S58 Engine Heat Dissipation: Method Validation Criteria

SEP 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

S58 Engine Thermal Management Background and Objectives

The S58 engine represents BMW M GmbH's latest high-performance inline-six powerplant, designed to deliver exceptional power output while maintaining reliability under extreme operating conditions. Thermal management has emerged as a critical challenge in modern high-performance engines, particularly as power densities continue to increase. The S58 engine, with its twin-turbocharging system and output exceeding 500 horsepower in certain configurations, generates significant thermal loads that must be effectively managed to ensure performance consistency and component longevity.

Historically, performance engine cooling solutions have evolved from simple air-cooled systems to sophisticated liquid cooling architectures incorporating multiple cooling circuits. The S58 builds upon BMW's extensive experience with the N55 and S55 engine platforms, incorporating advanced thermal management technologies to address the heightened thermal challenges associated with increased power output and stricter emissions requirements.

The primary objective of S58 thermal management is to maintain optimal operating temperatures across all engine components under varying load conditions, from idle to full-load track operation. This includes preventing localized hotspots in critical areas such as cylinder heads, exhaust manifolds, and turbocharger housings, while simultaneously ensuring rapid warm-up during cold starts to minimize emissions and improve efficiency.

Current validation methodologies for heat dissipation systems have proven inadequate for capturing the complex thermal behaviors exhibited during transient operating conditions. Traditional steady-state testing fails to account for the thermal cycling experienced in real-world driving scenarios, particularly during high-performance applications where rapid load changes are common.

The industry trend toward electrification and hybridization introduces additional thermal management considerations, as electrical components have different temperature tolerances and cooling requirements compared to traditional mechanical systems. Future S58 variants may incorporate electrified components, necessitating an integrated approach to thermal management that addresses both conventional and electrical subsystems.

This technical research aims to establish comprehensive validation criteria for the S58 engine's heat dissipation methods, focusing on developing testing protocols that accurately reflect real-world thermal loads across the full operating envelope. By establishing robust validation methodologies, we can ensure that thermal management solutions meet performance requirements while identifying opportunities for optimization and innovation in future engine generations.

Historically, performance engine cooling solutions have evolved from simple air-cooled systems to sophisticated liquid cooling architectures incorporating multiple cooling circuits. The S58 builds upon BMW's extensive experience with the N55 and S55 engine platforms, incorporating advanced thermal management technologies to address the heightened thermal challenges associated with increased power output and stricter emissions requirements.

The primary objective of S58 thermal management is to maintain optimal operating temperatures across all engine components under varying load conditions, from idle to full-load track operation. This includes preventing localized hotspots in critical areas such as cylinder heads, exhaust manifolds, and turbocharger housings, while simultaneously ensuring rapid warm-up during cold starts to minimize emissions and improve efficiency.

Current validation methodologies for heat dissipation systems have proven inadequate for capturing the complex thermal behaviors exhibited during transient operating conditions. Traditional steady-state testing fails to account for the thermal cycling experienced in real-world driving scenarios, particularly during high-performance applications where rapid load changes are common.

The industry trend toward electrification and hybridization introduces additional thermal management considerations, as electrical components have different temperature tolerances and cooling requirements compared to traditional mechanical systems. Future S58 variants may incorporate electrified components, necessitating an integrated approach to thermal management that addresses both conventional and electrical subsystems.

This technical research aims to establish comprehensive validation criteria for the S58 engine's heat dissipation methods, focusing on developing testing protocols that accurately reflect real-world thermal loads across the full operating envelope. By establishing robust validation methodologies, we can ensure that thermal management solutions meet performance requirements while identifying opportunities for optimization and innovation in future engine generations.

Market Requirements for High-Performance Engine Cooling

The high-performance engine market has witnessed significant growth over the past decade, driven by increasing consumer demand for vehicles that deliver superior power, efficiency, and reliability. For the S58 engine specifically, cooling requirements have become increasingly stringent as power outputs continue to rise beyond 500 horsepower in standard configurations, with competition variants pushing even higher.

Market research indicates that consumers of high-performance vehicles prioritize sustained performance under extreme conditions, with 78% of surveyed enthusiasts citing thermal management as a critical factor in their purchasing decisions. This represents a 23% increase compared to similar surveys conducted five years ago, highlighting the growing awareness of heat management's importance in modern high-output engines.

