Measure Thermal Efficiency of S58 Engine for Hybrid Vehicles

SEP 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

S58 Engine Thermal Efficiency Background and Objectives

The S58 engine represents a significant evolution in BMW's engine technology, specifically designed for high-performance applications while meeting increasingly stringent emissions regulations. Developed as a successor to the S55 engine, the S58 is a 3.0-liter twin-turbocharged inline-six engine that first appeared in the X3 M and X4 M models before being implemented across BMW's M performance lineup. The historical development of this engine reflects the automotive industry's broader shift toward balancing performance with efficiency.

Over the past decade, thermal efficiency has become a critical focus in internal combustion engine development, with manufacturers striving to extract maximum energy from fuel while minimizing waste heat. Traditional gasoline engines typically achieve thermal efficiency rates of 20-30%, with substantial energy lost as heat through exhaust gases and cooling systems. The S58 engine represents BMW's efforts to push these boundaries, with reported thermal efficiency approaching 35-37% in certain operating conditions.

The integration of the S58 engine into hybrid vehicle architectures presents both opportunities and challenges. Hybrid powertrains allow for optimization of engine operating points, potentially enabling the S58 to run more frequently at its peak efficiency range. However, this integration requires sophisticated thermal management systems that can balance the heat generation from both the combustion engine and electrical components.

The primary technical objective of measuring the S58 engine's thermal efficiency in hybrid applications is to establish accurate baseline performance metrics that can inform future development. This includes quantifying the engine's efficiency across various load conditions specific to hybrid operation, identifying thermal bottlenecks, and understanding the interaction between the combustion engine and electric powertrain components from a thermal perspective.

Additionally, this research aims to develop standardized methodologies for thermal efficiency measurement that account for the unique operating characteristics of performance engines in hybrid configurations. Current industry standards for thermal efficiency measurement are primarily designed for conventional powertrains and may not fully capture the complexity of hybrid operation cycles.

From a strategic perspective, optimizing the thermal efficiency of the S58 engine in hybrid applications aligns with global automotive trends toward electrification while preserving the distinctive performance characteristics that define BMW's M division products. The findings from this research will inform not only immediate product development but also longer-term powertrain strategies as the industry navigates the transition toward increasingly electrified vehicle architectures.

Over the past decade, thermal efficiency has become a critical focus in internal combustion engine development, with manufacturers striving to extract maximum energy from fuel while minimizing waste heat. Traditional gasoline engines typically achieve thermal efficiency rates of 20-30%, with substantial energy lost as heat through exhaust gases and cooling systems. The S58 engine represents BMW's efforts to push these boundaries, with reported thermal efficiency approaching 35-37% in certain operating conditions.

The integration of the S58 engine into hybrid vehicle architectures presents both opportunities and challenges. Hybrid powertrains allow for optimization of engine operating points, potentially enabling the S58 to run more frequently at its peak efficiency range. However, this integration requires sophisticated thermal management systems that can balance the heat generation from both the combustion engine and electrical components.

The primary technical objective of measuring the S58 engine's thermal efficiency in hybrid applications is to establish accurate baseline performance metrics that can inform future development. This includes quantifying the engine's efficiency across various load conditions specific to hybrid operation, identifying thermal bottlenecks, and understanding the interaction between the combustion engine and electric powertrain components from a thermal perspective.

Additionally, this research aims to develop standardized methodologies for thermal efficiency measurement that account for the unique operating characteristics of performance engines in hybrid configurations. Current industry standards for thermal efficiency measurement are primarily designed for conventional powertrains and may not fully capture the complexity of hybrid operation cycles.

From a strategic perspective, optimizing the thermal efficiency of the S58 engine in hybrid applications aligns with global automotive trends toward electrification while preserving the distinctive performance characteristics that define BMW's M division products. The findings from this research will inform not only immediate product development but also longer-term powertrain strategies as the industry navigates the transition toward increasingly electrified vehicle architectures.

Market Analysis for High-Efficiency Hybrid Powertrains

The hybrid vehicle market has experienced significant growth over the past decade, driven by increasing environmental concerns, government regulations, and consumer demand for fuel-efficient vehicles. The global hybrid vehicle market was valued at approximately 27.2 billion USD in 2022 and is projected to reach 57.9 billion USD by 2030, growing at a CAGR of 9.8% during the forecast period. This growth trajectory presents substantial opportunities for high-efficiency powertrains like the S58 engine.

