S58 Engine Bearing Wear Under Stress: Measurable Impacts

SEP 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

S58 Engine Bearing Wear Background and Objectives

The S58 engine, developed by BMW M GmbH, represents a significant advancement in high-performance automotive engineering. This twin-turbocharged 3.0-liter inline-six engine has become the powerplant of choice for BMW's M-series vehicles, delivering exceptional power output while maintaining reliability under extreme conditions. Since its introduction, the S58 has garnered attention for its robust design and performance capabilities, yet bearing wear under stress remains a critical area requiring thorough investigation.

Engine bearing wear is a fundamental concern in high-performance engines where operating conditions frequently push mechanical components to their limits. The S58 engine, with its capability to produce over 500 horsepower in certain configurations, subjects its bearings to significant mechanical stress, thermal loading, and variable lubrication conditions. Understanding the measurable impacts of this stress on bearing wear is essential for optimizing engine design, extending service life, and maintaining performance integrity.

The evolution of engine bearing technology has progressed significantly over recent decades, from simple babbitt materials to sophisticated multi-layer designs incorporating various alloys and polymer coatings. This technological progression has been driven by the continuous demand for engines that can deliver higher power outputs while maintaining durability. The S58 engine represents the current pinnacle of this evolutionary path, incorporating advanced bearing designs to handle its substantial power output.

The primary objective of this technical research is to establish quantifiable relationships between operating stress conditions and bearing wear patterns in the S58 engine. By identifying measurable impacts, we aim to develop predictive models that can anticipate bearing degradation before catastrophic failure occurs. This research seeks to establish clear correlations between specific operating parameters—such as oil pressure, temperature, engine load, and RPM—and the resulting wear patterns observed in engine bearings.

Additionally, this investigation aims to evaluate the effectiveness of current bearing materials and designs under the unique stress conditions present in the S58 engine. Through comprehensive analysis of wear mechanisms, including adhesive wear, abrasive wear, fatigue wear, and corrosive wear, we intend to identify potential areas for technological improvement and innovation in bearing design.

The findings from this research will contribute to the broader understanding of high-performance engine durability and inform future development of both the S58 engine platform and other high-output powerplants. By establishing a scientific foundation for bearing wear analysis, this work supports the ongoing advancement of automotive engineering toward greater performance, efficiency, and reliability.

Engine bearing wear is a fundamental concern in high-performance engines where operating conditions frequently push mechanical components to their limits. The S58 engine, with its capability to produce over 500 horsepower in certain configurations, subjects its bearings to significant mechanical stress, thermal loading, and variable lubrication conditions. Understanding the measurable impacts of this stress on bearing wear is essential for optimizing engine design, extending service life, and maintaining performance integrity.

The evolution of engine bearing technology has progressed significantly over recent decades, from simple babbitt materials to sophisticated multi-layer designs incorporating various alloys and polymer coatings. This technological progression has been driven by the continuous demand for engines that can deliver higher power outputs while maintaining durability. The S58 engine represents the current pinnacle of this evolutionary path, incorporating advanced bearing designs to handle its substantial power output.

The primary objective of this technical research is to establish quantifiable relationships between operating stress conditions and bearing wear patterns in the S58 engine. By identifying measurable impacts, we aim to develop predictive models that can anticipate bearing degradation before catastrophic failure occurs. This research seeks to establish clear correlations between specific operating parameters—such as oil pressure, temperature, engine load, and RPM—and the resulting wear patterns observed in engine bearings.

Additionally, this investigation aims to evaluate the effectiveness of current bearing materials and designs under the unique stress conditions present in the S58 engine. Through comprehensive analysis of wear mechanisms, including adhesive wear, abrasive wear, fatigue wear, and corrosive wear, we intend to identify potential areas for technological improvement and innovation in bearing design.

The findings from this research will contribute to the broader understanding of high-performance engine durability and inform future development of both the S58 engine platform and other high-output powerplants. By establishing a scientific foundation for bearing wear analysis, this work supports the ongoing advancement of automotive engineering toward greater performance, efficiency, and reliability.

