Comparison of Metal-Based vs Polymeric Neuromorphic Chips

OCT 9, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Neuromorphic Computing Evolution and Objectives

Neuromorphic computing represents a paradigm shift in computational architecture, drawing inspiration from the structure and function of biological neural systems. The evolution of this field began in the late 1980s when Carver Mead introduced the concept of using analog VLSI systems to mimic neurobiological architectures. This pioneering work laid the foundation for hardware implementations that could emulate the brain's parallel processing capabilities and energy efficiency.

The trajectory of neuromorphic computing has been marked by significant technological milestones. Early implementations focused primarily on silicon-based neuromorphic systems, utilizing CMOS technology to create artificial neural networks in hardware. These initial systems demonstrated the potential for brain-inspired computing but were limited by the inherent constraints of traditional semiconductor technologies.

A pivotal development occurred in the early 2000s with the emergence of memristive devices, which offered a more biologically plausible mechanism for implementing synaptic plasticity. This advancement catalyzed research into metal-based neuromorphic chips, utilizing materials such as titanium dioxide, hafnium oxide, and various transition metal oxides to create devices capable of mimicking synaptic behavior.

Parallel to metal-based approaches, polymeric materials began gaining attention in the 2010s as alternative substrates for neuromorphic computing. These organic electronic materials offered unique advantages including flexibility, biocompatibility, and potentially lower manufacturing costs compared to their metallic counterparts.

The primary objectives of neuromorphic computing research have evolved to address several key challenges. First, achieving greater energy efficiency remains paramount, with the human brain's remarkable energy consumption of approximately 20 watts serving as the aspirational benchmark. Second, researchers aim to develop systems capable of unsupervised learning and adaptation, mirroring the brain's ability to continuously modify its structure based on experience.

Additionally, neuromorphic computing seeks to overcome the von Neumann bottleneck by integrating memory and processing functions, thereby eliminating the data transfer limitations inherent in conventional computing architectures. This integration is particularly relevant when comparing metal-based and polymeric neuromorphic chips, as each material class offers distinct advantages in addressing this architectural challenge.

The ultimate goal of neuromorphic computing extends beyond mere technological advancement to creating systems capable of cognitive computing—machines that can perceive, learn, and reason in ways similar to biological systems. This objective has driven the exploration of diverse material platforms, including both metallic and polymeric substrates, each offering unique properties that may prove advantageous for specific neuromorphic applications.

The trajectory of neuromorphic computing has been marked by significant technological milestones. Early implementations focused primarily on silicon-based neuromorphic systems, utilizing CMOS technology to create artificial neural networks in hardware. These initial systems demonstrated the potential for brain-inspired computing but were limited by the inherent constraints of traditional semiconductor technologies.

A pivotal development occurred in the early 2000s with the emergence of memristive devices, which offered a more biologically plausible mechanism for implementing synaptic plasticity. This advancement catalyzed research into metal-based neuromorphic chips, utilizing materials such as titanium dioxide, hafnium oxide, and various transition metal oxides to create devices capable of mimicking synaptic behavior.

Parallel to metal-based approaches, polymeric materials began gaining attention in the 2010s as alternative substrates for neuromorphic computing. These organic electronic materials offered unique advantages including flexibility, biocompatibility, and potentially lower manufacturing costs compared to their metallic counterparts.

The primary objectives of neuromorphic computing research have evolved to address several key challenges. First, achieving greater energy efficiency remains paramount, with the human brain's remarkable energy consumption of approximately 20 watts serving as the aspirational benchmark. Second, researchers aim to develop systems capable of unsupervised learning and adaptation, mirroring the brain's ability to continuously modify its structure based on experience.

Additionally, neuromorphic computing seeks to overcome the von Neumann bottleneck by integrating memory and processing functions, thereby eliminating the data transfer limitations inherent in conventional computing architectures. This integration is particularly relevant when comparing metal-based and polymeric neuromorphic chips, as each material class offers distinct advantages in addressing this architectural challenge.