Consumer preferences are shifting toward vehicles that offer improved fuel economy without compromising performance. Market research indicates that 68% of consumers consider fuel efficiency as a "very important" factor when purchasing a new vehicle, while 42% specifically look for hybrid options. This trend is particularly pronounced in urban areas and regions with stringent emission regulations.

The competitive landscape for hybrid powertrains is intensifying, with major automotive manufacturers investing heavily in research and development. BMW's S58 engine positions itself in the premium segment, where thermal efficiency improvements directly translate to market differentiation. Competitors like Toyota, Honda, and Mercedes-Benz have achieved thermal efficiencies ranging from 38% to 41% in their latest hybrid systems, establishing a benchmark for the industry.

Regional market analysis reveals varying adoption rates for hybrid vehicles. Europe leads with a 25% market share of new vehicle sales being hybrids, followed by Asia-Pacific at 22% and North America at 17%. These regions also implement the strictest emission standards, creating natural markets for high-efficiency powertrains like the S58 engine for hybrid applications.

Fleet operators represent another significant market segment, with commercial fleets increasingly adopting hybrid vehicles to reduce operational costs. Total cost of ownership calculations demonstrate that high-efficiency hybrid powertrains can deliver 15-20% savings over a five-year period compared to conventional powertrains, despite higher initial acquisition costs.

Market forecasts indicate that performance-oriented hybrid vehicles, where the S58 engine would be positioned, will grow at 12.3% annually through 2028, outpacing the broader hybrid market. This premium segment values thermal efficiency not only for environmental benefits but also for performance advantages, as improved thermal efficiency translates to better power delivery and responsiveness.

Consumer willingness to pay for efficiency improvements suggests that a 1% increase in thermal efficiency can command a 0.8-1.2% price premium in luxury hybrid vehicles, creating a direct economic incentive for thermal efficiency optimization in engines like the S58.

Consumer preferences are shifting toward vehicles that offer improved fuel economy without compromising performance. Market research indicates that 68% of consumers consider fuel efficiency as a "very important" factor when purchasing a new vehicle, while 42% specifically look for hybrid options. This trend is particularly pronounced in urban areas and regions with stringent emission regulations.

The competitive landscape for hybrid powertrains is intensifying, with major automotive manufacturers investing heavily in research and development. BMW's S58 engine positions itself in the premium segment, where thermal efficiency improvements directly translate to market differentiation. Competitors like Toyota, Honda, and Mercedes-Benz have achieved thermal efficiencies ranging from 38% to 41% in their latest hybrid systems, establishing a benchmark for the industry.

Regional market analysis reveals varying adoption rates for hybrid vehicles. Europe leads with a 25% market share of new vehicle sales being hybrids, followed by Asia-Pacific at 22% and North America at 17%. These regions also implement the strictest emission standards, creating natural markets for high-efficiency powertrains like the S58 engine for hybrid applications.

Fleet operators represent another significant market segment, with commercial fleets increasingly adopting hybrid vehicles to reduce operational costs. Total cost of ownership calculations demonstrate that high-efficiency hybrid powertrains can deliver 15-20% savings over a five-year period compared to conventional powertrains, despite higher initial acquisition costs.

Market forecasts indicate that performance-oriented hybrid vehicles, where the S58 engine would be positioned, will grow at 12.3% annually through 2028, outpacing the broader hybrid market. This premium segment values thermal efficiency not only for environmental benefits but also for performance advantages, as improved thermal efficiency translates to better power delivery and responsiveness.

Consumer willingness to pay for efficiency improvements suggests that a 1% increase in thermal efficiency can command a 0.8-1.2% price premium in luxury hybrid vehicles, creating a direct economic incentive for thermal efficiency optimization in engines like the S58.

Current Thermal Efficiency Challenges in S58 Engine

The S58 engine, BMW's high-performance 3.0-liter twin-turbocharged inline-six engine, faces several significant thermal efficiency challenges when integrated into hybrid vehicle systems. Current thermal efficiency measurements indicate that the S58 operates at approximately 38-40% thermal efficiency under optimal conditions, which falls short of the theoretical maximum and the benchmarks set by leading hybrid powertrains in the market.

