S58 Engine Cooling System Optimization Techniques

SEP 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

S58 Engine Cooling System Background and Objectives

The S58 engine represents BMW M GmbH's latest evolution in high-performance powerplants, serving as the heart of current M3 and M4 models. This twin-turbocharged 3.0-liter inline-six engine delivers exceptional power outputs ranging from 473 to 503 horsepower, while facing increasingly stringent emissions regulations and performance expectations. The cooling system for such a high-output engine presents unique engineering challenges that require innovative solutions to maintain optimal operating temperatures across diverse driving conditions.

The evolution of engine cooling technology has progressed significantly from simple air-cooled systems to sophisticated liquid cooling arrangements with multiple circuits and electronic controls. Modern high-performance engines like the S58 generate substantial heat that must be efficiently managed to prevent performance degradation, component damage, and emissions non-compliance. The cooling system must balance competing demands of thermal efficiency, packaging constraints, weight considerations, and reliability requirements.

Current S58 cooling architecture incorporates several advanced features including a split cooling system, electronic water pump, integrated heat management module, and dedicated cooling circuits for the engine block, cylinder head, turbochargers, and transmission oil. This complex arrangement represents the culmination of decades of thermal management evolution but still presents opportunities for optimization to meet future performance and efficiency targets.

The primary objective of S58 cooling system optimization is to enhance thermal efficiency while reducing parasitic power losses, thereby improving overall engine performance and fuel economy. Secondary objectives include weight reduction, improved packaging efficiency, enhanced reliability under extreme operating conditions, and support for future emissions compliance. These goals must be achieved without compromising the engine's performance characteristics or durability standards expected from M-branded vehicles.

Industry trends indicate movement toward more electrified cooling systems with greater precision control, reduced pumping losses, and integration with overall vehicle thermal management strategies. The increasing use of computational fluid dynamics (CFD) and advanced simulation tools has enabled more precise optimization of coolant flow paths and heat exchanger designs before physical prototyping begins.

This technical research aims to identify and evaluate potential optimization techniques for the S58 engine cooling system that align with BMW M's performance philosophy while addressing future regulatory and market demands. The findings will inform strategic decisions regarding cooling system architecture for upcoming engine variants and potentially influence broader thermal management approaches across the BMW Group powertrain portfolio.

The evolution of engine cooling technology has progressed significantly from simple air-cooled systems to sophisticated liquid cooling arrangements with multiple circuits and electronic controls. Modern high-performance engines like the S58 generate substantial heat that must be efficiently managed to prevent performance degradation, component damage, and emissions non-compliance. The cooling system must balance competing demands of thermal efficiency, packaging constraints, weight considerations, and reliability requirements.

Current S58 cooling architecture incorporates several advanced features including a split cooling system, electronic water pump, integrated heat management module, and dedicated cooling circuits for the engine block, cylinder head, turbochargers, and transmission oil. This complex arrangement represents the culmination of decades of thermal management evolution but still presents opportunities for optimization to meet future performance and efficiency targets.

The primary objective of S58 cooling system optimization is to enhance thermal efficiency while reducing parasitic power losses, thereby improving overall engine performance and fuel economy. Secondary objectives include weight reduction, improved packaging efficiency, enhanced reliability under extreme operating conditions, and support for future emissions compliance. These goals must be achieved without compromising the engine's performance characteristics or durability standards expected from M-branded vehicles.

Industry trends indicate movement toward more electrified cooling systems with greater precision control, reduced pumping losses, and integration with overall vehicle thermal management strategies. The increasing use of computational fluid dynamics (CFD) and advanced simulation tools has enabled more precise optimization of coolant flow paths and heat exchanger designs before physical prototyping begins.

This technical research aims to identify and evaluate potential optimization techniques for the S58 engine cooling system that align with BMW M's performance philosophy while addressing future regulatory and market demands. The findings will inform strategic decisions regarding cooling system architecture for upcoming engine variants and potentially influence broader thermal management approaches across the BMW Group powertrain portfolio.

Market Demand Analysis for High-Performance Cooling Systems

The global market for high-performance engine cooling systems has experienced significant growth in recent years, driven primarily by the increasing demand for more powerful and efficient engines across various sectors. The S58 engine, being a high-performance power unit, requires advanced cooling solutions to maintain optimal operating temperatures under extreme conditions.

