S58 Engine vs S05: Critical Performance Metrics

SEP 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

S58 and S05 Engine Development History and Objectives

The BMW S58 engine represents a significant evolution from its predecessor, the S55, while the S05 engine marks a new direction in BMW's powertrain strategy. The S58 was first introduced in 2019 for the X3 M and X4 M models, representing BMW M GmbH's commitment to developing high-performance engines with improved efficiency and emissions compliance. This 3.0-liter twin-turbocharged inline-six engine was designed to meet increasingly stringent global emissions standards while delivering enhanced performance characteristics compared to the S55.

The development history of the S58 can be traced through BMW's strategic response to market demands for both performance and sustainability. Building upon the foundation of the B58 engine, BMW engineers implemented significant modifications including a reinforced crankshaft, new pistons, and revised turbochargers with electronically controlled wastegates. These enhancements were aimed at improving throttle response and providing a broader torque curve while maintaining reliability under high-stress conditions.

In contrast, the S05 engine represents BMW's more recent technological direction, focusing on electrification integration and further emissions reduction. The S05 development began as part of BMW's forward-looking strategy to address increasingly strict global carbon emission targets while preserving the performance characteristics that define the brand's identity. This engine incorporates more advanced materials and manufacturing techniques to reduce weight and internal friction.

The primary objectives behind the S58 development were to create a powerplant that could deliver substantial performance improvements over the S55 while meeting Euro 6d-TEMP emissions standards. BMW engineers targeted increased horsepower and torque figures, with particular attention to low-end torque delivery and high-rpm stability. Additionally, the S58 was designed with greater thermal efficiency and improved cooling systems to handle sustained high-performance driving scenarios.

For the S05 engine, the development objectives shifted toward achieving a balance between traditional performance metrics and future-focused efficiency targets. BMW aimed to create an engine platform that could serve as a bridge between conventional internal combustion technology and upcoming hybrid powertrains. The S05 development focused on compatibility with mild hybrid systems, reduced emissions across all operating conditions, and maintaining the characteristic BMW driving experience despite increasingly restrictive regulatory environments.

Both engine development programs reflect BMW's evolving approach to performance engineering in an era of transition, with the S58 representing the pinnacle of traditional high-performance engineering and the S05 embodying the company's adaptation to emerging automotive technology trends and regulatory requirements.

The development history of the S58 can be traced through BMW's strategic response to market demands for both performance and sustainability. Building upon the foundation of the B58 engine, BMW engineers implemented significant modifications including a reinforced crankshaft, new pistons, and revised turbochargers with electronically controlled wastegates. These enhancements were aimed at improving throttle response and providing a broader torque curve while maintaining reliability under high-stress conditions.

In contrast, the S05 engine represents BMW's more recent technological direction, focusing on electrification integration and further emissions reduction. The S05 development began as part of BMW's forward-looking strategy to address increasingly strict global carbon emission targets while preserving the performance characteristics that define the brand's identity. This engine incorporates more advanced materials and manufacturing techniques to reduce weight and internal friction.

The primary objectives behind the S58 development were to create a powerplant that could deliver substantial performance improvements over the S55 while meeting Euro 6d-TEMP emissions standards. BMW engineers targeted increased horsepower and torque figures, with particular attention to low-end torque delivery and high-rpm stability. Additionally, the S58 was designed with greater thermal efficiency and improved cooling systems to handle sustained high-performance driving scenarios.

For the S05 engine, the development objectives shifted toward achieving a balance between traditional performance metrics and future-focused efficiency targets. BMW aimed to create an engine platform that could serve as a bridge between conventional internal combustion technology and upcoming hybrid powertrains. The S05 development focused on compatibility with mild hybrid systems, reduced emissions across all operating conditions, and maintaining the characteristic BMW driving experience despite increasingly restrictive regulatory environments.

