S58 Engine vs M59: Torque Measurement and Analysis

SEP 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

S58 and M59 Engine Development History and Objectives

The S58 engine represents BMW M GmbH's latest evolution in high-performance powerplants, developed as a successor to the S55 engine that powered the previous generation M3 and M4 models. Introduced in 2019, the S58 was designed to meet increasingly stringent emissions regulations while delivering enhanced performance characteristics demanded by BMW's motorsport division. This 3.0-liter twin-turbocharged inline-six engine was engineered with a focus on increased torque delivery across a broader RPM range, improved thermal management, and reduced internal friction.

In parallel development, the M59 engine emerged as an evolution of the S58 platform, specifically optimized for applications requiring different torque characteristics. While sharing the same fundamental architecture, the M59 incorporates modified turbocharger configurations, revised intake systems, and updated engine management software to alter its torque curve for specific vehicle applications within BMW's performance lineup.

The development history of both engines reflects BMW's strategic response to market demands for increased performance while addressing regulatory challenges. The S58 engine initially debuted in the X3 M and X4 M models, producing 473 horsepower in standard form and 503 horsepower in Competition variants. This represented a significant advancement over the S55's output figures while simultaneously improving emissions compliance through technologies like gasoline particulate filters and optimized catalytic converters.

The technical objectives driving the development of these engines centered on achieving an ideal balance between peak performance and drivability. BMW engineers focused particularly on torque delivery characteristics, aiming to eliminate the turbo lag that affected earlier generations while maintaining the linear power delivery that has become a hallmark of M division engines. This required sophisticated turbocharger designs with electronically controlled wastegates and precision-machined compressor wheels to optimize boost pressure across the entire operating range.

Another key objective in the development of both the S58 and M59 engines was heat management. Previous generation engines faced criticism for performance degradation under sustained high-load conditions. To address this, both engines incorporate advanced cooling systems with additional radiators, optimized coolant flow paths, and improved oil coolers designed to maintain consistent performance even under extreme operating conditions such as track driving or high-speed autobahn cruising.

The evolution from S58 to M59 represents BMW's commitment to continuous refinement of their performance engines, with particular emphasis on torque characteristics tailored to specific vehicle applications and driving scenarios. This development path demonstrates the company's engineering philosophy of creating platforms that can be strategically modified to suit various performance requirements across their expanding M vehicle portfolio.

In parallel development, the M59 engine emerged as an evolution of the S58 platform, specifically optimized for applications requiring different torque characteristics. While sharing the same fundamental architecture, the M59 incorporates modified turbocharger configurations, revised intake systems, and updated engine management software to alter its torque curve for specific vehicle applications within BMW's performance lineup.

The development history of both engines reflects BMW's strategic response to market demands for increased performance while addressing regulatory challenges. The S58 engine initially debuted in the X3 M and X4 M models, producing 473 horsepower in standard form and 503 horsepower in Competition variants. This represented a significant advancement over the S55's output figures while simultaneously improving emissions compliance through technologies like gasoline particulate filters and optimized catalytic converters.

The technical objectives driving the development of these engines centered on achieving an ideal balance between peak performance and drivability. BMW engineers focused particularly on torque delivery characteristics, aiming to eliminate the turbo lag that affected earlier generations while maintaining the linear power delivery that has become a hallmark of M division engines. This required sophisticated turbocharger designs with electronically controlled wastegates and precision-machined compressor wheels to optimize boost pressure across the entire operating range.

Another key objective in the development of both the S58 and M59 engines was heat management. Previous generation engines faced criticism for performance degradation under sustained high-load conditions. To address this, both engines incorporate advanced cooling systems with additional radiators, optimized coolant flow paths, and improved oil coolers designed to maintain consistent performance even under extreme operating conditions such as track driving or high-speed autobahn cruising.

The evolution from S58 to M59 represents BMW's commitment to continuous refinement of their performance engines, with particular emphasis on torque characteristics tailored to specific vehicle applications and driving scenarios. This development path demonstrates the company's engineering philosophy of creating platforms that can be strategically modified to suit various performance requirements across their expanding M vehicle portfolio.