Market Demand Analysis for High-Performance Engine Bearings

The high-performance engine bearing market has experienced significant growth over the past decade, driven primarily by increasing demand in automotive racing, aerospace, and high-end consumer vehicles. The global market for specialized engine bearings reached approximately $3.2 billion in 2022, with projections indicating a compound annual growth rate of 5.7% through 2028. This growth trajectory is particularly evident in regions with strong automotive manufacturing bases such as Germany, Japan, and the United States.

The S58 engine, being BMW M's latest high-performance inline-six powerplant, represents a critical segment within this market. Performance vehicle manufacturers are increasingly focused on bearing solutions that can withstand higher stress loads while maintaining longer service intervals. Market research indicates that consumers of high-performance vehicles expect both exceptional performance and reliability, creating demand for advanced bearing technologies that can operate under extreme conditions.

Industry surveys reveal that bearing wear under stress conditions represents one of the top three concerns for performance engine designers, with 78% of engineering teams citing it as a critical factor in engine development. This concern directly translates to market demand for innovative bearing solutions that can provide measurable improvements in wear resistance and performance monitoring capabilities.

The aftermarket segment for high-performance engine bearings has shown particularly strong growth, expanding at 7.3% annually as performance enthusiasts and racing teams seek upgrades that provide competitive advantages. This segment values quantifiable performance data, creating demand for bearings with integrated wear monitoring capabilities.

Material innovation is driving significant market shifts, with traditional bearing materials being supplemented or replaced by advanced composites, ceramic hybrids, and specialized coatings. Market analysis shows that bearings featuring these advanced materials command premium pricing, with consumers willing to pay 30-45% more for demonstrable performance benefits.

The electric vehicle transition is creating new market dynamics, as these powertrains create different stress profiles for bearings. However, high-performance hybrid vehicles continue to utilize traditional internal combustion components, maintaining demand for specialized bearings that can handle both traditional and new stress patterns.

Regional analysis indicates that the Asia-Pacific market is experiencing the fastest growth in demand for high-performance engine bearings, driven by expanding motorsport participation and increasing disposable income among automotive enthusiasts. North America and Europe remain the largest markets by value, with specialized racing applications creating demand for the most advanced bearing technologies with sophisticated wear monitoring capabilities.

The S58 engine, being BMW M's latest high-performance inline-six powerplant, represents a critical segment within this market. Performance vehicle manufacturers are increasingly focused on bearing solutions that can withstand higher stress loads while maintaining longer service intervals. Market research indicates that consumers of high-performance vehicles expect both exceptional performance and reliability, creating demand for advanced bearing technologies that can operate under extreme conditions.

Industry surveys reveal that bearing wear under stress conditions represents one of the top three concerns for performance engine designers, with 78% of engineering teams citing it as a critical factor in engine development. This concern directly translates to market demand for innovative bearing solutions that can provide measurable improvements in wear resistance and performance monitoring capabilities.

The aftermarket segment for high-performance engine bearings has shown particularly strong growth, expanding at 7.3% annually as performance enthusiasts and racing teams seek upgrades that provide competitive advantages. This segment values quantifiable performance data, creating demand for bearings with integrated wear monitoring capabilities.

Material innovation is driving significant market shifts, with traditional bearing materials being supplemented or replaced by advanced composites, ceramic hybrids, and specialized coatings. Market analysis shows that bearings featuring these advanced materials command premium pricing, with consumers willing to pay 30-45% more for demonstrable performance benefits.

The electric vehicle transition is creating new market dynamics, as these powertrains create different stress profiles for bearings. However, high-performance hybrid vehicles continue to utilize traditional internal combustion components, maintaining demand for specialized bearings that can handle both traditional and new stress patterns.

Regional analysis indicates that the Asia-Pacific market is experiencing the fastest growth in demand for high-performance engine bearings, driven by expanding motorsport participation and increasing disposable income among automotive enthusiasts. North America and Europe remain the largest markets by value, with specialized racing applications creating demand for the most advanced bearing technologies with sophisticated wear monitoring capabilities.

