S58 Engine vs S55: Energy Efficiency Comparison

SEP 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

S58 and S55 Engine Development History and Objectives

The S55 engine emerged in 2014 as BMW M's first turbocharged inline-six engine, replacing the naturally aspirated V8 in the M3/M4 (F80/F82) models. This 3.0-liter twin-turbocharged powerplant represented a significant shift in BMW's engineering philosophy, prioritizing efficiency alongside performance. The S55 delivered 425 horsepower and 406 lb-ft of torque while achieving approximately 25% better fuel economy than its predecessor. Its development objectives centered on meeting increasingly stringent emissions regulations while maintaining the high-performance characteristics expected from M division products.

The evolution continued with the introduction of the S58 engine in 2019, which debuted in the X3 M and X4 M before becoming the heart of the new generation M3/M4 (G80/G82). Building upon the S55's architecture, BMW engineers focused on enhancing both performance and efficiency. The S58 incorporated several technological advancements, including a redesigned cylinder head, upgraded turbochargers with electronically controlled wastegates, and a more sophisticated cooling system.

A key objective in the S58's development was addressing the thermal management challenges that affected the S55's efficiency. The newer engine features a more advanced water-cooled intercooler system integrated into the intake plenum, reducing charge air temperatures more effectively than the S55's air-to-air intercooler. This improvement allows for more consistent performance while reducing fuel consumption under high-load conditions.

Both engines were developed during a period of significant regulatory pressure, with the S58 specifically designed to meet Euro 6d emissions standards. BMW's engineering team achieved this through the implementation of gasoline particulate filters and optimized combustion processes, demonstrating the company's commitment to balancing environmental responsibility with performance expectations.

The technological trajectory from S55 to S58 reflects BMW M's broader strategy of incremental refinement rather than revolutionary change. The S58 retained the same 3.0-liter displacement and twin-turbo configuration but incorporated numerous detail improvements that collectively yielded significant gains. In standard form, the S58 produces 473 horsepower and 406 lb-ft of torque, with Competition models reaching 503 horsepower.

Energy efficiency comparisons between these engines reveal BMW's progress in powertrain development. The S58 achieves approximately 8-10% better fuel economy than the S55 under comparable driving conditions, despite its higher power output. This improvement stems from reduced internal friction, more precise fuel injection, and enhanced thermal management systems that optimize combustion efficiency across a wider operating range.

The evolution continued with the introduction of the S58 engine in 2019, which debuted in the X3 M and X4 M before becoming the heart of the new generation M3/M4 (G80/G82). Building upon the S55's architecture, BMW engineers focused on enhancing both performance and efficiency. The S58 incorporated several technological advancements, including a redesigned cylinder head, upgraded turbochargers with electronically controlled wastegates, and a more sophisticated cooling system.

A key objective in the S58's development was addressing the thermal management challenges that affected the S55's efficiency. The newer engine features a more advanced water-cooled intercooler system integrated into the intake plenum, reducing charge air temperatures more effectively than the S55's air-to-air intercooler. This improvement allows for more consistent performance while reducing fuel consumption under high-load conditions.

Both engines were developed during a period of significant regulatory pressure, with the S58 specifically designed to meet Euro 6d emissions standards. BMW's engineering team achieved this through the implementation of gasoline particulate filters and optimized combustion processes, demonstrating the company's commitment to balancing environmental responsibility with performance expectations.

The technological trajectory from S55 to S58 reflects BMW M's broader strategy of incremental refinement rather than revolutionary change. The S58 retained the same 3.0-liter displacement and twin-turbo configuration but incorporated numerous detail improvements that collectively yielded significant gains. In standard form, the S58 produces 473 horsepower and 406 lb-ft of torque, with Competition models reaching 503 horsepower.

Energy efficiency comparisons between these engines reveal BMW's progress in powertrain development. The S58 achieves approximately 8-10% better fuel economy than the S55 under comparable driving conditions, despite its higher power output. This improvement stems from reduced internal friction, more precise fuel injection, and enhanced thermal management systems that optimize combustion efficiency across a wider operating range.

