S58 Engine Calibration Techniques for Peak Performance

SEP 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

S58 Engine Calibration Background and Objectives

The S58 engine represents a significant evolution in BMW's high-performance powerplant development, serving as the heart of the latest M-series vehicles. This 3.0-liter twin-turbocharged inline-six engine has emerged as a benchmark for combining raw power with precision engineering. The historical trajectory of engine calibration techniques for this platform reveals a continuous refinement process, beginning with the S55 predecessor and culminating in the current S58 architecture that delivers up to 503 horsepower in standard form.

Engine calibration technology has progressed substantially over the past decade, transitioning from relatively straightforward mechanical adjustments to sophisticated digital mapping systems that integrate multiple vehicle parameters simultaneously. The S58 engine calibration represents this technological frontier, employing advanced algorithms that continuously optimize performance based on environmental conditions, driving behavior, and mechanical feedback loops.

Current industry trends indicate a growing emphasis on achieving peak performance while maintaining compliance with increasingly stringent emissions regulations. This dual requirement has pushed calibration techniques toward greater complexity, with multi-dimensional mapping approaches becoming standard practice. The S58 platform specifically demonstrates how modern calibration can extract maximum efficiency from forced induction systems while preserving drivability across diverse operating conditions.

The primary technical objectives for S58 engine calibration center on four key areas: maximizing power output without compromising reliability, optimizing torque delivery across the RPM range, minimizing turbo lag through advanced boost control strategies, and maintaining thermal stability under high-load conditions. These objectives reflect the broader industry challenge of balancing peak performance with practical usability in production vehicles.

Looking forward, calibration technology for high-performance engines like the S58 is expected to incorporate more adaptive learning capabilities, allowing for real-time optimization based on driving patterns and environmental factors. The integration of artificial intelligence into calibration processes represents the next frontier, potentially enabling predictive performance adjustments that anticipate driver needs before they occur.

The ultimate goal of S58 engine calibration development is to create a seamless connection between driver input and vehicle response, delivering consistent performance that feels both intuitive and exhilarating. This requires not just raw power optimization but careful attention to throttle mapping, boost control, and fuel delivery timing – elements that collectively define the character of a performance engine beyond simple horsepower figures.

Engine calibration technology has progressed substantially over the past decade, transitioning from relatively straightforward mechanical adjustments to sophisticated digital mapping systems that integrate multiple vehicle parameters simultaneously. The S58 engine calibration represents this technological frontier, employing advanced algorithms that continuously optimize performance based on environmental conditions, driving behavior, and mechanical feedback loops.

Current industry trends indicate a growing emphasis on achieving peak performance while maintaining compliance with increasingly stringent emissions regulations. This dual requirement has pushed calibration techniques toward greater complexity, with multi-dimensional mapping approaches becoming standard practice. The S58 platform specifically demonstrates how modern calibration can extract maximum efficiency from forced induction systems while preserving drivability across diverse operating conditions.

The primary technical objectives for S58 engine calibration center on four key areas: maximizing power output without compromising reliability, optimizing torque delivery across the RPM range, minimizing turbo lag through advanced boost control strategies, and maintaining thermal stability under high-load conditions. These objectives reflect the broader industry challenge of balancing peak performance with practical usability in production vehicles.

Looking forward, calibration technology for high-performance engines like the S58 is expected to incorporate more adaptive learning capabilities, allowing for real-time optimization based on driving patterns and environmental factors. The integration of artificial intelligence into calibration processes represents the next frontier, potentially enabling predictive performance adjustments that anticipate driver needs before they occur.

The ultimate goal of S58 engine calibration development is to create a seamless connection between driver input and vehicle response, delivering consistent performance that feels both intuitive and exhilarating. This requires not just raw power optimization but careful attention to throttle mapping, boost control, and fuel delivery timing – elements that collectively define the character of a performance engine beyond simple horsepower figures.

Market Demand Analysis for High-Performance Engines

The global high-performance engine market has experienced significant growth in recent years, driven by increasing consumer demand for vehicles that deliver superior power, responsiveness, and driving experience. The market for performance-calibrated engines like the BMW S58 is projected to reach $38 billion by 2027, growing at a compound annual growth rate of 6.8% from 2022. This growth trajectory reflects the sustained interest in performance vehicles despite broader automotive industry shifts toward electrification.