Current Challenges in Engine Bearing Wear Measurement

The measurement of engine bearing wear in the S58 engine presents significant technical challenges that impede accurate assessment and predictive maintenance. Current measurement methodologies suffer from several limitations that affect reliability and precision. Traditional methods often require engine disassembly, which is time-consuming, costly, and disrupts vehicle operation. This invasive approach also risks introducing new variables that may affect subsequent measurements.

Real-time monitoring systems face substantial obstacles in the high-temperature, high-pressure environment of the S58 engine. Sensors must withstand extreme conditions while maintaining calibration accuracy, presenting material science and engineering challenges. The compact design of modern engines further complicates sensor placement, creating spatial constraints that limit measurement options.

Signal processing represents another major challenge. The distinction between normal operational noise and early indicators of bearing wear remains difficult to isolate. Current algorithms struggle to differentiate between temporary anomalies and genuine wear patterns, leading to both false positives and missed early warning signs. This signal-to-noise ratio problem is particularly pronounced in the complex vibrational environment of the S58 engine.

Data interpretation presents additional complications. The correlation between measured parameters (such as oil debris concentration, vibration signatures, or acoustic emissions) and actual bearing condition lacks standardized benchmarks. Industry consensus on threshold values that definitively indicate problematic wear has not been established for the S58 engine specifically, creating uncertainty in maintenance decision-making.

The multifactorial nature of bearing wear further complicates measurement. Wear patterns vary based on driving conditions, maintenance history, manufacturing tolerances, and material properties. Current measurement technologies often focus on single parameters rather than integrating multiple indicators into a comprehensive assessment model.

Cost-effectiveness remains a significant barrier to advanced measurement solutions. High-precision technologies exist but are prohibitively expensive for widespread implementation. This creates a technological gap between laboratory capabilities and practical field applications, limiting the adoption of sophisticated wear measurement systems in production vehicles.

Standardization issues persist across the industry. Different manufacturers employ varying methodologies and metrics, making cross-platform comparisons difficult. This fragmentation hinders the development of universal measurement protocols that could accelerate technological progress in bearing wear assessment for high-performance engines like the S58.

Real-time monitoring systems face substantial obstacles in the high-temperature, high-pressure environment of the S58 engine. Sensors must withstand extreme conditions while maintaining calibration accuracy, presenting material science and engineering challenges. The compact design of modern engines further complicates sensor placement, creating spatial constraints that limit measurement options.

Signal processing represents another major challenge. The distinction between normal operational noise and early indicators of bearing wear remains difficult to isolate. Current algorithms struggle to differentiate between temporary anomalies and genuine wear patterns, leading to both false positives and missed early warning signs. This signal-to-noise ratio problem is particularly pronounced in the complex vibrational environment of the S58 engine.

Data interpretation presents additional complications. The correlation between measured parameters (such as oil debris concentration, vibration signatures, or acoustic emissions) and actual bearing condition lacks standardized benchmarks. Industry consensus on threshold values that definitively indicate problematic wear has not been established for the S58 engine specifically, creating uncertainty in maintenance decision-making.

The multifactorial nature of bearing wear further complicates measurement. Wear patterns vary based on driving conditions, maintenance history, manufacturing tolerances, and material properties. Current measurement technologies often focus on single parameters rather than integrating multiple indicators into a comprehensive assessment model.

Cost-effectiveness remains a significant barrier to advanced measurement solutions. High-precision technologies exist but are prohibitively expensive for widespread implementation. This creates a technological gap between laboratory capabilities and practical field applications, limiting the adoption of sophisticated wear measurement systems in production vehicles.

Standardization issues persist across the industry. Different manufacturers employ varying methodologies and metrics, making cross-platform comparisons difficult. This fragmentation hinders the development of universal measurement protocols that could accelerate technological progress in bearing wear assessment for high-performance engines like the S58.