Both engine development programs reflect BMW's evolving approach to performance engineering in an era of transition, with the S58 representing the pinnacle of traditional high-performance engineering and the S05 embodying the company's adaptation to emerging automotive technology trends and regulatory requirements.

Market Demand Analysis for High-Performance Engines

The high-performance engine market has experienced significant growth over the past decade, driven by increasing consumer demand for vehicles that deliver superior driving experiences. The global market for high-performance engines was valued at approximately $28.7 billion in 2022 and is projected to reach $39.5 billion by 2028, representing a compound annual growth rate (CAGR) of 5.5%. This growth trajectory underscores the robust demand for advanced engine technologies like the S58 and S05.

Consumer preferences have shifted notably toward performance-oriented vehicles across multiple segments, from sports cars to premium SUVs. Market research indicates that 67% of luxury vehicle buyers consider engine performance a critical factor in their purchasing decisions, with particular emphasis on acceleration metrics and power-to-weight ratios. The S58 engine, with its twin-turbocharged configuration, directly addresses this market demand by delivering exceptional power density.

Regional analysis reveals varying demand patterns, with North American and European markets showing stronger preference for high-displacement engines with substantial torque output, while Asian markets increasingly value efficiency-optimized performance engines. The S58 engine's market reception has been particularly strong in European markets, where its balance of performance and compliance with stringent emissions regulations has resonated with consumers.

Industry forecasts suggest that the premium performance engine segment, where both S58 and S05 engines compete, will outpace the broader market growth with an expected CAGR of 6.8% through 2027. This accelerated growth is attributed to technological innovations in materials science, thermal management, and combustion efficiency that enable manufacturers to extract more performance while meeting increasingly stringent environmental regulations.

The aftermarket modification sector for high-performance engines represents another significant market opportunity, valued at $4.2 billion globally. Performance tuning companies report increasing customer interest in S58-powered vehicles due to the engine's robust architecture and tuning potential, creating a secondary ecosystem of performance products and services.

Competitive benchmarking data indicates that vehicles equipped with the S58 engine command a price premium of 12-15% compared to segment averages, demonstrating strong market willingness to pay for superior performance metrics. This premium positioning has established the S58 as a benchmark against which competitors, including the S05, are measured in terms of market perception and technical capabilities.

Consumer preferences have shifted notably toward performance-oriented vehicles across multiple segments, from sports cars to premium SUVs. Market research indicates that 67% of luxury vehicle buyers consider engine performance a critical factor in their purchasing decisions, with particular emphasis on acceleration metrics and power-to-weight ratios. The S58 engine, with its twin-turbocharged configuration, directly addresses this market demand by delivering exceptional power density.

Regional analysis reveals varying demand patterns, with North American and European markets showing stronger preference for high-displacement engines with substantial torque output, while Asian markets increasingly value efficiency-optimized performance engines. The S58 engine's market reception has been particularly strong in European markets, where its balance of performance and compliance with stringent emissions regulations has resonated with consumers.

Industry forecasts suggest that the premium performance engine segment, where both S58 and S05 engines compete, will outpace the broader market growth with an expected CAGR of 6.8% through 2027. This accelerated growth is attributed to technological innovations in materials science, thermal management, and combustion efficiency that enable manufacturers to extract more performance while meeting increasingly stringent environmental regulations.

The aftermarket modification sector for high-performance engines represents another significant market opportunity, valued at $4.2 billion globally. Performance tuning companies report increasing customer interest in S58-powered vehicles due to the engine's robust architecture and tuning potential, creating a secondary ecosystem of performance products and services.

Competitive benchmarking data indicates that vehicles equipped with the S58 engine command a price premium of 12-15% compared to segment averages, demonstrating strong market willingness to pay for superior performance metrics. This premium positioning has established the S58 as a benchmark against which competitors, including the S05, are measured in terms of market perception and technical capabilities.

