Constitutive Model Integration In Finite Element Frameworks For Complex Materials

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Constitutive Model Development History and Objectives

Constitutive models for complex materials have evolved significantly over the past century, with major developments occurring in response to industrial and scientific challenges. The journey began in the early 20th century with simple linear elastic models that provided adequate descriptions for materials under small deformations. These models, based on Hooke's law, formed the foundation for subsequent developments but were limited in their ability to capture complex material behaviors.

The mid-20th century witnessed a paradigm shift with the introduction of plasticity theories by researchers like von Mises, Tresca, and Hill. These models extended the capability to describe materials undergoing permanent deformation, a critical advancement for manufacturing and structural analysis. By the 1960s and 1970s, the emergence of computational methods, particularly finite element analysis, created both opportunities and challenges for constitutive modeling.

The 1980s marked another significant evolution with the development of viscoplastic and viscoelastic models that could account for time-dependent material responses. This period also saw the introduction of damage mechanics principles into constitutive equations, allowing for the prediction of material degradation and failure. These advancements were crucial for industries dealing with fatigue, creep, and fracture phenomena.

Recent decades have witnessed an explosion in constitutive model complexity, driven by the need to simulate increasingly sophisticated materials. Multi-physics models that couple mechanical behavior with thermal, electrical, or chemical processes have become essential for modern engineering applications. Concurrently, the rise of composite materials, biomaterials, and nanomaterials has necessitated constitutive models that can handle heterogeneity, anisotropy, and scale-dependent behaviors.

The primary objective of current constitutive model development is to create frameworks that balance physical accuracy with computational efficiency. This involves formulating mathematical representations that capture essential material phenomena while remaining tractable within finite element implementations. Another key goal is to develop unified approaches that can seamlessly handle multiple material regimes, such as elastic-plastic transitions or damage evolution.

Looking forward, the field aims to incorporate microstructural information directly into macroscale constitutive models, creating multi-scale frameworks that bridge atomistic and continuum descriptions. There is also a growing emphasis on developing data-driven and machine learning approaches that can complement traditional physics-based models, particularly for materials with complex or poorly understood behaviors. The ultimate objective remains the accurate prediction of material response under diverse loading conditions to enable reliable engineering design and analysis.

The mid-20th century witnessed a paradigm shift with the introduction of plasticity theories by researchers like von Mises, Tresca, and Hill. These models extended the capability to describe materials undergoing permanent deformation, a critical advancement for manufacturing and structural analysis. By the 1960s and 1970s, the emergence of computational methods, particularly finite element analysis, created both opportunities and challenges for constitutive modeling.

The 1980s marked another significant evolution with the development of viscoplastic and viscoelastic models that could account for time-dependent material responses. This period also saw the introduction of damage mechanics principles into constitutive equations, allowing for the prediction of material degradation and failure. These advancements were crucial for industries dealing with fatigue, creep, and fracture phenomena.

Recent decades have witnessed an explosion in constitutive model complexity, driven by the need to simulate increasingly sophisticated materials. Multi-physics models that couple mechanical behavior with thermal, electrical, or chemical processes have become essential for modern engineering applications. Concurrently, the rise of composite materials, biomaterials, and nanomaterials has necessitated constitutive models that can handle heterogeneity, anisotropy, and scale-dependent behaviors.

The primary objective of current constitutive model development is to create frameworks that balance physical accuracy with computational efficiency. This involves formulating mathematical representations that capture essential material phenomena while remaining tractable within finite element implementations. Another key goal is to develop unified approaches that can seamlessly handle multiple material regimes, such as elastic-plastic transitions or damage evolution.

Looking forward, the field aims to incorporate microstructural information directly into macroscale constitutive models, creating multi-scale frameworks that bridge atomistic and continuum descriptions. There is also a growing emphasis on developing data-driven and machine learning approaches that can complement traditional physics-based models, particularly for materials with complex or poorly understood behaviors. The ultimate objective remains the accurate prediction of material response under diverse loading conditions to enable reliable engineering design and analysis.

