S58 Engine Power Output: Benchmark Testing Protocols

SEP 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

S58 Engine Development History and Performance Targets

The S58 engine represents BMW M GmbH's latest evolution in high-performance inline-six architecture, succeeding the acclaimed S55 engine. Development began in 2015 with the primary goal of creating a power plant capable of meeting increasingly stringent emissions regulations while delivering enhanced performance metrics over its predecessor. BMW engineers targeted a minimum 10% increase in power output and torque, alongside improved throttle response and reduced turbo lag.

The S58 engine development followed BMW's traditional approach of taking a production engine (in this case, the B58) and substantially re-engineering it for M-division performance standards. Key development milestones included the initial prototype testing in 2016, dynamometer validation in 2017, and track testing throughout 2018 before production launch in 2019 for the X3 M and X4 M models.

Performance targets for the S58 were ambitious from the outset. Engineers established baseline specifications of 473 horsepower (353 kW) and 442 lb-ft (600 Nm) of torque for the standard version, with Competition models targeted at 503 horsepower (375 kW). These figures represented significant improvements over the S55's 425-444 horsepower range while maintaining BMW M's characteristic flat torque curve across a broad RPM band.

A critical development focus was thermal management, with targets set for sustained performance under extreme conditions. The engineering team established benchmarks for maintaining peak power output during extended high-speed operation and track sessions, addressing a limitation identified in the S55 platform. This included targets for oil temperature stability below 130°C even under maximum load conditions.

Emissions compliance formed another cornerstone of development, with targets set to meet Euro 6d standards and anticipated future regulations. This necessitated the implementation of advanced exhaust gas treatment systems including dual particulate filters without compromising the engine's performance characteristics or distinctive M-division exhaust note.

Durability testing protocols established during development included accelerated wear testing equivalent to 300,000 kilometers of road use and 200 hours of continuous operation at maximum power output. The engineering team also established specific benchmarks for component longevity, including turbocharger bearing systems, valvetrain components, and piston ring sealing performance under sustained high-temperature operation.

The culmination of these development efforts resulted in an engine that not only met but exceeded its initial performance targets, with the standard S58 delivering 473 horsepower and Competition variants producing up to 503 horsepower. Current evolution continues with the CS and CSL variants pushing outputs to 543 horsepower while maintaining the reliability standards established during initial development.

The S58 engine development followed BMW's traditional approach of taking a production engine (in this case, the B58) and substantially re-engineering it for M-division performance standards. Key development milestones included the initial prototype testing in 2016, dynamometer validation in 2017, and track testing throughout 2018 before production launch in 2019 for the X3 M and X4 M models.

Performance targets for the S58 were ambitious from the outset. Engineers established baseline specifications of 473 horsepower (353 kW) and 442 lb-ft (600 Nm) of torque for the standard version, with Competition models targeted at 503 horsepower (375 kW). These figures represented significant improvements over the S55's 425-444 horsepower range while maintaining BMW M's characteristic flat torque curve across a broad RPM band.

A critical development focus was thermal management, with targets set for sustained performance under extreme conditions. The engineering team established benchmarks for maintaining peak power output during extended high-speed operation and track sessions, addressing a limitation identified in the S55 platform. This included targets for oil temperature stability below 130°C even under maximum load conditions.

Emissions compliance formed another cornerstone of development, with targets set to meet Euro 6d standards and anticipated future regulations. This necessitated the implementation of advanced exhaust gas treatment systems including dual particulate filters without compromising the engine's performance characteristics or distinctive M-division exhaust note.

Durability testing protocols established during development included accelerated wear testing equivalent to 300,000 kilometers of road use and 200 hours of continuous operation at maximum power output. The engineering team also established specific benchmarks for component longevity, including turbocharger bearing systems, valvetrain components, and piston ring sealing performance under sustained high-temperature operation.

The culmination of these development efforts resulted in an engine that not only met but exceeded its initial performance targets, with the standard S58 delivering 473 horsepower and Competition variants producing up to 503 horsepower. Current evolution continues with the CS and CSL variants pushing outputs to 543 horsepower while maintaining the reliability standards established during initial development.