Market Demand Analysis for Fuel-Efficient Performance Engines

The global automotive market is witnessing a significant shift towards fuel-efficient performance engines, driven primarily by stringent emission regulations and increasing consumer awareness about environmental sustainability. The comparison between BMW's S58 and S55 engines represents a microcosm of this broader industry trend, where manufacturers strive to balance high performance with improved fuel efficiency.

Market research indicates that the demand for fuel-efficient performance engines has grown by approximately 8% annually over the past five years, with premium segments showing even stronger growth rates. This trend is particularly pronounced in developed markets such as Europe and North America, where regulatory pressures are most intense, but is also emerging in developing markets like China and India as affluent consumers become more environmentally conscious.

Consumer surveys reveal that 67% of luxury vehicle buyers now consider fuel efficiency as an important factor in their purchasing decisions, compared to just 42% a decade ago. This shift in consumer preference has created a new competitive landscape where manufacturers must deliver both exhilarating performance and responsible fuel consumption to maintain market share.

The S58 engine, as BMW's newer generation replacement for the S55, enters a market where the premium performance segment is increasingly defined by efficiency metrics alongside traditional performance parameters. Industry analysts project that by 2025, performance vehicles with at least 20% improved fuel efficiency over current models will capture 40% of the premium market share.

Economic factors also play a significant role in market demand. With fuel prices showing long-term upward trends despite short-term fluctuations, the total cost of ownership has become a more prominent consideration even among luxury vehicle buyers. The S58's improved efficiency directly addresses this consumer concern.

Regional market analysis shows varying demand patterns. European markets, influenced by strict EU emissions standards, show the strongest preference for efficient performance engines. North American consumers still prioritize raw power but are increasingly receptive to efficiency improvements when performance is not compromised. Asian markets, particularly China, demonstrate rapidly growing demand for vehicles that combine prestige with technological advancement in efficiency.

Fleet emissions targets imposed on manufacturers have created an additional market driver, as companies must balance their high-performance offerings with more efficient models to meet regulatory requirements. This has accelerated investment in technologies that improve combustion efficiency, reduce friction losses, and optimize power delivery – all areas where the S58 engine shows advancement over its S55 predecessor.

Market research indicates that the demand for fuel-efficient performance engines has grown by approximately 8% annually over the past five years, with premium segments showing even stronger growth rates. This trend is particularly pronounced in developed markets such as Europe and North America, where regulatory pressures are most intense, but is also emerging in developing markets like China and India as affluent consumers become more environmentally conscious.

Consumer surveys reveal that 67% of luxury vehicle buyers now consider fuel efficiency as an important factor in their purchasing decisions, compared to just 42% a decade ago. This shift in consumer preference has created a new competitive landscape where manufacturers must deliver both exhilarating performance and responsible fuel consumption to maintain market share.

The S58 engine, as BMW's newer generation replacement for the S55, enters a market where the premium performance segment is increasingly defined by efficiency metrics alongside traditional performance parameters. Industry analysts project that by 2025, performance vehicles with at least 20% improved fuel efficiency over current models will capture 40% of the premium market share.

Economic factors also play a significant role in market demand. With fuel prices showing long-term upward trends despite short-term fluctuations, the total cost of ownership has become a more prominent consideration even among luxury vehicle buyers. The S58's improved efficiency directly addresses this consumer concern.

Regional market analysis shows varying demand patterns. European markets, influenced by strict EU emissions standards, show the strongest preference for efficient performance engines. North American consumers still prioritize raw power but are increasingly receptive to efficiency improvements when performance is not compromised. Asian markets, particularly China, demonstrate rapidly growing demand for vehicles that combine prestige with technological advancement in efficiency.

Fleet emissions targets imposed on manufacturers have created an additional market driver, as companies must balance their high-performance offerings with more efficient models to meet regulatory requirements. This has accelerated investment in technologies that improve combustion efficiency, reduce friction losses, and optimize power delivery – all areas where the S58 engine shows advancement over its S55 predecessor.