The ultimate goal of neuromorphic computing extends beyond mere technological advancement to creating systems capable of cognitive computing—machines that can perceive, learn, and reason in ways similar to biological systems. This objective has driven the exploration of diverse material platforms, including both metallic and polymeric substrates, each offering unique properties that may prove advantageous for specific neuromorphic applications.

Market Analysis for Brain-Inspired Computing Solutions

The brain-inspired computing market is experiencing significant growth, driven by the increasing demand for efficient AI processing solutions. According to recent market research, the neuromorphic computing market is projected to reach $8.9 billion by 2028, growing at a CAGR of 26.3% from 2023. This growth is fueled by applications in edge computing, autonomous systems, and advanced pattern recognition where traditional computing architectures face limitations.

Metal-based neuromorphic chips currently dominate the market with approximately 78% market share, primarily due to their established manufacturing processes and integration with existing semiconductor technologies. Companies like Intel (with its Loihi chip) and IBM (with TrueNorth) have made substantial investments in metal-based neuromorphic solutions, leveraging their expertise in traditional semiconductor fabrication.

Polymeric neuromorphic chips, though representing a smaller market segment at 22%, are showing the fastest growth rate at 34.7% annually. This emerging technology is attracting significant venture capital, with over $1.2 billion invested in startups developing polymer-based neural computing solutions in the past three years. Their appeal stems from potential advantages in power efficiency, flexibility, and biocompatibility.

The market segmentation reveals interesting patterns across different industries. Healthcare applications represent the largest market for neuromorphic computing at 31%, where brain-inspired chips are being deployed for medical imaging analysis, brain-computer interfaces, and drug discovery. Automotive follows at 24%, with applications in autonomous driving systems that require real-time pattern recognition and decision-making capabilities.

Regional analysis shows North America leading with 42% market share, followed by Europe (28%) and Asia-Pacific (23%). However, Asia-Pacific is experiencing the fastest growth rate at 29.8% annually, driven by substantial investments from countries like China, Japan, and South Korea in neuromorphic research and manufacturing capabilities.

Customer demand patterns indicate a growing preference for hybrid solutions that combine the reliability of metal-based systems with the efficiency advantages of polymeric technologies. This trend is reflected in recent strategic partnerships between traditional semiconductor manufacturers and materials science companies, with 17 major collaborations announced in the past year alone.

The competitive landscape is evolving rapidly, with large technology corporations and specialized startups competing for market share. While established players focus on scaling existing metal-based technologies, startups are pioneering novel polymeric approaches that promise order-of-magnitude improvements in energy efficiency and neural density.

Metal-based neuromorphic chips currently dominate the market with approximately 78% market share, primarily due to their established manufacturing processes and integration with existing semiconductor technologies. Companies like Intel (with its Loihi chip) and IBM (with TrueNorth) have made substantial investments in metal-based neuromorphic solutions, leveraging their expertise in traditional semiconductor fabrication.

Polymeric neuromorphic chips, though representing a smaller market segment at 22%, are showing the fastest growth rate at 34.7% annually. This emerging technology is attracting significant venture capital, with over $1.2 billion invested in startups developing polymer-based neural computing solutions in the past three years. Their appeal stems from potential advantages in power efficiency, flexibility, and biocompatibility.

The market segmentation reveals interesting patterns across different industries. Healthcare applications represent the largest market for neuromorphic computing at 31%, where brain-inspired chips are being deployed for medical imaging analysis, brain-computer interfaces, and drug discovery. Automotive follows at 24%, with applications in autonomous driving systems that require real-time pattern recognition and decision-making capabilities.

Regional analysis shows North America leading with 42% market share, followed by Europe (28%) and Asia-Pacific (23%). However, Asia-Pacific is experiencing the fastest growth rate at 29.8% annually, driven by substantial investments from countries like China, Japan, and South Korea in neuromorphic research and manufacturing capabilities.

