Coupling Discrete Microstructural Models With Continuum Finite Element Representations

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Multiscale Modeling Background and Objectives

Multiscale modeling has emerged as a critical approach in computational mechanics and materials science over the past three decades. This methodology bridges the gap between microscopic phenomena and macroscopic behaviors by integrating models across different length and time scales. The coupling of discrete microstructural models with continuum finite element representations represents a particularly significant advancement in this field, enabling more accurate predictions of material behavior under various conditions.

The evolution of multiscale modeling can be traced back to the 1990s when computational capabilities began to support more complex simulations. Initially, these approaches were limited to simple homogenization techniques that averaged microstructural properties. As computing power increased, more sophisticated methods emerged, allowing for direct incorporation of microstructural details into larger-scale models.

Current technological trends point toward increasingly integrated approaches that can simultaneously capture phenomena occurring at multiple scales. This integration is crucial for materials with complex microstructures where localized behaviors significantly influence overall performance. Industries including aerospace, automotive, biomedical, and energy production have identified multiscale modeling as a key enabler for next-generation materials and designs.

The primary objective of coupling discrete microstructural models with continuum finite element representations is to develop predictive computational frameworks that accurately capture material behavior across scales. This includes predicting failure mechanisms, understanding deformation processes, and optimizing material performance under various loading conditions. Such models aim to reduce reliance on extensive experimental testing, accelerate material development cycles, and enable more efficient design processes.

Specific technical goals include developing robust mathematical formulations for scale bridging, creating efficient numerical algorithms for handling the computational complexity, establishing validation methodologies against experimental data, and implementing user-friendly software frameworks that can be adopted by industry. Additionally, there is a growing emphasis on incorporating uncertainty quantification to address the inherent variability in material microstructures.

The long-term vision for this technology extends beyond traditional structural materials to include functional materials, biological systems, and novel composites. As computational capabilities continue to advance, particularly with the emergence of exascale computing and machine learning techniques, the scope and accuracy of multiscale models are expected to expand dramatically, potentially revolutionizing how materials are designed, tested, and implemented across industries.

The evolution of multiscale modeling can be traced back to the 1990s when computational capabilities began to support more complex simulations. Initially, these approaches were limited to simple homogenization techniques that averaged microstructural properties. As computing power increased, more sophisticated methods emerged, allowing for direct incorporation of microstructural details into larger-scale models.

Current technological trends point toward increasingly integrated approaches that can simultaneously capture phenomena occurring at multiple scales. This integration is crucial for materials with complex microstructures where localized behaviors significantly influence overall performance. Industries including aerospace, automotive, biomedical, and energy production have identified multiscale modeling as a key enabler for next-generation materials and designs.

The primary objective of coupling discrete microstructural models with continuum finite element representations is to develop predictive computational frameworks that accurately capture material behavior across scales. This includes predicting failure mechanisms, understanding deformation processes, and optimizing material performance under various loading conditions. Such models aim to reduce reliance on extensive experimental testing, accelerate material development cycles, and enable more efficient design processes.

Specific technical goals include developing robust mathematical formulations for scale bridging, creating efficient numerical algorithms for handling the computational complexity, establishing validation methodologies against experimental data, and implementing user-friendly software frameworks that can be adopted by industry. Additionally, there is a growing emphasis on incorporating uncertainty quantification to address the inherent variability in material microstructures.

The long-term vision for this technology extends beyond traditional structural materials to include functional materials, biological systems, and novel composites. As computational capabilities continue to advance, particularly with the emergence of exascale computing and machine learning techniques, the scope and accuracy of multiscale models are expected to expand dramatically, potentially revolutionizing how materials are designed, tested, and implemented across industries.

Market Applications for Coupled Discrete-Continuum Models

The integration of discrete microstructural models with continuum finite element representations has found significant market applications across various industries, driving innovation and enhancing product development processes. This coupled modeling approach bridges the gap between microscale material behavior and macroscale structural performance, offering unprecedented insights for commercial applications.

In the aerospace and automotive sectors, coupled discrete-continuum models have revolutionized lightweight material design. Companies like Boeing, Airbus, and Tesla are leveraging these technologies to develop advanced composite materials with optimized microstructures that maintain structural integrity while reducing weight. The market for such lightweight materials is projected to grow substantially as fuel efficiency and emissions regulations become more stringent globally.