One primary challenge is heat management during the transition between combustion and electric power modes. The frequent switching between power sources in hybrid operation creates thermal cycling that affects engine temperature stability. This temperature fluctuation reduces overall thermal efficiency by up to 3-5% compared to steady-state operation, particularly during cold starts and low-load conditions when the electric motor is primarily engaged.

The integration of exhaust heat recovery systems presents another significant challenge. While the S58 engine generates substantial exhaust heat that could potentially be recovered to improve overall system efficiency, the current implementation of heat recovery technologies remains suboptimal. Measurements show that only about 30-35% of available exhaust heat energy is effectively captured and repurposed, leaving significant room for improvement.

Friction losses within the engine also contribute to thermal efficiency challenges. Despite advanced coating technologies and improved lubricants, the S58 engine still experiences approximately 10-12% energy loss due to friction under typical hybrid operating conditions. These losses are particularly pronounced during the frequent transitions between power sources characteristic of hybrid operation.

Cooling system limitations further compound thermal efficiency issues. The current cooling architecture struggles to maintain optimal temperature profiles across all engine components during varied hybrid operation modes. Temperature differentials of up to 15°C have been measured across critical engine components during mode transitions, leading to thermal stress and efficiency losses.

Turbocharger heat management represents another critical challenge. The twin-turbo configuration of the S58 engine creates complex thermal dynamics, particularly when operating in conjunction with hybrid electric systems. Measurements indicate that turbocharger efficiency drops by approximately 8-10% during rapid load changes common in hybrid operation, directly impacting overall thermal efficiency.

Finally, calibration challenges between the engine management system and hybrid control unit create inefficiencies in combustion timing and air-fuel mixture optimization. Current calibration approaches struggle to maintain optimal combustion parameters across the wide range of operating conditions experienced in hybrid applications, resulting in combustion efficiency penalties of 2-4% compared to optimized steady-state operation.

One primary challenge is heat management during the transition between combustion and electric power modes. The frequent switching between power sources in hybrid operation creates thermal cycling that affects engine temperature stability. This temperature fluctuation reduces overall thermal efficiency by up to 3-5% compared to steady-state operation, particularly during cold starts and low-load conditions when the electric motor is primarily engaged.

The integration of exhaust heat recovery systems presents another significant challenge. While the S58 engine generates substantial exhaust heat that could potentially be recovered to improve overall system efficiency, the current implementation of heat recovery technologies remains suboptimal. Measurements show that only about 30-35% of available exhaust heat energy is effectively captured and repurposed, leaving significant room for improvement.

Friction losses within the engine also contribute to thermal efficiency challenges. Despite advanced coating technologies and improved lubricants, the S58 engine still experiences approximately 10-12% energy loss due to friction under typical hybrid operating conditions. These losses are particularly pronounced during the frequent transitions between power sources characteristic of hybrid operation.

Cooling system limitations further compound thermal efficiency issues. The current cooling architecture struggles to maintain optimal temperature profiles across all engine components during varied hybrid operation modes. Temperature differentials of up to 15°C have been measured across critical engine components during mode transitions, leading to thermal stress and efficiency losses.

Turbocharger heat management represents another critical challenge. The twin-turbo configuration of the S58 engine creates complex thermal dynamics, particularly when operating in conjunction with hybrid electric systems. Measurements indicate that turbocharger efficiency drops by approximately 8-10% during rapid load changes common in hybrid operation, directly impacting overall thermal efficiency.

Finally, calibration challenges between the engine management system and hybrid control unit create inefficiencies in combustion timing and air-fuel mixture optimization. Current calibration approaches struggle to maintain optimal combustion parameters across the wide range of operating conditions experienced in hybrid applications, resulting in combustion efficiency penalties of 2-4% compared to optimized steady-state operation.

Existing Thermal Efficiency Measurement Methodologies

01 Advanced combustion strategies for S58 engine efficiency

Various combustion strategies are employed in S58 engines to enhance thermal efficiency. These include optimized fuel injection timing, improved air-fuel mixture formation, and advanced combustion chamber designs. By controlling the combustion process more precisely, these strategies reduce energy losses and increase the conversion of fuel energy into useful work, thereby improving the overall thermal efficiency of the engine.- Advanced combustion strategies for S58 engines: Various combustion strategies are employed in S58 engines to improve thermal efficiency. These include optimized fuel injection timing, enhanced air-fuel mixture formation, and controlled combustion phasing. By implementing these strategies, the combustion process becomes more complete, reducing energy losses and increasing the thermal efficiency of the engine. Advanced combustion control systems monitor and adjust parameters in real-time to maintain optimal efficiency across different operating conditions.