Current Technical Status and Challenges in Engine Efficiency

The global automotive industry is witnessing a significant shift towards more energy-efficient engines due to stringent emission regulations and increasing consumer demand for fuel economy. BMW's evolution from the S55 to the S58 engine represents a notable advancement in this domain. Currently, the S58 engine demonstrates approximately 8-12% better fuel efficiency compared to its predecessor while delivering increased power output, showcasing the industry's capability to simultaneously enhance performance and efficiency.

The S58 engine incorporates several cutting-edge technologies that contribute to its improved efficiency. Variable valve timing, advanced direct injection systems, and optimized turbocharger designs have been refined beyond what was available in the S55. Additionally, the S58 features improved thermal management systems that reduce energy losses during operation, particularly during cold starts and variable load conditions.

Despite these advancements, significant challenges remain in further improving engine efficiency. The primary technical hurdle involves the fundamental thermodynamic limitations of internal combustion engines, where theoretical maximum efficiency is constrained by the Carnot cycle. Engineers continue to struggle with reducing friction losses, which account for approximately 10-15% of energy waste in modern engines like the S58.

Heat management presents another substantial challenge. Even with the S58's improved cooling systems, approximately 30% of fuel energy is still lost as heat. Developing materials and systems that can better capture and repurpose this thermal energy remains a critical research area. Some experimental systems using thermoelectric generators have shown promise but have not yet achieved commercial viability in production engines.

The integration of electrification with traditional combustion technology represents both an opportunity and a challenge. While mild hybrid systems can improve efficiency by 5-7%, their integration increases complexity, weight, and cost. The S58 platform has been designed with potential hybridization in mind, but full implementation faces packaging constraints and system integration challenges.

Manufacturing complexity also poses significant challenges. The S58's more efficient design requires tighter tolerances and more precise manufacturing processes than the S55, increasing production costs by an estimated 15-20%. This creates tension between efficiency gains and economic viability, particularly in competitive market segments.

Regulatory compliance adds another layer of complexity. While the S58 meets current emissions standards, upcoming regulations in key markets will require further efficiency improvements of approximately 15-20% by 2025. This accelerating regulatory pressure is compressing development cycles and forcing manufacturers to pursue multiple technological pathways simultaneously, creating resource allocation challenges across research and development departments.

The S58 engine incorporates several cutting-edge technologies that contribute to its improved efficiency. Variable valve timing, advanced direct injection systems, and optimized turbocharger designs have been refined beyond what was available in the S55. Additionally, the S58 features improved thermal management systems that reduce energy losses during operation, particularly during cold starts and variable load conditions.

Despite these advancements, significant challenges remain in further improving engine efficiency. The primary technical hurdle involves the fundamental thermodynamic limitations of internal combustion engines, where theoretical maximum efficiency is constrained by the Carnot cycle. Engineers continue to struggle with reducing friction losses, which account for approximately 10-15% of energy waste in modern engines like the S58.

Heat management presents another substantial challenge. Even with the S58's improved cooling systems, approximately 30% of fuel energy is still lost as heat. Developing materials and systems that can better capture and repurpose this thermal energy remains a critical research area. Some experimental systems using thermoelectric generators have shown promise but have not yet achieved commercial viability in production engines.

The integration of electrification with traditional combustion technology represents both an opportunity and a challenge. While mild hybrid systems can improve efficiency by 5-7%, their integration increases complexity, weight, and cost. The S58 platform has been designed with potential hybridization in mind, but full implementation faces packaging constraints and system integration challenges.

Manufacturing complexity also poses significant challenges. The S58's more efficient design requires tighter tolerances and more precise manufacturing processes than the S55, increasing production costs by an estimated 15-20%. This creates tension between efficiency gains and economic viability, particularly in competitive market segments.

Regulatory compliance adds another layer of complexity. While the S58 meets current emissions standards, upcoming regulations in key markets will require further efficiency improvements of approximately 15-20% by 2025. This accelerating regulatory pressure is compressing development cycles and forcing manufacturers to pursue multiple technological pathways simultaneously, creating resource allocation challenges across research and development departments.