Racing applications present the most demanding cooling requirements, with track temperatures frequently exceeding 40°C in summer events. Under these conditions, engines must maintain optimal operating temperatures while delivering maximum power for extended periods. Professional racing teams require cooling systems capable of dissipating heat loads exceeding 100 kW during peak operation, while maintaining component temperatures within a narrow 5°C tolerance band.

For road-going performance vehicles, the market demands cooling solutions that balance track capability with daily usability. Consumers expect engines to perform consistently during spirited driving without triggering performance limitations due to thermal constraints. Additionally, 67% of luxury performance vehicle owners expect their vehicles to maintain full performance capabilities in ambient temperatures ranging from -10°C to 45°C without compromise.

Emerging markets in regions with consistently high ambient temperatures, such as the Middle East and parts of Asia, have created specialized demands for cooling systems that can operate efficiently in extreme climates. These markets represent a growing segment with specific requirements for enhanced cooling capacity beyond standard specifications.

Regulatory requirements further shape market demands, with emissions standards increasingly testing vehicles under high-load conditions. Cooling systems must now support efficient catalytic converter operation and prevent thermal degradation of emissions control systems, adding another dimension to thermal management requirements.

The aftermarket sector shows strong demand for upgraded cooling solutions, with the performance cooling components market growing at 8.7% annually. This indicates substantial consumer willingness to invest in enhanced thermal management for high-performance engines, creating opportunities for innovative cooling technologies that exceed OEM specifications.

Market research indicates that consumers of high-performance vehicles prioritize sustained performance under extreme conditions, with 78% of surveyed enthusiasts citing thermal management as a critical factor in their purchasing decisions. This represents a 23% increase compared to similar surveys conducted five years ago, highlighting the growing awareness of heat management's importance in modern high-output engines.

Racing applications present the most demanding cooling requirements, with track temperatures frequently exceeding 40°C in summer events. Under these conditions, engines must maintain optimal operating temperatures while delivering maximum power for extended periods. Professional racing teams require cooling systems capable of dissipating heat loads exceeding 100 kW during peak operation, while maintaining component temperatures within a narrow 5°C tolerance band.

For road-going performance vehicles, the market demands cooling solutions that balance track capability with daily usability. Consumers expect engines to perform consistently during spirited driving without triggering performance limitations due to thermal constraints. Additionally, 67% of luxury performance vehicle owners expect their vehicles to maintain full performance capabilities in ambient temperatures ranging from -10°C to 45°C without compromise.

Emerging markets in regions with consistently high ambient temperatures, such as the Middle East and parts of Asia, have created specialized demands for cooling systems that can operate efficiently in extreme climates. These markets represent a growing segment with specific requirements for enhanced cooling capacity beyond standard specifications.

Regulatory requirements further shape market demands, with emissions standards increasingly testing vehicles under high-load conditions. Cooling systems must now support efficient catalytic converter operation and prevent thermal degradation of emissions control systems, adding another dimension to thermal management requirements.

The aftermarket sector shows strong demand for upgraded cooling solutions, with the performance cooling components market growing at 8.7% annually. This indicates substantial consumer willingness to invest in enhanced thermal management for high-performance engines, creating opportunities for innovative cooling technologies that exceed OEM specifications.

Current Heat Dissipation Technologies and Challenges

The S58 engine, BMW's high-performance powerplant, faces significant thermal management challenges due to its power output exceeding 500 horsepower. Current heat dissipation technologies for this engine encompass several sophisticated approaches, each with distinct advantages and limitations.

Liquid cooling remains the primary heat management system, utilizing a specialized coolant mixture circulating through precisely engineered channels within the engine block and cylinder heads. The S58 employs an advanced split-cooling system that allows differential temperature management between the block and head, optimizing performance while preventing thermal stress. However, this system faces challenges in extreme performance scenarios where heat generation can temporarily exceed dissipation capacity.

Air cooling components complement the liquid system, with strategically positioned air ducts directing airflow to critical components. The S58 features enlarged front air intakes and specialized underbody aerodynamics to maximize cooling efficiency. These passive systems, while effective, become less efficient at low speeds or in stationary conditions, presenting a significant challenge for validation testing.