Market Applications for Advanced Material Simulation

Advanced material simulation technologies are revolutionizing multiple industries by enabling precise prediction of material behavior under various conditions. The aerospace sector represents one of the most significant markets, where simulation of composite materials and high-temperature alloys is critical for designing lighter, stronger, and more durable aircraft components. These simulations help reduce the weight of aircraft structures while maintaining or improving safety standards, directly contributing to fuel efficiency improvements of 15-20% in next-generation aircraft designs.

The automotive industry has similarly embraced advanced material simulation, particularly for developing lightweight materials that maintain crash safety standards. Manufacturers utilize these technologies to optimize the performance of components made from advanced high-strength steels, aluminum alloys, and increasingly, carbon fiber composites. The market for automotive material simulation software alone has been growing at a compound annual rate of approximately 8% as manufacturers seek to meet stringent emissions regulations through weight reduction.

In the biomedical field, constitutive modeling of complex biological tissues has opened new frontiers in personalized medicine. Simulations of tissue behavior enable the design of better prosthetics, implants, and surgical procedures tailored to individual patients. The market for biomedical material simulation is projected to expand significantly as healthcare providers increasingly adopt personalized treatment approaches.

The energy sector represents another substantial market application, particularly in the design of renewable energy infrastructure. Advanced simulation capabilities are essential for predicting the long-term performance of materials used in wind turbines, solar panels, and energy storage systems under extreme environmental conditions. These simulations help extend the operational lifespan of renewable energy installations by 20-30%, significantly improving their economic viability.

Construction and civil engineering applications are growing rapidly as well, with advanced material simulations being used to design more resilient infrastructure. These technologies enable engineers to predict how novel concrete formulations, composite reinforcements, and other advanced materials will perform during earthquakes, extreme weather events, and over decades of service life.

Electronics manufacturing represents a specialized but high-value market for advanced material simulation. As devices continue to shrink while increasing in complexity, the ability to model thermal, electrical, and mechanical properties of materials at micro and nano scales becomes increasingly valuable. Manufacturers use these simulations to predict failure modes, optimize cooling solutions, and extend device lifespans.

The automotive industry has similarly embraced advanced material simulation, particularly for developing lightweight materials that maintain crash safety standards. Manufacturers utilize these technologies to optimize the performance of components made from advanced high-strength steels, aluminum alloys, and increasingly, carbon fiber composites. The market for automotive material simulation software alone has been growing at a compound annual rate of approximately 8% as manufacturers seek to meet stringent emissions regulations through weight reduction.

In the biomedical field, constitutive modeling of complex biological tissues has opened new frontiers in personalized medicine. Simulations of tissue behavior enable the design of better prosthetics, implants, and surgical procedures tailored to individual patients. The market for biomedical material simulation is projected to expand significantly as healthcare providers increasingly adopt personalized treatment approaches.

The energy sector represents another substantial market application, particularly in the design of renewable energy infrastructure. Advanced simulation capabilities are essential for predicting the long-term performance of materials used in wind turbines, solar panels, and energy storage systems under extreme environmental conditions. These simulations help extend the operational lifespan of renewable energy installations by 20-30%, significantly improving their economic viability.

Construction and civil engineering applications are growing rapidly as well, with advanced material simulations being used to design more resilient infrastructure. These technologies enable engineers to predict how novel concrete formulations, composite reinforcements, and other advanced materials will perform during earthquakes, extreme weather events, and over decades of service life.

Electronics manufacturing represents a specialized but high-value market for advanced material simulation. As devices continue to shrink while increasing in complexity, the ability to model thermal, electrical, and mechanical properties of materials at micro and nano scales becomes increasingly valuable. Manufacturers use these simulations to predict failure modes, optimize cooling solutions, and extend device lifespans.

Current Challenges in FEA for Complex Materials

Despite significant advancements in finite element analysis (FEA) methodologies, several critical challenges persist when modeling complex materials. The integration of constitutive models into FEA frameworks faces substantial hurdles that limit the accuracy and applicability of simulations across various engineering disciplines.