Customer demand patterns indicate a growing preference for hybrid solutions that combine the reliability of metal-based systems with the efficiency advantages of polymeric technologies. This trend is reflected in recent strategic partnerships between traditional semiconductor manufacturers and materials science companies, with 17 major collaborations announced in the past year alone.

The competitive landscape is evolving rapidly, with large technology corporations and specialized startups competing for market share. While established players focus on scaling existing metal-based technologies, startups are pioneering novel polymeric approaches that promise order-of-magnitude improvements in energy efficiency and neural density.

Metal vs Polymer Neuromorphic Technologies: Current Landscape

The neuromorphic computing landscape is currently dominated by two primary material approaches: metal-based and polymer-based technologies. Metal-based neuromorphic chips, primarily utilizing materials such as titanium oxide, hafnium oxide, and various transition metal compounds, have established themselves as the industry standard due to their compatibility with existing CMOS fabrication processes. These chips benefit from decades of semiconductor manufacturing expertise, allowing for high-density integration and relatively mature fabrication techniques.

Silicon-based memristors and phase-change memory (PCM) devices represent the most commercially advanced metal-based neuromorphic components, with companies like Intel, IBM, and Samsung leading development efforts. These technologies offer excellent endurance characteristics, with some metal oxide memristors demonstrating switching capabilities exceeding 10^12 cycles, making them suitable for intensive neural network training applications.

In contrast, polymer-based neuromorphic technologies represent an emerging alternative that has gained significant research momentum over the past five years. These systems utilize organic electronic materials such as PEDOT:PSS, P3HT, and various conductive polymers to create flexible, biocompatible neural interfaces. The inherent advantages of polymeric systems include mechanical flexibility, biocompatibility, and potentially lower manufacturing costs through solution processing techniques.

Several research institutions, including Stanford University, MIT, and the Max Planck Institute, have demonstrated promising polymer-based synaptic devices that exhibit key neuromorphic characteristics such as spike-timing-dependent plasticity (STDP) and short-term/long-term potentiation. However, these technologies currently lag behind their metal counterparts in terms of switching speed, with typical response times in the millisecond range compared to nanoseconds for metal-based systems.

The energy efficiency landscape shows interesting contrasts between these approaches. While metal-based systems benefit from miniaturization and established fabrication techniques, polymer-based devices often demonstrate remarkably low energy consumption per synaptic event, sometimes as low as femtojoules per spike. This efficiency stems from their unique charge transport mechanisms that more closely mimic biological systems.

Scaling remains a significant challenge for polymer technologies, with current devices limited to laboratory demonstrations of small arrays rather than the large-scale integration achieved in metal-based systems. The stability and reliability of polymer devices in varied environmental conditions also presents ongoing challenges that researchers are actively addressing through material innovations and encapsulation techniques.

The coexistence of these two approaches has created a dynamic innovation ecosystem where metal-based systems continue to advance toward commercial deployment while polymer-based alternatives explore unique capabilities that may eventually complement or replace conventional approaches in specialized applications, particularly those requiring biointerfaces or extreme form factors.

Silicon-based memristors and phase-change memory (PCM) devices represent the most commercially advanced metal-based neuromorphic components, with companies like Intel, IBM, and Samsung leading development efforts. These technologies offer excellent endurance characteristics, with some metal oxide memristors demonstrating switching capabilities exceeding 10^12 cycles, making them suitable for intensive neural network training applications.

In contrast, polymer-based neuromorphic technologies represent an emerging alternative that has gained significant research momentum over the past five years. These systems utilize organic electronic materials such as PEDOT:PSS, P3HT, and various conductive polymers to create flexible, biocompatible neural interfaces. The inherent advantages of polymeric systems include mechanical flexibility, biocompatibility, and potentially lower manufacturing costs through solution processing techniques.

Several research institutions, including Stanford University, MIT, and the Max Planck Institute, have demonstrated promising polymer-based synaptic devices that exhibit key neuromorphic characteristics such as spike-timing-dependent plasticity (STDP) and short-term/long-term potentiation. However, these technologies currently lag behind their metal counterparts in terms of switching speed, with typical response times in the millisecond range compared to nanoseconds for metal-based systems.