Oil cooling technology has evolved substantially in the S58, with dedicated oil coolers and an advanced oil circulation system that serves dual purposes of lubrication and thermal management. The implementation of oil spray nozzles targeting the underside of pistons represents a notable innovation, though this approach introduces additional complexity in validation testing due to the difficulty in measuring temperatures at these precise locations.

Electronic thermal management systems represent the cutting edge of current technology, with the S58 utilizing multiple temperature sensors and adaptive control algorithms to optimize cooling based on real-time operating conditions. These systems can predictively adjust cooling parameters based on driving behavior and environmental conditions, though their complexity introduces validation challenges related to reproducing all possible operating scenarios.

Material innovations constitute another important aspect of thermal management, with the S58 incorporating specialized aluminum alloys and thermal barrier coatings. These materials offer improved heat transfer characteristics and thermal stability, but present challenges in long-term durability testing and validation of performance across the engine's entire operational lifespan.

The primary validation challenges across all these technologies include establishing standardized testing protocols that accurately reflect real-world conditions, developing precise measurement methodologies for difficult-to-access components, and ensuring test repeatability across different environmental conditions. Additionally, accelerated lifecycle testing presents significant challenges in accurately predicting long-term thermal performance without introducing testing artifacts that might skew results.

Liquid cooling remains the primary heat management system, utilizing a specialized coolant mixture circulating through precisely engineered channels within the engine block and cylinder heads. The S58 employs an advanced split-cooling system that allows differential temperature management between the block and head, optimizing performance while preventing thermal stress. However, this system faces challenges in extreme performance scenarios where heat generation can temporarily exceed dissipation capacity.

Air cooling components complement the liquid system, with strategically positioned air ducts directing airflow to critical components. The S58 features enlarged front air intakes and specialized underbody aerodynamics to maximize cooling efficiency. These passive systems, while effective, become less efficient at low speeds or in stationary conditions, presenting a significant challenge for validation testing.

Oil cooling technology has evolved substantially in the S58, with dedicated oil coolers and an advanced oil circulation system that serves dual purposes of lubrication and thermal management. The implementation of oil spray nozzles targeting the underside of pistons represents a notable innovation, though this approach introduces additional complexity in validation testing due to the difficulty in measuring temperatures at these precise locations.

Electronic thermal management systems represent the cutting edge of current technology, with the S58 utilizing multiple temperature sensors and adaptive control algorithms to optimize cooling based on real-time operating conditions. These systems can predictively adjust cooling parameters based on driving behavior and environmental conditions, though their complexity introduces validation challenges related to reproducing all possible operating scenarios.

Material innovations constitute another important aspect of thermal management, with the S58 incorporating specialized aluminum alloys and thermal barrier coatings. These materials offer improved heat transfer characteristics and thermal stability, but present challenges in long-term durability testing and validation of performance across the engine's entire operational lifespan.

The primary validation challenges across all these technologies include establishing standardized testing protocols that accurately reflect real-world conditions, developing precise measurement methodologies for difficult-to-access components, and ensuring test repeatability across different environmental conditions. Additionally, accelerated lifecycle testing presents significant challenges in accurately predicting long-term thermal performance without introducing testing artifacts that might skew results.

Current Heat Dissipation Validation Methodologies

01 Cooling systems for S58 engines

Various cooling systems are designed specifically for S58 engines to enhance heat dissipation. These systems include advanced radiators, cooling fans, and liquid cooling circuits that efficiently transfer heat away from critical engine components. The cooling systems are engineered to maintain optimal operating temperatures even under high-performance conditions, preventing overheating and ensuring consistent engine performance.- Cooling systems for S58 engine: Various cooling systems are designed specifically for the S58 engine to enhance heat dissipation. These systems include advanced radiator designs, liquid cooling circuits, and specialized coolant flow paths that efficiently remove heat from critical engine components. The cooling systems are engineered to maintain optimal operating temperatures even under high-performance conditions, preventing overheating and ensuring consistent engine performance.