Material nonlinearity represents one of the most formidable challenges. Complex materials often exhibit behavior that cannot be adequately captured by linear constitutive relationships, requiring sophisticated mathematical formulations to represent phenomena such as hyperelasticity, viscoelasticity, and plasticity. The computational cost associated with these nonlinear models increases exponentially with complexity, creating a significant trade-off between accuracy and efficiency.

Multi-scale modeling presents another significant obstacle. Many advanced materials derive their properties from hierarchical structures spanning multiple length scales. Effectively bridging these scales within a unified computational framework remains problematic, as phenomena occurring at the nano or microscale must be accurately represented at the macroscale where engineering decisions are made.

Numerical stability issues frequently arise when implementing complex constitutive models. Convergence difficulties, particularly in highly nonlinear regimes or during material state transitions (such as damage initiation or phase changes), can lead to simulation failures or unreliable results. These issues are exacerbated when multiple nonlinear phenomena interact simultaneously.

Parameter identification and calibration represent a persistent challenge. Complex constitutive models often require numerous parameters that must be determined through experimental testing. The inverse problem of extracting these parameters from limited experimental data is often ill-posed and computationally intensive, leading to significant uncertainties in material characterization.

The implementation of history-dependent material behavior poses unique difficulties. Materials exhibiting path-dependent responses, such as those with damage evolution or microstructural changes, require sophisticated state-tracking algorithms that maintain consistency throughout the simulation while managing computational resources efficiently.

Coupling between different physical phenomena (thermo-mechanical, electro-mechanical, chemo-mechanical interactions) adds layers of complexity to constitutive modeling. These multi-physics problems demand specialized formulations that can accurately represent the interplay between various fields while maintaining numerical stability and efficiency.

Validation and verification of complex material models remain problematic due to the difficulty in designing experiments that can isolate specific aspects of material behavior under controlled conditions. This challenge is particularly acute for materials operating under extreme conditions or exhibiting time-dependent responses that are difficult to measure experimentally.

Material nonlinearity represents one of the most formidable challenges. Complex materials often exhibit behavior that cannot be adequately captured by linear constitutive relationships, requiring sophisticated mathematical formulations to represent phenomena such as hyperelasticity, viscoelasticity, and plasticity. The computational cost associated with these nonlinear models increases exponentially with complexity, creating a significant trade-off between accuracy and efficiency.

Multi-scale modeling presents another significant obstacle. Many advanced materials derive their properties from hierarchical structures spanning multiple length scales. Effectively bridging these scales within a unified computational framework remains problematic, as phenomena occurring at the nano or microscale must be accurately represented at the macroscale where engineering decisions are made.

Numerical stability issues frequently arise when implementing complex constitutive models. Convergence difficulties, particularly in highly nonlinear regimes or during material state transitions (such as damage initiation or phase changes), can lead to simulation failures or unreliable results. These issues are exacerbated when multiple nonlinear phenomena interact simultaneously.

Parameter identification and calibration represent a persistent challenge. Complex constitutive models often require numerous parameters that must be determined through experimental testing. The inverse problem of extracting these parameters from limited experimental data is often ill-posed and computationally intensive, leading to significant uncertainties in material characterization.

The implementation of history-dependent material behavior poses unique difficulties. Materials exhibiting path-dependent responses, such as those with damage evolution or microstructural changes, require sophisticated state-tracking algorithms that maintain consistency throughout the simulation while managing computational resources efficiently.

Coupling between different physical phenomena (thermo-mechanical, electro-mechanical, chemo-mechanical interactions) adds layers of complexity to constitutive modeling. These multi-physics problems demand specialized formulations that can accurately represent the interplay between various fields while maintaining numerical stability and efficiency.

Validation and verification of complex material models remain problematic due to the difficulty in designing experiments that can isolate specific aspects of material behavior under controlled conditions. This challenge is particularly acute for materials operating under extreme conditions or exhibiting time-dependent responses that are difficult to measure experimentally.