The biomedical industry represents another significant market application, particularly in the development of implantable devices and prosthetics. Coupled models enable precise simulation of how biomaterials interact with human tissues at multiple scales. Companies specializing in orthopedic implants utilize these models to design products with microstructures that promote osseointegration while maintaining mechanical stability under physiological loading conditions.

Energy sector applications have emerged as a rapidly growing market segment, especially in battery technology and renewable energy systems. Manufacturers employ coupled modeling to optimize electrode microstructures in lithium-ion batteries, improving energy density and cycle life. Similarly, in solar cell development, understanding how microscale defects propagate to affect overall panel performance has led to efficiency improvements and reduced manufacturing costs.

The construction industry has adopted these modeling approaches for developing advanced concrete formulations and structural components. By simulating how microscale crack propagation affects macroscale structural integrity, companies can design more resilient building materials that withstand extreme conditions like earthquakes or severe weather events.

Advanced manufacturing processes, particularly additive manufacturing, represent perhaps the most transformative market application. The ability to predict how microstructural features created during 3D printing affect final part performance has enabled the production of functionally graded materials with properties tailored to specific applications. This capability has opened new markets for customized components in industries ranging from consumer electronics to industrial machinery.

Semiconductor manufacturing has also benefited significantly, with coupled models enabling the prediction of how microscale defects in silicon wafers propagate to affect chip performance. This application has become increasingly valuable as semiconductor geometries continue to shrink, requiring ever more precise control of material properties at multiple scales.

In the aerospace and automotive sectors, coupled discrete-continuum models have revolutionized lightweight material design. Companies like Boeing, Airbus, and Tesla are leveraging these technologies to develop advanced composite materials with optimized microstructures that maintain structural integrity while reducing weight. The market for such lightweight materials is projected to grow substantially as fuel efficiency and emissions regulations become more stringent globally.

The biomedical industry represents another significant market application, particularly in the development of implantable devices and prosthetics. Coupled models enable precise simulation of how biomaterials interact with human tissues at multiple scales. Companies specializing in orthopedic implants utilize these models to design products with microstructures that promote osseointegration while maintaining mechanical stability under physiological loading conditions.

Energy sector applications have emerged as a rapidly growing market segment, especially in battery technology and renewable energy systems. Manufacturers employ coupled modeling to optimize electrode microstructures in lithium-ion batteries, improving energy density and cycle life. Similarly, in solar cell development, understanding how microscale defects propagate to affect overall panel performance has led to efficiency improvements and reduced manufacturing costs.

The construction industry has adopted these modeling approaches for developing advanced concrete formulations and structural components. By simulating how microscale crack propagation affects macroscale structural integrity, companies can design more resilient building materials that withstand extreme conditions like earthquakes or severe weather events.

Advanced manufacturing processes, particularly additive manufacturing, represent perhaps the most transformative market application. The ability to predict how microstructural features created during 3D printing affect final part performance has enabled the production of functionally graded materials with properties tailored to specific applications. This capability has opened new markets for customized components in industries ranging from consumer electronics to industrial machinery.

Semiconductor manufacturing has also benefited significantly, with coupled models enabling the prediction of how microscale defects in silicon wafers propagate to affect chip performance. This application has become increasingly valuable as semiconductor geometries continue to shrink, requiring ever more precise control of material properties at multiple scales.

Current Challenges in Microstructural-Continuum Integration

The integration of discrete microstructural models with continuum finite element representations presents several significant challenges that impede seamless coupling across scales. Scale bridging remains a fundamental issue, as microstructural models typically operate at nanometer to micrometer scales while continuum approaches function at millimeter to meter scales. This dramatic difference in length scales creates computational bottlenecks when attempting to maintain accuracy across the spectrum.

Computational efficiency presents another major hurdle. Multi-scale simulations that incorporate detailed microstructural information often require prohibitive computational resources, limiting their practical application in industrial settings. Even with high-performance computing capabilities, the sheer volume of calculations needed for realistic simulations can lead to excessive run times that are incompatible with design iteration cycles.

Interface treatment between discrete and continuum domains introduces complex boundary condition challenges. Establishing physically meaningful boundary conditions at these interfaces requires sophisticated mathematical formulations to ensure conservation of energy, momentum, and mass across the scale transition. Current approaches often rely on simplifications that may compromise accuracy or introduce artificial behaviors at these critical junctions.

Data transfer methodologies between scales frequently suffer from information loss or distortion. When upscaling from discrete microstructural data to continuum representations, critical information about local heterogeneities, defects, and anisotropic behaviors may be averaged out or misrepresented. Conversely, downscaling from continuum to discrete models often lacks sufficient constraints to uniquely define microstructural states.