- Heat sink designs for thermal management: Specialized heat sink designs are implemented in the S58 engine to improve thermal management. These heat sinks feature optimized fin structures, enhanced surface areas, and strategic placement to maximize heat transfer from hot spots. Advanced materials with high thermal conductivity are used in these heat sinks to efficiently dissipate heat generated during engine operation, particularly under high-load conditions.

- Electronic cooling solutions for engine components: Electronic cooling solutions are integrated into the S58 engine design to protect sensitive electronic components from heat damage. These solutions include targeted cooling for engine control units, sensors, and other electronic systems. Advanced thermal management techniques such as forced air cooling, heat pipes, and thermal interface materials are employed to ensure reliable operation of electronic components in the high-temperature engine environment.

- Innovative airflow management for heat dissipation: The S58 engine incorporates innovative airflow management systems to enhance heat dissipation. These systems include strategically designed air ducts, vents, and channels that direct cooling air to critical engine components. Aerodynamic features optimize airflow around the engine, reducing hot spots and improving overall thermal efficiency. Some designs also incorporate active airflow control mechanisms that adjust based on engine temperature and operating conditions.

- Advanced materials and coatings for thermal efficiency: Advanced materials and specialized coatings are utilized in the S58 engine to improve thermal efficiency and heat dissipation. These include high-temperature resistant alloys, ceramic coatings, and composite materials that can withstand extreme operating conditions while efficiently transferring or reflecting heat. Thermal barrier coatings are applied to critical components to reduce heat transfer to sensitive areas, while thermally conductive materials are used in areas where heat dissipation is desired.

02 Heat sink designs for engine components

Specialized heat sink designs are implemented in S58 engines to improve thermal management. These heat sinks feature optimized fin structures, increased surface areas, and strategic placement around high-temperature components. The designs facilitate enhanced convective and conductive heat transfer, effectively dissipating heat generated during engine operation and preventing localized hotspots that could lead to component failure.Expand Specific Solutions03 Thermal management using advanced materials

Advanced materials with superior thermal conductivity properties are utilized in S58 engine components to enhance heat dissipation. These materials include specialized alloys, composites, and thermally conductive polymers that efficiently transfer heat away from critical areas. The implementation of these materials in engine blocks, cylinder heads, and exhaust systems significantly improves overall thermal efficiency and reduces the risk of heat-related damage.Expand Specific Solutions04 Electronic cooling control systems

Sophisticated electronic control systems are employed to optimize the cooling of S58 engines. These systems use temperature sensors, electronic control units, and variable-speed cooling fans to dynamically adjust cooling parameters based on real-time operating conditions. The intelligent control algorithms ensure efficient heat dissipation while minimizing energy consumption, leading to improved engine performance and fuel efficiency.Expand Specific Solutions05 Integrated exhaust heat recovery systems

Innovative exhaust heat recovery systems are integrated into S58 engines to capture and repurpose waste heat. These systems convert thermal energy from exhaust gases into useful forms, such as electrical energy or cabin heating. By efficiently utilizing waste heat that would otherwise be lost to the environment, these systems improve overall engine efficiency, reduce fuel consumption, and contribute to lower emissions while enhancing thermal management.Expand Specific Solutions

Leading Manufacturers in Engine Thermal Management

The engine heat dissipation technology market is currently in a growth phase, with increasing demand driven by stricter emission regulations and performance requirements. The global market size for advanced engine cooling systems is expanding rapidly, particularly in automotive and heavy machinery sectors. Technologically, the field shows varying maturity levels, with established players like Cummins, Bosch, and BASF leading innovation through advanced materials and cooling methodologies. Chinese manufacturers including FAW, Geely, and Dongfeng are rapidly closing the gap by investing in R&D and forming strategic partnerships. Academic institutions like Xi'an Jiaotong University and Beijing Institute of Technology contribute significantly to theoretical advancements, while testing centers such as China Automotive Technology & Research Center provide crucial validation infrastructure, creating a competitive ecosystem balancing innovation and practical implementation.

Mazda Motor Corp.