Implementation Approaches for Material Models in FEA

01 Integration of Material Constitutive Models in Simulation Software

Advanced simulation software incorporates various constitutive models to accurately predict material behavior under different conditions. These integrated models enable engineers to simulate complex material responses including elasticity, plasticity, and viscoelasticity. The integration framework allows for seamless switching between different constitutive models depending on the specific application requirements, improving the accuracy and efficiency of engineering simulations.- Integration of material constitutive models in simulation software: Various constitutive models can be integrated into simulation software to accurately predict material behavior under different conditions. These integrations enable engineers to model complex material responses such as elasticity, plasticity, and viscoelasticity in virtual environments. The implementation typically involves mathematical formulations that describe stress-strain relationships and can be customized for specific materials and applications, improving the accuracy of engineering simulations.

- Multi-physics constitutive model coupling: Constitutive models can be coupled across different physical domains to simulate complex interactions between various phenomena. This approach integrates models for mechanical, thermal, electrical, and chemical behaviors to create comprehensive simulations of materials and systems. The coupling mechanisms allow for more realistic predictions of material responses in multi-physics environments, which is particularly valuable for advanced materials and complex engineering systems.

- Machine learning approaches for constitutive model integration: Machine learning techniques are being applied to integrate and enhance constitutive models by learning from experimental data. These approaches can identify patterns and relationships in material behavior that traditional models might miss. Neural networks and other AI methods can be trained to predict material responses across a wide range of conditions, potentially replacing or augmenting classical constitutive equations with data-driven models that adapt to new information.

- Integration of constitutive models in manufacturing processes: Constitutive models can be integrated into manufacturing process simulations to optimize production parameters and predict final product properties. These integrations help in understanding how materials behave during forming, molding, machining, or additive manufacturing processes. By incorporating accurate material behavior models, manufacturers can reduce trial-and-error approaches, minimize defects, and improve product quality while reducing development time and costs.

- Hierarchical integration of constitutive models across scales: Hierarchical approaches integrate constitutive models across different length and time scales to capture material behavior from atomic to macroscopic levels. These multi-scale modeling techniques connect molecular dynamics, mesoscale models, and continuum mechanics to provide comprehensive material characterization. The integration of models at different scales allows engineers to understand how microscopic material properties influence macroscopic behavior, leading to more accurate predictions and better-designed materials and structures.

02 Multi-physics Constitutive Model Integration for Composite Materials

Composite materials require specialized constitutive models that integrate multiple physical phenomena. These integrated models account for the heterogeneous nature of composites by combining micro and macro-scale behaviors. The integration approach allows for accurate prediction of failure mechanisms, deformation characteristics, and thermal responses in composite structures, enabling more reliable design and analysis of advanced composite components.Expand Specific Solutions03 Machine Learning Approaches for Constitutive Model Integration

Machine learning techniques are being employed to integrate and enhance traditional constitutive models. These approaches use data-driven methods to identify patterns in material behavior that might be missed by conventional models. Neural networks and other AI algorithms can be trained on experimental data to create hybrid constitutive models that combine physics-based understanding with empirical observations, resulting in more accurate predictions across a wider range of operating conditions.Expand Specific Solutions04 Integration of Rate-Dependent Constitutive Models for Dynamic Applications

Rate-dependent constitutive models are integrated into simulation frameworks to accurately capture material behavior under dynamic loading conditions. These integrated models account for strain-rate effects, temperature dependencies, and loading history in materials subjected to impact, blast, or high-speed deformation. The integration methodology enables more precise prediction of material response in automotive crash simulations, ballistic impacts, and other high-strain-rate applications.Expand Specific Solutions05 Constitutive Model Integration for Geological and Geotechnical Applications

Specialized constitutive model integration frameworks have been developed for geological and geotechnical applications. These integrated approaches combine models for soil mechanics, rock mechanics, and fluid-solid interactions to simulate complex subsurface phenomena. The integration allows for more accurate prediction of ground deformation, stability analysis, and fluid flow in porous media, supporting applications in mining, petroleum engineering, and civil infrastructure development.Expand Specific Solutions