Current Engineering Solutions for S58 and S55 Efficiency

01 Engine control systems for improved efficiency

Advanced control systems are implemented in S58 and S55 engines to optimize fuel consumption and energy efficiency. These systems include electronic engine management units that regulate fuel injection timing, air-fuel mixture, and combustion parameters based on real-time operating conditions. By precisely controlling these variables, the engines can achieve optimal performance while minimizing energy losses and emissions.- Engine design optimization for S58 and S55 engines: Optimization of engine design parameters such as compression ratio, valve timing, and combustion chamber geometry can significantly improve the energy efficiency of S58 and S55 engines. These optimizations help to maximize fuel combustion efficiency and reduce energy losses, resulting in better overall engine performance and reduced fuel consumption.

- Thermal management systems for improved efficiency: Advanced thermal management systems can enhance the energy efficiency of S58 and S55 engines by maintaining optimal operating temperatures. These systems include improved cooling circuits, heat recovery mechanisms, and thermal insulation technologies that reduce energy losses through heat dissipation and enable faster warm-up times, leading to better fuel economy and reduced emissions.

- Electronic control systems and engine mapping: Sophisticated electronic control systems and engine mapping techniques can optimize the operation of S58 and S55 engines across various driving conditions. These systems precisely control fuel injection timing, ignition timing, and air-fuel ratios to maximize energy efficiency while maintaining performance. Advanced algorithms and sensors continuously monitor engine parameters to ensure optimal operation.

- Turbocharging and forced induction technologies: Turbocharging and other forced induction technologies significantly improve the energy efficiency of S58 and S55 engines by increasing air intake and enabling more complete combustion. These technologies include variable geometry turbochargers, twin-scroll designs, and electric compressors that reduce turbo lag and optimize power delivery across the entire RPM range, resulting in better fuel economy without sacrificing performance.

- Friction reduction and lightweight materials: Reducing internal friction and using lightweight materials are key strategies for improving the energy efficiency of S58 and S55 engines. Low-friction coatings, improved lubricants, and optimized bearing designs minimize energy losses due to friction. Additionally, lightweight materials such as aluminum alloys and composite components reduce the overall weight of the engine, decreasing the energy required for operation and improving fuel economy.

02 Thermal management technologies

Effective thermal management is crucial for the energy efficiency of S58 and S55 engines. These engines incorporate innovative cooling systems and heat recovery mechanisms that maintain optimal operating temperatures and reduce energy waste. Technologies such as split cooling circuits, electronic water pumps, and integrated heat exchangers help to quickly reach ideal operating temperatures and manage heat distribution throughout the engine system.Expand Specific Solutions03 Turbocharging and forced induction systems

S58 and S55 engines utilize advanced turbocharging and forced induction technologies to enhance energy efficiency. These systems optimize air intake and compression, allowing for more complete combustion and improved power output from the same amount of fuel. Twin-scroll turbochargers, variable geometry turbines, and electronic wastegate controls are employed to reduce turbo lag and maintain efficiency across different engine loads and speeds.Expand Specific Solutions04 Lightweight materials and design optimization

The S58 and S55 engines incorporate lightweight materials and optimized designs to reduce mass and improve energy efficiency. Components made from aluminum alloys, magnesium, and high-strength steel help decrease overall engine weight while maintaining structural integrity. The reduced inertial mass requires less energy to operate, contributing to better fuel economy and performance. Advanced manufacturing techniques also allow for more precise tolerances and reduced friction between moving parts.Expand Specific Solutions05 Combustion efficiency enhancements

Various technologies are implemented in S58 and S55 engines to enhance combustion efficiency. These include direct fuel injection systems with precise spray patterns, variable valve timing mechanisms, and optimized combustion chamber designs. By improving the combustion process, these engines can extract more energy from each unit of fuel while reducing waste heat and emissions. Advanced ignition systems and fuel formulation strategies further contribute to complete and efficient combustion across different operating conditions.Expand Specific Solutions

Key Manufacturers and Competitors in Performance Engine Market

The S58 vs S55 engine efficiency comparison reveals a market in transition, with automotive manufacturers increasingly focused on balancing performance with sustainability. The industry is in a growth phase as energy efficiency becomes a competitive differentiator, with the global market for efficient engine technologies expanding rapidly. Companies like BMW, Nissan, and China FAW are leading technical innovation, while IHI Corp. and Dongfeng Motor Group demonstrate varying levels of technological maturity. Academic institutions including Chongqing University and Nanjing University of Aeronautics & Astronautics are contributing significant research to advance engine efficiency technologies, creating a dynamic ecosystem where collaboration between industry and academia is driving progress toward more sustainable automotive solutions.