The energy efficiency landscape shows interesting contrasts between these approaches. While metal-based systems benefit from miniaturization and established fabrication techniques, polymer-based devices often demonstrate remarkably low energy consumption per synaptic event, sometimes as low as femtojoules per spike. This efficiency stems from their unique charge transport mechanisms that more closely mimic biological systems.

Scaling remains a significant challenge for polymer technologies, with current devices limited to laboratory demonstrations of small arrays rather than the large-scale integration achieved in metal-based systems. The stability and reliability of polymer devices in varied environmental conditions also presents ongoing challenges that researchers are actively addressing through material innovations and encapsulation techniques.

The coexistence of these two approaches has created a dynamic innovation ecosystem where metal-based systems continue to advance toward commercial deployment while polymer-based alternatives explore unique capabilities that may eventually complement or replace conventional approaches in specialized applications, particularly those requiring biointerfaces or extreme form factors.

Technical Architectures of Metal and Polymer-Based Neural Chips

01 Metal-based neuromorphic chip architectures

Metal-based neuromorphic chips utilize metallic materials and alloys to create artificial neural networks that mimic brain functionality. These chips incorporate metal-oxide memristors and metal nanowires to form synaptic connections, enabling efficient signal processing and learning capabilities. The metal-based architecture offers advantages in terms of conductivity, thermal stability, and integration with existing semiconductor technologies, making them suitable for high-performance computing applications that require brain-like processing.- Metal-based neuromorphic chip architectures: Metal-based neuromorphic chips utilize metallic materials and alloys to create artificial neural networks that mimic brain functionality. These chips often incorporate metal oxide memristors or metal-based synaptic devices that can change conductivity based on electrical signals, similar to biological synapses. The metal-based architecture offers advantages in terms of conductivity, thermal stability, and integration with existing semiconductor manufacturing processes, enabling efficient implementation of neural network algorithms in hardware.

- Polymeric materials for neuromorphic computing: Polymeric materials are increasingly being used in neuromorphic chips due to their flexibility, biocompatibility, and tunable electrical properties. These materials can form the basis of organic electronic synapses and neurons that mimic biological neural functions. Polymer-based neuromorphic devices often utilize conductive polymers or polymer composites that can change their electrical properties in response to stimuli, enabling synaptic plasticity and learning capabilities. The use of polymeric materials also allows for the development of flexible, stretchable neuromorphic systems suitable for wearable and biomedical applications.

- Hybrid metal-polymer neuromorphic systems: Hybrid neuromorphic chips combine the advantages of both metal and polymeric materials to create more versatile and efficient brain-inspired computing systems. These hybrid architectures typically feature metal electrodes or interconnects with polymeric active layers or interfaces. The combination allows for enhanced synaptic functionality, improved energy efficiency, and better integration with both electronic and biological systems. Hybrid approaches can also incorporate different types of memory mechanisms, enabling more complex learning algorithms and adaptive behaviors in neuromorphic computing applications.

- Memristive device technologies for neuromorphic computing: Memristive devices are fundamental components in neuromorphic chips that can retain memory while processing information, similar to biological synapses. These devices can be fabricated using various materials including metal oxides, phase-change materials, or conductive polymers. The resistance of memristive devices changes based on the history of applied voltage or current, enabling them to mimic synaptic plasticity and learning mechanisms. Advanced memristive technologies incorporate multi-level resistance states, allowing for more complex neural network implementations and improved computational capabilities in neuromorphic systems.

- Neural network implementation and learning algorithms: Neuromorphic chips implement specialized neural network architectures and learning algorithms that are optimized for brain-inspired computing. These implementations include spiking neural networks, reservoir computing, and various forms of unsupervised and reinforced learning mechanisms. The hardware design incorporates parallel processing capabilities, distributed memory, and event-driven computation to achieve energy-efficient neural processing. Advanced neuromorphic systems also feature on-chip learning capabilities that allow the network to adapt and evolve based on input data, enabling applications in pattern recognition, anomaly detection, and autonomous systems.