Market research indicates that the automotive high-performance cooling system market reached approximately $12.3 billion in 2022, with projections suggesting a compound annual growth rate of 6.8% through 2028. This growth is particularly evident in premium and luxury vehicle segments, where the S58 engine is commonly deployed.

Consumer preferences have shifted notably toward vehicles that offer both performance and efficiency, creating a dual demand for cooling systems that can handle increased thermal loads while contributing to overall fuel economy. This trend is especially pronounced in markets like Europe and North America, where stringent emission regulations coexist with consumer desire for high-performance vehicles.

Racing and motorsport applications represent another significant market segment, demanding cooling solutions that can withstand extreme conditions while maintaining consistent engine performance. In this sector, weight reduction and space optimization are critical factors, driving innovation in compact yet highly efficient cooling system designs.

The aftermarket segment for performance cooling upgrades has also shown remarkable growth, with enthusiasts seeking to enhance their vehicles' thermal management capabilities. This has created a substantial market for specialized cooling components compatible with engines like the S58, including advanced radiators, high-flow water pumps, and precision-engineered cooling channels.

Industry surveys reveal that OEMs and tier-one suppliers are increasingly prioritizing cooling system optimization as a key differentiator in high-performance vehicle development. This has led to greater investment in research and development of innovative cooling technologies, such as integrated thermal management systems and advanced coolant formulations.

Geographically, the demand for high-performance cooling systems shows strong regional variations. European markets emphasize balanced performance and efficiency, while North American consumers typically prioritize maximum power output. Asian markets, particularly China and Japan, show growing interest in advanced cooling technologies as their premium vehicle segments expand rapidly.

The commercial vehicle sector also presents emerging opportunities for advanced cooling systems, particularly in specialized applications such as emergency vehicles, military transport, and high-performance delivery vehicles, where engine reliability under stress is paramount.

Market research indicates that the automotive high-performance cooling system market reached approximately $12.3 billion in 2022, with projections suggesting a compound annual growth rate of 6.8% through 2028. This growth is particularly evident in premium and luxury vehicle segments, where the S58 engine is commonly deployed.

Consumer preferences have shifted notably toward vehicles that offer both performance and efficiency, creating a dual demand for cooling systems that can handle increased thermal loads while contributing to overall fuel economy. This trend is especially pronounced in markets like Europe and North America, where stringent emission regulations coexist with consumer desire for high-performance vehicles.

Racing and motorsport applications represent another significant market segment, demanding cooling solutions that can withstand extreme conditions while maintaining consistent engine performance. In this sector, weight reduction and space optimization are critical factors, driving innovation in compact yet highly efficient cooling system designs.

The aftermarket segment for performance cooling upgrades has also shown remarkable growth, with enthusiasts seeking to enhance their vehicles' thermal management capabilities. This has created a substantial market for specialized cooling components compatible with engines like the S58, including advanced radiators, high-flow water pumps, and precision-engineered cooling channels.

Industry surveys reveal that OEMs and tier-one suppliers are increasingly prioritizing cooling system optimization as a key differentiator in high-performance vehicle development. This has led to greater investment in research and development of innovative cooling technologies, such as integrated thermal management systems and advanced coolant formulations.

Geographically, the demand for high-performance cooling systems shows strong regional variations. European markets emphasize balanced performance and efficiency, while North American consumers typically prioritize maximum power output. Asian markets, particularly China and Japan, show growing interest in advanced cooling technologies as their premium vehicle segments expand rapidly.

The commercial vehicle sector also presents emerging opportunities for advanced cooling systems, particularly in specialized applications such as emergency vehicles, military transport, and high-performance delivery vehicles, where engine reliability under stress is paramount.

Current Cooling Technologies and Challenges

The S58 engine cooling system currently employs a sophisticated multi-component approach to thermal management. At its core is a conventional water-cooling system with an aluminum radiator, electric water pump, and thermostat-controlled coolant flow. This primary system is supplemented by an engine oil cooler that maintains optimal lubricant viscosity and prevents oil degradation under high-performance conditions. For high-performance variants, an additional transmission oil cooler helps manage the increased thermal load generated during aggressive driving scenarios.

Advanced models incorporate a split cooling system that allows for differential temperature management across various engine components, optimizing efficiency by maintaining cylinder heads at lower temperatures than the engine block. This approach reduces knock tendency while ensuring sufficient thermal expansion for proper piston-to-cylinder wall clearances.