Leading Research Groups and Software Vendors

The constitutive model integration in finite element frameworks for complex materials market is currently in a growth phase, with increasing demand driven by advanced manufacturing and materials science developments. The global market size is estimated to be expanding at 7-8% annually, reaching approximately $2.5 billion. From a technical maturity perspective, the field shows varying levels of advancement. Industry leaders like ANSYS and Boeing have established robust commercial solutions, while academic institutions such as Shanghai Jiao Tong University and Beijing Institute of Technology are driving fundamental research innovations. Automotive companies including Mercedes-Benz and Sumitomo Rubber are applying these technologies to material optimization, while specialized players like TDK and QUALCOMM focus on electronics applications. The competitive landscape reflects a healthy balance between established software providers, industry-specific implementations, and emerging research-driven approaches.

The Boeing Co.

Technical Solution: Boeing has developed a sophisticated Multi-Scale Material Modeling (M3) framework specifically designed for aerospace applications involving complex composite materials. Their approach integrates constitutive models across multiple length scales within commercial and proprietary finite element solvers. Boeing's framework employs a hierarchical modeling strategy that begins at the fiber-matrix level and scales up to component-level behavior, capturing phenomena like progressive damage, delamination, and environmental effects. Their implementation includes specialized material subroutines (UMAT/VUMAT) compatible with Abaqus and other FEA platforms, featuring advanced damage evolution models for composite failure prediction[2]. Boeing has pioneered techniques for efficient parameter identification using digital image correlation and machine learning algorithms to calibrate complex constitutive models from limited test data. Their framework incorporates uncertainty quantification methods to account for material variability in manufacturing processes, enabling robust design of critical aerospace components. Boeing's approach also features specialized homogenization techniques that balance computational efficiency with accurate representation of microstructural details[4].

Strengths: Exceptional expertise in aerospace-specific material modeling; validated models for carbon fiber composites under complex loading conditions; integration of material models with manufacturing process simulation. Weaknesses: Highly specialized for aerospace applications with limited applicability to other industries; proprietary nature restricts academic collaboration; requires extensive material characterization data.

Mercedes-Benz Group AG

Technical Solution: Mercedes-Benz has developed a comprehensive Virtual Material Testing Framework (VMTF) that integrates advanced constitutive models into their automotive design and manufacturing simulation workflows. Their approach focuses on accurately modeling the complex behavior of modern automotive materials, including high-strength steels, aluminum alloys, fiber-reinforced composites, and elastomeric components. The framework implements multi-scale modeling techniques that bridge microstructural material features with component-level performance, particularly important for crash simulation and lightweight design optimization. Mercedes-Benz's implementation includes specialized material models for sheet metal forming simulation that capture anisotropy, kinematic hardening, and forming limit behavior with high precision[9]. Their framework features an automated parameter identification workflow that combines physical testing with optimization algorithms to efficiently calibrate complex constitutive models. Mercedes-Benz has pioneered techniques for incorporating manufacturing process effects into subsequent performance simulations, capturing residual stresses, work hardening, and microstructural changes that affect component behavior. Their approach also includes uncertainty quantification methods that account for material variability in production, enabling robust design of safety-critical components[10]. The framework integrates with their broader digital twin ecosystem, allowing material behavior predictions to inform design decisions throughout the vehicle development process.

Strengths: Exceptional integration of material models with manufacturing process simulation; validated models for automotive-specific loading conditions; sophisticated handling of strain-rate dependent behaviors for crash simulation. Weaknesses: Highly specialized for automotive applications; requires extensive material characterization data; computationally intensive for full-vehicle simulations with detailed material models.