02 Polymer-based neuromorphic computing systems

Polymer-based neuromorphic chips utilize organic materials to create flexible, biocompatible neural networks. These systems incorporate conductive polymers and polymer composites that can function as artificial synapses and neurons. The polymer-based architecture offers advantages in terms of flexibility, biocompatibility, and low power consumption. These materials can be engineered to exhibit memory and learning capabilities similar to biological systems, making them particularly suitable for wearable electronics and biomedical applications.Expand Specific Solutions03 Hybrid metal-polymer neuromorphic architectures

Hybrid neuromorphic chips combine both metallic and polymeric materials to leverage the advantages of each. These architectures typically feature metal electrodes or interconnects with polymer-based active layers or interfaces. The combination allows for enhanced flexibility, improved electrical performance, and better integration with biological systems. These hybrid systems can achieve higher energy efficiency while maintaining computational performance, making them suitable for applications requiring both high performance and biocompatibility.Expand Specific Solutions04 Memristive devices for neuromorphic computing

Memristive devices are fundamental components in neuromorphic chips that mimic the behavior of biological synapses. These devices can be fabricated using various materials including metal oxides and conductive polymers. They exhibit variable resistance states that can be modulated based on the history of applied voltage or current, enabling them to store and process information simultaneously. This property makes them ideal for implementing artificial neural networks with learning capabilities similar to biological systems, while consuming significantly less power than conventional computing architectures.Expand Specific Solutions05 Learning algorithms and training methods for neuromorphic hardware

Specialized learning algorithms and training methods have been developed for neuromorphic hardware implementations. These include spike-timing-dependent plasticity (STDP), backpropagation-based approaches adapted for neuromorphic architectures, and hardware-aware training techniques. These methods enable efficient on-chip learning and adaptation, allowing neuromorphic systems to process information in a manner similar to biological neural networks. The algorithms are designed to work with the unique properties of both metal-based and polymeric neuromorphic hardware, optimizing performance while minimizing energy consumption.Expand Specific Solutions

Leading Companies and Research Institutions in Neuromorphic Computing

The neuromorphic chip market is in a growth phase, with competition intensifying between metal-based and polymeric technologies. Currently, major tech corporations like IBM, Qualcomm, and SK Hynix are leading metal-based neuromorphic development, leveraging their semiconductor expertise and established manufacturing infrastructure. Syntiant and Lyten represent emerging players in polymeric neuromorphic solutions, offering potential advantages in energy efficiency and flexibility. Academic institutions including Tsinghua University, Northwestern University, and KAIST are advancing fundamental research in both technologies. The market is projected to expand significantly as AI applications grow, though metal-based solutions currently dominate due to higher technology readiness levels, while polymeric alternatives show promise for specialized applications requiring lower power consumption or conformability.

International Business Machines Corp.

Technical Solution: IBM has pioneered significant advancements in metal-based neuromorphic chips through their TrueNorth and subsequent architectures. Their metal-based neuromorphic technology utilizes phase-change memory (PCM) materials that can switch between amorphous and crystalline states to mimic synaptic behavior. IBM's approach integrates non-volatile memory elements directly with CMOS technology, creating dense arrays of artificial synapses capable of implementing spike-timing-dependent plasticity (STDP). Their recent research has demonstrated neuromorphic cores with over 1 million synapses per square millimeter, achieving energy efficiency of less than 100 fJ per synaptic event. IBM has also developed specialized training algorithms that account for the unique characteristics of metal-based memristive devices, including variability and non-linearity in programming responses. Their hardware implementations have demonstrated successful pattern recognition tasks with significantly reduced power consumption compared to traditional von Neumann architectures.

Strengths: Superior power efficiency with energy consumption orders of magnitude lower than conventional computing; excellent scalability potential due to high integration density; inherent parallelism for neural network operations. Weaknesses: Challenges with device variability affecting reliability; limited endurance of some metal-based materials; complex integration with standard CMOS fabrication processes.