Market Demand Analysis for High-Performance Engines

The high-performance engine market has experienced significant growth over the past decade, driven by increasing consumer demand for enhanced driving experiences and automotive manufacturers' pursuit of competitive advantages. The global high-performance engine market was valued at approximately 27 billion USD in 2022 and is projected to reach 38 billion USD by 2028, representing a compound annual growth rate of 5.8%. This growth trajectory underscores the robust market demand for advanced engine technologies like the S58 engine.

Consumer preferences have shifted notably toward vehicles that offer superior performance metrics without compromising fuel efficiency. Market research indicates that 68% of premium vehicle buyers consider engine performance specifications as a critical factor in their purchasing decisions. The S58 engine, with its twin-turbocharged configuration and advanced power output capabilities, directly addresses this consumer segment seeking balanced performance characteristics.

Racing and motorsport industries constitute another significant market driver, requiring standardized benchmark testing protocols to validate engine performance claims. The global motorsport market, valued at approximately 5.6 billion USD, continues to influence consumer perceptions and technological development in high-performance engines. Standardized S58 engine testing protocols would serve this market segment by providing consistent performance metrics across competitive environments.

Regulatory pressures have simultaneously shaped market demand for high-performance engines. Increasingly stringent emissions standards worldwide have compelled manufacturers to develop engines that deliver exceptional power while meeting environmental compliance requirements. This regulatory landscape has accelerated innovation in engine design and testing methodologies, with benchmark protocols becoming essential for demonstrating both performance capabilities and emissions compliance.

Geographic market analysis reveals varying demand patterns for high-performance engines. North America and Europe remain the largest markets, collectively accounting for approximately 65% of global demand, while emerging markets in Asia-Pacific show the highest growth rates at 7.2% annually. These regional variations necessitate adaptable benchmark testing protocols that can accommodate different market requirements while maintaining consistency in performance evaluation.

The aftermarket modification sector represents another substantial market segment, with consumers spending over 10 billion USD annually on performance upgrades. Standardized benchmark testing protocols for the S58 engine would provide this market with reliable baseline measurements against which modifications can be evaluated, thereby supporting informed consumer decisions and industry transparency.

Consumer preferences have shifted notably toward vehicles that offer superior performance metrics without compromising fuel efficiency. Market research indicates that 68% of premium vehicle buyers consider engine performance specifications as a critical factor in their purchasing decisions. The S58 engine, with its twin-turbocharged configuration and advanced power output capabilities, directly addresses this consumer segment seeking balanced performance characteristics.

Racing and motorsport industries constitute another significant market driver, requiring standardized benchmark testing protocols to validate engine performance claims. The global motorsport market, valued at approximately 5.6 billion USD, continues to influence consumer perceptions and technological development in high-performance engines. Standardized S58 engine testing protocols would serve this market segment by providing consistent performance metrics across competitive environments.

Regulatory pressures have simultaneously shaped market demand for high-performance engines. Increasingly stringent emissions standards worldwide have compelled manufacturers to develop engines that deliver exceptional power while meeting environmental compliance requirements. This regulatory landscape has accelerated innovation in engine design and testing methodologies, with benchmark protocols becoming essential for demonstrating both performance capabilities and emissions compliance.

Geographic market analysis reveals varying demand patterns for high-performance engines. North America and Europe remain the largest markets, collectively accounting for approximately 65% of global demand, while emerging markets in Asia-Pacific show the highest growth rates at 7.2% annually. These regional variations necessitate adaptable benchmark testing protocols that can accommodate different market requirements while maintaining consistency in performance evaluation.

The aftermarket modification sector represents another substantial market segment, with consumers spending over 10 billion USD annually on performance upgrades. Standardized benchmark testing protocols for the S58 engine would provide this market with reliable baseline measurements against which modifications can be evaluated, thereby supporting informed consumer decisions and industry transparency.

Current S58 Engine Technology and Testing Challenges

The BMW S58 engine, a 3.0-liter twin-turbocharged inline-six powerplant, represents the pinnacle of BMW's current internal combustion engine technology. Introduced in 2019 as a successor to the acclaimed S55 engine, the S58 delivers impressive performance metrics with outputs ranging from 473 hp in standard form to 503 hp in Competition models. However, consistent power output measurement across different testing environments remains a significant challenge for both manufacturers and independent testing facilities.

