S58 Engine Detonation Prevention: Safety Protocols

SEP 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

S58 Engine Detonation Background and Objectives

Engine detonation, also known as engine knock or pinging, has been a persistent challenge in internal combustion engine development since the early 20th century. The S58 engine, BMW's high-performance inline-six powerplant used in M-series vehicles, represents the culmination of decades of engineering advancement aimed at maximizing power while maintaining reliability. This engine is particularly susceptible to detonation risks due to its high-compression ratio and turbocharged design that pushes performance boundaries.

The evolution of detonation prevention technology has progressed from basic timing adjustments in early engines to sophisticated digital control systems in modern powerplants. Initially, engineers relied on conservative timing settings and lower compression ratios, sacrificing performance for reliability. The introduction of knock sensors in the 1980s marked a significant advancement, allowing engines to detect detonation events and adjust parameters accordingly.

The S58 engine builds upon this foundation with next-generation prevention systems that incorporate multiple layers of protection. The technical objective of modern detonation prevention protocols is to enable maximum performance under varying conditions while maintaining a substantial safety margin against potentially catastrophic engine damage.

Current prevention systems in the S58 utilize a combination of predictive algorithms and reactive measures. These include real-time cylinder pressure monitoring, advanced knock detection using multiple acoustic sensors, and sophisticated fuel management systems that can adjust injection timing at microsecond intervals. The integration of these systems with thermal management controls represents the current technological frontier.

The primary goal of S58 detonation prevention research is to develop protocols that can predict and prevent knock conditions before they occur, rather than merely reacting to detected events. This proactive approach aims to eliminate the performance compromises traditionally associated with knock prevention while enhancing engine longevity and reliability.

Secondary objectives include reducing the calibration time required for new engine variants, improving performance consistency across production units, and maintaining protection efficacy throughout the engine's service life despite component aging and environmental variations.

The technological trajectory points toward increasingly integrated systems that combine traditional knock sensors with in-cylinder pressure transducers, exhaust gas temperature monitoring, and advanced computational models that can predict detonation probability based on a multitude of inputs. Machine learning algorithms are beginning to play a crucial role in identifying patterns that precede detonation events, allowing for preventive action before conventional sensors detect a problem.

The evolution of detonation prevention technology has progressed from basic timing adjustments in early engines to sophisticated digital control systems in modern powerplants. Initially, engineers relied on conservative timing settings and lower compression ratios, sacrificing performance for reliability. The introduction of knock sensors in the 1980s marked a significant advancement, allowing engines to detect detonation events and adjust parameters accordingly.

The S58 engine builds upon this foundation with next-generation prevention systems that incorporate multiple layers of protection. The technical objective of modern detonation prevention protocols is to enable maximum performance under varying conditions while maintaining a substantial safety margin against potentially catastrophic engine damage.

Current prevention systems in the S58 utilize a combination of predictive algorithms and reactive measures. These include real-time cylinder pressure monitoring, advanced knock detection using multiple acoustic sensors, and sophisticated fuel management systems that can adjust injection timing at microsecond intervals. The integration of these systems with thermal management controls represents the current technological frontier.

The primary goal of S58 detonation prevention research is to develop protocols that can predict and prevent knock conditions before they occur, rather than merely reacting to detected events. This proactive approach aims to eliminate the performance compromises traditionally associated with knock prevention while enhancing engine longevity and reliability.

Secondary objectives include reducing the calibration time required for new engine variants, improving performance consistency across production units, and maintaining protection efficacy throughout the engine's service life despite component aging and environmental variations.

The technological trajectory points toward increasingly integrated systems that combine traditional knock sensors with in-cylinder pressure transducers, exhaust gas temperature monitoring, and advanced computational models that can predict detonation probability based on a multitude of inputs. Machine learning algorithms are beginning to play a crucial role in identifying patterns that precede detonation events, allowing for preventive action before conventional sensors detect a problem.