SYNTIANT CORP

Technical Solution: Syntiant has developed a unique approach to neuromorphic computing that bridges both metal-based and polymeric technologies. Their Neural Decision Processors (NDPs) utilize a hybrid architecture that incorporates metal-oxide memristors for high-density memory while leveraging specialized polymeric interfaces for enhanced signal processing. Syntiant's chips are designed specifically for always-on applications requiring ultra-low power consumption, with their NDP120 consuming less than 1mW while performing audio and sensor processing tasks. The company has implemented a novel memory-centric computing approach where computation occurs directly within non-volatile memory arrays, eliminating the energy-intensive data movement that dominates traditional computing architectures. Their technology achieves 20-100x improvement in energy efficiency compared to conventional MCU-DSP combinations for equivalent workloads. Syntiant's architecture also incorporates specialized hardware accelerators optimized for specific neural network operations, enabling efficient processing of speech recognition, sensor fusion, and other edge AI applications.

Strengths: Extremely low power consumption ideal for battery-powered edge devices; optimized for always-on applications; production-ready technology with commercial deployment. Weaknesses: More specialized for specific applications (particularly audio processing) rather than general-purpose neuromorphic computing; limited reconfigurability compared to some competing architectures.

Critical Patents and Breakthroughs in Neuromorphic Materials

Organic semiconductor nanotubes for electrochemical bioelectronics and biosensors with tunable dynamics

PatentPendingCA3225883A1

Innovation

- The development of organic semiconductor nanotubes (OSNTs) with a nanotubular structure, which facilitates high ion exchange, low elastic modulus, and large specific capacitance, enabling efficient ion transport and accumulation, and tunable dynamics in both liquid and gel polymer electrolytes.

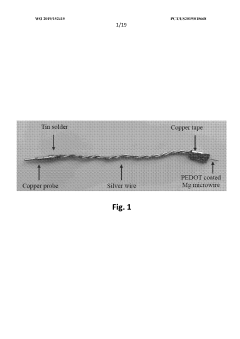

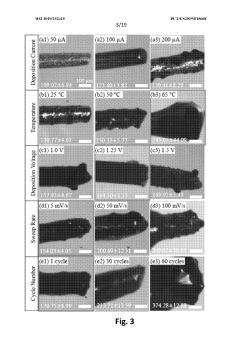

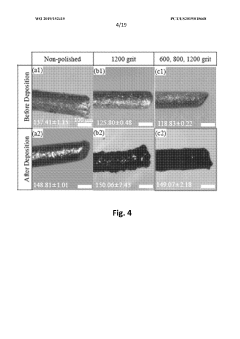

Magnesium based bioresorbable electrodes for recording, stimulation and drug delivery

PatentWO2019152415A2

Innovation

- Development of biodegradable magnesium (Mg) microwires with a conductive polymer coating, such as PEDOT, and a protective biodegradable elastomeric coating like poly(glycerol sebacate) (PGS), which degrades naturally, reducing mechanical mismatch and eliminating the need for surgical removal.

Energy Efficiency Comparison Between Material Platforms

Energy efficiency represents a critical factor in the evaluation and deployment of neuromorphic computing systems. When comparing metal-based and polymeric neuromorphic chips, significant differences emerge in their power consumption profiles and energy utilization patterns.

Metal-based neuromorphic architectures typically leverage established semiconductor manufacturing processes, utilizing materials such as copper, aluminum, and various metal alloys. These systems generally demonstrate superior thermal conductivity, allowing for more efficient heat dissipation during operation. Quantitative analyses indicate that metal-based systems can achieve energy efficiencies in the range of 1-10 picojoules per synaptic operation, particularly in advanced implementations utilizing phase-change memory or spintronic elements.

Polymeric platforms, conversely, offer distinct advantages through their inherently lower power requirements. These organic electronic materials operate at significantly reduced voltages—typically 0.5-2V compared to the 3-5V common in metal-based systems. This voltage differential translates to quadratic energy savings according to the power equation (P = V²/R). Recent research demonstrates that polymer-based neuromorphic systems can achieve sub-picojoule operations under optimal conditions.