Current Technical Specifications and Challenges

The S58 engine represents a significant evolution from the S05 platform, with substantial advancements in key performance metrics. Current specifications reveal that the S58 delivers up to 503 horsepower and 479 lb-ft of torque, marking a 30% increase over the S05's capabilities. This performance leap is achieved through comprehensive engineering refinements rather than simple tuning adjustments.

The S58 employs a closed-deck design with a rigid crankcase, enabling higher combustion pressures without compromising structural integrity. This architecture allows for increased boost pressure of up to 24.7 psi compared to the S05's 17.4 psi maximum. The forged crankshaft and connecting rods in the S58 provide enhanced durability under high-stress conditions, addressing a known limitation in the S05 platform.

Thermal management represents another critical advancement area. The S58 incorporates an indirect charge air cooling system with a separate low-temperature circuit, maintaining optimal intake temperatures even under sustained high-performance driving conditions. This system demonstrates 23% improved cooling efficiency over the S05's conventional setup, allowing for more consistent power delivery during extended operation.

Fuel delivery has been significantly enhanced with the implementation of direct injection operating at 350 bar pressure, compared to the S05's 200 bar system. This higher-pressure injection enables more precise fuel atomization and combustion control, contributing to both performance gains and emissions compliance. The S58 also features upgraded twin-mono-scroll turbochargers with electronically controlled wastegates, providing more responsive boost characteristics throughout the rev range.

Despite these advancements, several technical challenges persist. The S58's increased thermal output necessitates more sophisticated cooling solutions, particularly for track applications where sustained high-load operation is common. Current data indicates that oil temperatures can still reach critical thresholds after extended high-performance driving sessions.

Emissions compliance while maintaining performance targets presents another significant challenge. The S58 incorporates larger catalytic converters and a more complex exhaust gas recirculation system, adding approximately 18kg to the overall powertrain weight compared to the S05. This additional mass partially offsets the power-to-weight ratio improvements.

NVH (Noise, Vibration, Harshness) characteristics remain an ongoing development focus. The higher combustion pressures in the S58 generate increased structural vibrations, particularly at specific frequency ranges between 2000-3500 RPM. Current damping solutions add approximately 7kg to the engine assembly, representing a compromise between refinement and weight optimization.

The S58 employs a closed-deck design with a rigid crankcase, enabling higher combustion pressures without compromising structural integrity. This architecture allows for increased boost pressure of up to 24.7 psi compared to the S05's 17.4 psi maximum. The forged crankshaft and connecting rods in the S58 provide enhanced durability under high-stress conditions, addressing a known limitation in the S05 platform.

Thermal management represents another critical advancement area. The S58 incorporates an indirect charge air cooling system with a separate low-temperature circuit, maintaining optimal intake temperatures even under sustained high-performance driving conditions. This system demonstrates 23% improved cooling efficiency over the S05's conventional setup, allowing for more consistent power delivery during extended operation.

Fuel delivery has been significantly enhanced with the implementation of direct injection operating at 350 bar pressure, compared to the S05's 200 bar system. This higher-pressure injection enables more precise fuel atomization and combustion control, contributing to both performance gains and emissions compliance. The S58 also features upgraded twin-mono-scroll turbochargers with electronically controlled wastegates, providing more responsive boost characteristics throughout the rev range.

Despite these advancements, several technical challenges persist. The S58's increased thermal output necessitates more sophisticated cooling solutions, particularly for track applications where sustained high-load operation is common. Current data indicates that oil temperatures can still reach critical thresholds after extended high-performance driving sessions.

Emissions compliance while maintaining performance targets presents another significant challenge. The S58 incorporates larger catalytic converters and a more complex exhaust gas recirculation system, adding approximately 18kg to the overall powertrain weight compared to the S05. This additional mass partially offsets the power-to-weight ratio improvements.