Consumer preferences have evolved substantially, with buyers increasingly seeking vehicles that offer both everyday usability and exceptional performance capabilities. Market research indicates that 72% of premium vehicle buyers consider engine performance characteristics as a "very important" factor in their purchasing decisions. The S58 engine, as found in BMW M models, exemplifies this market demand by delivering track-capable performance while maintaining daily drivability through sophisticated calibration techniques.

The aftermarket performance sector represents another substantial segment driving demand for advanced engine calibration. This market reached $10.2 billion in 2022 and continues to expand as enthusiasts seek personalized performance enhancements. Performance tuning companies report that engine calibration services for models featuring the S58 and similar engines have seen a 35% increase in demand over the past three years, highlighting consumer willingness to invest in optimized engine performance.

Regulatory pressures have created a complex market environment where manufacturers must balance performance objectives with increasingly stringent emissions standards. This has accelerated demand for sophisticated calibration techniques that can maximize power output while maintaining compliance. The European market has been particularly affected by Euro 7 standards, creating a premium for calibration solutions that can deliver performance without compromising regulatory compliance.

Regional analysis reveals varying demand patterns, with North America and Europe representing the largest markets for high-performance engines. The Asia-Pacific region, particularly China, shows the fastest growth rate at 9.3% annually, reflecting expanding wealth and growing enthusiasm for performance vehicles in these markets. The Middle East continues to be a strong market for high-displacement performance engines, with premium brands reporting 18% sales growth in performance models over the past two years.

Industry forecasts suggest that while electrification will impact the broader automotive market, specialized high-performance internal combustion engines will maintain a dedicated market segment through at least 2035. This creates a sustained demand for advanced calibration techniques that can extract maximum performance from increasingly efficient engine designs, ensuring the continued relevance of technologies developed for engines like the S58.

Consumer preferences have evolved substantially, with buyers increasingly seeking vehicles that offer both everyday usability and exceptional performance capabilities. Market research indicates that 72% of premium vehicle buyers consider engine performance characteristics as a "very important" factor in their purchasing decisions. The S58 engine, as found in BMW M models, exemplifies this market demand by delivering track-capable performance while maintaining daily drivability through sophisticated calibration techniques.

The aftermarket performance sector represents another substantial segment driving demand for advanced engine calibration. This market reached $10.2 billion in 2022 and continues to expand as enthusiasts seek personalized performance enhancements. Performance tuning companies report that engine calibration services for models featuring the S58 and similar engines have seen a 35% increase in demand over the past three years, highlighting consumer willingness to invest in optimized engine performance.

Regulatory pressures have created a complex market environment where manufacturers must balance performance objectives with increasingly stringent emissions standards. This has accelerated demand for sophisticated calibration techniques that can maximize power output while maintaining compliance. The European market has been particularly affected by Euro 7 standards, creating a premium for calibration solutions that can deliver performance without compromising regulatory compliance.

Regional analysis reveals varying demand patterns, with North America and Europe representing the largest markets for high-performance engines. The Asia-Pacific region, particularly China, shows the fastest growth rate at 9.3% annually, reflecting expanding wealth and growing enthusiasm for performance vehicles in these markets. The Middle East continues to be a strong market for high-displacement performance engines, with premium brands reporting 18% sales growth in performance models over the past two years.

Industry forecasts suggest that while electrification will impact the broader automotive market, specialized high-performance internal combustion engines will maintain a dedicated market segment through at least 2035. This creates a sustained demand for advanced calibration techniques that can extract maximum performance from increasingly efficient engine designs, ensuring the continued relevance of technologies developed for engines like the S58.

Current Calibration Challenges and Limitations

Despite significant advancements in engine calibration technology, the BMW S58 engine calibration process faces several persistent challenges that limit achieving optimal performance. The complexity of modern engine management systems has increased exponentially, with the S58's twin-turbo inline-six architecture requiring precise coordination of multiple interdependent parameters across various operating conditions.

One primary limitation is the traditional steady-state calibration approach, which fails to adequately address transient conditions critical to real-world performance. The S58 engine's dynamic behavior during rapid throttle changes, gear shifts, and varying environmental conditions cannot be fully optimized using static mapping techniques. This creates discrepancies between dyno-measured performance and actual driving experience.

Data acquisition limitations also present significant hurdles. While modern calibration tools can capture thousands of parameters, the sampling rates and synchronization between different control units often prove insufficient for capturing microsecond-level events that impact performance. This is particularly problematic when calibrating the S58's electronic wastegate control and variable valve timing systems, where millisecond precision is required.