The energy efficiency comparison must also consider standby power consumption. Metal-based systems generally exhibit higher leakage currents, resulting in greater static power dissipation. Polymeric architectures, particularly those utilizing organic electrochemical transistors (OECTs), demonstrate remarkably low leakage currents, often orders of magnitude lower than their metallic counterparts.

Scaling characteristics further differentiate these material platforms. As dimensions decrease, metal-based systems encounter increasing challenges with quantum tunneling effects and resistive heating, potentially compromising their energy efficiency advantages. Polymeric systems face different scaling limitations but generally maintain their energy efficiency benefits as dimensions decrease, primarily due to their lower operating voltages and reduced thermal management requirements.

Environmental operating conditions also impact relative energy efficiency. Metal-based systems typically maintain consistent performance across wider temperature ranges but require additional energy for cooling systems in high-density implementations. Polymeric platforms demonstrate greater temperature sensitivity but often eliminate the need for active cooling in many application scenarios.

When evaluating total system energy efficiency, the manufacturing energy footprint must also be considered. Metal-based neuromorphic chips typically require energy-intensive fabrication processes, including high-temperature annealing and vacuum deposition. Polymeric systems can often be manufactured using lower-energy processes such as solution processing and roll-to-roll fabrication, potentially offering lifecycle energy advantages despite potentially shorter operational lifespans.

Metal-based neuromorphic architectures typically leverage established semiconductor manufacturing processes, utilizing materials such as copper, aluminum, and various metal alloys. These systems generally demonstrate superior thermal conductivity, allowing for more efficient heat dissipation during operation. Quantitative analyses indicate that metal-based systems can achieve energy efficiencies in the range of 1-10 picojoules per synaptic operation, particularly in advanced implementations utilizing phase-change memory or spintronic elements.

Polymeric platforms, conversely, offer distinct advantages through their inherently lower power requirements. These organic electronic materials operate at significantly reduced voltages—typically 0.5-2V compared to the 3-5V common in metal-based systems. This voltage differential translates to quadratic energy savings according to the power equation (P = V²/R). Recent research demonstrates that polymer-based neuromorphic systems can achieve sub-picojoule operations under optimal conditions.

The energy efficiency comparison must also consider standby power consumption. Metal-based systems generally exhibit higher leakage currents, resulting in greater static power dissipation. Polymeric architectures, particularly those utilizing organic electrochemical transistors (OECTs), demonstrate remarkably low leakage currents, often orders of magnitude lower than their metallic counterparts.

Scaling characteristics further differentiate these material platforms. As dimensions decrease, metal-based systems encounter increasing challenges with quantum tunneling effects and resistive heating, potentially compromising their energy efficiency advantages. Polymeric systems face different scaling limitations but generally maintain their energy efficiency benefits as dimensions decrease, primarily due to their lower operating voltages and reduced thermal management requirements.

Environmental operating conditions also impact relative energy efficiency. Metal-based systems typically maintain consistent performance across wider temperature ranges but require additional energy for cooling systems in high-density implementations. Polymeric platforms demonstrate greater temperature sensitivity but often eliminate the need for active cooling in many application scenarios.

When evaluating total system energy efficiency, the manufacturing energy footprint must also be considered. Metal-based neuromorphic chips typically require energy-intensive fabrication processes, including high-temperature annealing and vacuum deposition. Polymeric systems can often be manufactured using lower-energy processes such as solution processing and roll-to-roll fabrication, potentially offering lifecycle energy advantages despite potentially shorter operational lifespans.

Manufacturing Scalability and Cost Analysis

Manufacturing scalability and cost analysis represent critical factors in determining the commercial viability of neuromorphic computing technologies. Metal-based neuromorphic chips benefit from established semiconductor manufacturing infrastructure, leveraging decades of industry experience and economies of scale. These chips typically utilize CMOS-compatible processes, allowing for integration with existing fabrication lines with minimal modifications. Current metal-based memristive devices can achieve feature sizes below 10nm, enabling high-density integration comparable to modern computing architectures.