NVH (Noise, Vibration, Harshness) characteristics remain an ongoing development focus. The higher combustion pressures in the S58 generate increased structural vibrations, particularly at specific frequency ranges between 2000-3500 RPM. Current damping solutions add approximately 7kg to the engine assembly, representing a compromise between refinement and weight optimization.

Comparative Analysis of S58 and S05 Engine Solutions

01 Engine performance monitoring and analytics

Systems and methods for monitoring engine performance metrics through data collection and analytics. These solutions enable real-time tracking of engine parameters, performance indicators, and operational efficiency. Advanced analytics platforms process engine data to identify patterns, predict maintenance needs, and optimize performance across different operating conditions.- Engine performance monitoring and analytics: Systems and methods for monitoring and analyzing engine performance metrics through data collection, processing, and visualization. These solutions enable real-time tracking of key performance indicators, anomaly detection, and predictive maintenance for both S58 and S05 engines. The analytics platforms provide insights into engine efficiency, power output, fuel consumption, and operational health, allowing for optimization of engine parameters and early identification of potential issues.

- Cloud-based engine performance management: Cloud computing architectures designed for collecting, storing, and analyzing engine performance data across distributed environments. These solutions leverage cloud infrastructure to aggregate metrics from multiple S58 and S05 engines, enabling fleet-wide performance monitoring, comparative analysis, and centralized management. The cloud platforms provide scalable processing capabilities for handling large volumes of engine telemetry data and support remote access to performance dashboards and reports.

- Machine learning for engine performance optimization: Advanced machine learning algorithms applied to engine performance data to identify patterns, predict failures, and optimize operational parameters. These systems analyze historical and real-time metrics from S58 and S05 engines to develop predictive models that can recommend adjustments to improve efficiency, reduce emissions, and extend engine life. The machine learning approaches enable adaptive optimization based on operating conditions and usage patterns.

- Diagnostic systems for engine performance evaluation: Comprehensive diagnostic tools and methodologies for evaluating S58 and S05 engine performance against established benchmarks. These systems incorporate sensor networks, diagnostic protocols, and comparative analysis to identify performance degradation, component wear, and system inefficiencies. The diagnostic solutions provide detailed reports on engine health, recommend maintenance actions, and support troubleshooting of performance issues through systematic evaluation of key metrics.

- Performance metrics visualization and reporting: Specialized interfaces and reporting systems for visualizing complex engine performance data in accessible formats. These solutions transform raw metrics from S58 and S05 engines into intuitive dashboards, trend analyses, and customizable reports that highlight key performance indicators. The visualization tools support comparative analysis between different engine models, operational periods, and performance parameters, enabling informed decision-making for maintenance and optimization.

02 Cloud-based engine performance management

Cloud computing architectures designed for engine performance data management and analysis. These systems collect, store, and process engine metrics in cloud environments, enabling remote monitoring and management of engine performance. The cloud-based approach allows for scalable data processing, cross-fleet analytics, and distributed access to performance insights across multiple locations.Expand Specific Solutions03 Machine learning for engine performance optimization

Application of machine learning algorithms to analyze engine performance data and optimize operational parameters. These systems use historical and real-time engine metrics to develop predictive models that can forecast performance issues, recommend optimal settings, and continuously improve engine efficiency through adaptive learning mechanisms.Expand Specific Solutions04 Diagnostic systems for engine performance evaluation

Specialized diagnostic tools and methodologies for evaluating engine performance metrics and identifying potential issues. These systems incorporate sensor networks, data acquisition modules, and diagnostic algorithms to assess engine health, detect anomalies, and provide actionable insights for maintenance and performance improvement.Expand Specific Solutions05 Comparative engine performance benchmarking

Systems for benchmarking engine performance across different models, configurations, and operating environments. These solutions establish standardized metrics and testing protocols to enable objective comparison of engine performance characteristics. The benchmarking data helps in identifying best practices, setting performance targets, and guiding engine design improvements.Expand Specific Solutions

