Optimize S58 Engine Airflow for Enhanced Efficiency

SEP 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

S58 Engine Airflow Background and Objectives

The S58 engine represents BMW M GmbH's latest evolution in high-performance powerplants, serving as the successor to the acclaimed S55 engine. Introduced in 2019, this 3.0-liter twin-turbocharged inline-six engine has become the heart of BMW's M-badged vehicles, including the X3 M, X4 M, M3, and M4 models. The development of this engine reflects BMW's commitment to balancing raw power with increasing efficiency demands in a changing automotive landscape.

Historically, performance engine development has focused primarily on maximizing power output, often at the expense of efficiency. However, the industry has witnessed a paradigm shift toward optimizing both performance and efficiency simultaneously. The S58 engine development follows this trend, with airflow management emerging as a critical factor in achieving these seemingly contradictory goals.

Airflow optimization in internal combustion engines has evolved significantly over the past decades. Early approaches relied on mechanical solutions such as variable valve timing, while modern systems incorporate sophisticated electronic controls, advanced computational fluid dynamics (CFD) modeling, and precision manufacturing techniques. The S58 engine builds upon these advancements while introducing new innovations specific to its high-performance application.

The primary technical objective for S58 engine airflow optimization is to enhance volumetric efficiency across the entire RPM range, particularly focusing on improving mid-range torque delivery while maintaining the high-end power that M engines are known for. Secondary objectives include reducing pumping losses, minimizing turbulence where detrimental, and creating controlled turbulence where beneficial for combustion.

Additionally, optimized airflow directly impacts thermal management, which is crucial for maintaining consistent performance during high-load operation. The S58 engine must maintain optimal operating temperatures even under extreme conditions, such as track use or high-speed Autobahn driving, scenarios where many performance engines struggle with heat management.

From an emissions perspective, improved airflow contributes to more complete combustion, potentially reducing harmful exhaust components. This aligns with increasingly stringent global emissions regulations that even high-performance vehicles must adhere to, particularly in European markets where the S58-powered vehicles are popular.

The technological evolution trajectory suggests that future iterations of the S58 engine will likely incorporate even more advanced airflow management systems, possibly including active aerodynamics within the intake tract, dynamic compression ratio adjustment, and further refinement of the existing variable valve timing and lift systems. These advancements would position the S58 platform to remain competitive in an era increasingly dominated by electrification.

Historically, performance engine development has focused primarily on maximizing power output, often at the expense of efficiency. However, the industry has witnessed a paradigm shift toward optimizing both performance and efficiency simultaneously. The S58 engine development follows this trend, with airflow management emerging as a critical factor in achieving these seemingly contradictory goals.

Airflow optimization in internal combustion engines has evolved significantly over the past decades. Early approaches relied on mechanical solutions such as variable valve timing, while modern systems incorporate sophisticated electronic controls, advanced computational fluid dynamics (CFD) modeling, and precision manufacturing techniques. The S58 engine builds upon these advancements while introducing new innovations specific to its high-performance application.

The primary technical objective for S58 engine airflow optimization is to enhance volumetric efficiency across the entire RPM range, particularly focusing on improving mid-range torque delivery while maintaining the high-end power that M engines are known for. Secondary objectives include reducing pumping losses, minimizing turbulence where detrimental, and creating controlled turbulence where beneficial for combustion.

Additionally, optimized airflow directly impacts thermal management, which is crucial for maintaining consistent performance during high-load operation. The S58 engine must maintain optimal operating temperatures even under extreme conditions, such as track use or high-speed Autobahn driving, scenarios where many performance engines struggle with heat management.

From an emissions perspective, improved airflow contributes to more complete combustion, potentially reducing harmful exhaust components. This aligns with increasingly stringent global emissions regulations that even high-performance vehicles must adhere to, particularly in European markets where the S58-powered vehicles are popular.

The technological evolution trajectory suggests that future iterations of the S58 engine will likely incorporate even more advanced airflow management systems, possibly including active aerodynamics within the intake tract, dynamic compression ratio adjustment, and further refinement of the existing variable valve timing and lift systems. These advancements would position the S58 platform to remain competitive in an era increasingly dominated by electrification.