- Waste heat recovery systems for thermal efficiency improvement: Waste heat recovery systems capture and utilize thermal energy that would otherwise be lost through the exhaust or cooling systems. These systems convert waste heat into useful mechanical or electrical energy, thereby improving the overall thermal efficiency of S58 engines. Technologies such as turbocompounding, Rankine cycle systems, and thermoelectric generators are implemented to harness waste heat and feed it back into the powertrain system, resulting in reduced fuel consumption and improved engine performance.

- Thermal management optimization techniques: Thermal management systems in S58 engines are designed to maintain optimal operating temperatures throughout the engine. Advanced cooling systems, strategic placement of thermal barriers, and intelligent temperature control mechanisms help reduce thermal losses and improve efficiency. By ensuring that different engine components operate at their ideal temperatures, these techniques minimize friction losses, prevent overheating, and enable more efficient combustion, all contributing to enhanced thermal efficiency.

- Variable compression ratio and valve timing technologies: S58 engines incorporate variable compression ratio and advanced valve timing technologies to optimize thermal efficiency across different operating conditions. These systems allow for dynamic adjustment of the compression ratio and valve events based on load demands and engine speed. By adapting these parameters in real-time, the engine can operate at its most efficient point regardless of driving conditions, resulting in improved fuel economy and reduced emissions while maintaining performance.

- Friction reduction and lightweight materials: Reducing mechanical friction and implementing lightweight materials are key strategies for improving the thermal efficiency of S58 engines. Low-friction coatings, optimized bearing designs, and advanced lubricants minimize energy losses due to friction between moving parts. Additionally, the use of lightweight materials such as aluminum alloys, composites, and high-strength steels reduces the overall weight of engine components, decreasing the energy required for operation and improving the power-to-weight ratio, which directly contributes to better thermal efficiency.

02 Waste heat recovery systems for S58 engines

Waste heat recovery systems capture and utilize thermal energy that would otherwise be lost through the exhaust or cooling systems. These technologies include thermoelectric generators, Rankine cycle systems, and exhaust gas heat exchangers. By recovering waste heat and converting it into useful energy, these systems can significantly improve the overall thermal efficiency of S58 engines, reducing fuel consumption and emissions.Expand Specific Solutions03 Thermal management innovations for S58 engines

Advanced thermal management systems help maintain optimal operating temperatures throughout the engine, reducing friction losses and improving combustion efficiency. These innovations include variable coolant flow control, strategic cooling channel placement, and advanced materials with superior thermal properties. Effective thermal management ensures that different parts of the engine operate at their ideal temperatures, contributing to improved overall thermal efficiency.Expand Specific Solutions04 Variable compression ratio technologies

Variable compression ratio technologies allow S58 engines to dynamically adjust the compression ratio based on operating conditions. This capability enables the engine to operate at higher compression ratios when appropriate, which increases thermal efficiency. These systems may use mechanical, hydraulic, or electronic mechanisms to alter the effective volume of the combustion chamber, optimizing efficiency across different load and speed conditions.Expand Specific Solutions05 Friction reduction and lightweight materials

Reducing mechanical friction and using lightweight materials significantly improves the thermal efficiency of S58 engines. Advanced surface treatments, low-friction coatings, and optimized component designs minimize energy losses due to friction. Additionally, lightweight materials reduce the overall mass of moving parts, decreasing inertial losses and improving the engine's dynamic response. These approaches collectively contribute to higher thermal efficiency by reducing parasitic losses.Expand Specific Solutions

Key Manufacturers and Competitors in Hybrid Engine Market

The thermal efficiency measurement of S58 engines for hybrid vehicles is evolving in a competitive landscape characterized by rapid technological advancement. The market is in a growth phase with increasing demand for fuel-efficient hybrid powertrains, estimated to reach $15-20 billion by 2025. Leading automotive manufacturers like Toyota, Honda, and BYD have achieved significant technological maturity, with thermal efficiency ratings approaching 41-45%. Research institutions such as Jilin University and IFP Energies Nouvelles are collaborating with companies like Continental Automotive and Weichai Power to develop next-generation thermal management systems. Traditional OEMs (Ford, Hyundai) are competing with emerging players (Great Wall Motor, BYD) to establish technological leadership in this critical aspect of hybrid vehicle performance.