Validation and verification of coupled models present unique difficulties. The scarcity of experimental data that spans multiple length scales makes it challenging to validate these integrated approaches comprehensively. Additionally, error propagation across scales can amplify uncertainties, making it difficult to quantify confidence in simulation results.

Material behavior inconsistencies between scales further complicate integration efforts. Phenomena that emerge at intermediate scales may not be captured by either purely discrete or purely continuum approaches. For instance, crack propagation, phase transformations, and localized plasticity often involve mechanisms that span multiple scales and require specialized treatment at scale interfaces.

Temporal scale disparities add another dimension of complexity. Microstructural phenomena often evolve at much faster rates than macroscopic behaviors, necessitating sophisticated time-integration schemes that can efficiently handle these differences without sacrificing accuracy or stability in the coupled simulation.

Computational efficiency presents another major hurdle. Multi-scale simulations that incorporate detailed microstructural information often require prohibitive computational resources, limiting their practical application in industrial settings. Even with high-performance computing capabilities, the sheer volume of calculations needed for realistic simulations can lead to excessive run times that are incompatible with design iteration cycles.

Interface treatment between discrete and continuum domains introduces complex boundary condition challenges. Establishing physically meaningful boundary conditions at these interfaces requires sophisticated mathematical formulations to ensure conservation of energy, momentum, and mass across the scale transition. Current approaches often rely on simplifications that may compromise accuracy or introduce artificial behaviors at these critical junctions.

Data transfer methodologies between scales frequently suffer from information loss or distortion. When upscaling from discrete microstructural data to continuum representations, critical information about local heterogeneities, defects, and anisotropic behaviors may be averaged out or misrepresented. Conversely, downscaling from continuum to discrete models often lacks sufficient constraints to uniquely define microstructural states.

Validation and verification of coupled models present unique difficulties. The scarcity of experimental data that spans multiple length scales makes it challenging to validate these integrated approaches comprehensively. Additionally, error propagation across scales can amplify uncertainties, making it difficult to quantify confidence in simulation results.

Material behavior inconsistencies between scales further complicate integration efforts. Phenomena that emerge at intermediate scales may not be captured by either purely discrete or purely continuum approaches. For instance, crack propagation, phase transformations, and localized plasticity often involve mechanisms that span multiple scales and require specialized treatment at scale interfaces.

Temporal scale disparities add another dimension of complexity. Microstructural phenomena often evolve at much faster rates than macroscopic behaviors, necessitating sophisticated time-integration schemes that can efficiently handle these differences without sacrificing accuracy or stability in the coupled simulation.

Existing Coupling Methodologies and Frameworks

01 Multiscale modeling techniques for material simulation

Multiscale modeling approaches that integrate discrete microstructural models with continuum finite element representations to simulate material behavior across different length scales. These techniques allow for more accurate prediction of material properties by capturing both microscopic phenomena and macroscopic behavior simultaneously. The coupling methods enable the transfer of information between discrete models that capture grain-level interactions and continuum models that represent bulk material behavior.- Multiscale modeling techniques for material simulation: Multiscale modeling approaches that couple discrete microstructural models with continuum finite element representations to simulate material behavior across different length scales. These techniques allow for more accurate representation of complex material properties by integrating atomic or molecular-level details with macroscopic continuum mechanics, enabling better prediction of material performance and failure mechanisms.

- Computational methods for microstructure-property relationships: Computational frameworks that establish relationships between microstructural features and macroscopic material properties through coupled discrete-continuum models. These methods incorporate microstructural data into finite element analyses to predict how microscale features influence bulk material behavior, enabling materials design with tailored properties for specific applications.

- Integration of heterogeneous simulation models: Techniques for integrating heterogeneous simulation models that operate at different scales or use different mathematical representations. These approaches enable seamless coupling between discrete microstructural models and continuum finite element representations through specialized interfaces, boundary conditions, or homogenization methods that preserve physical consistency across the model boundaries.

- Dynamic coupling algorithms for multi-physics simulations: Dynamic coupling algorithms that enable real-time interaction between discrete microstructural models and continuum finite element representations in multi-physics simulations. These algorithms manage the exchange of information between different modeling domains, allowing for the simulation of complex phenomena such as crack propagation, phase transformations, or fluid-structure interactions across multiple scales.