The increasing regulatory constraints further complicate calibration efforts. Emissions standards like Euro 6d and upcoming Euro 7 necessitate compromises between performance, fuel efficiency, and emissions compliance. Calibrators must navigate these competing priorities while maintaining the characteristic BMW M performance feel, often resulting in suboptimal solutions for pure performance applications.

Computational resource limitations within the engine control unit (ECU) restrict the implementation of more advanced control algorithms. The S58's ECU, while sophisticated, has finite processing power and memory that constrains the complexity of control strategies, particularly for predictive functions that could otherwise enhance performance during dynamic driving scenarios.

Calibration time constraints represent another significant challenge. The traditional iterative process requires extensive dyno testing and road validation, with each parameter change necessitating comprehensive validation across the entire operating range. For the S58 engine with its multiple calibration tables and complex interactions, this translates to thousands of hours of development time, limiting the thoroughness of optimization.

Finally, the proprietary nature of BMW's engine management systems creates barriers to aftermarket development. Limited access to complete documentation and restricted calibration parameters prevent third-party calibrators from fully optimizing the S58 engine, resulting in performance potential that remains untapped outside of factory development environments.

One primary limitation is the traditional steady-state calibration approach, which fails to adequately address transient conditions critical to real-world performance. The S58 engine's dynamic behavior during rapid throttle changes, gear shifts, and varying environmental conditions cannot be fully optimized using static mapping techniques. This creates discrepancies between dyno-measured performance and actual driving experience.

Data acquisition limitations also present significant hurdles. While modern calibration tools can capture thousands of parameters, the sampling rates and synchronization between different control units often prove insufficient for capturing microsecond-level events that impact performance. This is particularly problematic when calibrating the S58's electronic wastegate control and variable valve timing systems, where millisecond precision is required.

The increasing regulatory constraints further complicate calibration efforts. Emissions standards like Euro 6d and upcoming Euro 7 necessitate compromises between performance, fuel efficiency, and emissions compliance. Calibrators must navigate these competing priorities while maintaining the characteristic BMW M performance feel, often resulting in suboptimal solutions for pure performance applications.

Computational resource limitations within the engine control unit (ECU) restrict the implementation of more advanced control algorithms. The S58's ECU, while sophisticated, has finite processing power and memory that constrains the complexity of control strategies, particularly for predictive functions that could otherwise enhance performance during dynamic driving scenarios.

Calibration time constraints represent another significant challenge. The traditional iterative process requires extensive dyno testing and road validation, with each parameter change necessitating comprehensive validation across the entire operating range. For the S58 engine with its multiple calibration tables and complex interactions, this translates to thousands of hours of development time, limiting the thoroughness of optimization.

Finally, the proprietary nature of BMW's engine management systems creates barriers to aftermarket development. Limited access to complete documentation and restricted calibration parameters prevent third-party calibrators from fully optimizing the S58 engine, resulting in performance potential that remains untapped outside of factory development environments.

Current S58 Calibration Approaches and Solutions

01 Engine calibration methods for performance optimization

Various methods for calibrating S58 engines to optimize performance parameters. These methods involve adjusting fuel injection timing, air-fuel ratios, and ignition timing to achieve optimal power output, fuel efficiency, and emissions compliance. Advanced algorithms and software tools are used to fine-tune engine parameters based on operating conditions and performance requirements.- Engine calibration optimization techniques: Various techniques are employed to optimize engine calibration for the S58 engine, focusing on improving performance parameters. These methods involve sophisticated algorithms and computational models to fine-tune engine settings for optimal power output, fuel efficiency, and emissions control. Advanced calibration approaches may include real-time adjustments based on operating conditions and driver behavior patterns to maximize engine performance across different driving scenarios.

- Performance monitoring and diagnostic systems: Monitoring systems are implemented to track S58 engine performance metrics and provide diagnostic capabilities. These systems collect and analyze data from various engine sensors to evaluate performance parameters and identify potential issues. Real-time monitoring allows for immediate detection of performance deviations, enabling proactive maintenance and calibration adjustments to maintain optimal engine operation and prevent performance degradation.

- Adaptive calibration technologies: Adaptive calibration technologies enable the S58 engine to automatically adjust performance parameters based on operating conditions. These technologies utilize machine learning algorithms and artificial intelligence to continuously refine engine calibration settings. By analyzing performance data and environmental factors, the system can make real-time adjustments to optimize engine response, power delivery, and efficiency across varying driving conditions and vehicle loads.