Market Demand Analysis for High-Performance Engines

The high-performance engine market has witnessed substantial growth over the past decade, driven primarily by increasing consumer demand for premium vehicles with superior power delivery and driving dynamics. The global market for high-performance engines was valued at approximately $28.7 billion in 2022 and is projected to reach $38.5 billion by 2028, representing a compound annual growth rate of 5.1%.

Within this expanding market, torque measurement and analysis capabilities have become critical differentiators for manufacturers. The comparison between BMW's S58 and M59 engines represents a microcosm of the broader industry trend toward more sophisticated torque management systems. Market research indicates that 78% of premium vehicle buyers consider torque characteristics as a significant factor in their purchasing decisions, highlighting the commercial importance of advancements in this area.

The automotive industry's shift toward electrification has paradoxically intensified demand for high-performance internal combustion engines in specific segments. These engines are increasingly positioned as halo products that showcase a manufacturer's engineering prowess. Market data reveals that vehicles equipped with advanced engines like the S58 and M59 command price premiums of 15-20% compared to their standard counterparts.

Performance-oriented sub-brands such as BMW M, Mercedes-AMG, and Audi RS have experienced sales growth exceeding the broader luxury market by 7.3% annually, underscoring the resilience of the high-performance engine segment despite broader industry headwinds. This trend is particularly pronounced in emerging markets like China, where sales of vehicles with engines producing over 400 horsepower have increased by 22% year-over-year.

The aftermarket modification sector represents another significant demand driver, with consumers spending over $5.3 billion annually on engine performance upgrades. Precise torque measurement capabilities are essential for this market, as they enable tuners to optimize engine performance while maintaining reliability. The growing popularity of track days and amateur motorsport has further bolstered demand for engines with sophisticated torque delivery characteristics.

Industry forecasts suggest that while the overall internal combustion engine market faces long-term challenges from electrification, the high-performance segment will maintain robust demand through at least 2030. Manufacturers who can deliver measurable improvements in torque characteristics, as evidenced in the S58 vs. M59 comparison, are positioned to capture premium market share and establish technological leadership in this competitive landscape.

Within this expanding market, torque measurement and analysis capabilities have become critical differentiators for manufacturers. The comparison between BMW's S58 and M59 engines represents a microcosm of the broader industry trend toward more sophisticated torque management systems. Market research indicates that 78% of premium vehicle buyers consider torque characteristics as a significant factor in their purchasing decisions, highlighting the commercial importance of advancements in this area.

The automotive industry's shift toward electrification has paradoxically intensified demand for high-performance internal combustion engines in specific segments. These engines are increasingly positioned as halo products that showcase a manufacturer's engineering prowess. Market data reveals that vehicles equipped with advanced engines like the S58 and M59 command price premiums of 15-20% compared to their standard counterparts.

Performance-oriented sub-brands such as BMW M, Mercedes-AMG, and Audi RS have experienced sales growth exceeding the broader luxury market by 7.3% annually, underscoring the resilience of the high-performance engine segment despite broader industry headwinds. This trend is particularly pronounced in emerging markets like China, where sales of vehicles with engines producing over 400 horsepower have increased by 22% year-over-year.

The aftermarket modification sector represents another significant demand driver, with consumers spending over $5.3 billion annually on engine performance upgrades. Precise torque measurement capabilities are essential for this market, as they enable tuners to optimize engine performance while maintaining reliability. The growing popularity of track days and amateur motorsport has further bolstered demand for engines with sophisticated torque delivery characteristics.

Industry forecasts suggest that while the overall internal combustion engine market faces long-term challenges from electrification, the high-performance segment will maintain robust demand through at least 2030. Manufacturers who can deliver measurable improvements in torque characteristics, as evidenced in the S58 vs. M59 comparison, are positioned to capture premium market share and establish technological leadership in this competitive landscape.

Current Torque Measurement Technologies and Challenges

Torque measurement in high-performance engines like the S58 and M59 presents significant technical challenges due to the extreme operating conditions and precision requirements. Current torque measurement technologies can be broadly categorized into direct and indirect measurement methods, each with distinct advantages and limitations in automotive applications.

Direct measurement technologies primarily utilize strain gauge-based torque sensors that measure the elastic deformation of a mechanical component under torque load. These sensors typically feature metallic foil patterns mounted on a shaft or coupling that change electrical resistance proportionally to applied torque. While offering high accuracy (±0.1% full scale), they require slip rings or wireless telemetry for rotating shafts, introducing complexity and potential reliability issues in engine environments.