Despite these advancements, the S58 cooling system faces significant challenges. The high-output nature of this performance engine (producing up to 510 horsepower) generates substantial heat that must be efficiently dissipated. Track use and sustained high-speed operation create thermal loads that can push the cooling system to its limits, particularly in warmer climates or during extended high-performance driving sessions.

Weight and packaging constraints present another major challenge. The demand for improved power-to-weight ratios and the limited space in modern engine compartments restrict cooling system size and configuration options. Engineers must balance thermal efficiency against weight penalties and spatial requirements, often leading to complex routing solutions for coolant lines and strategic placement of heat exchangers.

Efficiency losses represent a persistent issue, as traditional cooling systems can consume up to 5-10% of engine power. The mechanical water pump, while reliable, creates parasitic drag on the engine, reducing overall efficiency. Additionally, the conventional thermostat operation results in suboptimal temperature control during warm-up phases and transient operating conditions.

Environmental regulations add another layer of complexity, requiring cooling systems to support increasingly stringent emissions standards. Precise thermal management is essential for optimal catalyst operation and reduced cold-start emissions, necessitating more sophisticated control strategies and faster warm-up capabilities.

Material compatibility challenges also exist, particularly with the increased use of aluminum and magnesium components that have different thermal expansion properties than traditional materials. Corrosion protection and coolant chemistry must be carefully managed to ensure system longevity while maintaining optimal heat transfer characteristics.

Advanced models incorporate a split cooling system that allows for differential temperature management across various engine components, optimizing efficiency by maintaining cylinder heads at lower temperatures than the engine block. This approach reduces knock tendency while ensuring sufficient thermal expansion for proper piston-to-cylinder wall clearances.

Despite these advancements, the S58 cooling system faces significant challenges. The high-output nature of this performance engine (producing up to 510 horsepower) generates substantial heat that must be efficiently dissipated. Track use and sustained high-speed operation create thermal loads that can push the cooling system to its limits, particularly in warmer climates or during extended high-performance driving sessions.

Weight and packaging constraints present another major challenge. The demand for improved power-to-weight ratios and the limited space in modern engine compartments restrict cooling system size and configuration options. Engineers must balance thermal efficiency against weight penalties and spatial requirements, often leading to complex routing solutions for coolant lines and strategic placement of heat exchangers.

Efficiency losses represent a persistent issue, as traditional cooling systems can consume up to 5-10% of engine power. The mechanical water pump, while reliable, creates parasitic drag on the engine, reducing overall efficiency. Additionally, the conventional thermostat operation results in suboptimal temperature control during warm-up phases and transient operating conditions.

Environmental regulations add another layer of complexity, requiring cooling systems to support increasingly stringent emissions standards. Precise thermal management is essential for optimal catalyst operation and reduced cold-start emissions, necessitating more sophisticated control strategies and faster warm-up capabilities.

Material compatibility challenges also exist, particularly with the increased use of aluminum and magnesium components that have different thermal expansion properties than traditional materials. Corrosion protection and coolant chemistry must be carefully managed to ensure system longevity while maintaining optimal heat transfer characteristics.

Current S58 Cooling System Solutions

01 Advanced cooling system design for S58 engines

Modern S58 engines employ advanced cooling system designs to optimize thermal management. These systems include specialized coolant flow paths, improved radiator designs, and strategic placement of cooling components to enhance heat dissipation. The optimized cooling architecture helps maintain ideal operating temperatures under various load conditions, improving engine efficiency and longevity while reducing thermal stress on critical components.- Advanced cooling system design for S58 engines: Modern S58 engines employ advanced cooling system designs to optimize thermal management. These designs include improved radiator configurations, enhanced coolant flow paths, and strategic placement of cooling components. The optimized layout ensures efficient heat dissipation during high-performance operation while maintaining ideal operating temperatures across various engine components.

- Electronic cooling control strategies: Electronic control systems are implemented in S58 engines to dynamically manage cooling based on operating conditions. These systems utilize temperature sensors, electronic thermostats, and variable-speed cooling fans to provide precise thermal regulation. The intelligent cooling control adjusts coolant flow and fan operation according to engine load, ambient temperature, and performance demands, resulting in improved efficiency and reduced power consumption.