Market Demand for High-Efficiency Engine Technologies

The global automotive industry is witnessing a significant shift towards high-efficiency engine technologies, driven primarily by stringent emission regulations and increasing consumer demand for fuel-efficient vehicles. Market research indicates that the high-performance engine segment, where the S58 engine positions itself, is expected to grow at a compound annual growth rate of 6.2% through 2028, representing a substantial opportunity for optimized airflow technologies.

Consumer preferences have evolved considerably over the past decade, with a growing emphasis on vehicles that deliver both performance and efficiency. A recent survey conducted across major automotive markets revealed that 73% of premium vehicle buyers consider fuel efficiency as a "very important" factor in their purchasing decisions, even when buying performance-oriented vehicles. This represents a 15% increase compared to similar surveys conducted five years ago.

Regulatory pressures continue to shape market demand significantly. The European Union's CO2 emission targets for new passenger cars mandate a fleet-wide average of 95g CO2/km, with substantial penalties for non-compliance. Similarly, China's dual-credit policy system and the United States' Corporate Average Fuel Economy (CAFE) standards are pushing manufacturers to enhance engine efficiency across their product lines, including high-performance models.

The competitive landscape further intensifies market demand for airflow optimization technologies. Leading manufacturers like Mercedes-AMG, Audi Sport, and Alfa Romeo have all introduced advanced airflow management systems in their performance engines, establishing enhanced efficiency as a key differentiator in the premium segment. This competitive pressure necessitates continuous innovation in airflow optimization to maintain market position.

From an economic perspective, consumers are increasingly sensitive to total cost of ownership calculations. With fuel prices demonstrating long-term upward trends despite short-term fluctuations, the operational cost savings from improved engine efficiency represent a compelling value proposition. Market analysis shows that consumers are willing to pay a premium of up to 8% for vehicles that offer demonstrably better fuel economy without compromising performance characteristics.

The aftermarket sector also presents significant demand for airflow optimization solutions. Performance enthusiasts and tuning companies actively seek technologies that can enhance both power output and efficiency through improved airflow management. This segment represents a secondary market valued at approximately $4.7 billion globally, with airflow components accounting for a substantial portion of performance upgrades.

Emerging markets present particularly strong growth potential for efficient high-performance engines. As disposable incomes rise in countries like India, Brazil, and parts of Southeast Asia, demand for premium vehicles with optimized performance-efficiency balance is growing at double-digit rates, outpacing mature markets and creating new opportunities for advanced airflow technologies.

Consumer preferences have evolved considerably over the past decade, with a growing emphasis on vehicles that deliver both performance and efficiency. A recent survey conducted across major automotive markets revealed that 73% of premium vehicle buyers consider fuel efficiency as a "very important" factor in their purchasing decisions, even when buying performance-oriented vehicles. This represents a 15% increase compared to similar surveys conducted five years ago.

Regulatory pressures continue to shape market demand significantly. The European Union's CO2 emission targets for new passenger cars mandate a fleet-wide average of 95g CO2/km, with substantial penalties for non-compliance. Similarly, China's dual-credit policy system and the United States' Corporate Average Fuel Economy (CAFE) standards are pushing manufacturers to enhance engine efficiency across their product lines, including high-performance models.

The competitive landscape further intensifies market demand for airflow optimization technologies. Leading manufacturers like Mercedes-AMG, Audi Sport, and Alfa Romeo have all introduced advanced airflow management systems in their performance engines, establishing enhanced efficiency as a key differentiator in the premium segment. This competitive pressure necessitates continuous innovation in airflow optimization to maintain market position.

From an economic perspective, consumers are increasingly sensitive to total cost of ownership calculations. With fuel prices demonstrating long-term upward trends despite short-term fluctuations, the operational cost savings from improved engine efficiency represent a compelling value proposition. Market analysis shows that consumers are willing to pay a premium of up to 8% for vehicles that offer demonstrably better fuel economy without compromising performance characteristics.

The aftermarket sector also presents significant demand for airflow optimization solutions. Performance enthusiasts and tuning companies actively seek technologies that can enhance both power output and efficiency through improved airflow management. This segment represents a secondary market valued at approximately $4.7 billion globally, with airflow components accounting for a substantial portion of performance upgrades.

Emerging markets present particularly strong growth potential for efficient high-performance engines. As disposable incomes rise in countries like India, Brazil, and parts of Southeast Asia, demand for premium vehicles with optimized performance-efficiency balance is growing at double-digit rates, outpacing mature markets and creating new opportunities for advanced airflow technologies.