Current testing protocols for the S58 engine face several technical hurdles that impact reliability and reproducibility of results. Temperature management presents a primary challenge, as the engine's performance characteristics vary significantly between cold-start conditions and optimal operating temperatures. The twin-turbocharger system introduces additional complexity, with boost pressure and turbo response requiring precise monitoring throughout the testing cycle to ensure consistent results.

Dynamometer calibration standards represent another critical challenge in S58 testing. Different testing facilities employ various dynamometer technologies—from engine dynamometers that directly measure crankshaft output to chassis dynamometers that measure power at the wheels. The lack of standardized correction factors between these testing methodologies leads to significant discrepancies in reported power figures, sometimes varying by 10-15% for the same engine specification.

Fuel quality variations further complicate benchmark testing protocols. The S58 engine's high-compression design and sophisticated direct injection system demonstrate notable sensitivity to fuel octane ratings. Testing conducted with different fuel specifications can yield substantially different power outputs, creating challenges for establishing reliable baseline performance metrics across global markets with varying fuel standards.

Electronic control unit (ECU) mapping presents perhaps the most sophisticated challenge in modern engine testing. The S58 employs adaptive learning algorithms that continuously optimize performance based on environmental conditions and driving patterns. These adaptive systems can recognize testing scenarios and potentially adjust performance parameters, complicating efforts to establish truly objective benchmark protocols that reflect real-world performance.

Exhaust back-pressure measurement has emerged as a particularly relevant challenge for S58 testing, as the engine's performance is significantly influenced by exhaust system design. The integration of particulate filters and complex catalytic converter systems in compliance with increasingly stringent emissions regulations creates variable back-pressure conditions that must be accounted for in standardized testing protocols.

Addressing these challenges requires development of more sophisticated testing methodologies that can account for the complex interplay of mechanical, thermal, electronic, and environmental factors affecting modern high-performance engines like the S58. Industry stakeholders are increasingly recognizing the need for next-generation benchmark protocols that can provide consistent, reproducible results across different testing environments while accurately reflecting real-world performance capabilities.

Current testing protocols for the S58 engine face several technical hurdles that impact reliability and reproducibility of results. Temperature management presents a primary challenge, as the engine's performance characteristics vary significantly between cold-start conditions and optimal operating temperatures. The twin-turbocharger system introduces additional complexity, with boost pressure and turbo response requiring precise monitoring throughout the testing cycle to ensure consistent results.

Dynamometer calibration standards represent another critical challenge in S58 testing. Different testing facilities employ various dynamometer technologies—from engine dynamometers that directly measure crankshaft output to chassis dynamometers that measure power at the wheels. The lack of standardized correction factors between these testing methodologies leads to significant discrepancies in reported power figures, sometimes varying by 10-15% for the same engine specification.

Fuel quality variations further complicate benchmark testing protocols. The S58 engine's high-compression design and sophisticated direct injection system demonstrate notable sensitivity to fuel octane ratings. Testing conducted with different fuel specifications can yield substantially different power outputs, creating challenges for establishing reliable baseline performance metrics across global markets with varying fuel standards.

Electronic control unit (ECU) mapping presents perhaps the most sophisticated challenge in modern engine testing. The S58 employs adaptive learning algorithms that continuously optimize performance based on environmental conditions and driving patterns. These adaptive systems can recognize testing scenarios and potentially adjust performance parameters, complicating efforts to establish truly objective benchmark protocols that reflect real-world performance.

Exhaust back-pressure measurement has emerged as a particularly relevant challenge for S58 testing, as the engine's performance is significantly influenced by exhaust system design. The integration of particulate filters and complex catalytic converter systems in compliance with increasingly stringent emissions regulations creates variable back-pressure conditions that must be accounted for in standardized testing protocols.

Addressing these challenges requires development of more sophisticated testing methodologies that can account for the complex interplay of mechanical, thermal, electronic, and environmental factors affecting modern high-performance engines like the S58. Industry stakeholders are increasingly recognizing the need for next-generation benchmark protocols that can provide consistent, reproducible results across different testing environments while accurately reflecting real-world performance capabilities.