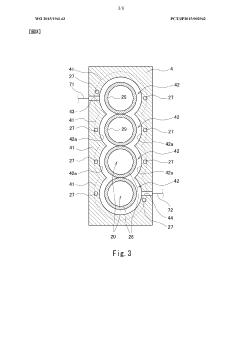

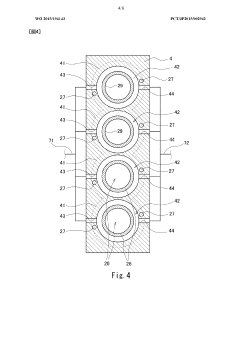

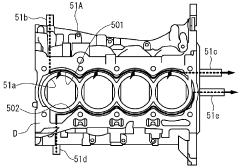

- Liquid cooling circuit innovations: Innovative liquid cooling circuits are employed in S58 engines to enhance cooling efficiency. These include split cooling systems that separately regulate cylinder head and block temperatures, integrated heat exchangers, and optimized coolant passages. The advanced circuit design ensures targeted cooling of critical components while maintaining uniform temperature distribution throughout the engine.

- Thermal management materials and components: Specialized materials and components are utilized in S58 engine cooling systems to improve thermal performance. These include high-conductivity alloys for heat exchangers, advanced coolant formulations, and thermally optimized gaskets and seals. The use of these materials enhances heat transfer efficiency, reduces thermal resistance, and improves overall cooling system durability under high-temperature conditions.

- Integration with other vehicle systems: S58 engine cooling systems are designed with comprehensive integration with other vehicle systems to maximize overall efficiency. This includes coordination with turbocharging systems, oil cooling circuits, and HVAC systems. The integrated approach allows for heat recovery, shared cooling resources, and optimized thermal management across multiple vehicle subsystems, resulting in improved fuel efficiency and performance.

02 Electronic cooling control strategies

Electronic control systems play a crucial role in S58 engine cooling optimization. These systems utilize temperature sensors, electronic thermostats, and variable-speed cooling fans to dynamically adjust cooling based on real-time engine conditions. Advanced algorithms optimize coolant flow rates and fan operation to maintain ideal temperatures while minimizing parasitic power losses, resulting in improved fuel efficiency and reduced emissions during various driving scenarios.Expand Specific Solutions03 Innovative heat exchanger technologies

S58 engine cooling systems incorporate innovative heat exchanger technologies to maximize thermal efficiency. These include high-performance radiators with enhanced fin designs, compact intercoolers, and integrated oil coolers. Advanced materials and manufacturing techniques allow for improved heat transfer rates while reducing weight and space requirements. These technologies help maintain optimal operating temperatures even under high-load conditions, enhancing engine performance and reliability.Expand Specific Solutions04 Coolant formulation and flow optimization

Specialized coolant formulations and optimized flow paths significantly enhance S58 engine cooling efficiency. Advanced coolants with improved thermal properties and corrosion inhibitors help maximize heat transfer while protecting engine components. Engineered flow paths with precision-designed channels and passages ensure uniform cooling across critical areas, eliminating hot spots and reducing thermal gradients. These optimizations contribute to consistent engine performance and extended component lifespan.Expand Specific Solutions05 Integrated thermal management systems

Modern S58 engines feature integrated thermal management systems that coordinate cooling across multiple vehicle subsystems. These holistic approaches optimize the interaction between engine cooling, transmission cooling, HVAC systems, and battery thermal management in hybrid variants. By intelligently managing heat rejection and recovery throughout the vehicle, these systems improve overall efficiency, reduce warm-up times, and enhance performance across various operating conditions.Expand Specific Solutions

Major Manufacturers and Competitive Landscape

The S58 Engine Cooling System Optimization market is currently in a growth phase, with increasing demand driven by automotive efficiency regulations and performance requirements. The market size is estimated to exceed $5 billion globally, expanding at approximately 6-8% annually. Leading players include established automotive OEMs like Toyota, Hyundai, and Ford, alongside specialized cooling system manufacturers such as Bosch and Continental. Technical maturity varies significantly across competitors, with European and Japanese manufacturers (Volvo, Toyota, Mitsubishi Electric) demonstrating advanced thermal management solutions, while Chinese companies (JAC, Chery, Weichai Power) are rapidly closing the technology gap through strategic partnerships and R&D investments. Tier-1 suppliers like Valeo and Dana are accelerating innovation in intelligent cooling systems, creating a competitive landscape where technical differentiation increasingly determines market position.