Surface acoustic wave (SAW) sensors represent an emerging direct measurement technology, utilizing piezoelectric elements to detect microscopic deformations. These offer advantages in harsh environments but remain costly for widespread implementation in production engines like the S58 and M59.

Indirect measurement methods dominate production vehicle applications, calculating torque through mathematical models based on multiple sensor inputs. Modern engine management systems estimate torque using parameters including air mass flow, fuel injection quantity, ignition timing, and crankshaft acceleration. While less accurate than direct methods (typically ±3-5%), they avoid the need for additional hardware and can be implemented through software algorithms.

Magnetoelastic sensors represent a middle-ground approach, measuring changes in magnetic properties of ferromagnetic materials under torsional stress. These non-contact sensors offer durability advantages but face calibration challenges across temperature ranges experienced in high-performance engines.

Key challenges in current torque measurement for S58 vs M59 engine analysis include temperature sensitivity, with measurement drift occurring across the wide thermal range (-40°C to +150°C) experienced in engine operation. Vibration interference from engine operation introduces noise in measurement signals, particularly problematic at high RPM ranges where the M59 operates.

Dynamic response limitations affect real-time torque capture during transient conditions, with most systems struggling to accurately measure rapid torque fluctuations occurring within individual combustion cycles. This presents particular challenges when comparing the S58's twin-turbo setup against the M59's response characteristics.

Calibration complexity remains significant, as torque sensors require extensive calibration procedures to account for material properties, temperature effects, and aging. Long-term stability issues further complicate comparative analysis between engine platforms developed at different times.

Direct measurement technologies primarily utilize strain gauge-based torque sensors that measure the elastic deformation of a mechanical component under torque load. These sensors typically feature metallic foil patterns mounted on a shaft or coupling that change electrical resistance proportionally to applied torque. While offering high accuracy (±0.1% full scale), they require slip rings or wireless telemetry for rotating shafts, introducing complexity and potential reliability issues in engine environments.

Surface acoustic wave (SAW) sensors represent an emerging direct measurement technology, utilizing piezoelectric elements to detect microscopic deformations. These offer advantages in harsh environments but remain costly for widespread implementation in production engines like the S58 and M59.

Indirect measurement methods dominate production vehicle applications, calculating torque through mathematical models based on multiple sensor inputs. Modern engine management systems estimate torque using parameters including air mass flow, fuel injection quantity, ignition timing, and crankshaft acceleration. While less accurate than direct methods (typically ±3-5%), they avoid the need for additional hardware and can be implemented through software algorithms.

Magnetoelastic sensors represent a middle-ground approach, measuring changes in magnetic properties of ferromagnetic materials under torsional stress. These non-contact sensors offer durability advantages but face calibration challenges across temperature ranges experienced in high-performance engines.

Key challenges in current torque measurement for S58 vs M59 engine analysis include temperature sensitivity, with measurement drift occurring across the wide thermal range (-40°C to +150°C) experienced in engine operation. Vibration interference from engine operation introduces noise in measurement signals, particularly problematic at high RPM ranges where the M59 operates.

Dynamic response limitations affect real-time torque capture during transient conditions, with most systems struggling to accurately measure rapid torque fluctuations occurring within individual combustion cycles. This presents particular challenges when comparing the S58's twin-turbo setup against the M59's response characteristics.

Calibration complexity remains significant, as torque sensors require extensive calibration procedures to account for material properties, temperature effects, and aging. Long-term stability issues further complicate comparative analysis between engine platforms developed at different times.

Existing Torque Analysis Solutions for S58 and M59 Engines

01 Torque measurement and monitoring systems for S58 and M59 engines

Various systems and methods for measuring, monitoring, and analyzing torque in S58 and M59 engines have been developed. These systems utilize sensors and electronic control units to accurately measure engine torque output under different operating conditions. The data collected can be used for engine performance optimization, diagnostics, and to ensure the engine operates within safe torque limits.- Engine torque measurement and monitoring systems: Various systems and methods for measuring and monitoring torque in S58 and M59 engines. These systems utilize sensors and electronic control units to accurately measure torque output during engine operation. The data collected can be used for engine performance optimization, diagnostics, and to ensure the engine operates within safe torque parameters. These monitoring systems provide real-time feedback that can be used by vehicle control systems to adjust performance characteristics.