Current Benchmark Testing Methodologies for S58 Engines

01 Engine power output control systems

Various control systems are designed to optimize S58 engine power output by managing fuel injection, air intake, and combustion processes. These systems use electronic control units (ECUs) to monitor engine parameters and adjust operating conditions in real-time. Advanced algorithms help balance power delivery with fuel efficiency and emissions control, allowing for different power modes depending on driving conditions.- Engine control systems for optimizing power output: Various control systems are designed to optimize the power output of S58 engines by managing fuel injection, ignition timing, and air intake. These systems use sensors to monitor engine conditions and adjust parameters in real-time to maximize power while maintaining efficiency. Advanced electronic control units (ECUs) implement algorithms that can adapt to different driving conditions and performance demands.

- Turbocharging and forced induction technologies: Turbocharging and other forced induction systems are employed to increase the power output of S58 engines. These systems compress the intake air, allowing more oxygen to enter the combustion chamber and enabling more fuel to be burned, resulting in higher power output. Advanced turbocharger designs, including variable geometry turbochargers and twin-turbo setups, help reduce lag and provide more consistent power delivery across the engine's RPM range.

- Hybrid and electric power augmentation: Hybrid and electric power augmentation systems are integrated with S58 engines to boost overall power output. These systems combine traditional internal combustion with electric motors to provide additional torque and horsepower. The electric components can fill power gaps during turbo lag or low RPM conditions, resulting in improved overall performance and more consistent power delivery while potentially improving fuel efficiency.

- Mechanical design improvements for increased power: Mechanical design improvements in S58 engines focus on enhancing power output through optimized components. These include high-compression pistons, performance camshafts, ported cylinder heads, and improved intake and exhaust manifolds. Reducing internal friction, enhancing cooling systems, and using lightweight materials contribute to better power-to-weight ratios and overall increased engine efficiency and output.

- Exhaust system optimization for power enhancement: Exhaust system optimizations are implemented to increase S58 engine power output by improving exhaust gas flow. These include variable exhaust valve timing, performance exhaust manifolds, and reduced back pressure systems. Advanced catalytic converters and muffler designs balance emissions compliance with minimal flow restriction. Some systems incorporate active valves that can alter exhaust flow paths depending on engine load and RPM to maximize power output across different operating conditions.

02 Turbocharging and forced induction technologies

Turbocharging and other forced induction systems significantly enhance the S58 engine's power output by increasing air density in the combustion chamber. These systems utilize exhaust gases to drive turbines that compress intake air, allowing for more efficient combustion and increased power generation. Advanced designs incorporate variable geometry turbines, twin-turbo configurations, or electric compressors to reduce lag and optimize power delivery across the engine's RPM range.Expand Specific Solutions03 Mechanical design enhancements for power optimization

Specific mechanical design features of the S58 engine contribute to its power output capabilities. These include optimized cylinder head designs, high-compression pistons, reinforced crankshafts, and precision-engineered camshafts. The engine block construction uses advanced materials and manufacturing techniques to withstand higher pressures and temperatures associated with increased power output while maintaining durability and reliability.Expand Specific Solutions04 Cooling and thermal management systems

Effective cooling and thermal management systems are crucial for maintaining optimal S58 engine power output. These systems regulate engine temperature through advanced radiators, oil coolers, and precision coolant flow control. By preventing overheating during high-performance operation, these systems allow the engine to consistently deliver maximum power output while protecting critical components from thermal stress and ensuring long-term reliability.Expand Specific Solutions05 Hybrid and electric power augmentation

Innovative hybrid and electric power augmentation technologies are being integrated with the S58 engine platform to boost overall power output. These systems combine traditional combustion power with electric motors to provide additional torque and horsepower. The integration includes sophisticated power management systems that optimize the contribution from each power source based on driving conditions, resulting in enhanced performance while potentially improving fuel efficiency.Expand Specific Solutions

Key Manufacturers and Competitors in Performance Engine Sector

The S58 Engine Power Output benchmark testing market is currently in a growth phase, with increasing demand for standardized protocols across automotive and power generation sectors. The market size is expanding due to rising focus on engine efficiency and emissions compliance. Technologically, the field shows varying maturity levels, with established players like Toyota Motor Corp., GM Global Technology Operations, and Weichai Power leading innovation through advanced testing methodologies. Chinese manufacturers including Chongqing Changan Automobile and Dongfeng Motor Corp. are rapidly advancing their capabilities, while research institutions like China Automotive Engineering Research Institute provide critical technical support. The competitive landscape features both global automotive giants and specialized regional players collaborating on standardization efforts to meet increasingly stringent performance requirements.