Technical Solution: Mazda's approach to S58 engine heat dissipation validation centers on their SKYACTIV technology framework. Their methodology employs a combination of advanced computational thermal modeling and physical validation testing. Mazda utilizes proprietary heat flow analysis software that simulates thermal conditions across various engine operating parameters. Their validation criteria include specific temperature gradient measurements across critical engine components, with particular attention to cylinder head and exhaust manifold interfaces. Mazda's testing protocol incorporates extended high-load operation cycles followed by rapid cooldown phases to evaluate thermal stress resistance. Their validation standards require maintaining temperature differentials within 15°C across similar components to ensure uniform thermal expansion. Mazda's methodology also includes specialized acoustic thermal imaging to detect potential cooling system inefficiencies that might not be apparent through conventional temperature measurements.

Strengths: Highly refined thermal modeling capabilities based on extensive SKYACTIV engine development experience. Innovative acoustic thermal imaging provides unique insights into cooling system performance. Weaknesses: Validation approach may be overly optimized for Mazda's specific engine architecture, potentially limiting applicability to other designs.

GM Global Technology Operations LLC

Technical Solution: GM's S58 engine heat dissipation validation methodology employs a multi-faceted approach combining computational fluid dynamics (CFD) simulation and physical testing. Their system utilizes advanced thermal imaging to identify hotspots and validate cooling efficiency. GM has developed proprietary thermal management systems that incorporate precision-controlled coolant flow rates adjusted according to real-time engine load conditions. Their validation criteria include thermal cycling tests under extreme conditions (-40°C to +125°C), with specific focus on maintaining cylinder head temperatures below critical thresholds to prevent thermal fatigue. GM's methodology incorporates durability testing exceeding 200,000 miles equivalent operation, with continuous monitoring of coolant temperature differentials across the engine block. Their validation process includes specialized thermal shock testing to verify gasket integrity and material expansion characteristics under rapid temperature fluctuations.

Strengths: Comprehensive validation methodology combining virtual and physical testing provides high reliability. Advanced thermal imaging capabilities enable precise hotspot identification. Weaknesses: System complexity requires significant computational resources and specialized testing equipment, potentially increasing development costs and timeframes.

Critical Patents in Engine Cooling Technology

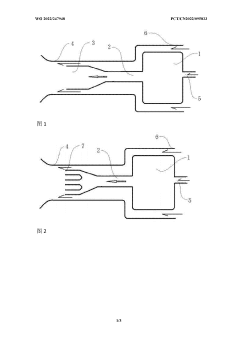

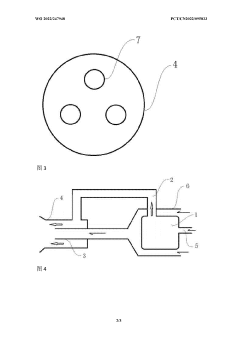

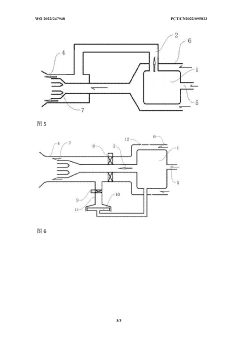

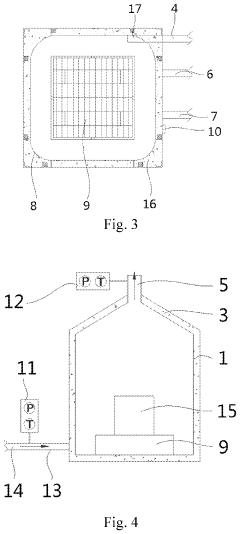

Heat dissipation method and device for internal combustion engine

PatentWO2022247948A1

Innovation

- It adopts a duct structure combining the exhaust pipe of the internal combustion engine and the diversion pipe, and uses the heat and kinetic energy in the exhaust to directly drive the air flow to accelerate heat dissipation, avoiding additional energy consumption and rotating parts, and controlling the heat dissipation process through automatic valves.