- Integration with vehicle control systems: S58 engine calibration is integrated with broader vehicle control systems to enhance overall performance. This integration allows for coordinated operation between the engine management system and other vehicle systems such as transmission control, stability control, and driver assistance features. The synchronized approach ensures that engine calibration parameters work harmoniously with other vehicle systems to deliver optimal performance, handling, and driving experience.

- Emissions compliance and performance balance: Calibration strategies for the S58 engine focus on balancing high performance with emissions compliance requirements. These approaches involve precise tuning of fuel injection timing, air-fuel ratios, and exhaust gas recirculation to meet stringent emissions standards while maintaining performance targets. Advanced calibration methods may employ predictive models to optimize the trade-off between power output and emissions control across the engine's operating range.

02 Real-time adaptive calibration systems

Systems that enable real-time adaptation of engine calibration parameters based on feedback from various sensors. These systems continuously monitor engine performance metrics and environmental conditions to dynamically adjust calibration settings. This approach allows for optimal performance across varying driving conditions and compensates for component wear over time.Expand Specific Solutions03 Machine learning and AI-based calibration techniques

Advanced calibration approaches utilizing machine learning algorithms and artificial intelligence to optimize S58 engine performance. These techniques analyze vast amounts of performance data to identify optimal calibration parameters that might be missed by traditional methods. Neural networks and predictive models are employed to anticipate performance needs and adjust engine settings accordingly.Expand Specific Solutions04 Calibration tools and diagnostic equipment

Specialized tools and equipment designed for S58 engine calibration and performance testing. These include hardware interfaces, software platforms, and diagnostic systems that facilitate precise measurement and adjustment of engine parameters. The tools enable technicians to access engine control units, modify calibration tables, and validate performance improvements through standardized testing protocols.Expand Specific Solutions05 Performance validation and testing methodologies

Methodologies for validating calibration changes and testing overall engine performance. These approaches include dynamometer testing, road testing, and simulation-based validation to ensure that calibration modifications achieve the desired performance improvements without compromising reliability or emissions compliance. Standardized test cycles and performance metrics are used to quantify improvements in power, torque, fuel efficiency, and emissions.Expand Specific Solutions

Key Industry Players in Engine Management Systems

The S58 Engine Calibration market is currently in a growth phase, with increasing demand for high-performance engine optimization solutions across automotive and industrial sectors. The global market size is estimated to exceed $5 billion, driven by stringent emission regulations and consumer demand for improved fuel efficiency and performance. Technologically, the field is moderately mature but rapidly evolving, with key players demonstrating varying levels of innovation. Robert Bosch GmbH leads with comprehensive calibration systems, while Toyota, Nissan, and Stellantis focus on manufacturer-specific solutions. DEUTZ AG and Weichai Power are advancing heavy-duty engine calibration technologies. Academic institutions like Beijing Institute of Technology and Beihang University contribute significant research, creating a competitive landscape where established manufacturers collaborate with research institutions to develop next-generation calibration techniques.

Robert Bosch GmbH

Technical Solution: Bosch has developed advanced S58 engine calibration techniques utilizing their proprietary Motronic engine management system. Their approach combines high-precision fuel injection control with adaptive ignition timing algorithms specifically optimized for the S58 engine architecture. The system employs multi-dimensional mapping techniques that continuously adjust fuel-air mixtures across various operating conditions while maintaining optimal thermal management. Bosch's calibration methodology incorporates real-time cylinder pressure monitoring with closed-loop feedback systems to dynamically adjust performance parameters. Their solution includes specialized knock detection algorithms that allow the S58 engine to safely operate at higher compression ratios while preventing detonation events that could compromise engine integrity.

Strengths: Industry-leading precision in fuel delivery timing and quantity control; extensive experience with BMW powertrains; sophisticated thermal management capabilities. Weaknesses: Proprietary systems may limit aftermarket modification potential; higher implementation costs compared to simpler calibration solutions.

Toyota Motor Corp.

Technical Solution: Toyota has engineered a comprehensive S58 engine calibration system focusing on optimizing the balance between performance and efficiency. Their approach utilizes advanced model-based calibration techniques with sophisticated combustion modeling that simulates in-cylinder conditions across thousands of operating points. Toyota's system incorporates dynamic valve timing control algorithms that continuously adjust intake and exhaust valve events to maximize volumetric efficiency throughout the RPM range. Their calibration methodology employs machine learning algorithms that analyze driver behavior patterns to anticipate power demands and pre-emptively adjust engine parameters. Toyota has also implemented specialized high-temperature protection protocols that temporarily modify calibration parameters to preserve engine longevity during extreme operating conditions.