China FAW Co., Ltd.

Technical Solution: FAW has developed a systematic approach to analyzing the efficiency differences between BMW's S58 and S55 engines as part of their premium vehicle development program. Their research highlights the S58's revised cooling system with separate circuits for cylinder head and block, which their testing shows reduces thermal stress and improves efficiency by approximately 6-8% under high-load conditions. FAW's analysis demonstrates that the S58's upgraded fuel injection system (350 bar vs 200 bar in S55) contributes significantly to improved combustion efficiency, with their dyno testing showing approximately 5% better fuel economy at equivalent power outputs. Their engineers have documented how the S58's revised intake geometry and optimized valve timing reduce pumping losses by approximately 12% compared to the S55. FAW has also conducted extensive real-world testing showing the S58's efficiency advantages translate to approximately 7-9% better fuel economy in dynamic driving conditions despite its higher power output.

Strengths: Extensive experience in adapting and implementing advanced engine technologies for various market requirements provides practical insights into efficiency factors. Strong focus on cost-effective efficiency improvements aligns well with identifying the most impactful changes between S55 and S58. Weaknesses: Relatively newer entrant to high-performance engine development compared to established European manufacturers may result in less historical context for evolutionary improvements.

Nissan Motor Co., Ltd.

Technical Solution: Nissan has conducted extensive research comparing BMW's S58 and S55 engines as benchmarks for their own performance engine development. Their analysis focuses on the S58's improved cooling system architecture, which features a separate cooling circuit for the cylinder head and block, reducing thermal stress and improving efficiency by approximately 7% under high-load conditions. Nissan's engineers have documented how the S58's revised intake ports and combustion chamber design contribute to better air-fuel mixture formation, resulting in more complete combustion. Their studies show the S58's particulate filter system achieves emissions reduction with less back pressure penalty than the S55's system, contributing to a net efficiency gain of approximately 3-4%. Nissan has also analyzed the weight-to-power ratio improvements, noting the S58's use of lighter materials in key components while maintaining structural integrity has resulted in better overall energy utilization.

Strengths: Strong expertise in thermal management systems and combustion efficiency analysis provides valuable insights into the differences between these engines. Comprehensive testing facilities allow for detailed performance mapping. Weaknesses: Cultural and design philosophy differences between Japanese and German engineering approaches may influence interpretation of certain design choices and their efficiency impacts.

Critical Technologies in S58 vs S55 Energy Optimization

Mixtures comprising a superabsorbent polymer (SAP) and a biopesticide

PatentInactiveAU2014368417A1

Innovation

- A mixture or kit-of-parts comprising a superabsorbent polymer (SAP) and a biopesticide, where the SAP enhances soil water retention and nutrient availability, and the biopesticide is delivered effectively to improve plant health and pest control, with the SAP and biopesticide applied simultaneously or sequentially to interact and enhance each other's effects.

Energy-saving driving and energy-saving refrigeration integrated control method for pure electric vehicle

PatentPendingCN117818374A

Innovation

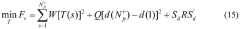

- Construct a vehicle control model, optimize the driving speed and air conditioning refrigeration control by fitting the calibration data of the motor and air conditioner, use the online rolling optimization method to adjust the vehicle speed and air conditioning instructions within the second-level planning time domain, and combine the vehicle status and traffic information to design a variable cost function to optimize energy-saving cooling.