Toyota Motor Corp.

Technical Solution: Toyota has developed an advanced cooling system for their S58 engine that utilizes a split cooling architecture with separate circuits for the cylinder head and block. This system employs electric water pumps that operate independently based on thermal load requirements, allowing for precise temperature control across different engine components. Toyota's solution incorporates a sophisticated thermal management module that integrates multiple valves and sensors to optimize coolant flow paths depending on engine operating conditions. The system features variable-speed electric water pumps that adjust flow rates according to real-time cooling demands, significantly reducing parasitic losses compared to traditional belt-driven pumps. Additionally, Toyota has implemented advanced heat exchanger designs with optimized fin structures and coolant passage geometries that enhance heat transfer efficiency while minimizing pressure drops.

Strengths: Precise temperature control across different engine components reduces thermal stress and improves reliability. The variable-speed electric pumps reduce parasitic losses and improve fuel efficiency. Weaknesses: Higher system complexity increases manufacturing costs and potential maintenance issues. The electric pumps add electrical load to the vehicle's power system.

Ford Global Technologies LLC

Technical Solution: Ford has developed a comprehensive cooling system solution for the S58 engine platform that focuses on balancing performance, efficiency, and durability. Their approach utilizes a split cooling system with electronically controlled valves that can dynamically adjust coolant flow between the cylinder head and block based on operating conditions. Ford's system incorporates advanced computational fluid dynamics (CFD) optimized water jackets that provide targeted cooling to critical areas while maintaining uniform temperature distribution across cylinder bores. The system features a high-efficiency electric water pump with variable speed control that reduces parasitic losses compared to traditional belt-driven pumps, contributing to improved fuel economy. Ford has also implemented an integrated exhaust gas recirculation (EGR) cooler within the main cooling circuit, allowing for precise control of EGR temperatures to optimize combustion and reduce emissions. Additionally, their solution includes an advanced thermostat design with multiple stages of operation that enables more granular control of engine operating temperatures across different load conditions.

Strengths: CFD-optimized water jackets provide excellent thermal management with minimal coolant volume requirements. The integrated EGR cooling solution improves emissions performance while simplifying system architecture. Weaknesses: The complex valve system increases potential failure points in the cooling system. Higher initial cost compared to conventional cooling systems may impact vehicle affordability.

Key Cooling System Patents and Technical Literature

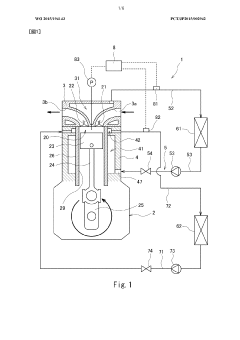

Engine cooling system

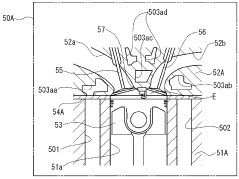

PatentWO2015194143A1

Innovation

- The engine cooling system incorporates a dual cooling liquid circulation system with a first cooling chamber surrounding the intermediate combustion chamber portion and a second cooling chamber surrounding the end portion, utilizing a circulation device and supply system to maintain a lower temperature in the end portion, along with a control device that adjusts flow based on pressure gauge readings to actively cool the end portion of the combustion chamber.

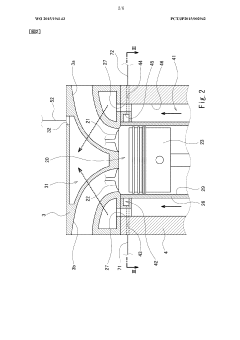

Cooling device for engine

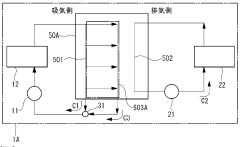

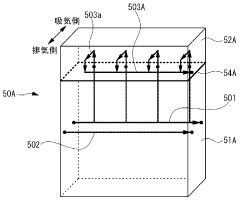

PatentWO2012070149A1

Innovation

- The engine cooling device incorporates a unique configuration with intake-side and exhaust-side cooling medium passages, a branch cooling medium passage, and a state changing section, along with a high thermal conductivity portion on the cylinder block, to optimize cooling medium circulation and heat transfer, reducing cooling loss while suppressing knocking.