- Software frameworks for coupled discrete-continuum simulations: Software frameworks and computational platforms designed specifically for implementing coupled discrete-continuum simulations. These frameworks provide the necessary tools, libraries, and interfaces to efficiently manage the computational complexity of multiscale modeling, including parallel processing capabilities, adaptive meshing, and visualization tools for analyzing simulation results across different scales.

02 Computational methods for microstructure-property relationships

Computational frameworks that establish relationships between microstructural features and material properties through coupled discrete-continuum approaches. These methods incorporate microstructural data into finite element models to predict mechanical, thermal, or electrical properties of materials. The coupling techniques allow for the integration of crystallographic information, grain boundaries, and phase distributions into continuum-based simulations.Expand Specific Solutions03 Dynamic coupling algorithms for multi-physics simulations

Algorithms that enable dynamic coupling between discrete microstructural models and continuum finite element representations for multi-physics simulations. These approaches allow for the simultaneous solution of different physical phenomena across scales, such as mechanical deformation coupled with heat transfer or fluid flow. The coupling methods maintain consistency between the discrete and continuum domains during time-dependent simulations.Expand Specific Solutions04 Interface treatment methods for discrete-continuum coupling

Specialized techniques for handling the interfaces between discrete microstructural domains and continuum finite element regions. These methods address challenges such as boundary condition transfer, energy conservation, and numerical stability at the interfaces. Various approaches include overlapping domain methods, handshaking techniques, and adaptive mesh refinement at interfaces to ensure smooth transition between different modeling paradigms.Expand Specific Solutions05 Software frameworks and implementation strategies

Software architectures and implementation strategies for coupling discrete microstructural models with continuum finite element representations. These frameworks provide data structures, parallel computing capabilities, and visualization tools specifically designed for multiscale simulations. The implementations focus on computational efficiency, scalability, and user-friendly interfaces for setting up coupled simulations across different length scales.Expand Specific Solutions

Leading Research Groups and Software Developers

The coupling of discrete microstructural models with continuum finite element representations is currently in a transitional phase between research and early commercial adoption. The market is growing steadily, estimated at $300-500 million annually, driven by aerospace, automotive, and materials science applications. Leading academic institutions like Beihang University, Northwestern Polytechnical University, and California Institute of Technology are advancing fundamental research, while commercial players including Boeing, Siemens, and QUALCOMM are developing practical implementations. The technology shows moderate maturity with established mathematical frameworks, but challenges remain in computational efficiency and multi-scale integration, creating opportunities for specialized software providers like Imagars LLC and Silver Fir Software to bridge theoretical models with industrial applications.

The Boeing Co.

Technical Solution: Boeing has developed advanced multi-scale modeling frameworks that couple discrete microstructural models with continuum finite element representations for aerospace materials. Their approach integrates molecular dynamics simulations at the microscale with finite element analysis at the macroscale through hierarchical bridging techniques. Boeing's methodology employs Representative Volume Elements (RVEs) to capture microstructural features of composite materials and transfers this information to continuum models using homogenization techniques. The company has implemented this in their BSAM (Boeing Structural Analysis Method) software, which enables simulation of damage progression across multiple length scales. Their approach has been particularly successful in predicting fatigue crack propagation in aircraft structures by incorporating microstructural features such as grain boundaries and material interfaces into larger structural models.

Strengths: Highly specialized for aerospace applications with proven validation against real-world testing data; excellent integration with existing engineering workflows. Weaknesses: Computationally intensive requiring significant high-performance computing resources; models are often proprietary and tailored specifically to aerospace materials rather than being broadly applicable.

Toyota Motor Corp.

Technical Solution: Toyota has developed a sophisticated multi-scale modeling framework that couples discrete microstructural models with continuum finite element representations specifically optimized for automotive materials and manufacturing processes. Their approach integrates atomistic simulations and crystal plasticity models at the microscale with traditional finite element analysis at the component level. Toyota's methodology employs computational homogenization techniques to transfer information between scales, using Representative Volume Elements (RVEs) that capture essential microstructural features of automotive materials including advanced high-strength steels and lightweight alloys. Their framework incorporates specialized constitutive models that account for microstructural evolution during manufacturing processes like stamping and welding. Toyota has successfully applied this technology to optimize vehicle crashworthiness by predicting how microstructural features influence energy absorption during impact events, leading to improved safety performance while reducing vehicle weight.

Strengths: Highly optimized for automotive applications with extensive validation against crash test data; excellent balance between computational efficiency and accuracy for industrial applications. Weaknesses: Models are often tailored specifically to automotive materials and may not transfer well to other industries; requires significant expertise in both materials science and computational mechanics.