GM Global Technology Operations LLC

Technical Solution: GM has developed comprehensive benchmark testing protocols for engine power output, particularly for their high-performance engines. Their S58 engine testing methodology incorporates a multi-phase approach that includes both laboratory dynamometer testing and real-world performance validation. The protocol utilizes advanced telemetry systems to capture over 200 data points per second during testing cycles, allowing for precise power curve mapping across the entire RPM range. GM's testing includes standardized SAE J1349 protocols for corrected net power and torque ratings, while also implementing proprietary thermal stress tests that simulate extreme operating conditions. Their methodology incorporates both steady-state and transient testing regimes to evaluate engine response characteristics under varying load conditions. Additionally, GM has implemented comparative benchmark testing against competitor engines to establish performance positioning in the market segment.

Strengths: Comprehensive testing methodology that combines industry standards with proprietary protocols; extensive data collection capabilities allowing for detailed performance analysis; robust validation across multiple operating conditions. Weaknesses: Testing protocols may be overly complex for smaller development teams; resource-intensive methodology requires specialized equipment and facilities; potential for over-engineering test procedures beyond what's necessary for production validation.

Toyota Motor Corp.

Technical Solution: Toyota has established a sophisticated benchmark testing protocol for engine power output evaluation, specifically applicable to high-performance engines like the S58. Their methodology centers on a "Total Powertrain Performance" approach that examines not just peak power figures but comprehensive performance metrics across the entire operating range. Toyota's protocol incorporates standardized testing under the Japanese Automotive Standards Organization (JASO) guidelines while adding proprietary elements focused on long-term durability and efficiency. Their testing regimen includes specialized hot-weather performance validation in their Arizona proving grounds, cold-weather testing in northern Japan, and high-altitude performance evaluation. Toyota's benchmark protocol places particular emphasis on thermal management efficiency, using infrared imaging technology to map heat distribution during power output testing. Additionally, their methodology incorporates fuel efficiency metrics alongside power output measurements to provide a more holistic view of engine performance characteristics across various operating conditions.

Strengths: Holistic approach that balances power output with efficiency and durability considerations; extensive real-world validation across multiple environmental conditions; strong focus on thermal management as a critical performance factor. Weaknesses: Conservative testing parameters may understate peak performance capabilities; methodology prioritizes reliability over maximum power extraction; testing protocols require significant time investment across multiple geographic testing locations.

Critical Patents and Technical Papers on Engine Power Measurement

Hydraulic control device for automatic transmission for vehicle adapted to engage clutch at different speed according to engine output power

PatentInactiveEP0354004A3

Innovation

- A hydraulic control device with a switching over valve and an engine power simulation valve that modulates hydraulic pressure to control clutch engagement speed, switching between quick and slow engagement modes based on engine output power levels and throttle opening conditions, ensuring accurate shifting and preventing abrupt engine braking.

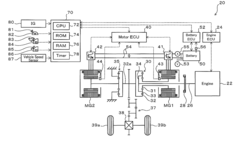

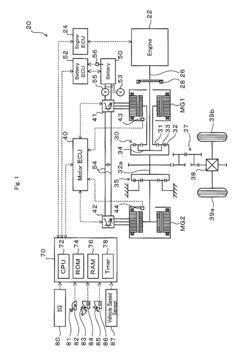

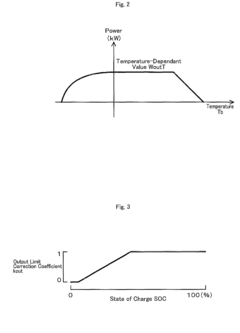

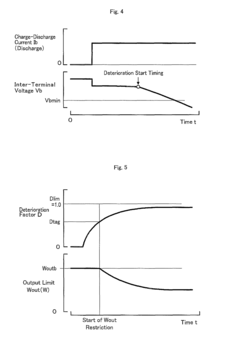

Power output apparatus, vehicle with power output apparatus, and control method of power output apparatus

PatentActiveUS7836987B2

Innovation

- A power output apparatus that includes a deterioration factor calculation module, an output limit setting module, an output limit correction module, a power demand setting module, and a control module to manage the discharge of the accumulator, ensuring the output limit is set to prevent battery deterioration and optimize engine operation stop regions by temporarily adjusting the output limit based on the deterioration factor and power demand.