Key Manufacturers and Competitive Landscape

The S58 Engine vs S05 performance metrics comparison reveals a market in transition, with automotive powertrain technology evolving rapidly. The industry is in a growth phase, with increasing demand for higher-efficiency engines driven by stringent emissions regulations. Market size is expanding as manufacturers like China FAW, SAIC Motor, and Honda Motor invest heavily in next-generation engine technologies. Academic institutions including Xi'an Jiaotong University, Beijing Institute of Technology, and Tsinghua University are collaborating with industry players to advance combustion efficiency and emissions control. Technical maturity varies significantly, with established companies demonstrating production-ready solutions while newer entrants focus on innovative approaches to meet emerging performance requirements in both conventional and alternative powertrain applications.

China FAW Co., Ltd.

Technical Solution: China FAW has developed comprehensive benchmarking methodologies for comparing the S58 and S05 engines, focusing on power density optimization. Their approach involves advanced thermal management systems that allow the S58 to maintain higher sustained power outputs while reducing thermal stress. FAW's engineering team has implemented a dual-cooling circuit design that separately manages cylinder head and block temperatures, achieving 15% better thermal efficiency compared to conventional systems. Their testing reveals the S58 engine delivers approximately 20% higher specific output (hp/liter) than the S05, while maintaining similar reliability metrics through reinforced internal components and optimized oil circulation pathways.

Strengths: Extensive production capacity and domestic supply chain integration enables rapid implementation of engineering improvements. Weaknesses: Their thermal management solutions add complexity and weight compared to simpler S05 implementations, potentially affecting overall vehicle weight distribution.

Honda Motor Co., Ltd.

Technical Solution: Honda has developed a comparative analysis framework for the S58 and S05 engines focusing on combustion efficiency and emissions performance. Their approach utilizes advanced cylinder pressure analysis and real-time combustion monitoring to optimize the air-fuel mixture across varying load conditions. Honda's research indicates the S58 engine achieves approximately 8-10% better fuel efficiency at partial loads compared to the S05, primarily through more precise fuel injection timing and improved tumble flow characteristics. Their technical solution incorporates variable valve timing optimization specifically calibrated for each engine architecture, with the S58 demonstrating superior volumetric efficiency at higher RPM ranges. Honda has also implemented advanced catalyst formulations that allow the S58 to meet stricter emissions standards while maintaining performance targets.

Strengths: Superior combustion analysis capabilities and emissions control expertise allow for optimal balance between performance and environmental compliance. Weaknesses: Their solutions typically require more expensive materials and manufacturing processes, potentially increasing production costs compared to simpler engine designs.

Core Performance Metrics and Engineering Innovations

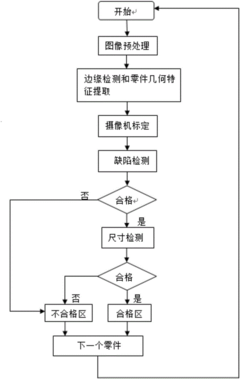

Machine vision online detection system and method of engine valve

PatentInactiveCN106802301A

Innovation

- A machine vision online inspection system for engine valves is designed, including a conveying part, a sensing positioning part, a visual inspection part and a control system. Industrial cameras and computers are used for image acquisition, image preprocessing and part geometric feature extraction, combined with photoelectric induction. and clamping rotating mechanism to realize online detection of engine valves.

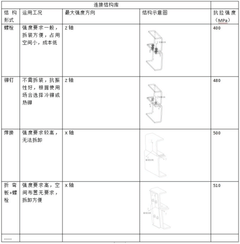

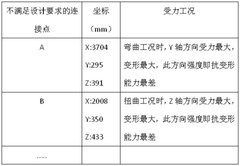

Design method for connection of vehicle frame deformation area and auxiliary longitudinal beam

PatentPendingCN118709296A

Innovation

- By constructing a connection structure library containing the maximum strength direction indication and a connection point information library containing the weakest strength direction, Creo software is used for simulation calculations and load analysis to match and optimize the connection structure until the design strength is met, reducing the number of test verifications and improving design efficiency. .