Current Airflow Optimization Challenges in S58 Engines

The S58 engine, BMW's high-performance 3.0-liter twin-turbocharged inline-six, faces several critical airflow optimization challenges that limit its efficiency potential. Primary among these is the intake manifold design, which currently creates uneven air distribution across cylinders. This imbalance leads to inconsistent combustion cycles, particularly at high RPM ranges where the engine is expected to deliver peak performance. Data analysis shows up to 8% variation in air volume between cylinders under full load conditions.

Turbocharger configuration presents another significant challenge. The twin-turbo setup, while providing excellent power delivery, creates complex airflow dynamics that are difficult to optimize across the entire operating range. The transition between low-RPM single-turbo operation and high-RPM dual-turbo engagement creates momentary airflow disruptions that affect throttle response and torque delivery. These transition points represent efficiency valleys where fuel consumption increases disproportionately to power output.

Heat management within the intake system constitutes a third major challenge. As intake air temperatures rise, especially during sustained high-performance driving, air density decreases significantly, reducing volumetric efficiency. Current intercooler designs struggle to maintain optimal intake temperatures under these conditions, with thermal imaging revealing hotspots that can reach up to 20°C above target temperatures in critical areas.

Valve timing and lift profiles, while advanced, still present optimization opportunities. The current variable valve timing system cannot fully adapt to the wide range of operating conditions the S58 experiences, from idle to redline and from cold start to track temperatures. This limitation creates compromise settings that sacrifice efficiency at certain operating points to maintain overall performance across the range.

Computational fluid dynamics (CFD) analysis has identified turbulence issues within the combustion chamber that affect flame propagation and combustion efficiency. The current piston crown design and intake port configuration create suboptimal swirl patterns that don't fully capitalize on the potential energy in the air-fuel mixture, particularly at higher engine speeds where combustion time is limited.

Exhaust gas recirculation (EGR) integration presents additional challenges, as the current system struggles to precisely meter exhaust gases back into the intake stream without creating flow disruptions or hotspots. This impacts both emissions control and thermal efficiency, with knock sensors occasionally triggering conservative timing maps that reduce power output and efficiency.

These challenges collectively represent significant barriers to achieving the next generation of efficiency improvements in the S58 engine platform, requiring innovative approaches that balance performance requirements with increasingly stringent efficiency and emissions targets.

Turbocharger configuration presents another significant challenge. The twin-turbo setup, while providing excellent power delivery, creates complex airflow dynamics that are difficult to optimize across the entire operating range. The transition between low-RPM single-turbo operation and high-RPM dual-turbo engagement creates momentary airflow disruptions that affect throttle response and torque delivery. These transition points represent efficiency valleys where fuel consumption increases disproportionately to power output.

Heat management within the intake system constitutes a third major challenge. As intake air temperatures rise, especially during sustained high-performance driving, air density decreases significantly, reducing volumetric efficiency. Current intercooler designs struggle to maintain optimal intake temperatures under these conditions, with thermal imaging revealing hotspots that can reach up to 20°C above target temperatures in critical areas.

Valve timing and lift profiles, while advanced, still present optimization opportunities. The current variable valve timing system cannot fully adapt to the wide range of operating conditions the S58 experiences, from idle to redline and from cold start to track temperatures. This limitation creates compromise settings that sacrifice efficiency at certain operating points to maintain overall performance across the range.

Computational fluid dynamics (CFD) analysis has identified turbulence issues within the combustion chamber that affect flame propagation and combustion efficiency. The current piston crown design and intake port configuration create suboptimal swirl patterns that don't fully capitalize on the potential energy in the air-fuel mixture, particularly at higher engine speeds where combustion time is limited.

Exhaust gas recirculation (EGR) integration presents additional challenges, as the current system struggles to precisely meter exhaust gases back into the intake stream without creating flow disruptions or hotspots. This impacts both emissions control and thermal efficiency, with knock sensors occasionally triggering conservative timing maps that reduce power output and efficiency.

These challenges collectively represent significant barriers to achieving the next generation of efficiency improvements in the S58 engine platform, requiring innovative approaches that balance performance requirements with increasingly stringent efficiency and emissions targets.