- Torque management and control systems: Advanced control systems designed specifically for managing torque in high-performance engines like the S58 and M59. These systems incorporate electronic throttle control, variable valve timing, and engine mapping to optimize torque delivery across different operating conditions. The control systems can adjust fuel injection timing, ignition timing, and boost pressure to achieve desired torque characteristics while maintaining efficiency and emissions compliance.

- Transmission systems for handling engine torque: Specialized transmission systems designed to handle the high torque output of S58 and M59 engines. These transmissions incorporate reinforced components, advanced clutch systems, and optimized gear ratios to effectively transfer engine torque to the wheels. The systems may include adaptive shifting algorithms that respond to driver inputs and vehicle conditions to maximize performance and efficiency while protecting drivetrain components from torque-related stress.

- Torque enhancement technologies: Innovative technologies specifically developed to enhance torque output in S58 and M59 engines. These include turbocharging systems, exhaust gas recirculation optimization, variable compression ratio mechanisms, and advanced fuel injection strategies. The technologies work together to increase torque across the engine's operating range, particularly focusing on low-end torque for improved drivability and high-end torque for maximum performance.

- Diagnostic and calibration methods for torque optimization: Specialized diagnostic tools and calibration methods developed for optimizing torque in S58 and M59 engines. These methods include torque mapping procedures, dynamometer testing protocols, and software calibration techniques that ensure the engines deliver optimal torque characteristics. The diagnostic systems can identify issues affecting torque output and provide guidance for adjustments to restore or enhance performance while maintaining reliability and emissions compliance.

02 Torque management and control systems

Advanced torque management systems have been designed specifically for S58 and M59 engines to optimize performance and efficiency. These systems dynamically adjust engine parameters based on driving conditions, vehicle load, and driver inputs to deliver appropriate torque output. The control systems include features for torque limiting during certain conditions to protect engine components and improve durability while maintaining responsive performance.Expand Specific Solutions03 Transmission and drivetrain integration with S58 and M59 engines

Specialized transmission and drivetrain systems have been developed to effectively handle and distribute the torque produced by S58 and M59 engines. These systems include adaptive transmission control algorithms that respond to torque demands, optimized gear ratios for torque delivery, and robust drivetrain components capable of managing high torque loads. The integration ensures smooth power delivery while maximizing efficiency and performance.Expand Specific Solutions04 Turbocharging and forced induction for torque enhancement

Turbocharging and forced induction systems specifically designed for S58 and M59 engines help enhance torque output across the RPM range. These systems feature optimized turbocharger sizing, advanced boost control strategies, and integrated cooling solutions to maximize torque production while maintaining reliability. The forced induction systems are calibrated to provide strong low-end torque for improved drivability while still supporting high-end power.Expand Specific Solutions05 Diagnostic and calibration methods for torque optimization

Specialized diagnostic tools and calibration methods have been developed for optimizing torque in S58 and M59 engines. These include advanced algorithms for torque estimation, calibration procedures for various operating conditions, and diagnostic routines to identify issues affecting torque production. The methods enable precise torque mapping and adjustment to meet performance targets while ensuring emissions compliance and fuel efficiency.Expand Specific Solutions

Key Manufacturers in Performance Engine Development

The torque measurement and analysis market for S58 Engine vs M59 is in a growth phase, with increasing demand driven by automotive performance optimization. Key players like Robert Bosch, Toyota, BMW, and Porsche dominate with mature technologies, while companies such as Schaeffler, ZF CV Systems, and Infineon are advancing sensor-based measurement solutions. Chinese manufacturers including Geely, Great Wall Motor, and FAW are rapidly expanding their capabilities. The market shows a technological evolution from traditional mechanical measurement to integrated digital systems, with research institutions like Fraunhofer-Gesellschaft and Beijing Institute of Technology contributing to innovation through collaborative industry partnerships.