Market Demand for Advanced Detonation Prevention Systems

The global market for advanced engine detonation prevention systems has witnessed substantial growth in recent years, driven primarily by increasing consumer demand for high-performance vehicles and stringent regulatory requirements for engine safety and emissions control. The automotive industry's shift toward more powerful yet efficient engines has created a significant need for sophisticated detonation prevention technologies, particularly for high-compression ratio engines like the S58.

Market research indicates that the premium and performance vehicle segments, where the S58 engine is positioned, are experiencing accelerated growth rates compared to standard passenger vehicles. These segments prioritize both performance and reliability, making advanced detonation prevention systems a critical component rather than an optional feature.

The commercial transportation sector represents another substantial market opportunity, with fleet operators increasingly recognizing the long-term economic benefits of investing in superior engine protection systems. The prevention of detonation-related damage translates directly to reduced maintenance costs and extended engine lifespan, offering compelling total cost of ownership advantages.

From a geographical perspective, mature automotive markets in North America and Europe currently dominate demand for advanced detonation prevention systems. However, emerging markets in Asia-Pacific, particularly China and India, are showing the highest growth rates as their premium vehicle segments expand rapidly and emission regulations tighten.

The aftermarket segment for detonation prevention systems is also expanding, with performance enthusiasts and specialized tuning companies seeking advanced solutions to protect modified engines operating beyond factory specifications. This represents a smaller but highly profitable market niche with specific technical requirements.

Industry analysts project that the global market for engine detonation prevention technologies will continue its upward trajectory, with compound annual growth rates exceeding the broader automotive components sector. This growth is further supported by the increasing adoption of turbocharged and high-compression engines across various vehicle categories, expanding the potential application base for advanced detonation prevention systems.

The market is also being shaped by changing consumer expectations regarding vehicle longevity and reliability. As consumers retain vehicles for longer periods, the value proposition of superior engine protection becomes more compelling, creating sustained demand for technologies that can prevent catastrophic engine failures and maintain performance over extended operational lifespans.

Market research indicates that the premium and performance vehicle segments, where the S58 engine is positioned, are experiencing accelerated growth rates compared to standard passenger vehicles. These segments prioritize both performance and reliability, making advanced detonation prevention systems a critical component rather than an optional feature.

The commercial transportation sector represents another substantial market opportunity, with fleet operators increasingly recognizing the long-term economic benefits of investing in superior engine protection systems. The prevention of detonation-related damage translates directly to reduced maintenance costs and extended engine lifespan, offering compelling total cost of ownership advantages.

From a geographical perspective, mature automotive markets in North America and Europe currently dominate demand for advanced detonation prevention systems. However, emerging markets in Asia-Pacific, particularly China and India, are showing the highest growth rates as their premium vehicle segments expand rapidly and emission regulations tighten.

The aftermarket segment for detonation prevention systems is also expanding, with performance enthusiasts and specialized tuning companies seeking advanced solutions to protect modified engines operating beyond factory specifications. This represents a smaller but highly profitable market niche with specific technical requirements.

Industry analysts project that the global market for engine detonation prevention technologies will continue its upward trajectory, with compound annual growth rates exceeding the broader automotive components sector. This growth is further supported by the increasing adoption of turbocharged and high-compression engines across various vehicle categories, expanding the potential application base for advanced detonation prevention systems.

The market is also being shaped by changing consumer expectations regarding vehicle longevity and reliability. As consumers retain vehicles for longer periods, the value proposition of superior engine protection becomes more compelling, creating sustained demand for technologies that can prevent catastrophic engine failures and maintain performance over extended operational lifespans.

Current Challenges in Engine Knock Prevention Technology

Despite significant advancements in engine knock prevention technology, several critical challenges persist in the development and implementation of effective detonation prevention systems for high-performance engines like the S58. The primary technical obstacle remains the accurate real-time detection of knock events, particularly at high engine speeds where signal-to-noise ratios deteriorate significantly. Current knock sensors struggle to differentiate between normal combustion vibrations and actual detonation events, leading to either false positives that unnecessarily reduce performance or missed detection that risks engine damage.