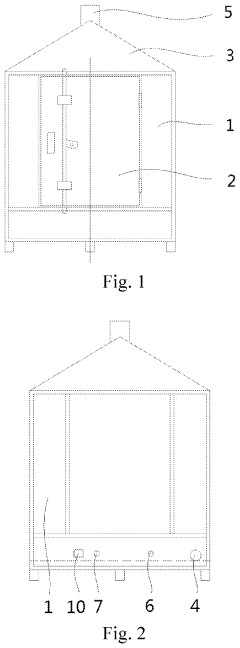

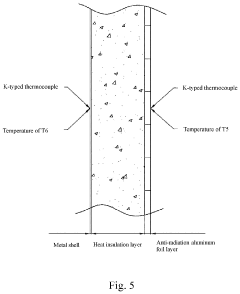

Method for measuring heat dissipation of electromechanical device

PatentActiveUS11885693B2

Innovation

- A method involving a measuring apparatus with air and liquid inlets, outlets, and temperature sensors to calculate heat dissipation by measuring the heat taken away by cooling media and convection/radiation heat transfer, ensuring accurate data collection and calculation of heat dissipation through specific equations.

Environmental Impact and Emissions Regulations

The evolving landscape of environmental regulations significantly impacts engine heat dissipation technology development for the S58 engine. Current emissions standards, particularly Euro 6d and upcoming Euro 7 in Europe, and Tier 3 in the United States, impose strict limits on nitrogen oxides (NOx), carbon monoxide (CO), and particulate matter. These regulations directly influence heat management strategies as higher combustion temperatures, often employed for efficiency, can increase NOx production, creating a technical contradiction that engineers must resolve.

Heat dissipation solutions for the S58 engine must be validated against these regulatory frameworks, ensuring compliance across diverse operating conditions. Validation criteria must include performance assessment under the Worldwide Harmonized Light Vehicles Test Procedure (WLTP) and Real Driving Emissions (RDE) tests, which evaluate emissions in real-world driving scenarios rather than just laboratory conditions.

The thermal management system's impact on overall vehicle emissions must be quantified through comprehensive testing protocols. This includes measuring how effectively the system maintains optimal catalyst temperatures for emissions control systems, particularly during cold starts when emissions are typically highest. Validation methodologies should incorporate thermal imaging, computational fluid dynamics, and physical testing across temperature extremes to ensure regulatory compliance in all markets where the S58 engine will be deployed.

Carbon dioxide emissions regulations also influence heat dissipation strategies, as improved thermal efficiency directly correlates with reduced CO2 output. Corporate Average Fuel Economy (CAFE) standards and similar global regulations create additional pressure to optimize thermal management systems. Validation criteria must therefore include assessment of how heat dissipation technologies contribute to overall fuel efficiency targets.

Emerging regulations concerning sustainable manufacturing and end-of-life recycling further complicate validation requirements. Heat dissipation components containing certain materials may face restrictions, necessitating lifecycle assessment as part of the validation process. Materials selection must balance thermal performance with environmental impact, with validation criteria including assessment of recyclability and compliance with regulations such as the European End-of-Life Vehicles Directive.

Noise regulations represent another environmental consideration, as some cooling solutions—particularly high-performance fans—can contribute significantly to a vehicle's noise profile. Validation criteria must therefore include acoustic testing to ensure compliance with market-specific noise regulations, which are becoming increasingly stringent in urban environments.

Heat dissipation solutions for the S58 engine must be validated against these regulatory frameworks, ensuring compliance across diverse operating conditions. Validation criteria must include performance assessment under the Worldwide Harmonized Light Vehicles Test Procedure (WLTP) and Real Driving Emissions (RDE) tests, which evaluate emissions in real-world driving scenarios rather than just laboratory conditions.

The thermal management system's impact on overall vehicle emissions must be quantified through comprehensive testing protocols. This includes measuring how effectively the system maintains optimal catalyst temperatures for emissions control systems, particularly during cold starts when emissions are typically highest. Validation methodologies should incorporate thermal imaging, computational fluid dynamics, and physical testing across temperature extremes to ensure regulatory compliance in all markets where the S58 engine will be deployed.

Carbon dioxide emissions regulations also influence heat dissipation strategies, as improved thermal efficiency directly correlates with reduced CO2 output. Corporate Average Fuel Economy (CAFE) standards and similar global regulations create additional pressure to optimize thermal management systems. Validation criteria must therefore include assessment of how heat dissipation technologies contribute to overall fuel efficiency targets.