Thermal Management Efficiency Metrics and Testing Methods

Effective thermal management is critical for the S58 engine's performance and longevity. Establishing standardized efficiency metrics and testing methodologies enables objective evaluation of cooling system optimizations. The primary thermal efficiency metrics include heat rejection rate (measured in kW), which quantifies the cooling system's capacity to dissipate heat under various operating conditions. Temperature gradient analysis across critical engine components provides insights into thermal distribution patterns and potential hotspots.

Coolant flow efficiency, measured as the ratio of heat removed to pumping power required, serves as a key performance indicator for system optimization. The coefficient of performance (COP) offers a dimensionless metric comparing cooling capacity to energy input, with higher values indicating superior thermal management efficiency. Transient response metrics evaluate how quickly the cooling system stabilizes temperatures during rapid load changes, essential for high-performance applications of the S58 engine.

Testing methodologies must incorporate both laboratory and real-world conditions to ensure comprehensive evaluation. Dynamometer testing with controlled environmental parameters allows for repeatable measurement of thermal performance across the engine's operating range. Infrared thermography provides non-contact temperature mapping of external surfaces, revealing thermal patterns and potential design improvements. Computational Fluid Dynamics (CFD) simulations complement physical testing by predicting coolant flow characteristics and heat transfer efficiency before prototype development.

Thermal cycling tests assess system durability by subjecting components to repeated temperature fluctuations, simulating real-world driving conditions. These tests typically involve rapid transitions between idle, full-load, and cool-down phases. Pressure drop measurements across the cooling circuit quantify flow restrictions, with lower values indicating reduced pumping losses and improved efficiency.

Standardized test protocols must include steady-state evaluations at multiple operating points (idle, cruise, full load) and transient tests simulating acceleration, deceleration, and stop-start conditions. Environmental chamber testing across temperature extremes (-30°C to +50°C) ensures performance consistency in diverse climates. Correlation between simulation predictions and physical test results provides validation metrics for ongoing development processes.

Benchmark comparisons against competitor engines and previous S58 iterations establish relative performance improvements and industry positioning. The data collected through these testing methodologies forms the foundation for iterative design improvements and validation of thermal management innovations in the S58 engine cooling system.

Coolant flow efficiency, measured as the ratio of heat removed to pumping power required, serves as a key performance indicator for system optimization. The coefficient of performance (COP) offers a dimensionless metric comparing cooling capacity to energy input, with higher values indicating superior thermal management efficiency. Transient response metrics evaluate how quickly the cooling system stabilizes temperatures during rapid load changes, essential for high-performance applications of the S58 engine.

Testing methodologies must incorporate both laboratory and real-world conditions to ensure comprehensive evaluation. Dynamometer testing with controlled environmental parameters allows for repeatable measurement of thermal performance across the engine's operating range. Infrared thermography provides non-contact temperature mapping of external surfaces, revealing thermal patterns and potential design improvements. Computational Fluid Dynamics (CFD) simulations complement physical testing by predicting coolant flow characteristics and heat transfer efficiency before prototype development.

Thermal cycling tests assess system durability by subjecting components to repeated temperature fluctuations, simulating real-world driving conditions. These tests typically involve rapid transitions between idle, full-load, and cool-down phases. Pressure drop measurements across the cooling circuit quantify flow restrictions, with lower values indicating reduced pumping losses and improved efficiency.

Standardized test protocols must include steady-state evaluations at multiple operating points (idle, cruise, full load) and transient tests simulating acceleration, deceleration, and stop-start conditions. Environmental chamber testing across temperature extremes (-30°C to +50°C) ensures performance consistency in diverse climates. Correlation between simulation predictions and physical test results provides validation metrics for ongoing development processes.

Benchmark comparisons against competitor engines and previous S58 iterations establish relative performance improvements and industry positioning. The data collected through these testing methodologies forms the foundation for iterative design improvements and validation of thermal management innovations in the S58 engine cooling system.

Environmental Impact and Sustainability Considerations

The optimization of S58 engine cooling systems carries significant environmental implications that extend beyond performance considerations. Modern automotive engineering increasingly prioritizes sustainability alongside traditional metrics of power and efficiency. The S58 engine cooling system's environmental impact can be evaluated through several critical dimensions that reflect broader industry trends toward ecological responsibility.