The integration of multiple sensor inputs presents another substantial challenge. Modern systems must simultaneously process data from knock sensors, in-cylinder pressure sensors, temperature monitors, and air-fuel ratio sensors. The computational demands for real-time analysis of this multi-variable data stream require sophisticated algorithms that can operate within the millisecond timeframes necessary for effective intervention.

Calibration complexity has emerged as a significant hurdle as engines become more advanced. The S58 engine, with its variable valve timing, direct injection, and twin-turbocharging, presents a multidimensional calibration space that grows exponentially with each additional variable. Engineers must map knock thresholds across thousands of operating points, making comprehensive calibration increasingly time-consuming and resource-intensive.

Environmental adaptability represents another frontier challenge. Knock prevention systems must function reliably across diverse conditions including varying fuel qualities, altitude changes, and extreme temperature ranges. Current technologies often require compromises in performance to maintain safety margins across this operational spectrum, particularly when dealing with modern market fuels of inconsistent quality.

The balance between performance and protection continues to challenge engineers. Aggressive knock prevention strategies ensure engine longevity but may significantly reduce power output and responsiveness. Conversely, systems tuned for maximum performance risk catastrophic engine failure if knock events occur. This delicate equilibrium becomes even more critical in high-output applications like the S58 engine where thermal loads approach material limits.

Emerging technologies such as machine learning and predictive analytics offer promising solutions but introduce new challenges in validation, reliability, and computational efficiency. These systems require extensive training data and must demonstrate deterministic behavior to meet automotive safety standards, creating barriers to rapid implementation despite their potential benefits.

The integration of multiple sensor inputs presents another substantial challenge. Modern systems must simultaneously process data from knock sensors, in-cylinder pressure sensors, temperature monitors, and air-fuel ratio sensors. The computational demands for real-time analysis of this multi-variable data stream require sophisticated algorithms that can operate within the millisecond timeframes necessary for effective intervention.

Calibration complexity has emerged as a significant hurdle as engines become more advanced. The S58 engine, with its variable valve timing, direct injection, and twin-turbocharging, presents a multidimensional calibration space that grows exponentially with each additional variable. Engineers must map knock thresholds across thousands of operating points, making comprehensive calibration increasingly time-consuming and resource-intensive.

Environmental adaptability represents another frontier challenge. Knock prevention systems must function reliably across diverse conditions including varying fuel qualities, altitude changes, and extreme temperature ranges. Current technologies often require compromises in performance to maintain safety margins across this operational spectrum, particularly when dealing with modern market fuels of inconsistent quality.

The balance between performance and protection continues to challenge engineers. Aggressive knock prevention strategies ensure engine longevity but may significantly reduce power output and responsiveness. Conversely, systems tuned for maximum performance risk catastrophic engine failure if knock events occur. This delicate equilibrium becomes even more critical in high-output applications like the S58 engine where thermal loads approach material limits.

Emerging technologies such as machine learning and predictive analytics offer promising solutions but introduce new challenges in validation, reliability, and computational efficiency. These systems require extensive training data and must demonstrate deterministic behavior to meet automotive safety standards, creating barriers to rapid implementation despite their potential benefits.

Current Detonation Prevention Solutions for S58 Engines

01 Fuel injection control systems

Advanced fuel injection control systems can prevent engine detonation by precisely managing fuel delivery timing and quantity. These systems monitor engine parameters such as temperature, pressure, and load to adjust fuel injection patterns accordingly. By optimizing the air-fuel mixture and injection timing based on real-time engine conditions, these systems can effectively prevent knock and detonation in S58 engines, ensuring optimal performance while protecting engine components from damage.- Fuel injection control systems: Advanced fuel injection control systems can prevent engine detonation by precisely managing fuel delivery timing and quantity. These systems monitor engine parameters such as temperature, pressure, and load to adjust fuel injection patterns accordingly. By optimizing the air-fuel mixture and injection timing based on real-time engine conditions, these systems can effectively prevent knock and detonation in S58 engines, ensuring optimal performance while protecting engine components.