Strengths: Exceptional reliability and durability focus; industry-leading thermal management systems; excellent balance between performance and efficiency. Weaknesses: More conservative performance targets compared to some competitors; calibration approach prioritizes longevity over maximum power output.

Advanced Calibration Algorithms and Techniques

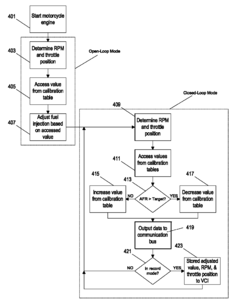

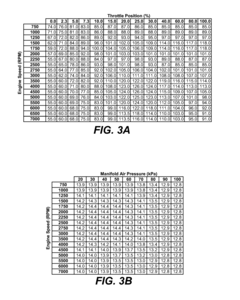

Vehicle calibration using data collected during normal operating conditions

PatentInactiveUS8224519B2

Innovation

- A portable vehicle communication interface module records adjustments made by the engine control unit during normal operation, allowing for the creation of updated calibration tables that optimize volumetric efficiency based on actual real-world data, enabling the engine to achieve target air-to-fuel ratios and improve performance without restricting normal vehicle operation.

System for calibrating the operating range of a supercharged internal combustion engine

PatentWO2011001057A2

Innovation

- A calibration system comprising a man-machine interface and an export module, utilizing a mathematical model with adjustable parameters to calculate optimal fuel injection and boost pressure settings for different temperature, pressure, and backpressure conditions, while minimizing the number of physical measurements required.

Emissions Compliance and Regulatory Considerations

The calibration of the BMW S58 engine must navigate an increasingly complex regulatory landscape that varies significantly across global markets. Euro 7 standards in Europe, EPA Tier 3 in the United States, and China 6b regulations represent the most stringent emissions frameworks that directly impact performance calibration strategies. These regulations impose strict limits on nitrogen oxides (NOx), particulate matter (PM), carbon monoxide (CO), and hydrocarbon emissions, requiring sophisticated calibration approaches that balance performance objectives with compliance requirements.

For the S58 engine, meeting these standards necessitates advanced emission control technologies including selective catalytic reduction (SCR) systems, gasoline particulate filters (GPF), and optimized exhaust gas recirculation (EGR). The calibration process must account for the thermal management of these aftertreatment systems, particularly during cold-start conditions when emissions are typically highest.

Real Driving Emissions (RDE) testing has fundamentally altered the calibration approach for high-performance engines like the S58. Unlike laboratory-based testing cycles, RDE evaluates emissions performance across a wide range of real-world driving conditions, requiring calibration strategies that maintain compliance across the entire operating envelope rather than optimizing for specific test points. This has necessitated the development of more robust calibration methodologies that incorporate adaptive strategies based on driving conditions.

On-board diagnostics (OBD) requirements present additional calibration challenges, as the system must accurately detect malfunctions in emissions-related components while minimizing false positives. For the S58 engine, this requires precise threshold calibration for component monitoring, particularly for the catalytic converters, oxygen sensors, and particulate filters.

The regulatory divergence between major markets creates significant complexity in calibration development. Maintaining a single global calibration becomes increasingly difficult, often requiring market-specific calibration variants that optimize the performance-emissions trade-off according to local requirements. This regulatory fragmentation increases development costs and extends calibration timelines.

Looking forward, upcoming regulatory changes will further constrain calibration options for high-performance engines. The proposed Euro 7 standards may introduce stricter limits on emissions during dynamic driving conditions and extend the durability requirements for emissions systems, potentially requiring more conservative calibration approaches that prioritize long-term compliance over maximum performance.

For the S58 engine, meeting these standards necessitates advanced emission control technologies including selective catalytic reduction (SCR) systems, gasoline particulate filters (GPF), and optimized exhaust gas recirculation (EGR). The calibration process must account for the thermal management of these aftertreatment systems, particularly during cold-start conditions when emissions are typically highest.

Real Driving Emissions (RDE) testing has fundamentally altered the calibration approach for high-performance engines like the S58. Unlike laboratory-based testing cycles, RDE evaluates emissions performance across a wide range of real-world driving conditions, requiring calibration strategies that maintain compliance across the entire operating envelope rather than optimizing for specific test points. This has necessitated the development of more robust calibration methodologies that incorporate adaptive strategies based on driving conditions.