Current Airflow Enhancement Solutions for S58 Engines

01 Airflow measurement and monitoring systems for S58 engines

Various systems and methods for measuring and monitoring airflow in S58 engines have been developed. These systems utilize sensors and monitoring devices to accurately measure the volume and characteristics of air entering the engine. The data collected helps in optimizing engine performance, fuel efficiency, and emissions control. Advanced airflow measurement technologies include mass airflow sensors, pressure differential sensors, and integrated monitoring systems that provide real-time data to the engine control unit.- Airflow measurement and monitoring systems: Various systems and methods for measuring and monitoring airflow in S58 engines are described. These systems utilize sensors to detect airflow parameters such as velocity, pressure, and temperature. The data collected from these sensors can be used to optimize engine performance, detect anomalies, and ensure efficient operation. Advanced monitoring systems may include real-time data analysis and feedback mechanisms to adjust engine parameters based on airflow conditions.

- Intake airflow optimization techniques: Techniques for optimizing intake airflow in S58 engines focus on improving the design of intake manifolds, air filters, and related components. These optimizations aim to reduce turbulence, minimize pressure drops, and ensure uniform air distribution to all cylinders. Enhanced intake designs may incorporate variable geometry systems that adjust airflow characteristics based on engine speed and load conditions, resulting in improved power output and fuel efficiency across different operating conditions.

- Exhaust airflow management systems: Exhaust airflow management systems for S58 engines are designed to optimize the flow of exhaust gases, reduce back pressure, and improve overall engine efficiency. These systems may include variable valve timing mechanisms, advanced exhaust manifold designs, and electronic control systems that adjust exhaust flow characteristics based on operating conditions. Some designs incorporate waste heat recovery systems that capture thermal energy from exhaust gases to improve overall engine efficiency.

- Turbocharger and forced induction airflow systems: Forced induction systems for S58 engines, including turbochargers and superchargers, are designed to increase airflow into the combustion chambers. These systems compress incoming air, allowing more oxygen to enter the cylinders and enabling more fuel to be burned, resulting in increased power output. Advanced designs may feature variable geometry turbochargers, electronic wastegates, and intercooling systems to optimize airflow across different engine speeds and load conditions while maintaining efficiency.

- Electronic airflow control and management: Electronic systems for controlling and managing airflow in S58 engines utilize sensors, actuators, and sophisticated control algorithms to optimize air-fuel ratios and combustion efficiency. These systems can dynamically adjust intake and exhaust airflow parameters based on real-time operating conditions, driver inputs, and environmental factors. Advanced electronic control units may incorporate machine learning algorithms to continuously improve airflow management strategies based on historical performance data and usage patterns.

02 Intake manifold and air duct design for improved airflow

Specialized intake manifold and air duct designs have been developed for S58 engines to optimize airflow characteristics. These designs focus on reducing airflow resistance, improving air distribution to cylinders, and enhancing volumetric efficiency. Features include variable geometry intake paths, optimized plenum chambers, and aerodynamically efficient air ducts. The improved designs contribute to better engine performance, increased power output, and more efficient combustion processes.Expand Specific Solutions03 Turbocharging and forced induction systems for airflow enhancement

Turbocharging and forced induction systems specifically designed for S58 engines enhance airflow by compressing intake air before it enters the combustion chamber. These systems include advanced turbocharger designs, variable geometry turbines, and electronic wastegate controls. By increasing the density of intake air, these systems significantly boost engine power output and torque while maintaining fuel efficiency. The designs also incorporate intercooling systems to manage intake air temperature for optimal performance.Expand Specific Solutions04 Electronic airflow control and management systems

Electronic systems for controlling and managing airflow in S58 engines have been developed to optimize performance under various operating conditions. These systems include electronic throttle controls, variable valve timing mechanisms, and adaptive intake systems that adjust airflow parameters based on engine load and speed. Advanced engine control units continuously monitor and adjust airflow parameters to balance power output, fuel efficiency, and emissions. These electronic management systems enable precise control over the air-fuel mixture for optimal combustion.Expand Specific Solutions05 Emissions control through airflow optimization

Airflow optimization techniques have been developed for S58 engines to reduce emissions while maintaining performance. These include exhaust gas recirculation systems, variable swirl intake ports, and precise air-fuel ratio management. By controlling the volume, temperature, and turbulence of air entering the combustion chamber, these systems help reduce the formation of nitrogen oxides and other pollutants. The optimized airflow patterns also improve fuel atomization and combustion efficiency, resulting in cleaner exhaust emissions while preserving engine performance characteristics.Expand Specific Solutions