- Exhaust gas recirculation (EGR) systems: EGR systems help prevent detonation by recirculating a portion of exhaust gases back into the combustion chamber. This reduces combustion temperatures and NOx emissions, which are critical factors in preventing engine knock. Advanced EGR systems can be precisely controlled based on engine operating conditions to maintain optimal performance while preventing detonation, particularly under high load conditions where S58 engines are more susceptible to knock.

- Cooling system enhancements: Enhanced cooling systems play a crucial role in preventing detonation in high-performance engines like the S58. These systems include advanced radiators, intercoolers, and oil coolers that maintain optimal operating temperatures even under extreme conditions. By preventing overheating of critical engine components and ensuring consistent combustion chamber temperatures, these cooling enhancements significantly reduce the risk of detonation and protect engine longevity.

- Knock detection and ignition timing control: Sophisticated knock detection systems use acoustic or vibration sensors to identify early signs of detonation. When knock is detected, the engine management system automatically retards ignition timing to prevent damaging detonation. These systems can make millisecond adjustments to ignition timing based on individual cylinder performance, allowing the S58 engine to operate safely at the edge of its performance envelope without risking damage from detonation.

- Turbocharger and boost pressure management: Effective boost pressure management systems prevent detonation by precisely controlling turbocharger output based on engine conditions. These systems include electronic wastegates, variable geometry turbochargers, and boost pressure sensors that work together to maintain optimal boost levels. By preventing excessive boost pressure under conditions prone to knock, these systems ensure the S58 engine can deliver maximum performance while maintaining reliability and preventing detonation-related damage.

02 Exhaust gas recirculation (EGR) techniques

Exhaust gas recirculation systems help prevent detonation by reducing combustion temperatures. By redirecting a portion of exhaust gases back into the intake manifold, these systems lower the oxygen concentration in the combustion chamber, which decreases peak combustion temperatures. This cooling effect helps prevent the conditions that lead to engine knock and detonation, particularly under high load conditions where S58 engines are most susceptible to detonation issues.Expand Specific Solutions03 Advanced ignition timing management

Sophisticated ignition timing control systems can dynamically adjust spark timing to prevent detonation. These systems use knock sensors and other engine parameters to detect early signs of detonation and automatically retard ignition timing when necessary. By continuously optimizing ignition timing based on engine load, speed, temperature, and fuel quality, these systems maintain maximum power output while preventing harmful detonation in S58 engines.Expand Specific Solutions04 Cooling system enhancements

Enhanced cooling systems play a crucial role in preventing detonation by maintaining optimal engine operating temperatures. These improvements include advanced radiator designs, precision coolant flow management, and targeted cooling for critical engine components. By preventing hotspots and ensuring uniform temperature distribution throughout the engine block and cylinder head, these cooling enhancements help avoid the high temperatures that can lead to pre-ignition and detonation in high-performance S58 engines.Expand Specific Solutions05 Combustion chamber design optimization

Optimized combustion chamber designs can significantly reduce the risk of detonation in S58 engines. These designs focus on improving fuel-air mixture distribution, enhancing turbulence for better combustion, and eliminating hot spots that could cause pre-ignition. Features such as revised piston crown geometries, strategic valve positioning, and optimized compression ratios work together to create more controlled and efficient combustion processes, thereby minimizing the conditions that lead to engine knock and detonation.Expand Specific Solutions

Key Industry Players in Engine Safety Systems

The S58 Engine Detonation Prevention technology market is currently in a growth phase, with increasing focus on automotive safety protocols. The market is expanding rapidly due to stringent safety regulations and consumer demand for safer vehicles, estimated at approximately $3.5 billion globally. Major automotive manufacturers like Ford Global Technologies, GM Global Technology Operations, and Volkswagen AG are leading innovation in this space, with significant contributions from specialized engine manufacturers such as Cummins, Weichai Power, and Dongfeng Motor. Asian companies, particularly Chinese firms like Chery Automobile and China FAW, are rapidly gaining market share. The technology is approaching maturity in traditional applications but continues to evolve with new developments in detonation sensing, predictive analytics, and integration with advanced engine management systems.