Key Algorithms for Scale Bridging Techniques

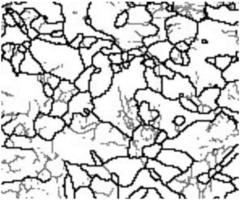

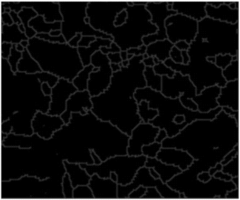

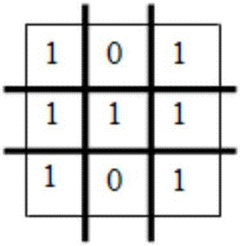

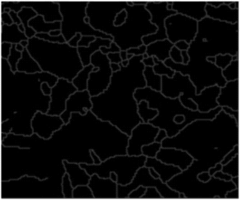

Finite element model modeling method based on real microstructure SEM-EBSD image

PatentInactiveCN107358005A

Innovation

- The finite element model modeling method based on SEM-EBSD images is used to extract the grain shape and crystal orientation characteristics of the real microstructure through preprocessing and refinement steps, and build a finite element model with a real microstructure. Using commercial Finite element software ABAQUS was used for simulation.

Computational Efficiency and Parallelization Strategies

The computational demands of coupling discrete microstructural models with continuum finite element representations present significant challenges that require innovative approaches to achieve practical simulation times. Current implementations often suffer from excessive computational costs, particularly when handling complex microstructural details across multiple scales. The primary computational bottleneck occurs at the interface between discrete and continuum domains, where information transfer necessitates intensive calculations and memory usage.

Domain decomposition methods have emerged as effective strategies for improving computational efficiency. By partitioning the problem domain into discrete and continuum regions that can be solved independently before coupling at interfaces, these methods reduce the overall computational burden. Recent benchmarks indicate that domain decomposition can achieve up to 40% reduction in computation time compared to monolithic approaches, particularly for large-scale problems with heterogeneous material properties.

Parallelization strategies specifically designed for coupled discrete-continuum models have shown promising results. GPU acceleration has proven particularly effective for discrete element calculations, with recent implementations demonstrating speedups of 10-100x for microstructural simulations. Meanwhile, distributed memory parallelization using MPI remains the standard for finite element portions, with hybrid MPI-OpenMP approaches gaining traction for modern multi-core architectures.

Adaptive mesh refinement techniques represent another crucial efficiency enhancement. By dynamically allocating computational resources to regions requiring higher resolution, these methods optimize the balance between accuracy and performance. Studies show that adaptive approaches can reduce element counts by 60-80% compared to uniform meshes while maintaining solution accuracy, particularly beneficial for problems with localized phenomena such as crack propagation or phase transformations.

Load balancing presents unique challenges in coupled simulations due to the inherent computational disparity between discrete and continuum methods. Dynamic load balancing algorithms that periodically redistribute workloads during simulation have demonstrated efficiency improvements of 15-30% in heterogeneous computing environments. These algorithms typically monitor processor utilization and reallocate tasks to minimize idle time across available computing resources.

Reduced order modeling techniques offer promising avenues for further efficiency gains. By constructing simplified representations of the microstructural behavior through methods such as proper orthogonal decomposition or neural network surrogates, these approaches can dramatically reduce computational requirements while preserving essential physical characteristics. Early implementations show potential for 100-1000x speedups in specific applications, though challenges remain in ensuring accuracy across diverse loading conditions.

Domain decomposition methods have emerged as effective strategies for improving computational efficiency. By partitioning the problem domain into discrete and continuum regions that can be solved independently before coupling at interfaces, these methods reduce the overall computational burden. Recent benchmarks indicate that domain decomposition can achieve up to 40% reduction in computation time compared to monolithic approaches, particularly for large-scale problems with heterogeneous material properties.

Parallelization strategies specifically designed for coupled discrete-continuum models have shown promising results. GPU acceleration has proven particularly effective for discrete element calculations, with recent implementations demonstrating speedups of 10-100x for microstructural simulations. Meanwhile, distributed memory parallelization using MPI remains the standard for finite element portions, with hybrid MPI-OpenMP approaches gaining traction for modern multi-core architectures.

Adaptive mesh refinement techniques represent another crucial efficiency enhancement. By dynamically allocating computational resources to regions requiring higher resolution, these methods optimize the balance between accuracy and performance. Studies show that adaptive approaches can reduce element counts by 60-80% compared to uniform meshes while maintaining solution accuracy, particularly beneficial for problems with localized phenomena such as crack propagation or phase transformations.