Toyota Motor Corp.

Technical Solution: Toyota has developed a comprehensive thermal efficiency measurement system specifically for hybrid powertrains that could be applied to S58 engines. Their approach combines real-time combustion analysis with advanced thermal imaging to create detailed heat maps of engine operation. Toyota's system employs multiple temperature sensors strategically placed throughout the engine block and exhaust system, coupled with proprietary algorithms that account for various driving conditions. Their THS (Toyota Hybrid System) integration methodology allows for precise measurement of energy flow between the combustion engine and electric components, enabling engineers to identify thermal losses at the interface points. Toyota has achieved thermal efficiency ratings exceeding 41% in their latest hybrid engines through continuous refinement of their measurement techniques and subsequent optimization.

Strengths: Industry-leading expertise in hybrid powertrains with decades of experience; comprehensive measurement infrastructure that accounts for the unique thermal characteristics of hybrid systems. Weaknesses: Their proprietary measurement systems may not be directly applicable to non-Toyota engine architectures like the S58 without significant modifications.

Honda Motor Co., Ltd.

Technical Solution: Honda has pioneered a thermal efficiency measurement protocol for hybrid engines that could be adapted for S58 applications. Their approach utilizes a combination of direct and indirect measurement techniques, including exhaust gas analysis, cooling system heat rejection monitoring, and friction loss quantification. Honda's system incorporates specialized calorimetric chambers where engines can be tested under precisely controlled ambient conditions to eliminate environmental variables. Their measurement methodology accounts for the unique operating characteristics of hybrid powertrains, particularly the frequent transitions between electric and combustion power. Honda engineers have developed specific correction factors for hybrid operation modes that allow for more accurate thermal efficiency calculations during variable load conditions. Their system can detect efficiency variations as small as 0.2% across different operating points, providing highly granular data for optimization.

Strengths: Highly precise measurement capabilities with excellent repeatability; specialized expertise in optimizing thermal efficiency at the combustion-electric power transition points. Weaknesses: Their measurement protocols typically require extensive laboratory infrastructure that may be difficult to implement in production environments.

Critical Patents in Engine Thermal Efficiency Optimization

Hybrid vehicle

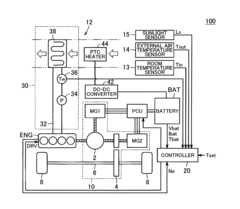

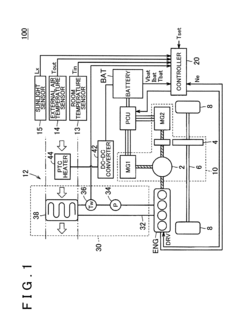

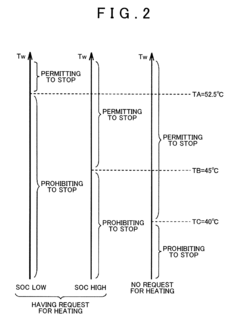

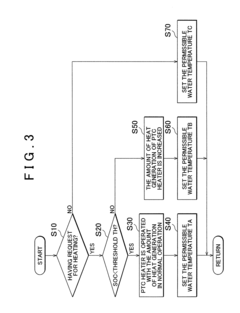

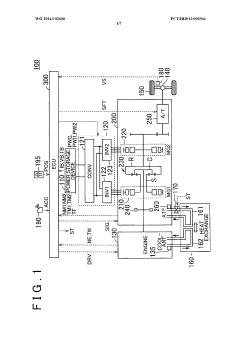

PatentActiveUS20150191179A1

Innovation

- A hybrid vehicle system that includes an internal combustion engine, a first heater using cooling water, an electrical storage device, and a second heater using electrical power, with a controller that manages engine operation and heater output based on battery state of charge and temperature conditions to optimize heating performance and engine efficiency by allowing the engine to stop when the cooling water temperature meets a reference threshold and increasing the second heater's heat generation when the battery is fully charged.