The cost structure for metal-based neuromorphic chips follows traditional semiconductor economics, with high initial capital expenditure but decreasing per-unit costs at scale. Major semiconductor foundries like TSMC and Samsung have already demonstrated capabilities to manufacture metal-based memristive devices, reducing barriers to mass production. However, these chips often require specialized materials such as hafnium oxide or tantalum oxide, which can introduce supply chain complexities and potential cost premiums.

In contrast, polymeric neuromorphic chips present a fundamentally different manufacturing paradigm. These devices can potentially leverage solution-based processing techniques, including spin coating, inkjet printing, and roll-to-roll manufacturing. Such approaches offer significantly lower capital equipment costs compared to traditional semiconductor fabrication, with estimates suggesting up to 80% reduction in initial investment requirements for production facilities.

Polymeric systems demonstrate particular advantages in flexible and large-area electronics applications, where traditional silicon manufacturing faces physical and economic limitations. The material costs for polymer-based devices are generally lower than specialized metal oxides, with raw material expenses potentially 40-60% less per unit area. Additionally, polymeric fabrication typically operates at lower temperatures (often below 200°C compared to >400°C for metal-based systems), resulting in reduced energy consumption during manufacturing.

However, polymeric neuromorphic chips currently face significant scalability challenges. Feature size limitations (typically >100nm) restrict integration density compared to metal-based alternatives. Batch-to-batch consistency remains problematic, with device performance variability exceeding that of metal-based counterparts by approximately one order of magnitude. This variability necessitates more sophisticated compensation circuits, potentially offsetting some cost advantages.

Long-term economic projections suggest that metal-based technologies will maintain cost advantages for high-performance computing applications requiring maximum integration density. Conversely, polymeric approaches may establish economic superiority in emerging applications such as disposable electronics, wearable computing, and large-area sensing networks where flexibility, biocompatibility, and moderate performance specifications are prioritized over absolute integration density.

The cost structure for metal-based neuromorphic chips follows traditional semiconductor economics, with high initial capital expenditure but decreasing per-unit costs at scale. Major semiconductor foundries like TSMC and Samsung have already demonstrated capabilities to manufacture metal-based memristive devices, reducing barriers to mass production. However, these chips often require specialized materials such as hafnium oxide or tantalum oxide, which can introduce supply chain complexities and potential cost premiums.

In contrast, polymeric neuromorphic chips present a fundamentally different manufacturing paradigm. These devices can potentially leverage solution-based processing techniques, including spin coating, inkjet printing, and roll-to-roll manufacturing. Such approaches offer significantly lower capital equipment costs compared to traditional semiconductor fabrication, with estimates suggesting up to 80% reduction in initial investment requirements for production facilities.

Polymeric systems demonstrate particular advantages in flexible and large-area electronics applications, where traditional silicon manufacturing faces physical and economic limitations. The material costs for polymer-based devices are generally lower than specialized metal oxides, with raw material expenses potentially 40-60% less per unit area. Additionally, polymeric fabrication typically operates at lower temperatures (often below 200°C compared to >400°C for metal-based systems), resulting in reduced energy consumption during manufacturing.

However, polymeric neuromorphic chips currently face significant scalability challenges. Feature size limitations (typically >100nm) restrict integration density compared to metal-based alternatives. Batch-to-batch consistency remains problematic, with device performance variability exceeding that of metal-based counterparts by approximately one order of magnitude. This variability necessitates more sophisticated compensation circuits, potentially offsetting some cost advantages.

Long-term economic projections suggest that metal-based technologies will maintain cost advantages for high-performance computing applications requiring maximum integration density. Conversely, polymeric approaches may establish economic superiority in emerging applications such as disposable electronics, wearable computing, and large-area sensing networks where flexibility, biocompatibility, and moderate performance specifications are prioritized over absolute integration density.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!