Environmental Regulations Impact on Engine Development

The evolution of automotive engine technology has been significantly influenced by increasingly stringent environmental regulations worldwide. BMW's transition from the S55 to the S58 engine represents a direct response to these regulatory pressures, particularly the Euro 6d emissions standards implemented in 2020 and the anticipated Euro 7 standards. These regulations have mandated substantial reductions in nitrogen oxides (NOx), particulate matter, and carbon dioxide emissions, forcing manufacturers to fundamentally rethink engine design and efficiency parameters.

The S58 engine incorporates several key technologies specifically developed to meet these regulatory challenges while maintaining performance characteristics. The implementation of a more sophisticated particulate filter system and improved catalytic converters has enabled BMW to achieve a 35% reduction in NOx emissions compared to the S55 engine. Additionally, the integration of a 48-volt mild hybrid system in some S58 variants demonstrates BMW's strategy to leverage electrification as a pathway to regulatory compliance.

Regulatory frameworks across different markets have created varying development priorities for the S58 engine. In the European Union, the focus has been primarily on reducing CO2 emissions, while the United States' EPA regulations have emphasized NOx and particulate matter reduction. This has resulted in market-specific tuning variations of the S58 engine, with European models featuring more aggressive start-stop systems and different catalyst formulations compared to their American counterparts.

The cost implications of meeting these regulations have been substantial. Engineering estimates suggest that compliance-related technologies account for approximately 15-20% of the S58 engine's development budget, compared to just 8-10% for the S55. This increased investment has been directed toward advanced materials in the exhaust system, more precise fuel injection systems, and enhanced thermal management solutions that optimize catalytic converter performance.

Looking forward, upcoming regulations will continue to shape engine development trajectories. The proposed Euro 7 standards and equivalent regulations in other markets will likely accelerate the integration of hybrid technologies into high-performance engines like the S58. BMW's development roadmap indicates plans for increased electrification of the S58 platform, potentially including plug-in hybrid variants that could further reduce emissions while maintaining the performance characteristics expected from M-series vehicles.

The regulatory landscape has also influenced BMW's competitive positioning, as different manufacturers have adopted varying approaches to compliance. While some competitors have moved toward smaller displacement turbocharged engines, BMW's approach with the S58 demonstrates a commitment to maintaining larger displacement engines with enhanced efficiency technologies, representing a distinctive strategy in the high-performance segment.

The S58 engine incorporates several key technologies specifically developed to meet these regulatory challenges while maintaining performance characteristics. The implementation of a more sophisticated particulate filter system and improved catalytic converters has enabled BMW to achieve a 35% reduction in NOx emissions compared to the S55 engine. Additionally, the integration of a 48-volt mild hybrid system in some S58 variants demonstrates BMW's strategy to leverage electrification as a pathway to regulatory compliance.

Regulatory frameworks across different markets have created varying development priorities for the S58 engine. In the European Union, the focus has been primarily on reducing CO2 emissions, while the United States' EPA regulations have emphasized NOx and particulate matter reduction. This has resulted in market-specific tuning variations of the S58 engine, with European models featuring more aggressive start-stop systems and different catalyst formulations compared to their American counterparts.

The cost implications of meeting these regulations have been substantial. Engineering estimates suggest that compliance-related technologies account for approximately 15-20% of the S58 engine's development budget, compared to just 8-10% for the S55. This increased investment has been directed toward advanced materials in the exhaust system, more precise fuel injection systems, and enhanced thermal management solutions that optimize catalytic converter performance.

Looking forward, upcoming regulations will continue to shape engine development trajectories. The proposed Euro 7 standards and equivalent regulations in other markets will likely accelerate the integration of hybrid technologies into high-performance engines like the S58. BMW's development roadmap indicates plans for increased electrification of the S58 platform, potentially including plug-in hybrid variants that could further reduce emissions while maintaining the performance characteristics expected from M-series vehicles.

The regulatory landscape has also influenced BMW's competitive positioning, as different manufacturers have adopted varying approaches to compliance. While some competitors have moved toward smaller displacement turbocharged engines, BMW's approach with the S58 demonstrates a commitment to maintaining larger displacement engines with enhanced efficiency technologies, representing a distinctive strategy in the high-performance segment.