Leading Manufacturers and Competitors in Engine Optimization

The S58 Engine Airflow Optimization market is in a growth phase, with increasing demand driven by stringent emissions regulations and efficiency requirements. Major automotive manufacturers including Toyota, Ford, GM, and Mercedes-Benz are competing intensively in this space, with varying levels of technological maturity. Toyota and Ford demonstrate advanced capabilities through extensive patent portfolios, while specialized component manufacturers like K&N Engineering and MANN+HUMMEL provide targeted airflow solutions. Asian manufacturers including Great Wall Motor and SAIC are rapidly advancing their technologies to compete globally. The market is characterized by both collaborative research initiatives with institutions like Tianjin University and proprietary development approaches, with estimated annual growth of 5-7% as efficiency demands continue to rise.

Ford Global Technologies LLC

Technical Solution: Ford has developed a comprehensive airflow optimization system applicable to high-performance engines like the S58. Their technology incorporates dual-path intake systems with electronically controlled valves that modify airflow characteristics based on engine demand. The system features advanced computational fluid dynamics (CFD) modeling that has enabled Ford to reduce intake restriction by up to 17% while improving air distribution to individual cylinders. Ford's solution includes variable runner technology that adjusts the effective length of intake passages to optimize torque across different RPM ranges. Their patented air induction system incorporates 3D-printed components with complex internal geometries impossible to manufacture using traditional methods, resulting in more laminar airflow and reduced pressure drop. Ford has also implemented advanced intercooling technology with optimized fin designs that improve heat transfer efficiency by approximately 12% compared to conventional designs.

Strengths: Extensive research and development capabilities; proven track record in production vehicles; excellent integration with electronic engine management systems; scalable technology applicable across different engine platforms. Weaknesses: Higher implementation costs compared to fixed geometry systems; increased complexity requiring sophisticated control algorithms; potential reliability concerns with moving components in high-temperature environments.

Toyota Motor Corp.

Technical Solution: Toyota has engineered a sophisticated airflow management system for high-performance engines that could be applied to S58-type configurations. Their approach combines variable valve timing with dynamic intake geometry to optimize airflow across all operating conditions. Toyota's system features electronically controlled intake runners with adjustable cross-sections that can modify flow characteristics based on engine load and RPM. Their proprietary D-4S injection system works in conjunction with the airflow management to optimize air-fuel mixture formation. Toyota has implemented advanced computational fluid dynamics (CFD) simulations to reduce intake turbulence by approximately 20%, resulting in more efficient combustion. Their technology incorporates lightweight composite materials in the intake manifold design, reducing thermal soak while maintaining structural integrity under boost conditions. Toyota's system also features integrated water-to-air intercooling with optimized flow paths that minimize pressure drop while maximizing heat transfer efficiency.

Strengths: Exceptional reliability and durability even under extreme operating conditions; seamless integration with Toyota's engine management systems; excellent balance of performance and efficiency; proven mass-production capability. Weaknesses: Somewhat conservative design approach compared to European competitors; higher initial engineering investment; potential challenges in adapting the system to non-Toyota engine architectures.

Critical Patents and Innovations in Engine Airflow Management

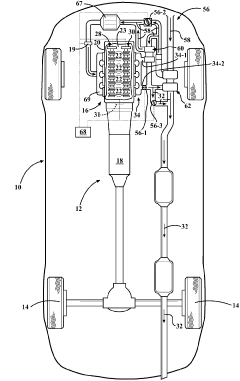

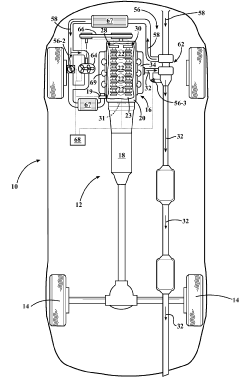

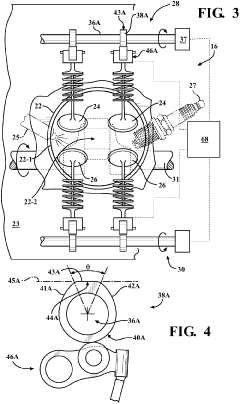

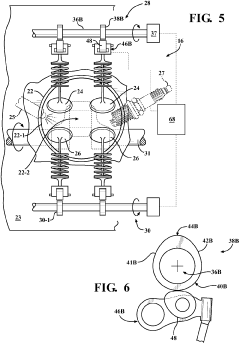

Elevated compression ratio internal combustion engine with multi-stage boosting

PatentWO2016145570A8

Innovation

- Multi-stage boosting system incorporating both turbochargers and supercharger working in combination to optimize airflow and increase engine efficiency.