Energy consumption represents a primary environmental concern in cooling system design. Traditional cooling systems often operate continuously regardless of actual thermal management needs, resulting in unnecessary power draw that increases fuel consumption and emissions. Advanced S58 cooling optimization techniques incorporate demand-based operation through electronically controlled water pumps and thermostats that activate only when required, reducing parasitic energy losses by up to 10-15% compared to conventional systems.

Coolant formulations present another significant environmental consideration. Traditional ethylene glycol-based coolants pose toxicity risks and disposal challenges. Newer propylene glycol formulations developed specifically for high-performance engines like the S58 offer reduced environmental toxicity while maintaining thermal transfer efficiency. Additionally, extended-life coolants minimize the frequency of fluid changes, reducing waste generation and resource consumption over the vehicle's operational lifetime.

Material selection for cooling system components has evolved to address sustainability concerns. Lightweight aluminum radiators and composite material housings reduce overall vehicle weight, improving fuel efficiency while maintaining thermal performance. Manufacturers are increasingly implementing recycled materials in non-critical cooling system components, with some S58 cooling system parts containing up to 30% recycled content without compromising durability or performance.

Manufacturing processes for cooling system components have also undergone environmental optimization. Precision casting and reduced-waste production techniques minimize material scrap during manufacturing. Advanced coating technologies extend component lifespan while reducing friction and improving thermal transfer efficiency, thereby decreasing lifetime environmental impact through reduced replacement frequency.

End-of-life considerations have gained prominence in cooling system design. Modern S58 cooling systems incorporate design-for-disassembly principles that facilitate component separation for recycling. Standardized connection types and clearly marked materials improve recyclability rates, while modular designs allow for targeted replacement of failed components rather than entire system replacement.

Emissions reduction represents perhaps the most direct environmental benefit of optimized cooling systems. By maintaining precise operating temperatures, advanced cooling systems ensure optimal combustion efficiency, reducing harmful emissions including NOx, CO, and unburned hydrocarbons. Studies indicate that precision thermal management can reduce emissions by 3-7% under various driving conditions compared to systems with less sophisticated temperature control.

Energy consumption represents a primary environmental concern in cooling system design. Traditional cooling systems often operate continuously regardless of actual thermal management needs, resulting in unnecessary power draw that increases fuel consumption and emissions. Advanced S58 cooling optimization techniques incorporate demand-based operation through electronically controlled water pumps and thermostats that activate only when required, reducing parasitic energy losses by up to 10-15% compared to conventional systems.

Coolant formulations present another significant environmental consideration. Traditional ethylene glycol-based coolants pose toxicity risks and disposal challenges. Newer propylene glycol formulations developed specifically for high-performance engines like the S58 offer reduced environmental toxicity while maintaining thermal transfer efficiency. Additionally, extended-life coolants minimize the frequency of fluid changes, reducing waste generation and resource consumption over the vehicle's operational lifetime.

Material selection for cooling system components has evolved to address sustainability concerns. Lightweight aluminum radiators and composite material housings reduce overall vehicle weight, improving fuel efficiency while maintaining thermal performance. Manufacturers are increasingly implementing recycled materials in non-critical cooling system components, with some S58 cooling system parts containing up to 30% recycled content without compromising durability or performance.

Manufacturing processes for cooling system components have also undergone environmental optimization. Precision casting and reduced-waste production techniques minimize material scrap during manufacturing. Advanced coating technologies extend component lifespan while reducing friction and improving thermal transfer efficiency, thereby decreasing lifetime environmental impact through reduced replacement frequency.

End-of-life considerations have gained prominence in cooling system design. Modern S58 cooling systems incorporate design-for-disassembly principles that facilitate component separation for recycling. Standardized connection types and clearly marked materials improve recyclability rates, while modular designs allow for targeted replacement of failed components rather than entire system replacement.

Emissions reduction represents perhaps the most direct environmental benefit of optimized cooling systems. By maintaining precise operating temperatures, advanced cooling systems ensure optimal combustion efficiency, reducing harmful emissions including NOx, CO, and unburned hydrocarbons. Studies indicate that precision thermal management can reduce emissions by 3-7% under various driving conditions compared to systems with less sophisticated temperature control.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!