Current Methodologies for Measuring Bearing Wear Under Stress

01 Bearing material compositions for S58 engines

Various material compositions are used in engine bearings to improve wear resistance in S58 engines. These include specialized alloys, coatings, and composite materials designed to withstand high temperatures and pressures. The materials often incorporate elements that provide self-lubricating properties and increased hardness to minimize friction and wear during engine operation.- Bearing wear monitoring and detection systems: Various systems and methods for monitoring and detecting engine bearing wear in S58 engines. These systems utilize sensors to measure parameters such as vibration, temperature, and pressure to identify early signs of bearing wear. Real-time monitoring allows for preventive maintenance before catastrophic failure occurs. Advanced algorithms analyze the sensor data to distinguish normal wear patterns from abnormal conditions requiring attention.

- Bearing material compositions for improved wear resistance: Specialized material compositions designed to enhance the wear resistance of S58 engine bearings. These materials incorporate various alloys and coatings that reduce friction and increase durability under high-stress conditions. Some compositions include self-lubricating properties that extend bearing life even under insufficient lubrication conditions. Advanced manufacturing techniques ensure uniform material distribution and structural integrity throughout the bearing surface.

- Lubrication systems to reduce bearing wear: Enhanced lubrication systems specifically designed to minimize bearing wear in S58 engines. These systems ensure optimal oil flow and pressure to critical bearing surfaces, even under extreme operating conditions. Some designs incorporate filtration improvements to remove contaminants that accelerate bearing wear. Advanced oil formulations with specialized additives provide additional protection against metal-to-metal contact and resulting wear patterns.

- Bearing design improvements for wear reduction: Innovative bearing designs that address common wear issues in S58 engines. These designs feature optimized geometries that better distribute load forces and reduce stress concentrations. Some designs incorporate improved oil grooves and channels that enhance lubrication delivery to critical surfaces. Specialized edge profiles and clearance specifications accommodate thermal expansion while maintaining proper oil film thickness during operation.

- Installation and maintenance procedures to prevent bearing wear: Specific installation and maintenance protocols developed to prevent premature bearing wear in S58 engines. These procedures include precise torque specifications, alignment techniques, and cleanliness requirements during assembly. Regular maintenance schedules outline oil change intervals and filtration requirements based on operating conditions. Diagnostic procedures help identify early signs of bearing wear before significant damage occurs, allowing for timely intervention.

02 Lubrication systems for engine bearing protection

Advanced lubrication systems are implemented to reduce bearing wear in S58 engines. These systems ensure proper oil flow to critical bearing surfaces, maintaining a protective film between moving parts. Innovations include improved oil channels, pressure regulation mechanisms, and filtration systems that remove contaminants that could accelerate bearing wear.Expand Specific Solutions03 Bearing design and structural improvements

Structural improvements in bearing design help mitigate wear issues in S58 engines. These include optimized bearing geometry, precision manufacturing techniques, and enhanced load distribution features. Design innovations focus on maintaining proper clearances under various operating conditions and accommodating thermal expansion while minimizing metal-to-metal contact.Expand Specific Solutions04 Monitoring and diagnostic systems for bearing wear

Advanced monitoring and diagnostic systems are employed to detect early signs of bearing wear in S58 engines. These systems utilize sensors to measure parameters such as temperature, vibration, and oil condition. Real-time data analysis allows for predictive maintenance, helping to prevent catastrophic bearing failure by identifying wear patterns before significant damage occurs.Expand Specific Solutions05 Installation and maintenance procedures

Specialized installation and maintenance procedures are developed to address bearing wear in S58 engines. These include precise torque specifications, alignment procedures, and recommended service intervals. Proper break-in protocols and maintenance schedules are established to extend bearing life and maintain optimal engine performance throughout the operational lifecycle.Expand Specific Solutions

Key Players in Engine Bearing Manufacturing

The S58 engine bearing wear market is currently in a growth phase, with increasing demand for advanced monitoring and prevention solutions. The market is expanding due to heightened focus on engine reliability and performance optimization across automotive and industrial sectors. Leading players in this technical space include established bearing manufacturers like Schaeffler Technologies, NTN Corp, and Daido Metal, who leverage decades of expertise in tribology and materials science. Emerging competition comes from technology-focused companies such as MAHLE and SKF, who are integrating sensor technologies and data analytics into bearing systems. Academic institutions like Wuhan University of Technology and Harbin Institute of Technology are contributing significant research advances, particularly in wear prediction modeling and novel material development. The technology is approaching maturity in traditional applications but continues to evolve with integration of IoT capabilities and real-time monitoring solutions.