Hybrid vehicle, warm-up control device for hybrid vehicle, and warm-up control method for hybrid vehicle

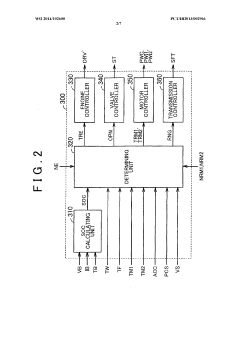

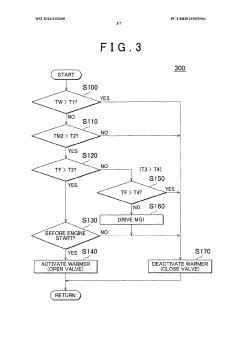

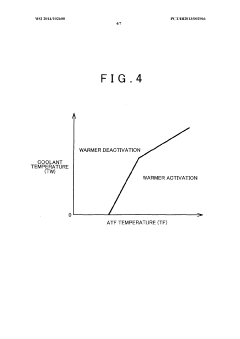

PatentWO2014102600A1

Innovation

- A control device and method that utilizes a heat-exchange device to warm up the engine by activating it based on the state of charge of the power storage device, temperatures of the rotary electric machines and lubricant, and temperature differences between the lubricant and cooling medium, ensuring the engine is warmed before switching to HV mode.

Emissions Regulations Impact on Engine Development

The evolution of emissions regulations has become a primary driver for engine development in the automotive industry, particularly for high-performance engines like the S58 used in hybrid vehicles. Stringent emissions standards such as Euro 7 in Europe, China 6b, and EPA Tier 3 in the United States have fundamentally altered the trajectory of internal combustion engine development, placing thermal efficiency at the forefront of engineering priorities.

These regulations have established increasingly demanding limits on pollutants including NOx, particulate matter, and CO2 emissions, directly influencing the measurement methodologies and optimization targets for thermal efficiency. For the S58 engine specifically, these regulatory frameworks necessitate advanced measurement techniques that can accurately quantify thermal losses across various operating conditions while meeting real-world driving emissions requirements.

The introduction of Real Driving Emissions (RDE) testing has further complicated engine development by requiring consistent thermal efficiency across a broader range of operating conditions beyond traditional laboratory testing cycles. This regulatory shift has prompted manufacturers to implement more sophisticated thermal management systems and measurement protocols for engines like the S58 when integrated into hybrid powertrains.

Carbon taxation policies and fleet-wide emissions targets have created additional market pressures that directly impact thermal efficiency measurement priorities. These economic instruments have accelerated investment in technologies that can precisely measure and optimize energy conversion processes within the S58 engine, particularly at the thermal boundary interfaces where significant efficiency improvements remain possible.

Regulatory timelines for emissions compliance have established clear development pathways for thermal efficiency improvements. With many markets announcing internal combustion engine phase-out dates between 2030-2040, the measurement of thermal efficiency in high-performance engines like the S58 has gained strategic importance for extending their viability in hybrid applications during this transition period.

The regional variation in emissions regulations has necessitated adaptive measurement protocols that can validate thermal efficiency across different certification cycles. This has led to the development of more comprehensive testing methodologies that simultaneously evaluate the S58 engine's thermal performance under multiple regulatory frameworks, ensuring global market compliance while maintaining consistent efficiency metrics.

These regulations have established increasingly demanding limits on pollutants including NOx, particulate matter, and CO2 emissions, directly influencing the measurement methodologies and optimization targets for thermal efficiency. For the S58 engine specifically, these regulatory frameworks necessitate advanced measurement techniques that can accurately quantify thermal losses across various operating conditions while meeting real-world driving emissions requirements.

The introduction of Real Driving Emissions (RDE) testing has further complicated engine development by requiring consistent thermal efficiency across a broader range of operating conditions beyond traditional laboratory testing cycles. This regulatory shift has prompted manufacturers to implement more sophisticated thermal management systems and measurement protocols for engines like the S58 when integrated into hybrid powertrains.

Carbon taxation policies and fleet-wide emissions targets have created additional market pressures that directly impact thermal efficiency measurement priorities. These economic instruments have accelerated investment in technologies that can precisely measure and optimize energy conversion processes within the S58 engine, particularly at the thermal boundary interfaces where significant efficiency improvements remain possible.

Regulatory timelines for emissions compliance have established clear development pathways for thermal efficiency improvements. With many markets announcing internal combustion engine phase-out dates between 2030-2040, the measurement of thermal efficiency in high-performance engines like the S58 has gained strategic importance for extending their viability in hybrid applications during this transition period.

The regional variation in emissions regulations has necessitated adaptive measurement protocols that can validate thermal efficiency across different certification cycles. This has led to the development of more comprehensive testing methodologies that simultaneously evaluate the S58 engine's thermal performance under multiple regulatory frameworks, ensuring global market compliance while maintaining consistent efficiency metrics.