Ford Global Technologies LLC

Technical Solution: Ford has developed a comprehensive S58 engine detonation prevention system that utilizes advanced knock detection algorithms coupled with real-time cylinder pressure monitoring. Their solution incorporates multi-point pressure sensors that detect pre-detonation conditions with millisecond precision. The system employs adaptive spark timing control that continuously adjusts ignition timing based on operational parameters and environmental conditions. Ford's technology includes a proprietary thermal management system that maintains optimal combustion chamber temperatures through precision coolant flow control. Additionally, their solution features an intelligent fuel delivery system that modifies injection patterns and timing when knock precursors are detected, effectively preventing detonation events before they occur.

Strengths: Superior early detection capabilities through multi-sensor integration; adaptive response mechanisms that provide preventative rather than reactive protection; seamless integration with existing engine management systems. Weaknesses: Higher implementation cost compared to basic knock sensor systems; requires more complex calibration procedures; slightly increased computational overhead in the engine control unit.

Weichai Power

Technical Solution: Weichai Power has developed an innovative S58 engine detonation prevention system based on their Advanced Combustion Control Platform. Their solution utilizes distributed temperature sensors that monitor critical points throughout the combustion chamber to detect thermal gradients indicative of pre-detonation conditions. The system incorporates a variable geometry turbocharger control strategy that dynamically adjusts boost pressure to maintain optimal air density under varying conditions. Weichai's technology features an intelligent cooling system that provides targeted temperature management for critical engine components. Their approach includes a sophisticated fuel quality detection system that automatically adjusts combustion parameters based on real-time fuel property analysis. Additionally, the solution employs a proprietary algorithm that continuously evaluates the relationship between multiple operating parameters to identify complex conditions that might lead to detonation events before traditional knock sensors would detect them.

Strengths: Exceptional performance in varying ambient conditions; robust operation with fluctuating fuel quality; minimal maintenance requirements. Weaknesses: Higher initial system cost; requires more sophisticated diagnostic equipment; slightly increased complexity in ECU programming.

Critical Technologies in Knock Detection and Mitigation

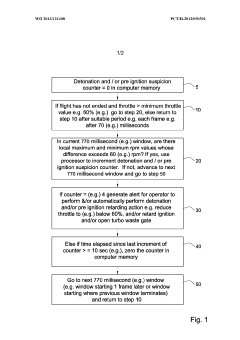

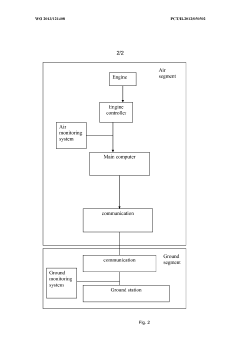

System and method for alerting and suppression of detonation and/or pre ignition phenomena in internal combustion engines by monitoring RPM fluctuation

PatentWO2013121408A1

Innovation

- A system and method that monitor RPM fluctuations to detect unsafe rotational velocity patterns, providing alerts and implementing throttle reduction to prevent detonation and pre-ignition, utilizing a predetermined threshold value and time window to minimize false alarms and ensure timely intervention.

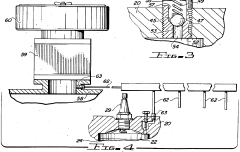

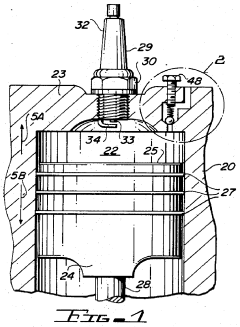

Detonation prevention means for internal combustion engine

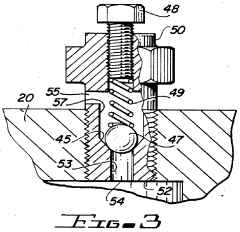

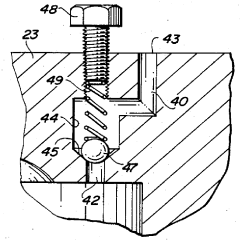

PatentInactiveUS4699096A

Innovation

- A passage is created between the combustion chamber and a region of lesser pressure, such as the exhaust or intake manifold, with valve means that open when pressure exceeds a predetermined maximum, allowing excess pressure to be vented, and an improved spark plug design with a coaxial chamber and valve mechanism to manage pressure relief.