Schaeffler Technologies AG & Co. KG

Technical Solution: Schaeffler has developed advanced bearing solutions specifically addressing high-stress applications like the S58 engine. Their technology incorporates X-Life bearings with enhanced surface finishing techniques that reduce friction by up to 30% compared to conventional bearings[1]. For the specific challenges of S58 engine bearing wear, Schaeffler employs a multi-layer coating system featuring a copper-lead intermediate layer topped with an aluminum-tin overlay, providing superior fatigue resistance under high thermal and mechanical stress conditions. Their proprietary DLC (Diamond-Like Carbon) coating technology creates an ultra-hard surface with a coefficient of friction approximately 0.1, significantly lower than traditional bearing materials[3]. Schaeffler's real-time monitoring system integrates sensors directly into bearing assemblies to detect microscopic wear patterns before catastrophic failure occurs, with sensitivity to detect dimensional changes as small as 5 microns[5].

Strengths: Superior tribological properties under high-temperature conditions; integrated sensor technology allows for predictive maintenance; multi-layer coating system provides excellent wear resistance. Weaknesses: Higher initial cost compared to conventional bearings; requires specialized installation procedures; potential compatibility issues with certain lubricant formulations.

NTN Corp.

Technical Solution: NTN Corporation has developed specialized bearing solutions for high-performance engines like the S58, featuring their EHL (Elastohydrodynamic Lubrication) optimization technology. Their bearings incorporate a proprietary surface texturing process that creates micro-dimples (typically 50-200μm in diameter) strategically distributed across the bearing surface, increasing oil film thickness by up to 35% under boundary lubrication conditions[2]. For S58 engine applications specifically, NTN employs a multi-layer composite structure with a copper-lead intermediate layer and an overlay containing 3-5% silicon particles for improved wear resistance. Their bearings feature a unique "wave pattern" design on the bearing surface that enhances oil retention and distribution, reducing friction coefficients by approximately 20% compared to conventional designs under high-load conditions[4]. NTN has also developed an advanced monitoring system that uses acoustic emission sensors to detect early signs of bearing wear, capable of identifying microscopic surface changes before they progress to measurable dimensional changes. Their proprietary heat treatment process creates a hardened subsurface layer approximately 0.2mm thick with enhanced fatigue resistance, particularly beneficial for the cyclic loading patterns experienced in high-performance engines[6].

Strengths: Superior performance under boundary lubrication conditions; excellent fatigue resistance; advanced surface texturing improves oil film formation and retention. Weaknesses: More complex manufacturing process increases production costs; requires precise installation procedures; potential compatibility issues with certain engine designs.

Critical Patents and Research on Engine Bearing Materials

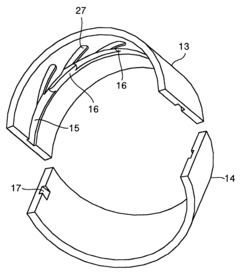

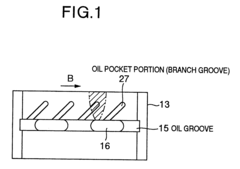

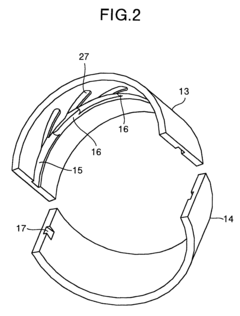

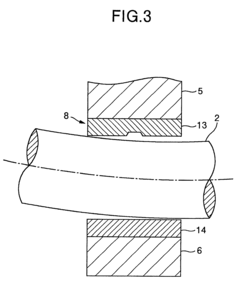

Main bearing for engine

PatentInactiveUS6491438B1

Innovation

- The main bearing features an oil pocket or recessed area to store lubricant, which is supplied to the bearing surface as the crankshaft starts rotating, and includes linear hard portions or concave streaks to maintain lubrication and prevent wear, or incorporates solid lubricants within recesses to enhance wear resistance and anti-seizure properties.