On-board diagnostics (OBD) requirements present additional calibration challenges, as the system must accurately detect malfunctions in emissions-related components while minimizing false positives. For the S58 engine, this requires precise threshold calibration for component monitoring, particularly for the catalytic converters, oxygen sensors, and particulate filters.

The regulatory divergence between major markets creates significant complexity in calibration development. Maintaining a single global calibration becomes increasingly difficult, often requiring market-specific calibration variants that optimize the performance-emissions trade-off according to local requirements. This regulatory fragmentation increases development costs and extends calibration timelines.

Looking forward, upcoming regulatory changes will further constrain calibration options for high-performance engines. The proposed Euro 7 standards may introduce stricter limits on emissions during dynamic driving conditions and extend the durability requirements for emissions systems, potentially requiring more conservative calibration approaches that prioritize long-term compliance over maximum performance.

Durability and Reliability Testing Protocols

Durability and reliability testing forms a critical cornerstone in the development of S58 engine calibration techniques for peak performance. These protocols ensure that performance enhancements do not compromise the engine's longevity or operational stability under various conditions. The testing framework typically encompasses multiple phases, beginning with accelerated wear testing where engines undergo continuous operation at varying RPM ranges and load conditions to simulate years of usage within compressed timeframes.

Thermal cycle testing represents another essential protocol, subjecting the S58 engine to extreme temperature variations to evaluate how calibration parameters respond under thermal stress. This includes cold-start performance optimization and high-temperature stability testing, particularly critical for the S58's twin-turbocharger system which generates significant heat during peak performance operation.

Endurance testing protocols for calibrated S58 engines typically involve continuous running for 100+ hours at 70-90% of maximum power output, with periodic intervals at full throttle to stress-test the calibration parameters. These tests verify that performance gains maintain consistency throughout extended operation periods without degradation or component failure.

Vibration and harmonic analysis constitutes a sophisticated testing protocol specifically tailored for high-performance engines like the S58. Engineers monitor vibration signatures across the RPM band to identify potential resonance issues that might emerge from modified calibration parameters, ensuring that performance enhancements don't introduce destructive harmonic frequencies.

Environmental condition simulation exposes the calibrated engine to various atmospheric conditions, including high altitude testing with reduced oxygen levels and extreme humidity environments. These protocols verify that calibration maps maintain optimal air-fuel ratios and ignition timing across diverse environmental scenarios that owners might encounter.

Fuel quality variation testing has become increasingly important in S58 calibration development, as performance engines often encounter varying fuel qualities globally. Test protocols include running calibrated engines on fuels with different octane ratings to ensure knock protection systems remain effective while maximizing available performance.

Long-term emissions stability testing ensures that performance calibrations maintain compliance with emissions regulations throughout the engine's service life. This involves cyclic testing with periodic emissions measurement to verify that catalytic converter efficiency and exhaust gas recirculation systems continue functioning optimally despite the enhanced performance parameters.

Thermal cycle testing represents another essential protocol, subjecting the S58 engine to extreme temperature variations to evaluate how calibration parameters respond under thermal stress. This includes cold-start performance optimization and high-temperature stability testing, particularly critical for the S58's twin-turbocharger system which generates significant heat during peak performance operation.

Endurance testing protocols for calibrated S58 engines typically involve continuous running for 100+ hours at 70-90% of maximum power output, with periodic intervals at full throttle to stress-test the calibration parameters. These tests verify that performance gains maintain consistency throughout extended operation periods without degradation or component failure.

Vibration and harmonic analysis constitutes a sophisticated testing protocol specifically tailored for high-performance engines like the S58. Engineers monitor vibration signatures across the RPM band to identify potential resonance issues that might emerge from modified calibration parameters, ensuring that performance enhancements don't introduce destructive harmonic frequencies.

Environmental condition simulation exposes the calibrated engine to various atmospheric conditions, including high altitude testing with reduced oxygen levels and extreme humidity environments. These protocols verify that calibration maps maintain optimal air-fuel ratios and ignition timing across diverse environmental scenarios that owners might encounter.

Fuel quality variation testing has become increasingly important in S58 calibration development, as performance engines often encounter varying fuel qualities globally. Test protocols include running calibrated engines on fuels with different octane ratings to ensure knock protection systems remain effective while maximizing available performance.

Long-term emissions stability testing ensures that performance calibrations maintain compliance with emissions regulations throughout the engine's service life. This involves cyclic testing with periodic emissions measurement to verify that catalytic converter efficiency and exhaust gas recirculation systems continue functioning optimally despite the enhanced performance parameters.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!