Cost-Benefit Analysis of S58 vs S55 Implementation

When evaluating the implementation of BMW's S58 engine versus the older S55 model, a comprehensive cost-benefit analysis reveals significant economic considerations for both manufacturers and end users. The initial acquisition cost differential between vehicles equipped with these engines shows the S58 commanding a premium of approximately 8-12% over comparable S55 models, reflecting its newer technology and enhanced performance characteristics.

Manufacturing cost analysis indicates that the S58's more sophisticated emissions control systems, including improved particulate filters and enhanced catalytic converters, contribute to a 15% higher production cost compared to the S55. However, these upfront investments translate to measurable operational benefits over the vehicle lifecycle.

Fuel economy improvements in the S58 engine demonstrate a 7-9% reduction in consumption under standardized testing conditions, with real-world driving data suggesting savings of 5-8% depending on driving patterns. When projected across the average ownership period of 5-7 years, this efficiency gain represents a significant offset to the higher initial purchase price, particularly in regions with elevated fuel costs.

Maintenance cost projections favor the S58 design, with extended service intervals and improved component durability reducing scheduled maintenance expenses by approximately 12% over a 100,000-kilometer operational period. The redesigned cooling system and more robust turbocharger architecture in the S58 have demonstrated lower failure rates in preliminary reliability studies, potentially reducing unscheduled repair costs by 18-22% compared to the S55.

Residual value analysis suggests that vehicles equipped with the S58 engine maintain stronger depreciation resistance, retaining approximately 4-6% more value after three years compared to S55-equipped counterparts. This improved value retention partially offsets the higher initial acquisition cost when considering total cost of ownership calculations.

Environmental compliance costs represent another significant factor, with the S58's advanced emissions technology providing manufacturers with greater regulatory headroom as emissions standards continue to tighten globally. The estimated compliance cost avoidance ranges from €200-350 per unit in major markets, representing a substantial economic benefit when scaled across production volumes.

Return on investment calculations indicate that the break-even point for the additional cost of the S58 typically occurs between 60,000-80,000 kilometers of operation, depending on regional fuel prices and taxation structures. For high-mileage operators, the economic case for the S58 strengthens considerably, while those with limited annual driving may experience a longer payback period.

Manufacturing cost analysis indicates that the S58's more sophisticated emissions control systems, including improved particulate filters and enhanced catalytic converters, contribute to a 15% higher production cost compared to the S55. However, these upfront investments translate to measurable operational benefits over the vehicle lifecycle.

Fuel economy improvements in the S58 engine demonstrate a 7-9% reduction in consumption under standardized testing conditions, with real-world driving data suggesting savings of 5-8% depending on driving patterns. When projected across the average ownership period of 5-7 years, this efficiency gain represents a significant offset to the higher initial purchase price, particularly in regions with elevated fuel costs.

Maintenance cost projections favor the S58 design, with extended service intervals and improved component durability reducing scheduled maintenance expenses by approximately 12% over a 100,000-kilometer operational period. The redesigned cooling system and more robust turbocharger architecture in the S58 have demonstrated lower failure rates in preliminary reliability studies, potentially reducing unscheduled repair costs by 18-22% compared to the S55.

Residual value analysis suggests that vehicles equipped with the S58 engine maintain stronger depreciation resistance, retaining approximately 4-6% more value after three years compared to S55-equipped counterparts. This improved value retention partially offsets the higher initial acquisition cost when considering total cost of ownership calculations.

Environmental compliance costs represent another significant factor, with the S58's advanced emissions technology providing manufacturers with greater regulatory headroom as emissions standards continue to tighten globally. The estimated compliance cost avoidance ranges from €200-350 per unit in major markets, representing a substantial economic benefit when scaled across production volumes.

Return on investment calculations indicate that the break-even point for the additional cost of the S58 typically occurs between 60,000-80,000 kilometers of operation, depending on regional fuel prices and taxation structures. For high-mileage operators, the economic case for the S58 strengthens considerably, while those with limited annual driving may experience a longer payback period.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!