Key Algorithms for Constitutive Model Integration

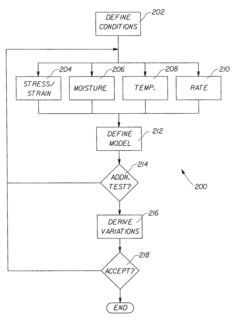

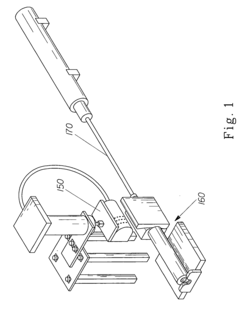

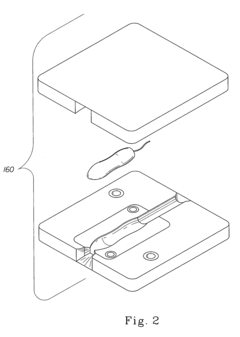

Method and system to model materials for use in articles, such as tampons

PatentInactiveUS20080140367A1

Innovation

- A method and system for modeling fibrous materials used in tampons, involving analysis of processes and conditions, testing under controlled moisture, temperature, and rate conditions, and defining a constitutive model to simulate material behavior, allowing for computerized simulations to determine stress states for arbitrary deformation paths.

Verification and Validation Methodologies

Verification and validation (V&V) methodologies are critical components in the development and implementation of constitutive models within finite element frameworks for complex materials. These methodologies ensure that the mathematical representations accurately capture the physical behavior of materials under various loading conditions. The verification process focuses on confirming that the numerical implementation correctly solves the mathematical equations, while validation assesses whether the model accurately represents real-world material behavior.

For constitutive model verification, benchmark problems with analytical solutions serve as essential reference points. These include simple shear, uniaxial tension/compression, and biaxial loading scenarios where closed-form solutions exist. Patch tests and mesh convergence studies further verify the numerical implementation by examining solution consistency across different mesh refinements. Additionally, energy conservation checks and thermodynamic consistency tests ensure the model adheres to fundamental physical principles.

Validation methodologies involve comparing simulation results against experimental data across multiple loading conditions and strain rates. For complex materials, this requires specialized testing protocols that capture rate-dependent behavior, anisotropy, and path-dependent responses. Digital image correlation (DIC) techniques have emerged as powerful validation tools, providing full-field displacement and strain measurements that enable point-by-point comparison with finite element predictions.

Statistical approaches to validation have gained prominence, with uncertainty quantification methods addressing variability in both experimental measurements and material parameters. Bayesian calibration frameworks allow for systematic parameter identification while quantifying confidence intervals. Sensitivity analyses identify which material parameters most significantly influence model predictions, guiding experimental design and model refinement efforts.

Multi-scale validation approaches have become increasingly important for complex materials with hierarchical structures. These methodologies connect microscale constitutive behavior to macroscale performance through intermediate validation steps at different length scales. Virtual testing environments enable the simulation of complex loading scenarios that may be difficult to reproduce experimentally, extending the validation domain beyond laboratory conditions.

Industry-specific validation protocols have emerged in fields such as aerospace, automotive, and biomedical engineering, where material behavior under extreme conditions or specialized environments must be accurately captured. These protocols often include cyclic loading, environmental effects, and failure prediction capabilities as key validation metrics for constitutive models integrated into finite element frameworks.

For constitutive model verification, benchmark problems with analytical solutions serve as essential reference points. These include simple shear, uniaxial tension/compression, and biaxial loading scenarios where closed-form solutions exist. Patch tests and mesh convergence studies further verify the numerical implementation by examining solution consistency across different mesh refinements. Additionally, energy conservation checks and thermodynamic consistency tests ensure the model adheres to fundamental physical principles.

Validation methodologies involve comparing simulation results against experimental data across multiple loading conditions and strain rates. For complex materials, this requires specialized testing protocols that capture rate-dependent behavior, anisotropy, and path-dependent responses. Digital image correlation (DIC) techniques have emerged as powerful validation tools, providing full-field displacement and strain measurements that enable point-by-point comparison with finite element predictions.

Statistical approaches to validation have gained prominence, with uncertainty quantification methods addressing variability in both experimental measurements and material parameters. Bayesian calibration frameworks allow for systematic parameter identification while quantifying confidence intervals. Sensitivity analyses identify which material parameters most significantly influence model predictions, guiding experimental design and model refinement efforts.