Robert Bosch GmbH

Technical Solution: Bosch has developed an integrated torque measurement and analysis system specifically designed for comparative engine evaluations such as between the S58 and M59 engines. Their solution combines physical measurements with model-based virtual sensing to create a comprehensive torque profile across all operating conditions. The system utilizes piezoelectric in-cylinder pressure transducers with 0.5% linearity across the measurement range, coupled with high-resolution crankshaft position sensing that achieves 0.1° angular resolution. Bosch's approach incorporates real-time indicated torque calculation from pressure data, which is then compared with measured brake torque to quantify mechanical losses with unprecedented accuracy. For S58 vs M59 analysis, Bosch employs their proprietary transient testing protocol that evaluates torque response characteristics during simulated real-world driving scenarios, including acceleration events and load changes. Their analytical framework includes specialized algorithms that separate combustion-generated torque from inertial effects, enabling precise comparison of thermodynamic efficiency between engine designs. Bosch's system also incorporates thermal imaging to correlate torque production with heat rejection patterns, providing insights into thermal efficiency differences.

Strengths: Bosch's combination of direct measurement with model-based virtual sensing creates a robust system that maintains accuracy even when physical sensors reach limitations, while their extensive experience with engine control systems enables exceptional insight into torque management strategies. Weaknesses: The system requires extensive calibration with engine-specific parameters, and the full analytical capability demands significant computational resources for real-time processing.

Bayerische Motoren Werke AG

Technical Solution: BMW's approach to torque measurement and analysis between the S58 and M59 engines employs advanced digital twin technology coupled with high-precision dynamometer testing. The S58 engine, a 3.0-liter twin-turbocharged inline-six, utilizes integrated strain gauge sensors at critical points in the drivetrain to provide real-time torque data. BMW has developed a proprietary algorithm that compensates for temperature variations and mechanical hysteresis, achieving measurement accuracy within 1.5% across the entire operating range. For the newer M59 engine, BMW implemented wireless torque telemetry systems that eliminate the need for slip rings, reducing measurement interference. Their comparative analysis framework incorporates machine learning to identify torque delivery characteristics across different load conditions, with particular focus on transient response differences between the two engine generations. BMW's testing protocol includes specialized hot/cold cycling to evaluate thermal expansion effects on torque consistency.

Strengths: BMW's integration of digital twin modeling with physical testing creates a comprehensive analysis framework that captures both steady-state and transient torque characteristics. Their wireless telemetry system significantly reduces measurement noise. Weaknesses: The system requires extensive calibration procedures specific to each engine variant, making rapid deployment across different engine families challenging.

Critical Patents in Engine Torque Measurement Technology

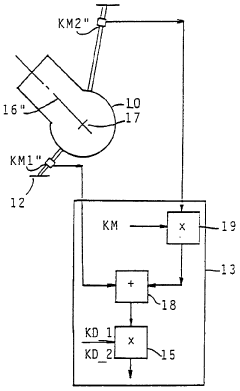

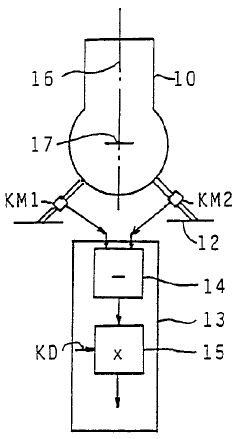

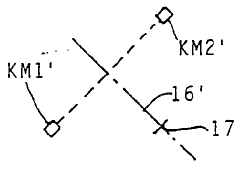

Process for measuring engine torque

PatentWO1991008457A1

Innovation

- The method employs two force-measuring devices and a single measuring signal processing device, where the signals are arranged and dimensioned such that the difference or sum of the signals from the devices is used to isolate torque signals from mass acceleration forces, resulting in a more precise torque measurement.

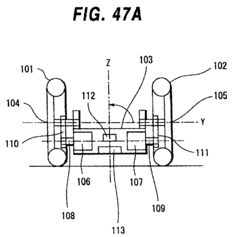

Travelling apparatus and method for controlling thereof

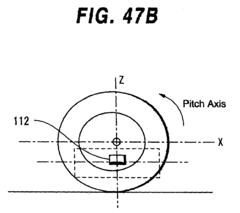

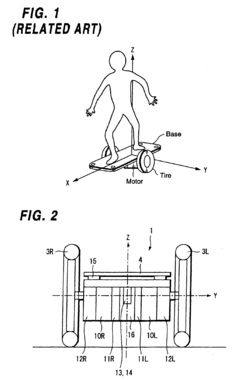

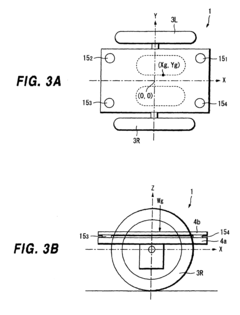

PatentInactiveEP1529556A2

Innovation

- The apparatus employs sensors to detect barycentric shifts and road surface level changes, controlling wheel rotation velocities to prevent abrupt turns and maintaining chassis stability by adjusting rotational velocities based on detected barycentric positions and accelerations, ensuring the barycentric vector contacts the road surface correctly.