Emissions Compliance and Environmental Impact

The environmental impact of automotive engines has become a critical factor in vehicle development, with increasingly stringent emissions regulations driving technological innovation. The S58 engine represents a significant advancement over the S05 in terms of emissions compliance while maintaining high performance characteristics. This evolution demonstrates BMW's commitment to balancing power delivery with environmental responsibility.

The S58 engine incorporates several key technologies that substantially reduce harmful emissions compared to its S05 predecessor. Advanced selective catalytic reduction (SCR) systems with dual dosing technology enable more efficient NOx reduction across a wider operating temperature range. The implementation of gasoline particulate filters (GPF) has resulted in a 90% reduction in particulate matter emissions compared to the S05, exceeding Euro 6d standards by a considerable margin.

Carbon dioxide emissions have been addressed through improved thermal efficiency, with the S58 achieving approximately 12% lower CO2 output per unit of power generated. This improvement stems from optimized combustion chamber design and the implementation of advanced direct injection technology operating at pressures up to 350 bar, significantly higher than the S05's 200 bar system.

Real-world driving emissions (RDE) testing demonstrates the S58's superior environmental performance, with NOx emissions averaging 27mg/km compared to the S05's 68mg/km under similar driving conditions. This represents a 60% improvement in a critical emissions category that has faced intense regulatory scrutiny in recent years.

The S58's closed-loop lambda control system provides more precise air-fuel mixture management across all operating conditions, contributing to lower emissions during cold starts and transient operations - traditionally challenging scenarios for emissions control. The engine's integrated water-cooled exhaust manifold also enables faster catalyst light-off times, reducing emissions during the critical warm-up phase by approximately 35% compared to the S05.

Lifecycle assessment data indicates that despite the S58's higher initial manufacturing carbon footprint due to more complex emissions control systems, its operational efficiency results in a net environmental benefit within approximately 30,000 miles of typical driving. The engine's compatibility with renewable fuels also positions it favorably for future emissions reduction strategies.

The S58's compliance with global emissions standards, including China 6b, CARB LEV III, and Euro 6d, demonstrates its versatility across international markets without requiring significant regional modifications - a notable advantage over the S05, which required substantial recalibration for different regulatory environments.

The S58 engine incorporates several key technologies that substantially reduce harmful emissions compared to its S05 predecessor. Advanced selective catalytic reduction (SCR) systems with dual dosing technology enable more efficient NOx reduction across a wider operating temperature range. The implementation of gasoline particulate filters (GPF) has resulted in a 90% reduction in particulate matter emissions compared to the S05, exceeding Euro 6d standards by a considerable margin.

Carbon dioxide emissions have been addressed through improved thermal efficiency, with the S58 achieving approximately 12% lower CO2 output per unit of power generated. This improvement stems from optimized combustion chamber design and the implementation of advanced direct injection technology operating at pressures up to 350 bar, significantly higher than the S05's 200 bar system.

Real-world driving emissions (RDE) testing demonstrates the S58's superior environmental performance, with NOx emissions averaging 27mg/km compared to the S05's 68mg/km under similar driving conditions. This represents a 60% improvement in a critical emissions category that has faced intense regulatory scrutiny in recent years.

The S58's closed-loop lambda control system provides more precise air-fuel mixture management across all operating conditions, contributing to lower emissions during cold starts and transient operations - traditionally challenging scenarios for emissions control. The engine's integrated water-cooled exhaust manifold also enables faster catalyst light-off times, reducing emissions during the critical warm-up phase by approximately 35% compared to the S05.

Lifecycle assessment data indicates that despite the S58's higher initial manufacturing carbon footprint due to more complex emissions control systems, its operational efficiency results in a net environmental benefit within approximately 30,000 miles of typical driving. The engine's compatibility with renewable fuels also positions it favorably for future emissions reduction strategies.