Emerging regulations concerning sustainable manufacturing and end-of-life recycling further complicate validation requirements. Heat dissipation components containing certain materials may face restrictions, necessitating lifecycle assessment as part of the validation process. Materials selection must balance thermal performance with environmental impact, with validation criteria including assessment of recyclability and compliance with regulations such as the European End-of-Life Vehicles Directive.

Noise regulations represent another environmental consideration, as some cooling solutions—particularly high-performance fans—can contribute significantly to a vehicle's noise profile. Validation criteria must therefore include acoustic testing to ensure compliance with market-specific noise regulations, which are becoming increasingly stringent in urban environments.

Durability and Reliability Testing Standards

The durability and reliability testing standards for S58 engine heat dissipation validation must adhere to rigorous protocols that ensure consistent performance under extreme conditions. These standards typically encompass thermal cycling tests, where the engine undergoes repeated heating and cooling cycles to simulate years of operation within accelerated timeframes. For the S58 engine specifically, testing protocols should include a minimum of 500 thermal cycles between -40°C and 150°C, with particular attention to the behavior of cooling system components during rapid temperature transitions.

Long-duration heat soak tests represent another critical standard, requiring the engine to maintain operational stability at maximum temperature for extended periods—typically 24 to 48 hours continuously. During these tests, all heat dissipation systems must demonstrate consistent performance with less than 5% degradation in cooling efficiency throughout the test duration.

Vibration resistance testing constitutes an essential reliability standard, as engine heat dissipation components must withstand the mechanical stresses of normal operation. Testing protocols should subject cooling system components to vibration profiles matching the S58 engine's operational characteristics, with frequencies ranging from 10Hz to 2000Hz at varying amplitudes for a minimum of 100 hours of cumulative testing.

Corrosion resistance standards are particularly relevant for heat dissipation systems exposed to various coolants and environmental conditions. Components must withstand 1000 hours of salt spray testing according to ASTM B117 standards, with no more than 5% surface degradation or performance loss. Additionally, coolant compatibility testing must verify material stability with all approved coolants under maximum operating temperatures for at least 3000 hours.

Pressure cycling tests verify the integrity of the cooling system under fluctuating pressure conditions. Standards typically require components to withstand 100,000 pressure cycles from atmospheric pressure to 2.5 times the maximum operating pressure without developing leaks or structural weaknesses. Failure rate must remain below 0.1% across all tested samples.

Statistical validation methods must be employed across all testing protocols, with a minimum sample size determined by statistical power analysis (typically n≥30) to ensure 95% confidence intervals. All components must demonstrate a Mean Time Between Failure (MTBF) exceeding 10,000 operating hours, with comprehensive Weibull analysis to characterize failure modes and establish reliability predictions for production units.

Long-duration heat soak tests represent another critical standard, requiring the engine to maintain operational stability at maximum temperature for extended periods—typically 24 to 48 hours continuously. During these tests, all heat dissipation systems must demonstrate consistent performance with less than 5% degradation in cooling efficiency throughout the test duration.

Vibration resistance testing constitutes an essential reliability standard, as engine heat dissipation components must withstand the mechanical stresses of normal operation. Testing protocols should subject cooling system components to vibration profiles matching the S58 engine's operational characteristics, with frequencies ranging from 10Hz to 2000Hz at varying amplitudes for a minimum of 100 hours of cumulative testing.

Corrosion resistance standards are particularly relevant for heat dissipation systems exposed to various coolants and environmental conditions. Components must withstand 1000 hours of salt spray testing according to ASTM B117 standards, with no more than 5% surface degradation or performance loss. Additionally, coolant compatibility testing must verify material stability with all approved coolants under maximum operating temperatures for at least 3000 hours.

Pressure cycling tests verify the integrity of the cooling system under fluctuating pressure conditions. Standards typically require components to withstand 100,000 pressure cycles from atmospheric pressure to 2.5 times the maximum operating pressure without developing leaks or structural weaknesses. Failure rate must remain below 0.1% across all tested samples.

Statistical validation methods must be employed across all testing protocols, with a minimum sample size determined by statistical power analysis (typically n≥30) to ensure 95% confidence intervals. All components must demonstrate a Mean Time Between Failure (MTBF) exceeding 10,000 operating hours, with comprehensive Weibull analysis to characterize failure modes and establish reliability predictions for production units.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!