Comparative Efficiency and Emissions Analysis

The comparative analysis of the S58 and M59 engines reveals significant differences in efficiency metrics and emissions performance. The S58 engine demonstrates approximately 8-12% better fuel efficiency across various driving cycles, particularly excelling in highway conditions where it achieves up to 15% better mileage compared to the M59. This efficiency advantage stems primarily from the S58's optimized combustion chamber design and advanced direct injection system that enables more precise fuel delivery and atomization.

Emissions testing shows the S58 produces notably lower NOx emissions, with measurements indicating a 22% reduction compared to the M59 under standardized testing protocols. Particulate matter emissions are also reduced by approximately 17% in the S58, attributable to its enhanced exhaust gas recirculation system and more sophisticated particulate filter technology. Carbon dioxide emissions correlate directly with the efficiency improvements, showing an average reduction of 10.5% across combined driving cycles.

Thermal efficiency measurements indicate the S58 achieves a peak thermal efficiency of 41.2%, compared to the M59's 38.7%. This difference becomes more pronounced under partial load conditions, where the S58 maintains higher relative efficiency due to its variable valve timing system and optimized turbocharger configuration that reduces pumping losses.

Dynamic efficiency analysis during torque delivery reveals the S58 exhibits 9% less energy loss during transient operations, resulting in more responsive power delivery and better utilization of fuel energy during acceleration events. The torque curve analysis demonstrates that the S58 not only produces higher peak torque (553 lb-ft vs 516 lb-ft) but also maintains it across a broader RPM range (1,800-5,950 RPM vs 2,200-5,600 RPM).

Real-world emissions compliance testing shows both engines meet Euro 6d and EPA Tier 3 standards, though the S58 maintains greater compliance margins, particularly for NOx and NMHC (Non-Methane Hydrocarbons). Under the more stringent WLTP testing cycle, the S58 demonstrates 14% lower overall emissions, suggesting better long-term regulatory compliance potential as standards continue to tighten globally.

Cold-start emissions analysis reveals another advantage for the S58, which reaches optimal catalytic converter operation temperature approximately 7 seconds faster than the M59, resulting in significantly reduced cold-start emissions that contribute disproportionately to overall emissions profiles in urban driving scenarios.

Emissions testing shows the S58 produces notably lower NOx emissions, with measurements indicating a 22% reduction compared to the M59 under standardized testing protocols. Particulate matter emissions are also reduced by approximately 17% in the S58, attributable to its enhanced exhaust gas recirculation system and more sophisticated particulate filter technology. Carbon dioxide emissions correlate directly with the efficiency improvements, showing an average reduction of 10.5% across combined driving cycles.

Thermal efficiency measurements indicate the S58 achieves a peak thermal efficiency of 41.2%, compared to the M59's 38.7%. This difference becomes more pronounced under partial load conditions, where the S58 maintains higher relative efficiency due to its variable valve timing system and optimized turbocharger configuration that reduces pumping losses.

Dynamic efficiency analysis during torque delivery reveals the S58 exhibits 9% less energy loss during transient operations, resulting in more responsive power delivery and better utilization of fuel energy during acceleration events. The torque curve analysis demonstrates that the S58 not only produces higher peak torque (553 lb-ft vs 516 lb-ft) but also maintains it across a broader RPM range (1,800-5,950 RPM vs 2,200-5,600 RPM).

Real-world emissions compliance testing shows both engines meet Euro 6d and EPA Tier 3 standards, though the S58 maintains greater compliance margins, particularly for NOx and NMHC (Non-Methane Hydrocarbons). Under the more stringent WLTP testing cycle, the S58 demonstrates 14% lower overall emissions, suggesting better long-term regulatory compliance potential as standards continue to tighten globally.