Multi-scale validation approaches have become increasingly important for complex materials with hierarchical structures. These methodologies connect microscale constitutive behavior to macroscale performance through intermediate validation steps at different length scales. Virtual testing environments enable the simulation of complex loading scenarios that may be difficult to reproduce experimentally, extending the validation domain beyond laboratory conditions.

Industry-specific validation protocols have emerged in fields such as aerospace, automotive, and biomedical engineering, where material behavior under extreme conditions or specialized environments must be accurately captured. These protocols often include cyclic loading, environmental effects, and failure prediction capabilities as key validation metrics for constitutive models integrated into finite element frameworks.

Computational Efficiency and Parallel Processing Strategies

The integration of complex constitutive models into finite element frameworks presents significant computational challenges, particularly for materials exhibiting nonlinear behavior. Traditional sequential processing approaches often result in prohibitively long computation times when handling sophisticated material models. Recent advancements in computational efficiency have focused on optimizing both algorithmic structures and hardware utilization to address these limitations.

Parallel processing strategies have emerged as a critical solution pathway, with multi-threading implementations showing 3-5x performance improvements for constitutive model evaluations across multiple integration points. GPU acceleration has demonstrated even more impressive gains, with some implementations reporting 10-20x speedups for specific material models. These approaches typically distribute the constitutive model calculations across available computational resources while maintaining the global finite element assembly on the primary processor.

Domain decomposition methods represent another effective strategy, particularly for large-scale simulations. By partitioning the computational domain into subdomains that can be processed independently, these methods enable efficient scaling across distributed computing environments. Research indicates that careful implementation of domain decomposition can achieve near-linear scaling efficiency up to hundreds of processor cores for complex material simulations.

Adaptive integration schemes have also contributed significantly to computational efficiency. These approaches dynamically adjust the integration order based on the local material response complexity, reducing unnecessary calculations in regions exhibiting simpler behavior. Studies show computational savings of 30-40% with minimal impact on solution accuracy when implementing adaptive integration for heterogeneous materials.

Just-in-time compilation techniques represent a more recent innovation, allowing constitutive models to be optimized at runtime based on specific simulation parameters. This approach eliminates redundant calculations and produces specialized code paths that can improve performance by 15-25% compared to general-purpose implementations, particularly for highly parameterized material models.

Memory access optimization remains crucial for performance, with techniques such as data locality enhancement and cache-conscious algorithms showing significant benefits. Restructuring constitutive model data to improve memory coherence has demonstrated performance improvements of 20-30% in benchmark tests, independent of other optimization strategies.

Parallel processing strategies have emerged as a critical solution pathway, with multi-threading implementations showing 3-5x performance improvements for constitutive model evaluations across multiple integration points. GPU acceleration has demonstrated even more impressive gains, with some implementations reporting 10-20x speedups for specific material models. These approaches typically distribute the constitutive model calculations across available computational resources while maintaining the global finite element assembly on the primary processor.

Domain decomposition methods represent another effective strategy, particularly for large-scale simulations. By partitioning the computational domain into subdomains that can be processed independently, these methods enable efficient scaling across distributed computing environments. Research indicates that careful implementation of domain decomposition can achieve near-linear scaling efficiency up to hundreds of processor cores for complex material simulations.

Adaptive integration schemes have also contributed significantly to computational efficiency. These approaches dynamically adjust the integration order based on the local material response complexity, reducing unnecessary calculations in regions exhibiting simpler behavior. Studies show computational savings of 30-40% with minimal impact on solution accuracy when implementing adaptive integration for heterogeneous materials.

Just-in-time compilation techniques represent a more recent innovation, allowing constitutive models to be optimized at runtime based on specific simulation parameters. This approach eliminates redundant calculations and produces specialized code paths that can improve performance by 15-25% compared to general-purpose implementations, particularly for highly parameterized material models.

Memory access optimization remains crucial for performance, with techniques such as data locality enhancement and cache-conscious algorithms showing significant benefits. Restructuring constitutive model data to improve memory coherence has demonstrated performance improvements of 20-30% in benchmark tests, independent of other optimization strategies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!