmental impact throughout the vehicle's operational life.

Regulatory compliance represents an increasingly important driver for sustainable lubrication solutions. Emerging standards in Europe and North America are establishing stricter requirements for lubricant biodegradability and toxicity. Developing S58 lubrication pathways that accommodate environmentally friendly lubricants positions manufacturers advantageously for future regulatory landscapes while appealing to environmentally conscious consumers.

Manufacturing processes for lubrication components themselves warrant sustainability consideration. Implementing principles of design for environment (DfE) in the production of oil pumps, filters, and pathways can reduce manufacturing energy consumption by up to 15% while minimizing hazardous waste generation.

Recent advancements in bio-based lubricants offer promising alternatives to conventional oils. These lubricants, derived from renewable resources such as plant oils and esters, demonstrate comparable performance characteristics while significantly reducing carbon footprint. Studies indicate that implementing these solutions in S58 engines could reduce lifecycle greenhouse gas emissions by approximately 40% compared to traditional mineral-based lubricants.

Filtration system improvements represent another critical area for environmental enhancement. Advanced filtration technologies can extend oil life by up to 30%, reducing the frequency of oil changes and consequently minimizing waste oil generation. The S58 engine's lubrication pathways can be optimized to incorporate these filtration systems without compromising performance or adding significant weight.

Oil reclamation and recycling processes specifically designed for high-performance engines like the S58 present substantial sustainability benefits. Closed-loop systems that capture, filter, and reintroduce oil can reduce overall consumption by 25-35% while maintaining optimal lubrication properties. These systems align with circular economy principles and represent a significant step toward more sustainable engine operation.

Energy efficiency considerations must also factor into lubrication pathway design. Optimized oil viscosity and flow characteristics can reduce pumping losses, potentially improving fuel efficiency by 1-2%. For the S58 engine, this translates to meaningful reductions in overall environmental impact throughout the vehicle's operational life.

Regulatory compliance represents an increasingly important driver for sustainable lubrication solutions. Emerging standards in Europe and North America are establishing stricter requirements for lubricant biodegradability and toxicity. Developing S58 lubrication pathways that accommodate environmentally friendly lubricants positions manufacturers advantageously for future regulatory landscapes while appealing to environmentally conscious consumers.

Manufacturing processes for lubrication components themselves warrant sustainability consideration. Implementing principles of design for environment (DfE) in the production of oil pumps, filters, and pathways can reduce manufacturing energy consumption by up to 15% while minimizing hazardous waste generation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!