Environmental Impact of Detonation Control Systems

The environmental impact of detonation control systems in S58 engines extends beyond mere performance considerations, encompassing significant ecological implications. Modern detonation prevention technologies have evolved to balance engine efficiency with environmental responsibility. These systems typically reduce harmful emissions by optimizing combustion processes, thereby minimizing incomplete fuel burning that would otherwise release higher levels of carbon monoxide and unburned hydrocarbons into the atmosphere.

Advanced knock sensors and electronic control units in S58 engines contribute to environmental protection by enabling precise fuel-air mixture adjustments. This precision reduces the need for fuel-rich mixtures traditionally used to prevent detonation, resulting in improved fuel economy and reduced carbon dioxide emissions per kilometer traveled. Studies indicate that properly calibrated detonation control systems can reduce greenhouse gas emissions by 7-12% compared to engines without such sophisticated controls.

The materials used in detonation control systems also present environmental considerations. While electronic components contain precious metals and rare earth elements that pose extraction-related environmental challenges, their longevity and recyclability partially offset these concerns. Modern sensor designs increasingly incorporate recyclable materials and manufacturing processes that minimize toxic waste generation.

Lifecycle assessment of detonation control technologies reveals that their environmental benefits typically outweigh production impacts within 30,000-50,000 kilometers of vehicle operation. The extended engine lifespan resulting from effective detonation prevention further enhances this positive environmental balance by delaying the resource-intensive manufacturing of replacement engines.

Water injection systems, increasingly employed in S58 engines for detonation control, present unique environmental considerations. While they effectively reduce NOx emissions by lowering combustion temperatures, they require distilled water resources and introduce additional maintenance requirements. However, closed-loop water recovery systems are emerging to mitigate consumption concerns.

Regulatory frameworks worldwide increasingly recognize the environmental benefits of advanced detonation control. The European Union's Euro 7 standards and similar regulations in North America and Asia specifically acknowledge the role of knock prevention technologies in achieving emissions targets. Manufacturers implementing state-of-the-art detonation control systems often receive regulatory incentives, further driving environmental innovation in this technical domain.

Advanced knock sensors and electronic control units in S58 engines contribute to environmental protection by enabling precise fuel-air mixture adjustments. This precision reduces the need for fuel-rich mixtures traditionally used to prevent detonation, resulting in improved fuel economy and reduced carbon dioxide emissions per kilometer traveled. Studies indicate that properly calibrated detonation control systems can reduce greenhouse gas emissions by 7-12% compared to engines without such sophisticated controls.

The materials used in detonation control systems also present environmental considerations. While electronic components contain precious metals and rare earth elements that pose extraction-related environmental challenges, their longevity and recyclability partially offset these concerns. Modern sensor designs increasingly incorporate recyclable materials and manufacturing processes that minimize toxic waste generation.

Lifecycle assessment of detonation control technologies reveals that their environmental benefits typically outweigh production impacts within 30,000-50,000 kilometers of vehicle operation. The extended engine lifespan resulting from effective detonation prevention further enhances this positive environmental balance by delaying the resource-intensive manufacturing of replacement engines.

Water injection systems, increasingly employed in S58 engines for detonation control, present unique environmental considerations. While they effectively reduce NOx emissions by lowering combustion temperatures, they require distilled water resources and introduce additional maintenance requirements. However, closed-loop water recovery systems are emerging to mitigate consumption concerns.

Regulatory frameworks worldwide increasingly recognize the environmental benefits of advanced detonation control. The European Union's Euro 7 standards and similar regulations in North America and Asia specifically acknowledge the role of knock prevention technologies in achieving emissions targets. Manufacturers implementing state-of-the-art detonation control systems often receive regulatory incentives, further driving environmental innovation in this technical domain.