Load balancing presents unique challenges in coupled simulations due to the inherent computational disparity between discrete and continuum methods. Dynamic load balancing algorithms that periodically redistribute workloads during simulation have demonstrated efficiency improvements of 15-30% in heterogeneous computing environments. These algorithms typically monitor processor utilization and reallocate tasks to minimize idle time across available computing resources.

Reduced order modeling techniques offer promising avenues for further efficiency gains. By constructing simplified representations of the microstructural behavior through methods such as proper orthogonal decomposition or neural network surrogates, these approaches can dramatically reduce computational requirements while preserving essential physical characteristics. Early implementations show potential for 100-1000x speedups in specific applications, though challenges remain in ensuring accuracy across diverse loading conditions.

Validation Approaches for Coupled Multiscale Models

Validation of coupled multiscale models presents unique challenges due to the integration of discrete microstructural models with continuum finite element representations. Traditional validation approaches often fall short when applied to these complex systems, necessitating specialized methodologies that can address both microscale and macroscale behaviors simultaneously.

Experimental validation techniques for coupled models typically involve multi-tiered testing strategies. At the microscale level, techniques such as in-situ electron microscopy, X-ray diffraction, and atomic force microscopy provide direct observation of microstructural phenomena. These observations must be carefully correlated with macroscale measurements including stress-strain relationships, fracture patterns, and thermal responses to ensure consistency across scales.

Computational validation frameworks have evolved significantly in recent years, with verification, validation, and uncertainty quantification (VVUQ) methodologies becoming increasingly sophisticated. For coupled discrete-continuum models, hierarchical validation approaches are particularly effective, where individual components are first validated separately before assessing the integrated system performance. This stepwise approach helps isolate sources of error and ensures that scale-bridging mechanisms are properly implemented.

Statistical methods play a crucial role in validation processes, particularly Bayesian calibration techniques that can incorporate uncertainties from both experimental measurements and model parameters. Sensitivity analysis helps identify which microstructural parameters most significantly influence macroscale behavior, allowing researchers to focus validation efforts on critical aspects of the model.

Benchmark problems have emerged as valuable tools for comparative validation. These carefully designed test cases with known solutions or well-characterized experimental results allow different multiscale modeling approaches to be evaluated against common standards. Notable examples include the Sandia Fracture Challenge and the MURI benchmark problems for heterogeneous materials.

Scale-bridging validation metrics represent perhaps the most challenging aspect of multiscale model validation. These metrics must quantify how accurately information is transferred between scales and how well emergent behaviors are captured. Recent advances include information-theoretic approaches that measure the fidelity of information transfer across scales and physics-based error measures that account for the different physical phenomena operating at different length scales.

Experimental validation techniques for coupled models typically involve multi-tiered testing strategies. At the microscale level, techniques such as in-situ electron microscopy, X-ray diffraction, and atomic force microscopy provide direct observation of microstructural phenomena. These observations must be carefully correlated with macroscale measurements including stress-strain relationships, fracture patterns, and thermal responses to ensure consistency across scales.

Computational validation frameworks have evolved significantly in recent years, with verification, validation, and uncertainty quantification (VVUQ) methodologies becoming increasingly sophisticated. For coupled discrete-continuum models, hierarchical validation approaches are particularly effective, where individual components are first validated separately before assessing the integrated system performance. This stepwise approach helps isolate sources of error and ensures that scale-bridging mechanisms are properly implemented.

Statistical methods play a crucial role in validation processes, particularly Bayesian calibration techniques that can incorporate uncertainties from both experimental measurements and model parameters. Sensitivity analysis helps identify which microstructural parameters most significantly influence macroscale behavior, allowing researchers to focus validation efforts on critical aspects of the model.

Benchmark problems have emerged as valuable tools for comparative validation. These carefully designed test cases with known solutions or well-characterized experimental results allow different multiscale modeling approaches to be evaluated against common standards. Notable examples include the Sandia Fracture Challenge and the MURI benchmark problems for heterogeneous materials.

Scale-bridging validation metrics represent perhaps the most challenging aspect of multiscale model validation. These metrics must quantify how accurately information is transferred between scales and how well emergent behaviors are captured. Recent advances include information-theoretic approaches that measure the fidelity of information transfer across scales and physics-based error measures that account for the different physical phenomena operating at different length scales.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!