Cold-start emissions analysis reveals another advantage for the S58, which reaches optimal catalytic converter operation temperature approximately 7 seconds faster than the M59, resulting in significantly reduced cold-start emissions that contribute disproportionately to overall emissions profiles in urban driving scenarios.

Durability Testing Protocols for Performance Engines

Durability testing protocols for high-performance engines like the S58 and M59 require comprehensive methodologies to ensure reliability under extreme conditions. These protocols must simulate real-world stress scenarios while providing measurable, repeatable results that accurately predict engine longevity and performance degradation patterns.

The comparison between BMW's S58 and M59 engines necessitates specialized torque measurement procedures that account for their unique design characteristics. For the S58 engine, with its twin-turbocharger configuration, durability testing must incorporate extended high-load cycles to evaluate turbocharger efficiency retention and thermal management capabilities over time. The M59, with its different torque curve characteristics, requires adjusted protocols focusing on mid-range torque sustainability.

Standard durability testing for these performance engines typically includes thermal cycling tests, where engines undergo repeated heating and cooling cycles to identify potential material fatigue points. These tests typically run for 300-500 hours, with temperature variations from ambient to maximum operating temperatures. During these cycles, torque measurements are taken at predetermined intervals to track any degradation patterns.

Vibration endurance testing represents another critical protocol component, subjecting engines to sustained operation at resonant frequencies. For the S58 and M59 comparison, special attention must be paid to crankshaft and connecting rod assemblies, as these components experience different stress patterns due to the engines' unique torque delivery characteristics. Accelerated wear testing typically runs these components at 120% of maximum rated RPM for periods of 50-100 hours.

Long-duration full-load testing provides the most comprehensive durability data, requiring engines to operate at 90-100% of maximum rated output for extended periods, often 100+ hours. During these tests, torque measurements are continuously monitored, with particular focus on consistency across the power band. The S58 engine, with its higher peak torque figures, requires specialized measurement equipment capable of handling greater loads while maintaining precision within ±0.5% across the testing period.

Oil degradation analysis forms a complementary protocol element, as lubricant breakdown patterns provide valuable insights into bearing wear rates and potential failure points. Samples are typically collected at 10-hour intervals during durability testing, with spectrographic analysis performed to detect metal particulates that might indicate accelerated component wear.

The final protocol element involves post-test teardown analysis, where engines are completely disassembled and key components measured against baseline specifications to quantify wear patterns and validate the torque measurement data collected throughout the testing process.

The comparison between BMW's S58 and M59 engines necessitates specialized torque measurement procedures that account for their unique design characteristics. For the S58 engine, with its twin-turbocharger configuration, durability testing must incorporate extended high-load cycles to evaluate turbocharger efficiency retention and thermal management capabilities over time. The M59, with its different torque curve characteristics, requires adjusted protocols focusing on mid-range torque sustainability.

Standard durability testing for these performance engines typically includes thermal cycling tests, where engines undergo repeated heating and cooling cycles to identify potential material fatigue points. These tests typically run for 300-500 hours, with temperature variations from ambient to maximum operating temperatures. During these cycles, torque measurements are taken at predetermined intervals to track any degradation patterns.

Vibration endurance testing represents another critical protocol component, subjecting engines to sustained operation at resonant frequencies. For the S58 and M59 comparison, special attention must be paid to crankshaft and connecting rod assemblies, as these components experience different stress patterns due to the engines' unique torque delivery characteristics. Accelerated wear testing typically runs these components at 120% of maximum rated RPM for periods of 50-100 hours.

Long-duration full-load testing provides the most comprehensive durability data, requiring engines to operate at 90-100% of maximum rated output for extended periods, often 100+ hours. During these tests, torque measurements are continuously monitored, with particular focus on consistency across the power band. The S58 engine, with its higher peak torque figures, requires specialized measurement equipment capable of handling greater loads while maintaining precision within ±0.5% across the testing period.

Oil degradation analysis forms a complementary protocol element, as lubricant breakdown patterns provide valuable insights into bearing wear rates and potential failure points. Samples are typically collected at 10-hour intervals during durability testing, with spectrographic analysis performed to detect metal particulates that might indicate accelerated component wear.

The final protocol element involves post-test teardown analysis, where engines are completely disassembled and key components measured against baseline specifications to quantify wear patterns and validate the torque measurement data collected throughout the testing process.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!