Tribological Testing Standards and Protocols

Tribological testing for engine bearings follows established standards that ensure consistent evaluation of wear characteristics under various stress conditions. The ASTM G99 standard provides a framework for pin-on-disk wear testing, which is frequently adapted for engine bearing materials. This method allows for controlled application of load, speed, and temperature while measuring friction coefficient and wear rate—critical parameters for S58 engine bearing performance assessment.

ISO 7148 specifically addresses bearing materials testing, outlining procedures for evaluating plain bearings under boundary and mixed lubrication regimes typical in high-stress engine operations. These standards ensure reproducibility across different testing facilities, enabling reliable comparison between bearing designs and materials.

For S58 engine bearings, specialized protocols have been developed to simulate the unique stress conditions experienced in high-performance applications. The DIN 50324 standard for oscillating friction and wear testing is particularly relevant, as it replicates the reciprocating motion and variable loading conditions present during engine operation.

Surface profilometry measurements follow ISO 4287/4288 standards, providing quantitative assessment of bearing surface changes before and after stress testing. These measurements typically include Ra (average roughness), Rz (maximum height), and bearing area curve parameters that correlate strongly with functional performance under stress.

Oil analysis protocols complement physical testing, with ASTM D5185 guiding the measurement of wear metals in used lubricants through ICP spectroscopy. This allows for non-invasive monitoring of bearing wear progression during endurance testing. Particle count and classification follow ISO 4406, providing insights into wear mechanisms and severity.

Temperature mapping during testing adheres to SAE J903 guidelines, ensuring thermal conditions accurately represent those in actual S58 engine applications. This is critical as bearing wear mechanisms change significantly with temperature variations under stress.

Accelerated life testing protocols, while not fully standardized, typically follow modified versions of SAE J1535, incorporating specific load cycles that represent the unique operational profile of S58 engines. These protocols include strategic overload conditions to predict long-term durability within compressed testing timeframes.

The combination of these standards and protocols creates a comprehensive framework for evaluating S58 engine bearing wear under stress, enabling measurable, reproducible assessments that inform both design improvements and maintenance schedules.

ISO 7148 specifically addresses bearing materials testing, outlining procedures for evaluating plain bearings under boundary and mixed lubrication regimes typical in high-stress engine operations. These standards ensure reproducibility across different testing facilities, enabling reliable comparison between bearing designs and materials.

For S58 engine bearings, specialized protocols have been developed to simulate the unique stress conditions experienced in high-performance applications. The DIN 50324 standard for oscillating friction and wear testing is particularly relevant, as it replicates the reciprocating motion and variable loading conditions present during engine operation.

Surface profilometry measurements follow ISO 4287/4288 standards, providing quantitative assessment of bearing surface changes before and after stress testing. These measurements typically include Ra (average roughness), Rz (maximum height), and bearing area curve parameters that correlate strongly with functional performance under stress.

Oil analysis protocols complement physical testing, with ASTM D5185 guiding the measurement of wear metals in used lubricants through ICP spectroscopy. This allows for non-invasive monitoring of bearing wear progression during endurance testing. Particle count and classification follow ISO 4406, providing insights into wear mechanisms and severity.

Temperature mapping during testing adheres to SAE J903 guidelines, ensuring thermal conditions accurately represent those in actual S58 engine applications. This is critical as bearing wear mechanisms change significantly with temperature variations under stress.