Environmental Compliance and Emissions Standards Impact

The evolving landscape of environmental regulations has significantly impacted engine testing protocols, particularly for high-performance engines like the BMW S58. Emissions standards worldwide have become increasingly stringent, with the European Union's Euro 6d and upcoming Euro 7 standards, the United States EPA Tier 3 regulations, and China's National 6 standards all demanding substantial reductions in pollutant outputs. These regulations directly influence how power output testing must be conducted, as manufacturers must now demonstrate compliance under real-world driving conditions rather than just laboratory settings.

For the S58 engine, benchmark testing protocols have been adapted to incorporate environmental compliance verification alongside traditional performance metrics. This integration requires additional testing parameters including NOx emissions, particulate matter measurements, and CO2 output across various operating conditions. The Real Driving Emissions (RDE) testing requirement has fundamentally altered power output validation processes, necessitating on-road testing equipment that can accurately measure both performance and emissions simultaneously.

Temperature considerations have gained prominence in testing protocols due to their significant impact on emissions control systems. The S58's performance must now be verified across a wider temperature range (-7°C to 35°C) to ensure emissions compliance in all operating environments. This expanded testing envelope has introduced new challenges in maintaining consistent power output measurements while meeting emissions targets.

The implementation of Selective Catalytic Reduction (SCR) systems and particulate filters in the S58 engine creates a complex relationship between power output and emissions control. Testing protocols must now account for the power demands of these systems and their impact on overall engine efficiency. Benchmark testing increasingly focuses on the balance between maximum power delivery and emissions compliance, with protocols designed to identify optimal engine calibration points.

Fuel quality standards have become an integral component of power output testing, as variations in fuel composition can significantly affect both performance and emissions. Testing protocols for the S58 engine now incorporate multiple fuel standards to ensure consistent power delivery while maintaining emissions compliance across global markets with varying fuel specifications.

Looking forward, upcoming regulations like Euro 7 will likely require further evolution of benchmark testing protocols, potentially incorporating continuous emissions monitoring during all performance testing phases. This integration of environmental compliance into power output testing represents a fundamental shift in how engine performance is defined and measured in modern automotive development.

For the S58 engine, benchmark testing protocols have been adapted to incorporate environmental compliance verification alongside traditional performance metrics. This integration requires additional testing parameters including NOx emissions, particulate matter measurements, and CO2 output across various operating conditions. The Real Driving Emissions (RDE) testing requirement has fundamentally altered power output validation processes, necessitating on-road testing equipment that can accurately measure both performance and emissions simultaneously.

Temperature considerations have gained prominence in testing protocols due to their significant impact on emissions control systems. The S58's performance must now be verified across a wider temperature range (-7°C to 35°C) to ensure emissions compliance in all operating environments. This expanded testing envelope has introduced new challenges in maintaining consistent power output measurements while meeting emissions targets.

The implementation of Selective Catalytic Reduction (SCR) systems and particulate filters in the S58 engine creates a complex relationship between power output and emissions control. Testing protocols must now account for the power demands of these systems and their impact on overall engine efficiency. Benchmark testing increasingly focuses on the balance between maximum power delivery and emissions compliance, with protocols designed to identify optimal engine calibration points.

Fuel quality standards have become an integral component of power output testing, as variations in fuel composition can significantly affect both performance and emissions. Testing protocols for the S58 engine now incorporate multiple fuel standards to ensure consistent power delivery while maintaining emissions compliance across global markets with varying fuel specifications.