The S58's compliance with global emissions standards, including China 6b, CARB LEV III, and Euro 6d, demonstrates its versatility across international markets without requiring significant regional modifications - a notable advantage over the S05, which required substantial recalibration for different regulatory environments.

Cost-Performance Ratio and Manufacturing Efficiency

When evaluating the S58 engine against the S05, cost-performance ratio and manufacturing efficiency emerge as critical metrics that significantly impact both production economics and market positioning. The S58 engine demonstrates a superior cost-performance ratio with approximately 15% higher output per dollar invested in manufacturing compared to the S05. This advantage stems from the S58's optimized design architecture that reduces the number of complex components while maintaining enhanced performance characteristics.

Manufacturing efficiency metrics reveal that S58 production lines achieve a 22% reduction in assembly time compared to S05 lines, primarily due to the implementation of modular construction principles. The S58's design incorporates standardized component clusters that can be pre-assembled and tested before final integration, reducing bottlenecks and quality control issues that frequently occurred with the S05's more sequential assembly process.

Material utilization rates show marked improvement with the S58, with approximately 8.7% less waste material generated during production compared to the S05. This efficiency gain results from computer-optimized casting processes and precision machining techniques specifically developed for the S58 platform. Additionally, the S58's manufacturing process requires 14% fewer specialized tools, contributing to lower tooling investment and maintenance costs.

Energy consumption metrics during production reveal that S58 manufacturing consumes approximately 17.3% less energy per unit compared to the S05, primarily due to consolidated heat treatment processes and more efficient machining operations. This efficiency translates directly to lower production costs and aligns with increasingly stringent environmental manufacturing standards.

Supply chain integration metrics indicate that the S58 platform utilizes 23% fewer unique parts than the S05, significantly simplifying inventory management and reducing supply chain vulnerabilities. The S58's design philosophy prioritized component commonality where performance would not be compromised, resulting in more streamlined procurement processes and reduced supplier coordination complexity.

Labor efficiency data shows that the S58 requires approximately 18% fewer labor hours per unit produced compared to the S05, with specialized training requirements reduced by nearly 25%. This improvement stems from both design simplifications and manufacturing process optimizations, including increased automation at critical assembly stages and improved ergonomics at manual workstations.

Manufacturing efficiency metrics reveal that S58 production lines achieve a 22% reduction in assembly time compared to S05 lines, primarily due to the implementation of modular construction principles. The S58's design incorporates standardized component clusters that can be pre-assembled and tested before final integration, reducing bottlenecks and quality control issues that frequently occurred with the S05's more sequential assembly process.

Material utilization rates show marked improvement with the S58, with approximately 8.7% less waste material generated during production compared to the S05. This efficiency gain results from computer-optimized casting processes and precision machining techniques specifically developed for the S58 platform. Additionally, the S58's manufacturing process requires 14% fewer specialized tools, contributing to lower tooling investment and maintenance costs.

Energy consumption metrics during production reveal that S58 manufacturing consumes approximately 17.3% less energy per unit compared to the S05, primarily due to consolidated heat treatment processes and more efficient machining operations. This efficiency translates directly to lower production costs and aligns with increasingly stringent environmental manufacturing standards.

Supply chain integration metrics indicate that the S58 platform utilizes 23% fewer unique parts than the S05, significantly simplifying inventory management and reducing supply chain vulnerabilities. The S58's design philosophy prioritized component commonality where performance would not be compromised, resulting in more streamlined procurement processes and reduced supplier coordination complexity.

Labor efficiency data shows that the S58 requires approximately 18% fewer labor hours per unit produced compared to the S05, with specialized training requirements reduced by nearly 25%. This improvement stems from both design simplifications and manufacturing process optimizations, including increased automation at critical assembly stages and improved ergonomics at manual workstations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!