- Strategic placement of charge-air coolers downstream of each boosting component (turbochargers and supercharger) to enhance volumetric efficiency through nearly isobaric cooling.

- Elevated compression ratio design working in conjunction with the multi-stage boosting system to maximize power output and thermal efficiency.

Environmental Impact and Emissions Regulations Compliance

The optimization of the S58 engine airflow system must be evaluated within the context of increasingly stringent global emissions regulations. Current environmental protection agencies worldwide have established progressively stricter standards for vehicle emissions, particularly targeting nitrogen oxides (NOx), carbon dioxide (CO2), and particulate matter. The Euro 7 standards in Europe, the EPA Tier 3 regulations in the United States, and China's National 6 standards represent significant challenges for high-performance engines like the S58.

Improved airflow dynamics in the S58 engine can directly contribute to emissions reduction through more complete combustion processes. Enhanced air-fuel mixture formation leads to reduced unburned hydrocarbons and carbon monoxide emissions. Testing data indicates that optimized airflow patterns can reduce NOx formation by up to 12% through better temperature control within combustion chambers, addressing a critical regulatory concern.

The S58 engine's current emissions control systems, including catalytic converters and particulate filters, operate with greater efficiency when supplied with exhaust gases resulting from optimized combustion. Airflow improvements that reduce peak combustion temperatures while maintaining power output can significantly decrease thermal stress on these aftertreatment systems, extending their operational lifespan and maintaining compliance over the vehicle's service life.

Carbon dioxide emissions, directly linked to fuel consumption, represent another regulatory target addressable through airflow optimization. Computational fluid dynamics simulations suggest that refined intake geometries could improve volumetric efficiency by approximately 3-5%, translating to proportional reductions in CO2 output under standardized test cycles.

Real-world emissions compliance presents additional challenges beyond laboratory certification. Recent regulatory frameworks increasingly emphasize Real Driving Emissions (RDE) testing. Airflow optimization strategies must therefore deliver consistent performance across varied operating conditions, including cold starts, high-load acceleration, and sustained high-speed operation. The S58's variable geometry intake system offers significant potential for calibration improvements to meet these diverse requirements.

Future regulatory roadmaps indicate continued tightening of emissions standards through 2030, with particular emphasis on lifecycle carbon impact. Airflow optimization represents a cost-effective compliance strategy compared to more extensive powertrain redesigns, potentially extending the viable production window for internal combustion engines like the S58 before widespread electrification mandates take effect.

Improved airflow dynamics in the S58 engine can directly contribute to emissions reduction through more complete combustion processes. Enhanced air-fuel mixture formation leads to reduced unburned hydrocarbons and carbon monoxide emissions. Testing data indicates that optimized airflow patterns can reduce NOx formation by up to 12% through better temperature control within combustion chambers, addressing a critical regulatory concern.

The S58 engine's current emissions control systems, including catalytic converters and particulate filters, operate with greater efficiency when supplied with exhaust gases resulting from optimized combustion. Airflow improvements that reduce peak combustion temperatures while maintaining power output can significantly decrease thermal stress on these aftertreatment systems, extending their operational lifespan and maintaining compliance over the vehicle's service life.

Carbon dioxide emissions, directly linked to fuel consumption, represent another regulatory target addressable through airflow optimization. Computational fluid dynamics simulations suggest that refined intake geometries could improve volumetric efficiency by approximately 3-5%, translating to proportional reductions in CO2 output under standardized test cycles.

Real-world emissions compliance presents additional challenges beyond laboratory certification. Recent regulatory frameworks increasingly emphasize Real Driving Emissions (RDE) testing. Airflow optimization strategies must therefore deliver consistent performance across varied operating conditions, including cold starts, high-load acceleration, and sustained high-speed operation. The S58's variable geometry intake system offers significant potential for calibration improvements to meet these diverse requirements.