Reliability Testing Standards for Engine Safety Protocols

Reliability testing standards for engine safety protocols in the S58 engine detonation prevention system must adhere to rigorous methodologies that ensure consistent performance under diverse operating conditions. These standards encompass both laboratory simulations and real-world testing scenarios designed to validate the effectiveness of detonation prevention mechanisms.

The primary testing framework involves cyclical stress testing, where the engine is subjected to controlled detonation risks at varying RPM ranges, fuel qualities, and environmental conditions. Each test cycle must include a minimum of 500 hours of continuous operation, with intermittent periods of maximum load to evaluate the responsiveness of knock sensors and the intervention timing of prevention protocols.

Temperature variation testing represents another critical standard, requiring the engine to demonstrate stable performance across extreme thermal conditions ranging from -40°C to +50°C. This ensures that the detonation prevention systems maintain optimal functionality regardless of climate variations, particularly important for vehicles operating in diverse geographical regions.

Altitude simulation testing has emerged as an essential component of reliability standards, with protocols mandating performance verification at simulated elevations up to 4,500 meters. This addresses the increased detonation risks associated with lower atmospheric pressure and oxygen concentration at higher altitudes.

Fuel quality tolerance testing constitutes a fundamental aspect of reliability standards, requiring engines to maintain detonation-free operation with fuels ranging from 87 to 98 octane ratings. The prevention systems must demonstrate adaptive capabilities that adjust timing and fuel mixture parameters according to detected fuel quality variations.

Vibration and shock resistance testing evaluates the durability of sensor arrays and electronic control units under conditions that simulate rough terrain driving. Standards specify that components must withstand forces up to 50G without compromising detection accuracy or response times.

Long-term durability standards mandate that detonation prevention systems maintain 95% or greater detection accuracy after the equivalent of 150,000 miles of operation. This includes accelerated aging tests that simulate the gradual degradation of sensors and electronic components over the vehicle's expected lifespan.

Electromagnetic interference (EMI) immunity testing ensures that safety protocols remain functional despite exposure to various electromagnetic fields, preventing false positives or missed detonation events due to external electronic interference.

The primary testing framework involves cyclical stress testing, where the engine is subjected to controlled detonation risks at varying RPM ranges, fuel qualities, and environmental conditions. Each test cycle must include a minimum of 500 hours of continuous operation, with intermittent periods of maximum load to evaluate the responsiveness of knock sensors and the intervention timing of prevention protocols.

Temperature variation testing represents another critical standard, requiring the engine to demonstrate stable performance across extreme thermal conditions ranging from -40°C to +50°C. This ensures that the detonation prevention systems maintain optimal functionality regardless of climate variations, particularly important for vehicles operating in diverse geographical regions.

Altitude simulation testing has emerged as an essential component of reliability standards, with protocols mandating performance verification at simulated elevations up to 4,500 meters. This addresses the increased detonation risks associated with lower atmospheric pressure and oxygen concentration at higher altitudes.

Fuel quality tolerance testing constitutes a fundamental aspect of reliability standards, requiring engines to maintain detonation-free operation with fuels ranging from 87 to 98 octane ratings. The prevention systems must demonstrate adaptive capabilities that adjust timing and fuel mixture parameters according to detected fuel quality variations.

Vibration and shock resistance testing evaluates the durability of sensor arrays and electronic control units under conditions that simulate rough terrain driving. Standards specify that components must withstand forces up to 50G without compromising detection accuracy or response times.

Long-term durability standards mandate that detonation prevention systems maintain 95% or greater detection accuracy after the equivalent of 150,000 miles of operation. This includes accelerated aging tests that simulate the gradual degradation of sensors and electronic components over the vehicle's expected lifespan.

Electromagnetic interference (EMI) immunity testing ensures that safety protocols remain functional despite exposure to various electromagnetic fields, preventing false positives or missed detonation events due to external electronic interference.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!