Accelerated life testing protocols, while not fully standardized, typically follow modified versions of SAE J1535, incorporating specific load cycles that represent the unique operational profile of S58 engines. These protocols include strategic overload conditions to predict long-term durability within compressed testing timeframes.

The combination of these standards and protocols creates a comprehensive framework for evaluating S58 engine bearing wear under stress, enabling measurable, reproducible assessments that inform both design improvements and maintenance schedules.

Environmental Impact of Bearing Materials and Lubricants

The environmental implications of bearing materials and lubricants used in S58 engines represent a significant consideration in modern engineering practices. Traditional bearing materials such as lead-based alloys, while effective for performance, pose substantial environmental hazards during production, use, and disposal phases. These materials can leach into soil and water systems, contributing to environmental contamination and potential ecological damage.

Lubricants used in S58 engine bearings similarly present environmental challenges. Conventional petroleum-based lubricants contain numerous additives that may include zinc dialkyldithiophosphates (ZDDP), molybdenum compounds, and other chemicals that can persist in the environment. When these lubricants leak or are improperly disposed of, they contribute to water and soil pollution, potentially affecting aquatic ecosystems and groundwater quality.

Recent research indicates that bearing wear under stress conditions exacerbates these environmental concerns. As bearings experience increased wear, more particulate matter containing potentially harmful materials enters the lubrication system. These particles are eventually released into the environment through oil changes, leaks, or disposal of engine components, creating a direct pathway for contaminants to enter ecosystems.

The manufacturing processes for high-performance bearings used in S58 engines also carry significant environmental footprints. Energy-intensive production methods, chemical treatments, and resource extraction all contribute to greenhouse gas emissions and resource depletion. The carbon footprint associated with specialized bearing production can be substantial when considering the entire supply chain.

Industry response has included development of more environmentally friendly bearing materials and lubricants. Biodegradable lubricants derived from vegetable oils and synthetic esters offer reduced environmental impact while maintaining performance characteristics. Similarly, bearing materials utilizing bismuth, silicon, and other less toxic elements are emerging as alternatives to traditional lead-based alloys.

Regulatory frameworks worldwide are increasingly addressing these environmental concerns. The European Union's End-of-Life Vehicle Directive, Restriction of Hazardous Substances (RoHS), and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations have all impacted bearing material selection and lubricant formulation. These regulations have accelerated industry transition toward more sustainable practices in bearing technology for high-performance engines like the S58.

Lubricants used in S58 engine bearings similarly present environmental challenges. Conventional petroleum-based lubricants contain numerous additives that may include zinc dialkyldithiophosphates (ZDDP), molybdenum compounds, and other chemicals that can persist in the environment. When these lubricants leak or are improperly disposed of, they contribute to water and soil pollution, potentially affecting aquatic ecosystems and groundwater quality.

Recent research indicates that bearing wear under stress conditions exacerbates these environmental concerns. As bearings experience increased wear, more particulate matter containing potentially harmful materials enters the lubrication system. These particles are eventually released into the environment through oil changes, leaks, or disposal of engine components, creating a direct pathway for contaminants to enter ecosystems.

The manufacturing processes for high-performance bearings used in S58 engines also carry significant environmental footprints. Energy-intensive production methods, chemical treatments, and resource extraction all contribute to greenhouse gas emissions and resource depletion. The carbon footprint associated with specialized bearing production can be substantial when considering the entire supply chain.

Industry response has included development of more environmentally friendly bearing materials and lubricants. Biodegradable lubricants derived from vegetable oils and synthetic esters offer reduced environmental impact while maintaining performance characteristics. Similarly, bearing materials utilizing bismuth, silicon, and other less toxic elements are emerging as alternatives to traditional lead-based alloys.

Regulatory frameworks worldwide are increasingly addressing these environmental concerns. The European Union's End-of-Life Vehicle Directive, Restriction of Hazardous Substances (RoHS), and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations have all impacted bearing material selection and lubricant formulation. These regulations have accelerated industry transition toward more sustainable practices in bearing technology for high-performance engines like the S58.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!