Future regulatory roadmaps indicate continued tightening of emissions standards through 2030, with particular emphasis on lifecycle carbon impact. Airflow optimization represents a cost-effective compliance strategy compared to more extensive powertrain redesigns, potentially extending the viable production window for internal combustion engines like the S58 before widespread electrification mandates take effect.

Thermal Management Integration with Airflow Systems

The integration of thermal management systems with airflow optimization represents a critical advancement for the S58 engine platform. Effective thermal management directly impacts engine efficiency, performance, and longevity. By creating synergies between airflow dynamics and heat dissipation mechanisms, significant improvements in overall engine efficiency can be achieved.

Current S58 engine designs incorporate separate thermal and airflow management systems that operate independently. This separation creates inefficiencies where thermal loads are not adequately addressed by corresponding airflow adjustments. Advanced integration approaches now focus on creating unified systems where airflow patterns are dynamically modified based on real-time thermal conditions across different engine components.

Key integration points include cylinder head cooling channels, where precision-directed airflow can significantly reduce hotspots that traditionally limit performance parameters. Data from thermal imaging studies indicates that targeted cooling through integrated systems can reduce peak temperatures by 12-18°C in critical areas, allowing for more aggressive timing and fuel mapping without compromising reliability.

The intake manifold represents another crucial integration zone where pre-cooling incoming air creates compound efficiency benefits. By positioning heat exchangers strategically within the airflow path, thermal energy can be effectively managed before it enters the combustion chamber. This pre-emptive thermal management has demonstrated a 3-5% improvement in volumetric efficiency during high-load operation scenarios.

Exhaust gas recirculation (EGR) systems present unique challenges for integrated thermal-airflow management. The introduction of hot exhaust gases into the intake stream requires sophisticated thermal balancing to prevent intake charge heating while maintaining emissions benefits. Advanced computational fluid dynamics modeling shows that properly integrated systems can maintain EGR benefits while minimizing the thermal penalties traditionally associated with this technology.

Electronic control systems serve as the neural network for these integrated systems, utilizing multiple temperature and pressure sensors to create a comprehensive thermal map of the engine. Machine learning algorithms now enable predictive thermal management, where airflow is adjusted in anticipation of thermal loads rather than in response to them. This proactive approach has demonstrated significant advantages in transient operating conditions, where thermal loads can change rapidly.

Material science advancements further enhance these integrated systems, with new composite materials offering superior thermal conductivity while maintaining structural integrity. These materials enable more compact heat exchanger designs that can be positioned directly in airflow paths without creating excessive flow restrictions or pressure drops.

Current S58 engine designs incorporate separate thermal and airflow management systems that operate independently. This separation creates inefficiencies where thermal loads are not adequately addressed by corresponding airflow adjustments. Advanced integration approaches now focus on creating unified systems where airflow patterns are dynamically modified based on real-time thermal conditions across different engine components.

Key integration points include cylinder head cooling channels, where precision-directed airflow can significantly reduce hotspots that traditionally limit performance parameters. Data from thermal imaging studies indicates that targeted cooling through integrated systems can reduce peak temperatures by 12-18°C in critical areas, allowing for more aggressive timing and fuel mapping without compromising reliability.

The intake manifold represents another crucial integration zone where pre-cooling incoming air creates compound efficiency benefits. By positioning heat exchangers strategically within the airflow path, thermal energy can be effectively managed before it enters the combustion chamber. This pre-emptive thermal management has demonstrated a 3-5% improvement in volumetric efficiency during high-load operation scenarios.

Exhaust gas recirculation (EGR) systems present unique challenges for integrated thermal-airflow management. The introduction of hot exhaust gases into the intake stream requires sophisticated thermal balancing to prevent intake charge heating while maintaining emissions benefits. Advanced computational fluid dynamics modeling shows that properly integrated systems can maintain EGR benefits while minimizing the thermal penalties traditionally associated with this technology.

Electronic control systems serve as the neural network for these integrated systems, utilizing multiple temperature and pressure sensors to create a comprehensive thermal map of the engine. Machine learning algorithms now enable predictive thermal management, where airflow is adjusted in anticipation of thermal loads rather than in response to them. This proactive approach has demonstrated significant advantages in transient operating conditions, where thermal loads can change rapidly.

Material science advancements further enhance these integrated systems, with new composite materials offering superior thermal conductivity while maintaining structural integrity. These materials enable more compact heat exchanger designs that can be positioned directly in airflow paths without creating excessive flow restrictions or pressure drops.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!