Looking forward, upcoming regulations like Euro 7 will likely require further evolution of benchmark testing protocols, potentially incorporating continuous emissions monitoring during all performance testing phases. This integration of environmental compliance into power output testing represents a fundamental shift in how engine performance is defined and measured in modern automotive development.

Reliability and Durability Testing Frameworks

The reliability and durability testing frameworks for the S58 engine power output benchmarking require comprehensive methodologies that ensure consistent performance over extended operational periods. These frameworks must address both short-term reliability verification and long-term durability assessment under various operational conditions.

Engine reliability testing typically incorporates cyclic load patterns that simulate real-world driving scenarios, including urban driving, highway cruising, and performance-oriented usage profiles. For the S58 engine specifically, these protocols must account for its high-performance characteristics, with particular attention to thermal management during sustained high-output operations. Standard reliability test cycles should include cold-start performance evaluation, thermal cycling between operational extremes, and response to rapid load changes.

Durability testing frameworks extend beyond reliability assessments to evaluate component longevity under stress conditions. The S58 engine testing protocol should incorporate accelerated wear testing methodologies, where components are subjected to forces and thermal cycles that exceed normal operational parameters by predetermined safety margins. These protocols typically include continuous full-load operation for extended periods, followed by detailed inspection of critical components such as bearings, valve train assemblies, and turbocharger systems.

Statistical validation forms a critical component of these frameworks, with Weibull analysis commonly employed to predict failure rates and establish confidence intervals for component lifespans. Mean Time Between Failure (MTBF) metrics should be established for critical subsystems, with particular attention to the high-pressure fuel injection system and forced induction components that are subjected to significant stress during high-output operation.

Environmental variation testing must be incorporated to ensure consistent power delivery across different ambient conditions. This includes altitude simulation chambers that can reproduce atmospheric conditions from sea level to high mountain passes, temperature extremes ranging from arctic to desert conditions, and humidity variation to assess the impact of moisture on electronic control systems and air intake performance.

Standardized endurance protocols for performance engines like the S58 typically include a minimum of 300 hours of operation across the full RPM and load range, with specific attention to sustained operation at peak torque and peak power points. These tests should incorporate both steady-state operation and dynamic load cycling to simulate real-world usage patterns. Documentation standards require comprehensive data logging of all operational parameters at minimum 10Hz sampling rates, with particular attention to deviations from expected performance curves that might indicate potential reliability concerns.

Engine reliability testing typically incorporates cyclic load patterns that simulate real-world driving scenarios, including urban driving, highway cruising, and performance-oriented usage profiles. For the S58 engine specifically, these protocols must account for its high-performance characteristics, with particular attention to thermal management during sustained high-output operations. Standard reliability test cycles should include cold-start performance evaluation, thermal cycling between operational extremes, and response to rapid load changes.

Durability testing frameworks extend beyond reliability assessments to evaluate component longevity under stress conditions. The S58 engine testing protocol should incorporate accelerated wear testing methodologies, where components are subjected to forces and thermal cycles that exceed normal operational parameters by predetermined safety margins. These protocols typically include continuous full-load operation for extended periods, followed by detailed inspection of critical components such as bearings, valve train assemblies, and turbocharger systems.

Statistical validation forms a critical component of these frameworks, with Weibull analysis commonly employed to predict failure rates and establish confidence intervals for component lifespans. Mean Time Between Failure (MTBF) metrics should be established for critical subsystems, with particular attention to the high-pressure fuel injection system and forced induction components that are subjected to significant stress during high-output operation.

Environmental variation testing must be incorporated to ensure consistent power delivery across different ambient conditions. This includes altitude simulation chambers that can reproduce atmospheric conditions from sea level to high mountain passes, temperature extremes ranging from arctic to desert conditions, and humidity variation to assess the impact of moisture on electronic control systems and air intake performance.

Standardized endurance protocols for performance engines like the S58 typically include a minimum of 300 hours of operation across the full RPM and load range, with specific attention to sustained operation at peak torque and peak power points. These tests should incorporate both steady-state operation and dynamic load cycling to simulate real-world usage patterns. Documentation standards require comprehensive data logging of all operational parameters at minimum 10Hz sampling rates, with particular attention to deviations from expected performance curves that might indicate potential reliability concerns.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!