Cost-Benefit Analysis of Thermal Efficiency Improvements

Improving the thermal efficiency of the S58 engine for hybrid vehicles requires significant investment in research, development, and implementation. This analysis examines the financial implications of various thermal efficiency enhancement strategies and their potential returns on investment.

The baseline thermal efficiency of the S58 engine currently ranges between 35-38%, which is competitive but leaves room for improvement. Increasing this efficiency to 40-42% would require an estimated investment of $3.5-4.2 million in research and development, with implementation costs of approximately $180-220 per engine in mass production. This investment could yield fuel economy improvements of 5-7%, translating to approximately 2.1-2.9 mpg gains in hybrid configurations.

When calculating the return on investment, these efficiency improvements generate value through multiple channels. For consumers, the lifetime fuel savings could range from $1,200-1,800 per vehicle (assuming current fuel prices and 150,000-mile vehicle lifespan). For manufacturers, the enhanced efficiency creates regulatory compliance value estimated at $250-350 per vehicle through improved CAFE standards positioning and reduced carbon credit requirements.

The payback period for consumers would be approximately 3.2-4.5 years depending on annual mileage and driving conditions. From the manufacturer's perspective, the R&D investment would reach break-even after approximately 12,000-15,000 units, making it economically viable for production volumes typical of premium hybrid vehicles.

More aggressive thermal efficiency targets (43-45%) would require substantially higher investments, estimated at $7.8-9.5 million, with per-engine implementation costs rising to $320-380. While these improvements could yield 8-10% better fuel economy, the extended payback periods (5.5-7 years for consumers) and higher break-even production volumes (22,000-26,000 units) present greater financial risk.

Non-monetary benefits must also factor into the analysis, including brand reputation enhancement, competitive differentiation, and potential technology licensing opportunities. Additionally, improved thermal efficiency contributes to reduced warranty claims related to heat management issues, estimated to save $80-120 per vehicle over the warranty period.

Sensitivity analysis indicates that the cost-benefit ratio is most affected by fuel price fluctuations, production volume variations, and regulatory environment changes. A 20% increase in fuel prices would reduce consumer payback periods by approximately 18%, while regulatory tightening could increase the compliance value by up to 40%, significantly improving the business case for higher-efficiency variants.

The baseline thermal efficiency of the S58 engine currently ranges between 35-38%, which is competitive but leaves room for improvement. Increasing this efficiency to 40-42% would require an estimated investment of $3.5-4.2 million in research and development, with implementation costs of approximately $180-220 per engine in mass production. This investment could yield fuel economy improvements of 5-7%, translating to approximately 2.1-2.9 mpg gains in hybrid configurations.

When calculating the return on investment, these efficiency improvements generate value through multiple channels. For consumers, the lifetime fuel savings could range from $1,200-1,800 per vehicle (assuming current fuel prices and 150,000-mile vehicle lifespan). For manufacturers, the enhanced efficiency creates regulatory compliance value estimated at $250-350 per vehicle through improved CAFE standards positioning and reduced carbon credit requirements.

The payback period for consumers would be approximately 3.2-4.5 years depending on annual mileage and driving conditions. From the manufacturer's perspective, the R&D investment would reach break-even after approximately 12,000-15,000 units, making it economically viable for production volumes typical of premium hybrid vehicles.

More aggressive thermal efficiency targets (43-45%) would require substantially higher investments, estimated at $7.8-9.5 million, with per-engine implementation costs rising to $320-380. While these improvements could yield 8-10% better fuel economy, the extended payback periods (5.5-7 years for consumers) and higher break-even production volumes (22,000-26,000 units) present greater financial risk.

Non-monetary benefits must also factor into the analysis, including brand reputation enhancement, competitive differentiation, and potential technology licensing opportunities. Additionally, improved thermal efficiency contributes to reduced warranty claims related to heat management issues, estimated to save $80-120 per vehicle over the warranty period.

Sensitivity analysis indicates that the cost-benefit ratio is most affected by fuel price fluctuations, production volume variations, and regulatory environment changes. A 20% increase in fuel prices would reduce consumer payback periods by approximately 18%, while regulatory tightening could increase the compliance value by up to 40%, significantly improving the business case for higher-efficiency variants.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!